FIBER FOX MINI 4R User manual

This User Manual explains the use, performance characteristics, and cautions about MINI4R

fusion splicer and how to install and operate it. The primary goal of this manual is to make the

user as familiar with the splicer as possible.

Chapter 3 Basic operation 14

Chapter Two Installation 6

1.1 Applied fiber type 4

1.2 Splice Loss 4

1.3 Splice mode 4

1.4 Fiber heating groove 4

1.5 Power supply 4

1.6 Size and weight 4

1.7 Environment Condition 5

5 rehtO 8.1

2.1 Safety warning and prevention measures 6

2.1.1 Operating safety warns 6

2.1.1 Operating safety warns 7

2.1.2 Maintenance and appearance protect 7

2.1.3 Transportation and Storage 7

2.2 Installation 8

2.2.1 Unpack 8

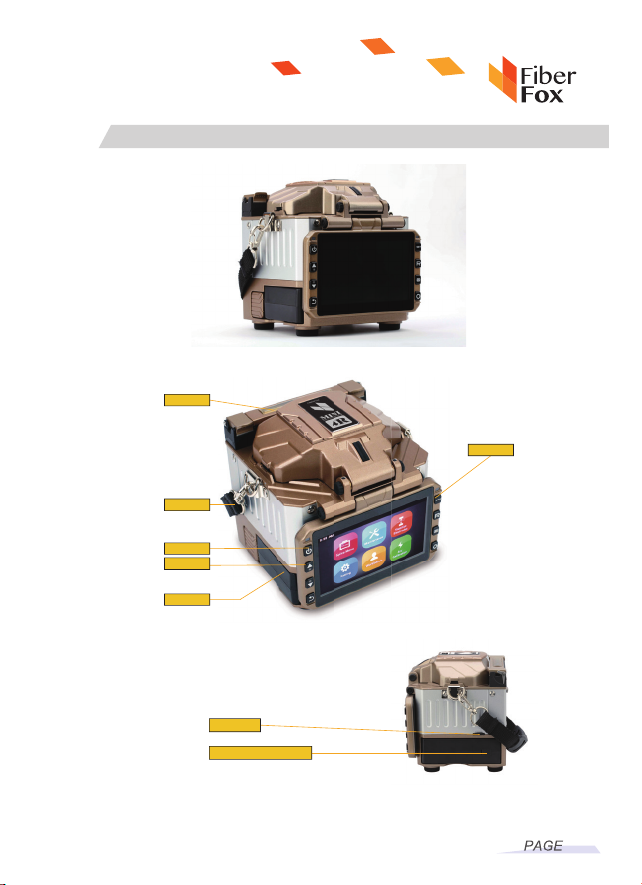

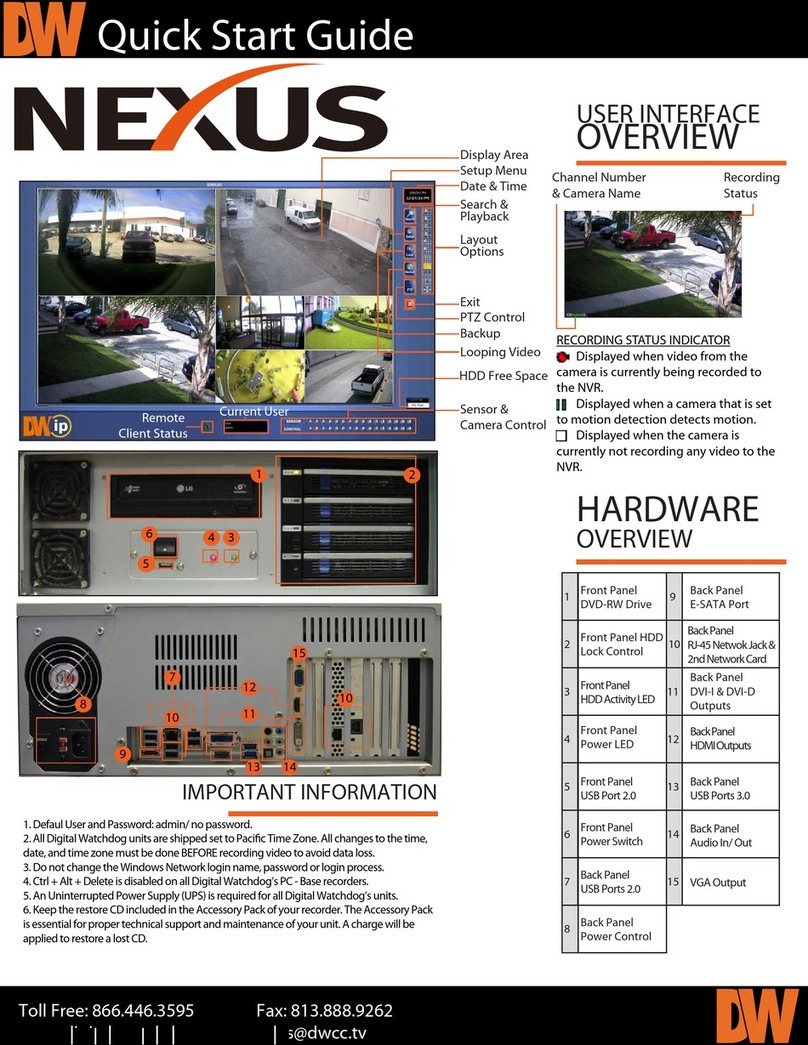

2.3 Appearance overview 9

2.4 Power supply mode 10

2.4.1 Two types of power supply mode 11

2.5 Battery charge 11

2.5.1 Charging process 11

2.5.2 Two kinds of charging methods 11

2.5.3 Battery state 12

2.6 Battery activate 13

2.7 Heating groove 13

Technical Parameters 4

Chapter 1 4

catalogue

3.1 How to use HCK construction toolbox workbench 14

3.2 Power connection 14

3.3 Battery operation 15

3.4 Starting up 15

3.4.1 Adjust the position of displayer 15

3.4.2 Adjust the brightness of LCD backlight 16

3.5 Fiber prepare 16

1. Clean the fiber 16

2. Install the fiber heat-shrinkable tubing 16

3.Strip and clean the fiber 16

4.Cut the fiber 17

3.6 Splice operation 17

3.6.1 Put fiber 17

3.6.2 Check fiber 18

3.6.3 Splice 18

Chapter 4 Splice Procedure 19

4.1 Display effective splice procedure 19

4.2 Select splice procedure 20

4.3 General splice procedure 21

4.3.1 Prefusing 21

4.3.2 Splice 21

4.3.3 Splice process 21

4.4 Splice parameter of general splice process 22

6.1 Heating template 25

6.2 Select heating mode 25

6.3 Edit the heating mode 25

Chapter 6 Heating Mode 24

Chapter 5 Splice option 23

Chapter 7 Maintenance Menu 27

6.5 Heating mode parameter 26

6.5 Heating mode parameter 26

7.5 Electrical machine alignment 29

7.6 Discharging alignment 29

7.7 Electrode setting 30

7.8 Software upgrading 30

7.4 Dust examination 29

7.1 Replace the electrode 27

7.2 Electrode stabilize 28

7.3 Autodiagnosis test 28

Chapter 8 Other functions and application 31

8.1 Data storage 31

8.1.1 Display splice record 31

8.1.2 Delete the splice record 31

8.1.3 Splice data storage 31

8.2 System setting 31

8.2.1 The displayer position 31

8.2.2 Energy saving position 32

8.2.3 System information 32

Appendix A: The reasons of high splicing loss and its solutions 33

Appendix B Error information sheet 34

Appendix C Common faults and solutions 36

Use the same fiber to continue, if adopt ITU-T standard insertion method to

measure its splice loss, the typical value is:

◆SM:0.05dB

◆MM:0.02dB

◆DS:0.08dB

◆NZDS:0.08dB

1.2 Splice Loss

◆External direct mains input: input voltage is 12V, input current 3A

◆Lithium battery supply: 12V, 5.2Ah, full charging time is about three hours.

1.5 Power supply

◆Size: Length*Width*Height=124mm*123mm*138mm

◆Weight:1.9kg (Battery included)

1.6 Size and weight

◆100 kinds of modes can be stored and 39 kinds of splice modes can be preset

◆2000 pieces of latest splice results record can be internally stored.

1.3 Splice mode

◆Heating time: 20 to 900s for choose

◆Typical heating time: 30s

◆Heating mode: 32 kinds of heating mode and 5 types of heating mode can be

preset

1.4 Fiber heating groove

◆SM(ITU-TG.652)/MM(ITU-TG.651)/DS(ITU-TG.653)/NZDS(ITU-TG.655)

/ITU-TG.657A/ITU-TG.657B

◆Applied cores: one to four cores

1.1 Applied fiber type

Chapter 1 Technical Parameters

◆Observe and display method: Two cameras, 4.3 inch color liquid crystal

screen (High intensity resistant protective layer on its surface)

◆One to four cores X and Y amplify 38 times, five to eight cores X and Y

amplify 28 times and nine to twelve cores X and Y amplify 18 times.

◆Strain relief test: 1.96-2.25N

◆Port:

1.8 Other

◆Operating conditions: Temperature: -10℃- 50℃; Humidity: 0-95%;

Altitude:0-2000m; Maximum wind speed: 15m/s

◆Storage environment: temperature: -10℃- 50℃; Humidity: 0 -95%;

Battery:-20℃--30℃for long time storage

1.7 Environment Condition

Internally installed, back apron inner side, SD card start, store program

SD card port

Serial port

Mini Hdmi port

Internally installed, back apron inner side, conduct debugging

External installed

Mini USB: Encryption and data transmission

USB 2.0: Software upgrading and image preserve

HS-12 : USB charge function

Port

Description

Chapter Two Installation

1). Please not use Fusion splicer in flammable and combustible place.

2) Please not touch the electrode when open the machine.

Note: Only special electrode bar can be used on Fusion splicer . When you need

to replace the electrode, please choose replace electrode option on maintenanc e

menu, or you must turn off the power ahead of time. Discharging operation is strictly

forbidden if couple electro de bars haven’t been installed.

2.1.1 Operating safety warns

2.1 Safety warning and prevention measures

Fumes, peculiar smell, abnormal sound or heating abnormal.

Liquid or foreign matters fall into the inner of Fusion splicer.

Fusion splicer suffered from strong vibration or impact.

I t is very important that M INI4R i s designed f or splice quartz glass f iber, not

applied for any other purpose. S ince Fusion splicer i s point-device m achine, you

should be seriously cautious when carry it. So, please keep strictly to the following

safety rules and general specification when you use and carry M INI4R. M anners

don’t take t hese safety m easurements or don’t comply w ith the warnings and

attention matters that this manual offered will violate the security standard of fusion

splicer design, manufacture and practical use.

Fiber Box assumes no responsibility due to violate the requirements.

3). Please not dismantle any part of Fusion splicer except the elements which can

be replaced b y users permitted in t his manual, components renewal o r internal

alignments can only be conduct by F iber Fox o r maintenance s taff authorized b y

Fiber Fox.

4) Please be careful when connect battery adapter cable, don’t pull the cable when

take it down from the socket, just hold the plug. Please make sure the cables are in

good condition for fear from the risk of fire or electric shock accidents.

5) Please not expose Fusion splicer to fire, electric shock or humidity environment.

6) P lease w ear p rotective g lasses when p repare fiber and i n splice course,

otherwise fiber scrap enter into your eyes, fall on your skin or swallow will lead to

serious outcomes.

7) When the following cases occurred, please turn off the Splicer and pull out the

adapter immediately, otherwise it will lead to serious consequences, such as Fusion

splicer will work abnormally or beyond repair.

2.1.2 Maintenance and appearance protect

1) Avoid using hard articles to clean V groove and electrode bar.

2) Avoid using acetone, painted diluents or alcohol to clean any part of the Fusion

splicer unless after careful consideration.

3) Please use dry cloth to clean the dust and dirt.

4) If the external appearance of the fusion splicer is very dirty, you can put soft

cloth into diluted cleaning fluid and then do the cleaning. Then use dry cloth to dry

the machine. Please not use furniture lighting material or other detergent.

5) Please adhere to the maintenance method that this manual introduced.

8) Please not use compress o r canned gas detergent t o clean Fusion splicer,

otherwise the arc produced in splice course will light the inflammable goods left.

9) P lease j ust use exclusive F iber Fox A C adapter. Inappropriate a lternating

current power supply will lead to fumes, electric shock or facility damage; even it

will result in fire accident, body hurt and death.

10). Please j ust use exclusive A C power cord. W eighty items should not be

placed on the power line, please not let power line heated or change the power

line. Inappropriate or damaged power line will lead to fumes, electric shock and

facility damage; even it will result in fire accident, body hurt or death.

2.1.3 Transportation and Storage

1)When move Fusion splicer to warm place from cold environment, try to adopt

gradual warming mode, otherwise condensation will be produced in the inner of

the device, thus will do adverse effects to it.

2)Please pack it when you don’t use it.

3)Please keep Fusion splicer clean and dry.

4)Fusion splicer have been precisely calibrate and alignment, please place it in

carrying case f or f ear i t will b e damaged o r polluted, p roper b uffer box shook

should be needed during long-distance transportation.

5)Please avoid direct sunlight or put it in overheated environment.

6)Keep the minimum humidity when preserve, relative humidity should be l ess

than 95%.

2.2 Installation

Hold the handle of the Fusion splicer upward and take it out. Please refer to the

following picture.

2.2.1 Unpack

2.2.2 Standard configuration of MINI4R Fusion splicer (depend on the goods as criterion)

MINI4R tool box/1/standard

configuration

MINI4R special fixture of heat

melt connector/one set/optional

Random user CD/standard

configuration

Battery/one piece

/standard configuration

Charger and adapter/one

/standard configuration

MINI4R Fusion splicer/one

piece/Standard configuration

1

2

3

4

5

6

7

Cooling rack

Power line(EU/UK/US)/one

/standard configuration

Cutting knife

Heat strip machine

Electrode bar (two pairs)

Important.

Please keep to the following explanations carefully.

Mini 4R

2.3 Appearance overview

09

Side

Charger connect

USB port

Battery

Carry handle

ON/OFF

Operating button

Hot stove

Battery

2.4.1 Two types of power supply mode

2.4 Power supply mode

1. Battery powered, please refer to the following picture:

2. Use power pack which connects to the alternating current to do power supply, the

method of install the power pack to fusion splicer is same as battery installation.

Please refer to the following picture about power supply connection:

10

10

Insert the battery until hear cracking sounds

Insert

Push the battery out

Retro reflector

Spotlight

V-groove

Fixture

Camera lens

Electrode bar

Fiber press hammer

Release the button

2.5.2 Two kinds of charging methods

2.5.1 Charging process

I ndication lights range from 20% to 100%, with the increase of the capacity,

these lights will be bright one by one until finish charging.

2.5 Battery charge

When battery connect with fusion splicer

When battery separate from fusion splicer

Note: Please not use battery to charge when the fusion splicer is splicing or

charging under battery power supply mode, otherwise will reduce the battery

service life.

Electric quantity indication

1) Electric quantity will be display if battery is connecting to fusion splicer. Power

supply indication is displayed on the upper right of the screen; please refer to the

following picture.

If power supply by connect the power pack of adapter, Power supply indication

is displayed on the upper right of the screen; please refer to the following picture.

2).LED indication light on the battery will show electric quantity (refer to the

following picture)

2.5.3 Battery state

You can check battery electric quantity through two ways.

<5%

<20%

<20-40% <80-100%

<60-80%

<40-60%

13

2.6 Battery activate

2.7 Heating groove

Open the heating groove

Cooling shelf

13

Battery activate

If the battery is using in short time after full charge,

maybe it o wns memorize e ffect, before next t ime

charging, you had better discharging the total

electric quantity.

Please keep fusion splicer in starting up state when

discharging until the electric quantity is use up and

automatically power off.

Chapter 3 Basic operation

3.2 Power connection

Power supply groove that locate on the downside of fusion splicer can contain two

types of power supply modes.

If use external power source to do power supply, please adopt AC adapter.

If use battery to do power supply, please use detachable battery.

Fix cutting knife to the worktable using screws.

Press the worktable which contain cutting knife to the relative groove of carry box .

14

14

Insert battery/power adapter

Insert battery

/power adapter

Pull out the battery/power adapter

Release button

Fix cutting knife to the

worktable using screws

3.4 Starting up

3.4.1 Adjust the position of displayer

Please check t he electric quantity whether i t is more than 2 0% before operate

fusion splicer, otherwise battery w ill not support fusion splicer d o splicing and

heating. (Please refer to chapter 2-battery state for checking method of battery

electric quantity).

Press the power button on the left side of fusion splicer and wait for its starting up

and enter into working interface, please refer to the following picture.

15

3.3 Battery operation

Adjust the angle of fusion splicer until you think it is the best place.

16

3.5 Fiber preparation

Four steps should be finished before inserting the fiber to fusion splicer.

2. Sheathe fiber heat-shrinkable tubing

1. Clean the fiber

3. Strip and clean fiber

Coat fiber with heat-shrinkable tubing

3.4.2 Adjust the brightness of LCD backlight

On initial interface, press upper and down key to rapid adjust LCD backlight

brightness until you think it is the most distinct display intensity.

Note: LCD infusion splicer is pin-point device that produced in strict quality control

factory. However, the screen may exist black, red, blue or green dots. Since screen

observation angle is different, the displayer b rightness w ill a lso be different. This

phenomenon is not flaw of LCD displayer, it is natural phenomena.

Put fiber in the fixture, if ribbon fiber is bent on its tail end about 100mm, please

smooths it.

Fiber fixture is divide into two kinds, respectively are used for left side and right

side, be sure to keep right fixture direction, with label upward.

Open the fixture cover, put number one fiber (generally is blue) near the slide and

retain 30-40mm outside, finally close the fixture cover.

O pen heating strip plier and outermost layer sheath, install fiber fixture to the

designated position, and close heat strip plier and protective layer. Hold fixture and

strip plier tightly, heating it for five seconds, and then smoothly slide to the outside

to remove the coating layer. Use gauze or thin tissue that dipped in alcohol to utterly

clean the fiber. Gauze and tissue cannot be repeatedly use.

Insert fiber

Heat shrinkable

-tubing

Fiber

Use cloth that dipped in alcohol or soft enough tissue to clean the fiber about

100mm from the tail end. If dust on the fiber coating layer enter into inner side of

heat-shrinkable tubing will lead to fiber broken or loss increase.

3.6.1 Put fiber

17

3.6 Splice operation

4. Cutting fiber

1) Gently hold the press arm of cutting knife and then slide the shackle to unlock

the cutting knife.

2) Propel the slide of cutting knife until it locked.

3) Put the stripped fiber on the cutting knife.

4) Screw down the press arm.

5) Gently loose the press arm, the elastic force will let it back to the initial position.

6) When press arm lift, fiber scrap collector will rotate and automatically roll th e

fiber scrap to debris taper.

7) Completely close the press arm and slide the shackle to lock the cutting knife.

Important: F rom now on t o make sure t he f iber w on’t b e dirty. ( For example,

please not put it on dirty worktable, or swing it on the air).Also you should check

the V-groove whether it is clean, otherwise, you must clean it.

1). Open the wind-proof cover.

2) Open the fiber gland.

3) Put fiber into V-groove and make sure the tail end is locate between V-groove

margin and electrode tip point.

4) Use fiber gland to hold down the fiber.

5) Close wind-proof cover.

Please use high-purity alcohol, more than 99% purity is better.

Surface adhesive force may lead neighbor fiber interlapping; gently flick it to

adjust the fiber.

During clean process, please use your finger to press the fixture cover.

3.6.2 Check fiber

3.6.3 Splice

1) Before splicing, you should check and confirm whether the fiber surface is clean

and smooth.

2) Through adjust the position of displayer to finish switching foresight and back vision.

3) If any flaw appears, please take off the fiber and rehandling it. Please refer to the

following picture.

Note: Fiber check is automatically, press splice button, fusion splicer will auto- focus

and checks the fiber whether there is damage or dust particle.

18

18

In order to guarantee better splice, an image processing system has been installed

in M INI4R to observe fiber. However, under some situation, t he i mage p rocessing

system may not check some splice error. So, to achieve better splice result, we need

to do v isual i nspection via displayer, t hen t he f ollowing described s tandard splice

procedure.

1) Fiber will do opposite direction movement after putting in fusion splicer, after clean

discharging, the fiber will stop to a specific position, and then fusion splicer will check

the cutting angle and end quality. If cutting angle is large than threshold value or the

fiber end face is not smooth, then the buzzer will ring, at the same time, displayer will

show error message t o warn o perator. After finish checking, f usion splicer w ill stop

work, the screen will display offset, clearance distance and cutting angle value.

If n o error message display, we should check t he f ollowing f iber e nd, i f similar

situation appear, we should take down the fiber from fusion splicer and prepare again.

Surface flaw on the fiber may lead to a failure splice.

X/Y

2.5.1 Charging process

Fiber B ox has a n easy program s tructure w hich can d irect b rowse and

effective. S plice procedure has defined splice current, splice time and various

kinds o f parameters used t o finish splicing. S elect a splice procedure that

consistent with your fiber type is very important.

Usually, fiber combination splice procedure has a predefine value, in this way, it

made easy for parameter optimize, modify and reestablish splice procedure if not

commonly used fiber combination.

Current effective splice procedure is display on the top of the screen.(Refer to the

following picture)

19

Chapter 4 Splice Procedure

4.1 Display effective splice procedure

NO.Name

1 Auto

2 MM AUTO

3 SM AUTO

4 DS AUTO

5 NZ AUTO

6 MM CALIBRATION

7 SM CALIBRATION

8 DS CALIBRATION

9 NZ CALIBRATION

Part predefine splice procedure

Table of contents

Other FIBER FOX Network Hardware manuals

Popular Network Hardware manuals by other brands

Extron electronics

Extron electronics DAS101CM Series Specifications

Symmetricom

Symmetricom TimeHub 5500 user guide

Cisco

Cisco CGR 1000 Series Getting connected guide

Digital Watchdog

Digital Watchdog Nexus quick start guide

Maiwe

Maiwe MPSE1202G-GTPOE30-GT-DC24 quick start guide

Dell EMC

Dell EMC XC6420 Series Solution guide