FIAMA SIMPLEX-E Series Guide

Display for linear measurement SIMPLEX-E

Data: 13/01/16 file: Simplex_ing.doc pag 1/8

USER’S MANUAL AND MAINTENANCE

ELECTRONIC DISPLAY FOR LINEAR MEASUREMENT

WITH BATTERY-OPERATED

Display for linear measurement SIMPLEX-E

Data: 13/01/16 file: Simplex_ing.doc pag 2/8

Manual purpose

This manual has been designed by the Manufacturer to provide the necessary information regarding the

instrument SIMPLEX-E to those who are authorized to carry out safely its installation, maintenance,

dismantling and disposal.

All the necessary information for the buyers and planners can be found in the Sales catalogue. Other than

adopting good technical construction methods, the information should be read carefully and strictly applied.

Inobservance of this information could cause risks for the health and safety of people and economical

damage. This information, provided by the Manufacturer in the original language(Italian) is also available in

other languages to satisfy legislative and/or commercial needs. This manual must be kept in good conditions

by a responsible person in an ideal place so that it is always available for consultation. In case this manual is

lost or deteriorates, a replacement should be requested directly from the manufacturer quoting the manual’s

code. This manual reflects the state of skill of the instrument at the time of input on the market: however the

manufacturer reserves the right to make changes, add or improve the manual without giving any reason to

hold the present manual inadequate.

Identification of the equipment

The identification plate represented is applied on the instrument.

To find out the identification code of the instrument, consult the sales catalogue.

Environmental conditions

Temperature setting: min. 0°C, max. + 50°C.

It is forbidden to use the instrument other than its specific use and in potentially explosive conditions or where

Anti-explosive elements are used.

Storage

Here below are some references to be followed for the storage of the instrument.

Avoid environments with excessive humidity and those exposed to bad weather (avoid open areas).

Avoid putting the instrument directly on the ground. Store the instrument in its original packing.

Conformity declaration and EC marking

The instrument answers to the following Communitarian Directives:

2014/30/EU Electromagnetic compatibility, 2011/65/EU RoHS.

Maintenance

The instrument does not needs a particular maintenance except cleaning to do only with a soft cloth dampen

with ethylic alcohol or water. Do not use hydrocarbon solvents (petrol, diluents, etc.): the using of these

products could affect the proper functioning of the instrument.

Reparations should be done only and exclusively at the FIAMA technical assistance centre.

Calibrations and tests

It is advisable to calibrate the instrument periodically, once every working year.

To do the calibration, follow the calibration procedure indicated in the present manual.

Assistance request procedure

For any kind of technical assistance request, contact the sales department of the Manufacturer directly

indicating the information given on the identification plate, the number of hours used and the type of defect.

Manufacturer’s responsibility

The manufacturer declines any responsibility in case of :

• Using the instrument contrary to the national safety and accident-prevention laws.

• Wrong installation, inobservance or wrong procedures of the instructions provided in the present manual.

• Defective electrical power supply.

• Modifications or tampering.

• Operations carried out by untrained or unqualified staff.

The safety of the instrument also depends on the strict observance of the procedures indicated in the

manual: always operate the instrument in its functioning capacity and carry out a careful routine maintenance.

• All phases of inspection and maintenance should be done by qualified staff.

• The configurations provided in the manual are the only ones permitted.

• Do not try to use it anyway contrary to the indications provided.

• The instructions in this manual do not substitute but accomplish the obligations of the current legislation

regarding the safety laws.

Display for linear measurement SIMPLEX-E

Data: 13/01/16 file: Simplex_ing.doc pag 3/8

Installation

Before installing the instrument, read the following warnings:

a) Connect the instrument strictly following the instructions of the manual.

b) It is the responsibility of the user to check, before using, the correct settings of the parameters of the

instrument to avoid damage to persons or things.

c) The instrument CANNOT function in a dangerous environment (inflammable or explosive).

d) The unit has sensible parts to electrostatic charge, therefore the handling of the inner electronic cards has

to be carried out with appropriate care to avoid permanent damages.

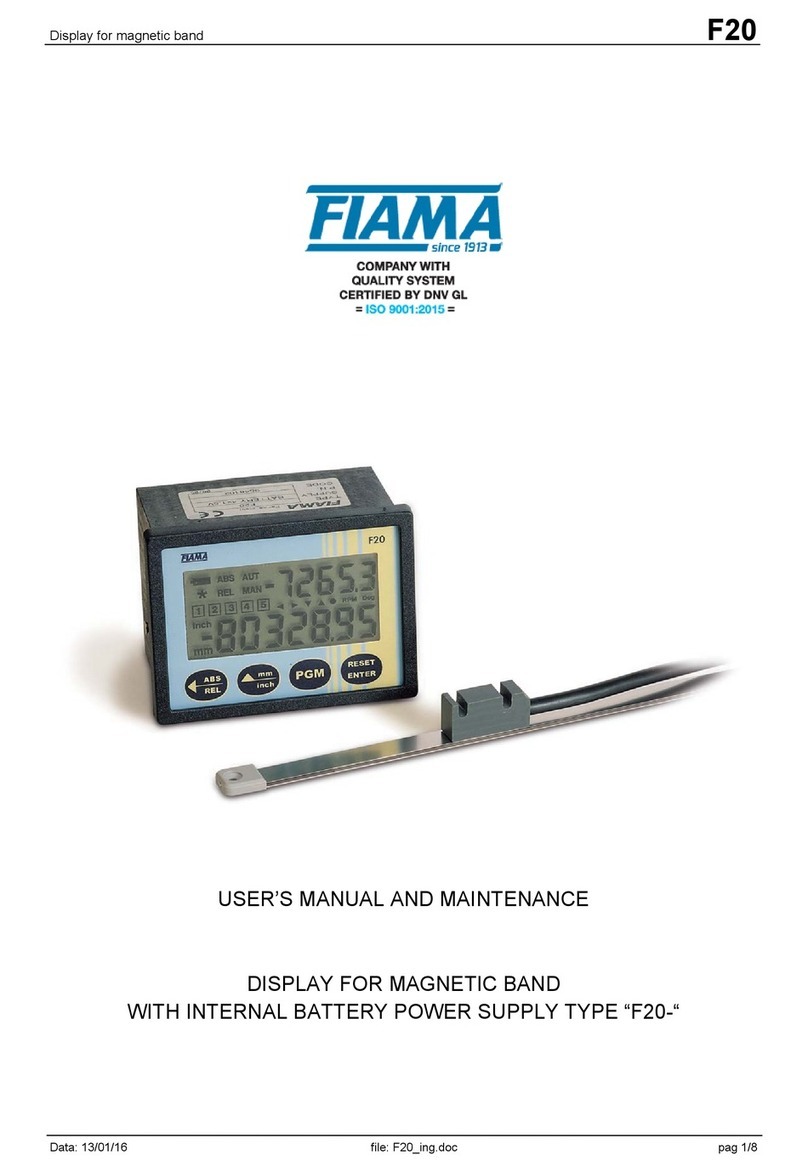

Description

The Electronic Simplex is a dimension display for the measure of linear shifting that combines in the same

case the magnetic position transducer, the display and the battery supply. The display-unit runs on an

aluminium bar in which is seated a magnetic band.

The display-unit running on the bar measures the real shifting carried out, removing clearances and

misalignments. The LCD-display has 6 digits plus sign (range from -999999 to 999999); the digit height is

10mm that allows a very good readability also by distances.

With 3 frontal keys is possible to adapt the value that has be showed for a given shifting and switch on the

functions of reset/preset of quota, absolute/relative quota and conversion mm/Inch. Battery-operated with 2

batteries 1,5V, 1-year-life with low-battery indicator, which simplify the assembling avoiding the laying of

cables. There are also available 3 distinct origins for the correction of quota by using different tools and the

offset function for the balancing of tool wear. The display can be rotated at 90° for a parallel or orthogonal

view to the measure bar. The easy assembling, and the measure accuracy make the SIMPLEX-E suitable for

a large number of applications within industry machinery (packaging, wood-, aluminium-, sheet-working, silk-

screen printing. etc.). Available version with serial output RS485, with MODBUS-RTU protocol, and power

supply 24Vdc and inner rechargeable battery (5 months functioning without power supply) for connection with

remote units.

Programming

To step into the parameter programming press key and on the display appears

, now press 2

times key RESET and appear 4 zeroes, the first on the right is blinking, with keys (digit increase) and

(digit selection), set out password 0273 and confirm with RESET. In case of wrong set-out of password it goes

out of the programming. The parameters that have to be set can be run with key and in order of

appearance they are:

0

0 0

0 value to be displayed for every turn of the shaft,

+%

+%+%

+% number of decimal digits,

%.+

%.+%.+

%.+ count direction,

//

////

// keys opening mode

,/

,/,/

,/ displacement of origin,

/

/ /

/ not used.

To enter into the modification of the selected parameter press two times RESET (one time displays only the

value) and with keys and set the wanted value to be confirmed with RESET.

To go out of the programming press

Value to be displayed for every turn of the hollow shaft 0

0 0

0

This parameter together with the following one allows to programme the value which has to be displayed for a

given shifting of the movable part. Practically its necessary to set the value that has to display corresponding

to a shifting of 100mm. Manufacture’s value is VISUAL=100.0, which is the necessary value to read the

shifting in millimetres.

The range allowed is from 0,00001 to 999999 with setting of decimal point position that is, after programming

of the last digit on the left, pressing key will blink the decimal pinpoint and with key it can be moved to

the wanted position. Confirm with RESET.

Number of decimal digits +%

+%+%

+%

It is the number of decimal digits to visualize on the display, range allowed from 0 to 5.

Example 1: each turn of the hollow shaft will have a displacement on the machine of 50, set

0 =50 and +%=0.

Example 2: each turn of the hollow shaft will have a displacement of 12,345 and on display has to appear

12,3. The constant has to be set at 12,3450 and constant at 1.

Display for linear measurement SIMPLEX-E

Data: 13/01/16 file: Simplex_ing.doc pag 4/8

Count direction %.+

%.+%.+

%.+

Set out the count direction of the display, range allowed 0 or 1.

Setting 0 the value on the display increases, turning the hollow shaft clockwise.

Setting 1 the value on the display decreases, turning the hollow shaft clockwise.

Keys opening mode //

////

//

This parameter programmes the functions linked to the keys.

The value to set is a number of three digits so each key corresponds to a digit; the digit on the right stands for

setting of key RESET, the digit in the middle stands for key while the last digit on the left stand for key .

The values allowed are the following:

VALUE KEY KEY KEY RESET

0 Not open Not open Not open

1 Function ABS/REL Conversion mm/inch Reset

2 Not open Display in degrees Preset

3 Not open Not open Fast Preset

4 Not open Not open Change of origin 0,1,2

Reset: function of reset of quota, pressing on key RESET the quota is zero-set .

Preset: function of preset of quota, pressing on key RESET the quota on the display became the same of the

one set in parameter Preset. The setting of Preset value appears immediately after parameter //

////

// (if

chose value 2).

Fast Preset: the fast setting of the quota on the display, pressing on key RESET appears Preset and pressing

still 2 times RESET is possible to set the value directly (use keys and confirm with RESET). This

function is useful when the quote on the display has often be corrected.

Origin change (quota correction for tool change): with this function 3 different origins (0,1,2) are

programmable and passes from an origin to the other wit key RESET. Activating the function of origin change

on the display appear two small arrows and the indication of the selected origin happens with the switching

on of the origin indicators (see paragraph meaning of symbols ). After setting 4 in the first digit on the right of

//

////

//, will appear PrS0 and pressing 2 times RESET has to be set the value to be read in this position of

shaft for origin 0, confirm with RESET. It will appear PrS1 which is the value to be read for origin 1 in the

present position of shaft: set the correct value and confirm with RESET. It will appears PrS2 which is the value

to be read for origin 2 in the present position of shaft: set the correct value and confirm with RESET. It means

PrS0, PrS1, PrS2 are references for the calibration, in a certain position of the shaft, in three different origins.

Function ABS/REL:Enables the pass from absolute to relative value, pressing key zero-set temporary the

value to allow a relative shifting. On the display switches on indicator REL to indicate that the current quote is

relative to the zero-point just created. Pressing still key reappears the absolute value and on the display

switches on the indicator ABS.

Conversion mm/inch: Pressing key converts the measure from millimetre to inches and back with

indication of inch/mm on the display and a decimal number more then for millimetres. By choosing 5

decimals for millimetres the conversion in inches is not allowed.

Visualization in degrees: Pressing on key on the display appears Deg to indicate the visualization of

measure in degrees.

Origin displacement ,/

,/,/

,/

This parameter is added or subtracted from the current quota to correct the value showed on the display, for

example following wear or changing of tool. Setting a positive value on display appears the current quota added

to this value.

Set zero to exclude the offset function (manufacturer’s value).

The offset is not available if the function of tool-change is selected.

Display for linear measurement SIMPLEX-E

Data: 13/01/16 file: Simplex_ing.doc pag 5/8

Adjusting of quota

After the assembling of instrument on the machine and setting of all parameters, to visualize on the display

the correct measure it is necessary to carry out the reset or preset of quota. Position the transducer in point

where is known exactly the correct measure to display (ex. check-stroke) or measure the quota in that point

of the axis.

Programme parameter //

////

// with value 3 in the first digit on the right and go out of the programming.

Now press RESET and it will appear Preset, press again 2 times RESET and set on the display the correct

measure to visualize, confirm with RESET and on the display appears the correct measure.

If the adjusting quota is worth to zero instead of the preset is possible use reset, setting value 1 on the first digit

on the right of //

////

//, this way pressing RESET the value on the display will be zeroed.

Now that the instrument is adjusted its necessary re-establish to the wanted value parameter //

////

// to avoid

accidental reset/preset of quota.

Battery change

The instrument is supplied with 2 batteries type AA of 1,5V (alkaline type) which assures a functioning of

about 1 year. When the loading level goes under a certain value, the indicator of flat-battery begins to blink in

occasional way and when it keeps switched on its necessary to change the batteries within a month.

To enter into the battery-holder its necessary to take off the cover and screw-off the 4 seal-screws on the two

hollows placed on a side of the instrument.

Take off the cover and take out the battery-holder and change the batteries paying attention to the polarity

indicated. Without batteries the instrument switches off: in this phase do not rotate the hollow shaft to avoid

loosing of correct quota.

As soon as the batteries are fitted inside, the instrument switches on with the same value on the display as at

the moment of the switching off and if the shaft has not be moved the value will be correct. In case the shaft

is moved during the switching off, to re-establish the correct measure its necessary to repeat the adjustment

proceeding.

Rotation of display

The Simplex-E is supplied standard with mounting position A.

To modify assembling position to A in B or vice versa, screw off the 4 screws M3, turn the instrument to the

required position and screw again.

AB

Display for linear measurement SIMPLEX-E

Data: 13/01/16 file: Simplex_ing.doc pag 6/8

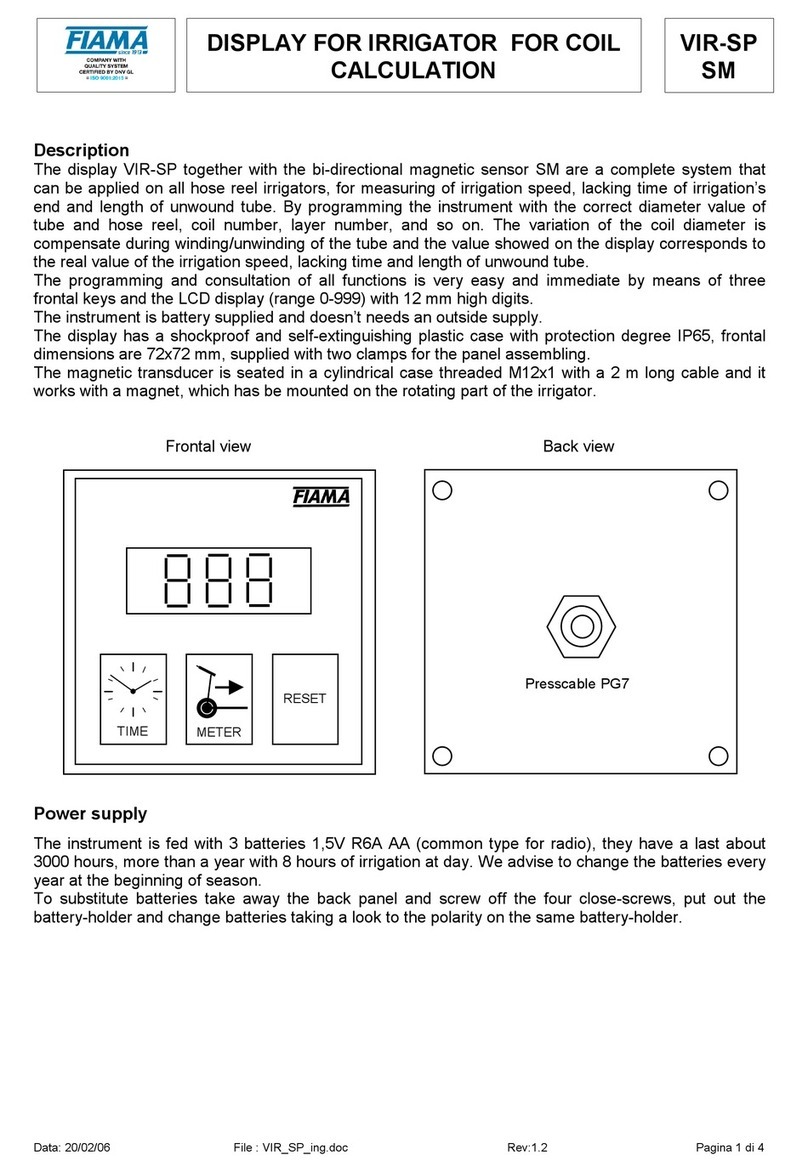

Meaning of the symbols on the display

1. Indicator of flat battery: begins to blink when the level of loading goes under a certain value and when it

keeps switched on its necessary to change the batteries within 1 month.

2. Indicator of absolute quota

3. Indicator of relative quota

4. Indicator of mm

5. Indicator of inches

6. Indicator of degrees

7. Indicator of positive Offset: indicates that the measure is corrected by a positive offset

8. Indicator of negative Offset: indicates that the measure is corrected by a negative offset

9. Indicator of values changing: it blinks during the programming phase

10. Indicator of origins: indicates that the origin changing mode is opened

11. Indicator for origin 1

12. Indicator for origin 2

Erros messages

overfl: the current quota passed the maximum value that can be visualized (from –999999 to 999999);

error1: its necessary to adjust again the quota;

notape: inner failure, contact the technical assistance..

1278 10 3

9

6

5

4

11

12

Display for linear measurement SIMPLEX-E

Data: 13/01/16 file: Simplex_ing.doc pag 7/8

Overall dimensions

SIMPLEX – E 50 100 200 300 500 700

Mesaure 55 105 205 305 505 705

Display 55.00 105.00 205.00 305.00 505.00 705.00

Guidance lengh t 180 230 330 430 630 830

Fori Ø4,2 di bloccaggio strumento

Bores Ø4,2 for instrument fixing

Bohrungen Ø4,2 für Gerät Befestigung

Banda magnetica

Magnetic tape

Magnet Band

Limitatori di corsa

Stroke limiting device

Hubbegrenzer

Guida scorrevole

Sliding guidance

Führungsschiene

Rialzo per guida

Height for guidance

Führungserhebung

62

74

25

Ø4,1 Ø4,2

L

25

7,5

38 12.5 2.5 6

Display for linear measurement SIMPLEX-E

Data: 13/01/16 file: Simplex_ing.doc pag 8/8

Specifications

Power supply 2 alkaline batteries 1,5V type AA

Resolution 0,01 mm

Max speed 1,5 m/s

Reading range -999999; 999999

Display LCD high-visibility-digit

Measure lengths 55, 105, 205, 305, 505, 705 mm

Keyboard 3 keys for programming and Offset

Available functions Reset/preset, absolute/incremental quota , conversion mm/inches 3

distinct origin for tool change and balancing of tool wear.

Measure bar Anodized aluminium

Box Strengthen polyamide glass, oil-, fat-proof

Protection degree IP54 - optional IP65

Working temperature 0-50°C

Relative humidity 30-90%

Directive: 2014/30/EU Electromagnetic compatibility, 2011/65/EU RoHS

Manufacturer

All communications to the manufacturer should be addressed to:

FIAMA s.r.l., Via G. Di Vittorio, 5/A - 43016 San Pancrazio (Parma) - Italy

Tel. (+39) 0521.672.341 - Fax. (+39) 0521.672.537 – e-mail: info@fiama.it - www.fiama.it

FIAMA Srl is not responsible for any damage to persons or things caused by tampering and wrong

use and in any case that are not consistent with the features of the instrument.

This manual suits for next models

6

Table of contents

Other FIAMA Monitor manuals