FIBERNET LADY Operating instructions

Blowing machine

mod. Lady

User & maintenance manual

Ver.2.2 –August 04 2022

Fibernet srl

Connectivity Solutions

www.fibernet.it

INDEX

1. GENERAL ........................................................................................................................................................................ 4

2. TECHNICAL CHARACTERISTICS ............................................................................................................................... 5

2.1. PRODUCT CONFIGURATION .................................................................................................................................6

2.2. ACCESSORY KIT ..........................................................................................................................................................7

3. OPERATING INSTRUCTION ....................................................................................................................................... 9

3.1. PRELIMINARY OPERATIONS ................................................................................................................................... 9

3.2. POSING PROCEDURE WITHOUT COMPRESSED AIR.................................................................................. 10

3.2.1. CABLE AND DUCT POSITIONING........................................................................................................... 10

3.3. POSING PROCEDURE WITH COMPRESSED AIR ........................................................................................... 12

3.3.1. CABLE AND DUCT POSITIONING........................................................................................................... 12

3.3.2. AIR COMPRESSOR CONNECTION .......................................................................................................... 15

3.4. CABLE POSING ......................................................................................................................................................... 15

3.5. CABLE POSING IN AN INTERMEDIATE STOP................................................................................................. 17

3.6. DISPLAY INFORMATION ....................................................................................................................................... 21

3.7. DRIVE BELTS HANDLING ...................................................................................................................................... 22

3.8. METER COUNTER PULLEY HANDLING............................................................................................................ 23

4. MAINTENANCE ...........................................................................................................................................................24

4.1. CLEANING .................................................................................................................................................................. 24

4.2. DRIVE BELTS SUBSTITUTION .............................................................................................................................. 24

4.3. SEAL ADAPTER GASKETS SUBSTITUTION ...................................................................................................... 26

4.4. BATTERY RECHARGING ........................................................................................................................................ 29

FIBERNET SRL

Headquarters: Via degli Olmetti,18 –00060 Formello (RM) - Italy

Share Capital € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

3

USER MANUAL

LADY

SAFETY RULES

Before operating, make sure to have set and fixed the device on a solid surface.

Check that the blowing machine is correctly connected to the minitube and that

the cable is properly positioned between the two drive belts.

Air pressure shall never exceed the limit indicated in this user manual.

To avoid possible finger injury, make sure not to touch the cable when it is close to

the working device; also ensure that the cable doesn’t tangle up, causing hazard

situations to the personnel involved.

Make sure

Before performing any type of alteration and/or maintenance make sure to have

previously disconnected the machine from all energy sources such as air compressor

and USB port.

Do not remove the plexiglass protections during posing operations (it could cause

injuries to the hands).

Before getting started, ensure that nobody is placed near the cable spools to avoid

possible risks.

Do not open the lids of the blowing machine while operating with air compressor.

FIBERNET SRL

Sede Operativa: Via degli Olmetti,18 –00060 Formello (RM) - Italia

Capitale € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

4

USER MANUAL

LADY

1. GENERAL

Lady is a blowing machine entirely designed and developed by Fibernet Srl to blow cables inside

minitubes.

The device is provided with a polypropylene waterproof case for a safe and easy transport and an

accessory kit.

The machine is designed to be actuated by an external electric screwdriver equipped with a clutch (or

an electric battery motor or even a pneumatic motor). To ease the blowing operation, the device can

use the help of compressed air.

Figure 1: Fibernet blowing machine –Lady model.

FIBERNET SRL

Headquarters: Via degli Olmetti,18 –00060 Formello (RM) - Italy

Share Capital € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

5

USER MANUAL

LADY

2. TECHNICAL CHARACTERISTICS

Lady blowing machine can be actuated by an external battery screwdriver equipped with a clutch, that

operates the internal rubber belts transmission mechanism (LINATEX) specifically contoured to

increase friction with the cable.

In case of electric, battery or pneumatic motor use, please refer to the specific supplied guides.

The main features of the Lady blowing machine are listed below:

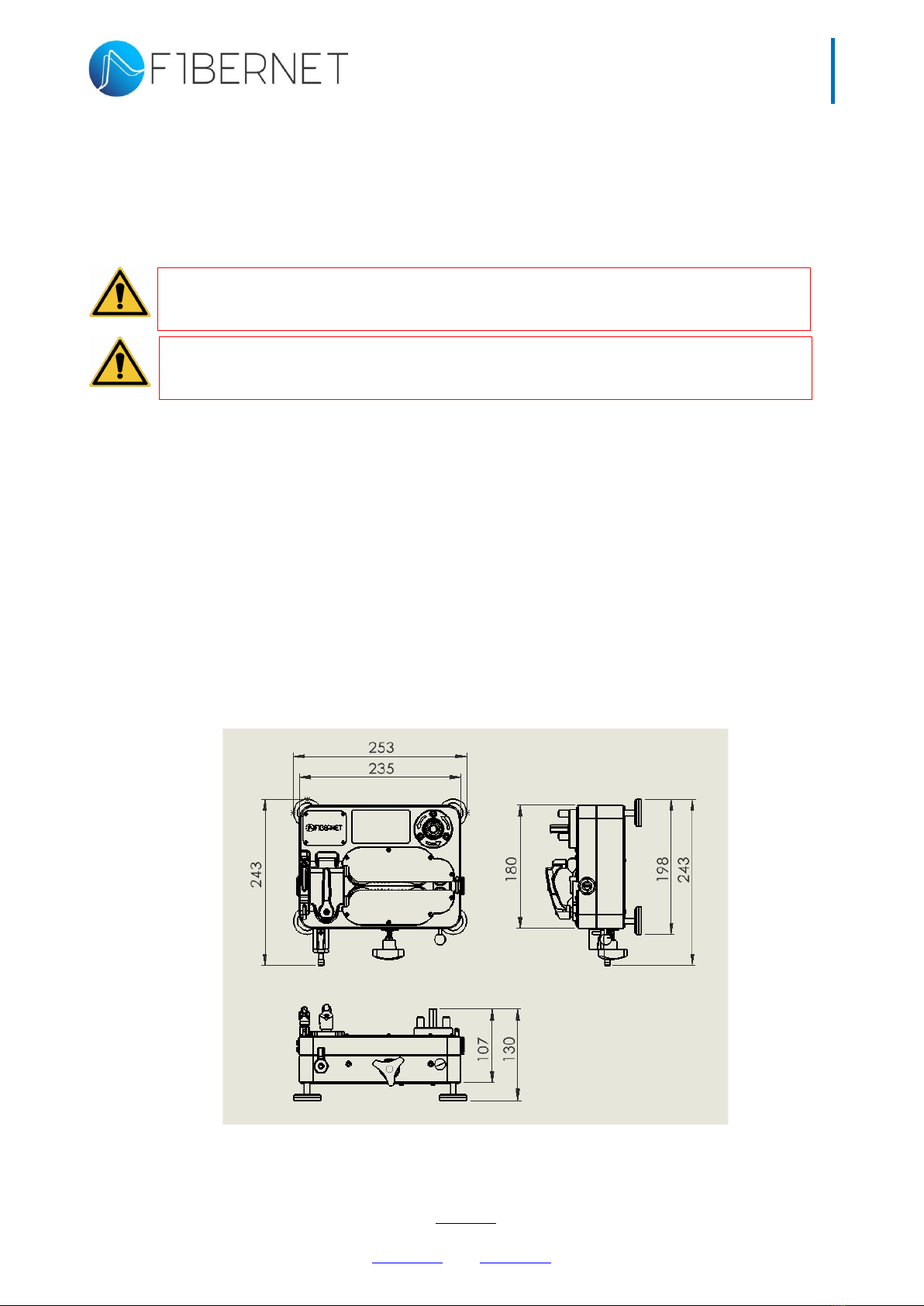

•Weight: approximately 6 kg

•Compact dimensions: 253 x 243 x 130 mm

•Use temperature -10 °C / +60 °C

•Digital display with operative information (blow direction, speed, meter counter, compressed

air pressure)

•Drive belt protection screens

•Cable diameters: 1,2 ÷ 10 mm

•Minitubes diameters: 5 ÷ 16 mm

Figure 2: Lady –External dimensions.

Do not use electric screwdriver at a higher speed of 550 rpm/min.

Do not use drilling machine to operate the machine.

FIBERNET SRL

Sede Operativa: Via degli Olmetti,18 –00060 Formello (RM) - Italia

Capitale € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

6

USER MANUAL

LADY

2.1. PRODUCT CONFIGURATION

To ensure greater sturdiness and reliability, the device is made of only two anticorodal aluminum bodies

designed to contain all the mechanic and the electronic parts required for a proper functioning.

Below listed the main blowing machine constituent parts (Figure 3.)

Figure 3: list of parts.

Number

Elements’ name

1

Air lid

2

LCD Display

3

Cable entry adapter fixing lever

4

Cable entry

4.a

Upper cable entry adapter

4.b

Lower cable entry adapter

5

Meter counter wheel opening

knob

6

Drive belts pressure regulation

knob

7

Compressed air connector

8

Electric screwdriver connector

9

USB plug

10

Adjustable pin

11

Minitube adapter kit

11.a

Upper minitube adapter

11.b

Lower minitube adapter

11.c

Minitube fixing adapter

12

Minitube fixing clamp

13

Cable adapter kit

13.a

Upper cable adapter

13.b

Lower cable adapter

FIBERNET SRL

Headquarters: Via degli Olmetti,18 –00060 Formello (RM) - Italy

Share Capital € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

7

USER MANUAL

LADY

2.2. ACCESSORY KIT

The device is provided with the following accessories:

Description

Quantity

Pictures

Lubricant for minitubes

1 L

USB cable

1

3 mm and 8 mm hex wrenches

1

½” to 3/8” junction

1

Air hose

1

Microduct cutter

1

Linear gasket Ø 3 mm

0,5 m

Utensil bag

1

Waterproof polipropylene case

1

FIBERNET SRL

Sede Operativa: Via degli Olmetti,18 –00060 Formello (RM) - Italia

Capitale € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

8

USER MANUAL

LADY

Adapters kit:

Description

Quantity

Pictures

Duct adapters kit at customer’s choice (included in

Lady’s price)

1+1+1

5 mm duct gasket

7 mm duct gasket

8 mm duct gasket

10 mm duct gasket

12 mm duct gasket

14 mm duct gasket

16 mm duct gasket

1 Set

Cable adapters at customer’s choice

(included in Lady’s price)

1+1

1-10 mm cable gasket

1 Set

Cable entry adapters

1+1

Other adapters kits are to be required separately

See “Accessories list & spare parts”

Table 1: accessories kit.

FIBERNET SRL

Headquarters: Via degli Olmetti,18 –00060 Formello (RM) - Italy

Share Capital € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

9

USER MANUAL

LADY

3. OPERATING INSTRUCTION

Listed below procedures to follow for a proper machine use.

They are devided in:

•3.1 Preliminary operations

•3.2 Posing procedure without compressed air

•3.3 Posing procedure with compressed air

•3.4 Cable posing

•3.5 Cable posing in an intermediate stop

3.1. PRELIMINARY OPERATIONS

Before getting started it is recommended to verify that the minitube is clean and dry in the inside

(for this purpose we recommend to use compressed air inside the tube to eliminate any solid or liquid

residues).

To ease the blowing operation, use the lubricant (provided among the accessories kit) following the

amounts listed in Table 2 shown below:

internal diameter of minitube [mm]

Lubricant approximate quantity per 1000 m

Volume [ml]

Minitube filling height [cm]

4

10

78 ÷ 82

8

18

35 ÷ 38

10

23

29 ÷ 32

12

27

24 ÷ 26

Table 2: correspondence between minitube diameter and lubricant quantity

Figure 4: minitube lubricant filling example.

Rubber foam

Minitube filling amount

➢Insert inside the minitube a small piece of rubber foam

(length 1 cm);

➢pour the recommended amount of lubricant depending

on the minitube diameter

➢Insert a second piece of rubber foam (length 1 cm);

➢Use compressed air to move the foams inside the tube

and lubricate it

➢utilizzare l’aria compressa per far scorrere il sistema

all’interno del tubo.

FIBERNET SRL

Sede Operativa: Via degli Olmetti,18 –00060 Formello (RM) - Italia

Capitale € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

10

USER MANUAL

LADY

3.2. POSING PROCEDURE WITHOUT COMPRESSED AIR

To blow short length cables, the mechanical drive belts will be sufficient. Cable flow will be easier if

the path doesn’t have curves. To reduce friction, obtain better performances and reach greater

distances, however, it is recommended to use compressed air.

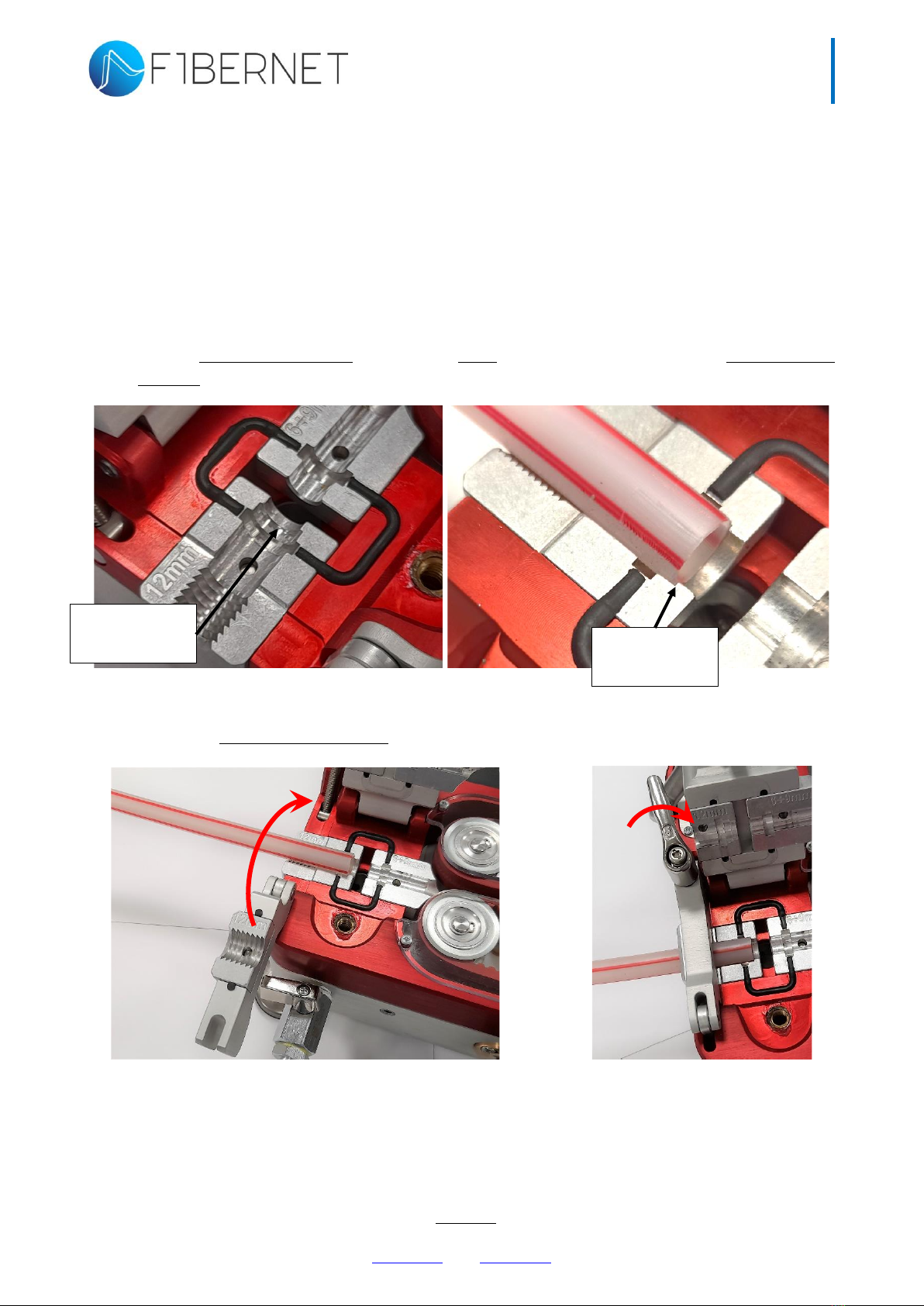

3.2.1. CABLE AND DUCT POSITIONING

Procedure to connect the minitube to the machine:

a. Lift the “minitube fixing clamp” (12) and the “air lid” (1). Set the minitube onto the “lower minitube

adapter”(11.b) making sure that it is properly inserted till the end.

Figure 5: minitube proper positioning.

b. Close the “minitube fixing adapter”(11.c) using the “minitube fixing clamp” (12).

Figure 6: closing the minitube fixing clamp

Minitube

stop

Minitube

stop

FIBERNET SRL

Headquarters: Via degli Olmetti,18 –00060 Formello (RM) - Italy

Share Capital € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

11

USER MANUAL

LADY

Round the head of the cable (with a heat source) to avoid catching edges in correspondence of the

minitube joints.

Adjust the belts’distance to ease the cable’s insertion using the “drive belts pressure regulation knob”

(6). Insert the cable into the “cable entry”(4), loosen the meter counter wheels pulling the “meter

counter wheel opening knob” (5) and push the cable up to the “cable adapters ”(13.a e 13.b).

Figure 7: Setting belts distance and cable insertion

c. Close the “air lid”(1) using the specific lever

Figure 8: closing the air lid

d. Set pressure between cable and drive belts using the “drive belts pressure regulation knob” (6) to

have a good grip and avoid cable slipping during blowing operation.

Meter counter wheel

opening knob

drive belts pressure

regulation knob

Air lid closing lever

FIBERNET SRL

Sede Operativa: Via degli Olmetti,18 –00060 Formello (RM) - Italia

Capitale € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

12

USER MANUAL

LADY

After you have carried out all these preliminary actions, refer to paragraph 3.4 for cable posing.

3.3. POSING PROCEDURE WITH COMPRESSED AIR

Use Lady with the aid of compressed air to minimize friction between cable and minitube. Air pressure

shall not exceed 16 bar. Below listed the instructions to follow.

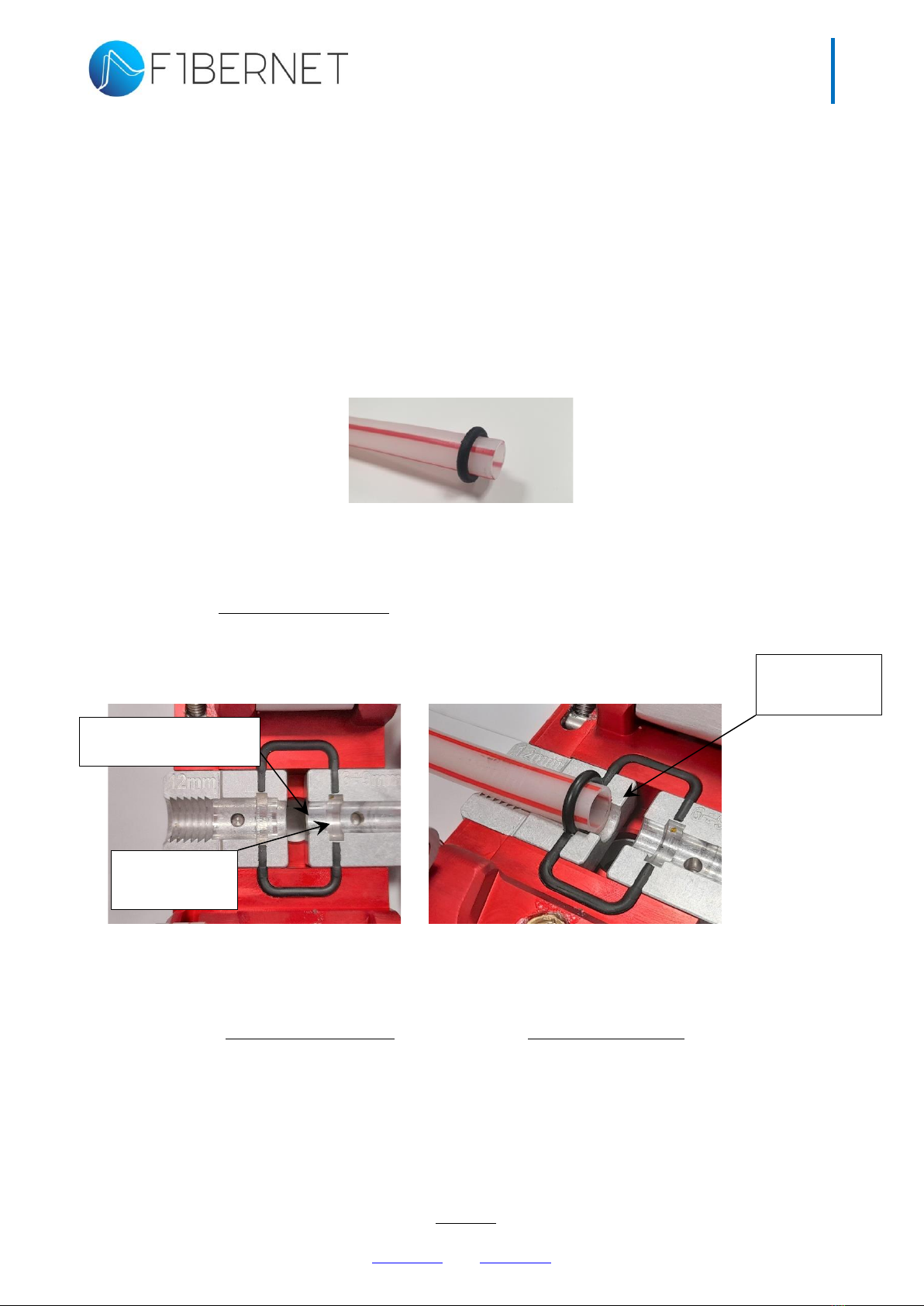

3.3.1. CABLE AND DUCT POSITIONING

Connecting the minitube to the device:

a. Choose from the accessory kit the proper duct gasket and insert it on the minitube.

Figure 9: duct gasket insertion.

b. Open the “minitube fixing adapter” (11.c), open the “air lid” (1) set the minitube onto the “lower

minitube adapter” (11.b) making sure that it is inserted till the end and that the duct gasket is

correctly inserted.

Figure 10: minitube proper insertion.

c. Close the “minitube fixing adapter”(11.c) using the “minitube fixing clamp”(12).

Minitube

stop

Duct gasket housing

Minitube

stop

FIBERNET SRL

Headquarters: Via degli Olmetti,18 –00060 Formello (RM) - Italy

Share Capital € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

13

USER MANUAL

LADY

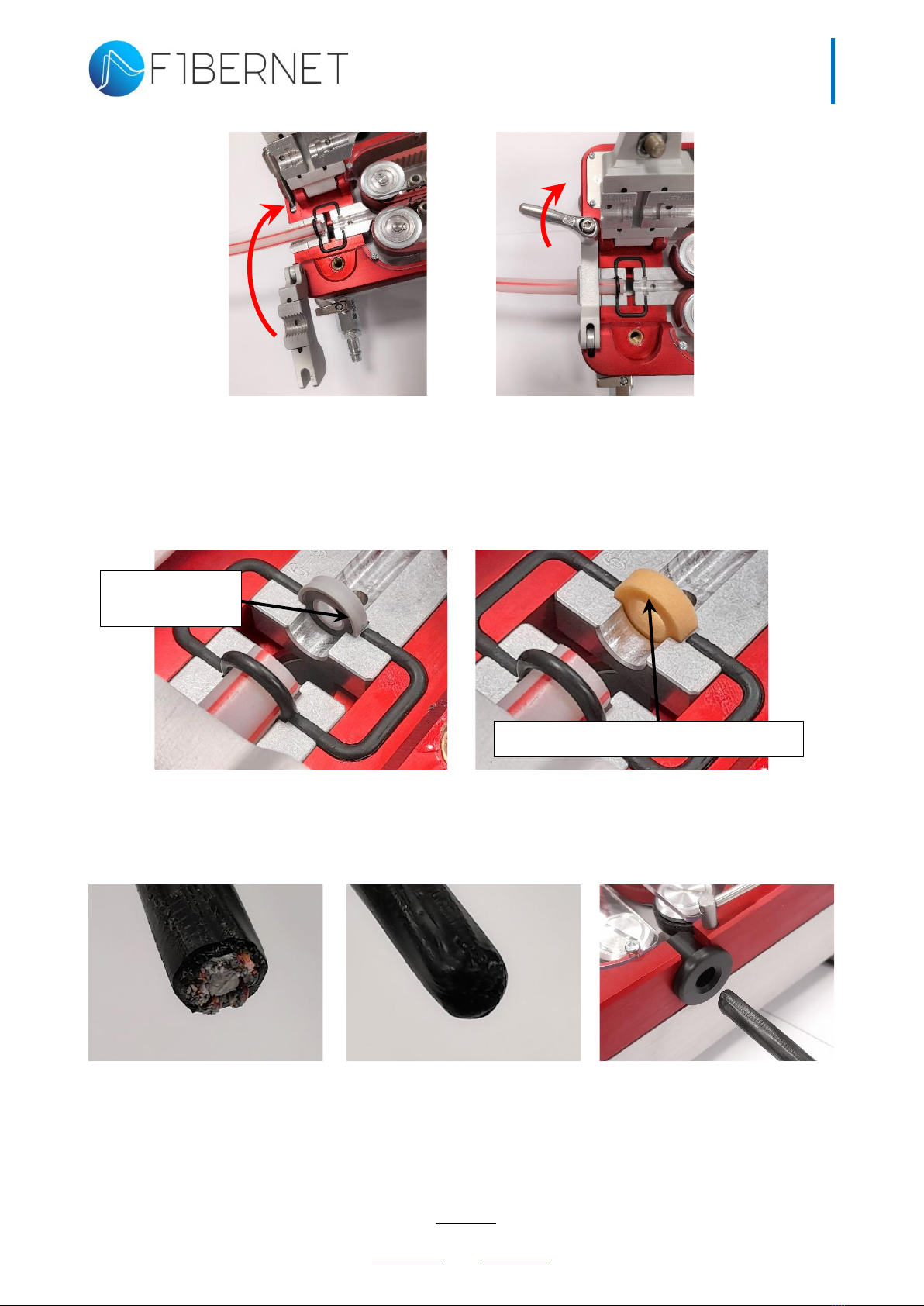

Figure 11: closing the minitube fixing clamp

Inserting the fiber optic cable:

d. Set the right cable gasket according to the cable diameter, making sure that the “lip” side is

facing the minitube.

Figure 12: Proper positioning of lip and flat gasket

Round the head of the cable (with a heat source) to avoid catching edges in correspondence of the

minitube joints.

“lip” side of the

gasket

Flat gasket can be placed either way

FIBERNET SRL

Sede Operativa: Via degli Olmetti,18 –00060 Formello (RM) - Italia

Capitale € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

14

USER MANUAL

LADY

e. Set pressure between cable and drive belts using the “drive belts pressure regulation knob” (6)

insert the cable inside the “cable entry” (4) and into the lip gasket.

f.

Figure 13: Setting belts distance and cable insertion inside lip gasket

f. Close the “air lid” (1) using the specific lever

Figure 14: closing the air lid

AIR PRESSURE HAZARD: do not open air lid while operating with compressed air

Air lid closing lever

Meter counter wheel

opening knob

Drive belts pressure

regulation knob

FIBERNET SRL

Headquarters: Via degli Olmetti,18 –00060 Formello (RM) - Italy

Share Capital € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

15

USER MANUAL

LADY

g. Set pressure between cable and drive belts using the “drive belts pressure regulation knob” (6) to

have a good grip and avoid cable slipping during operation.

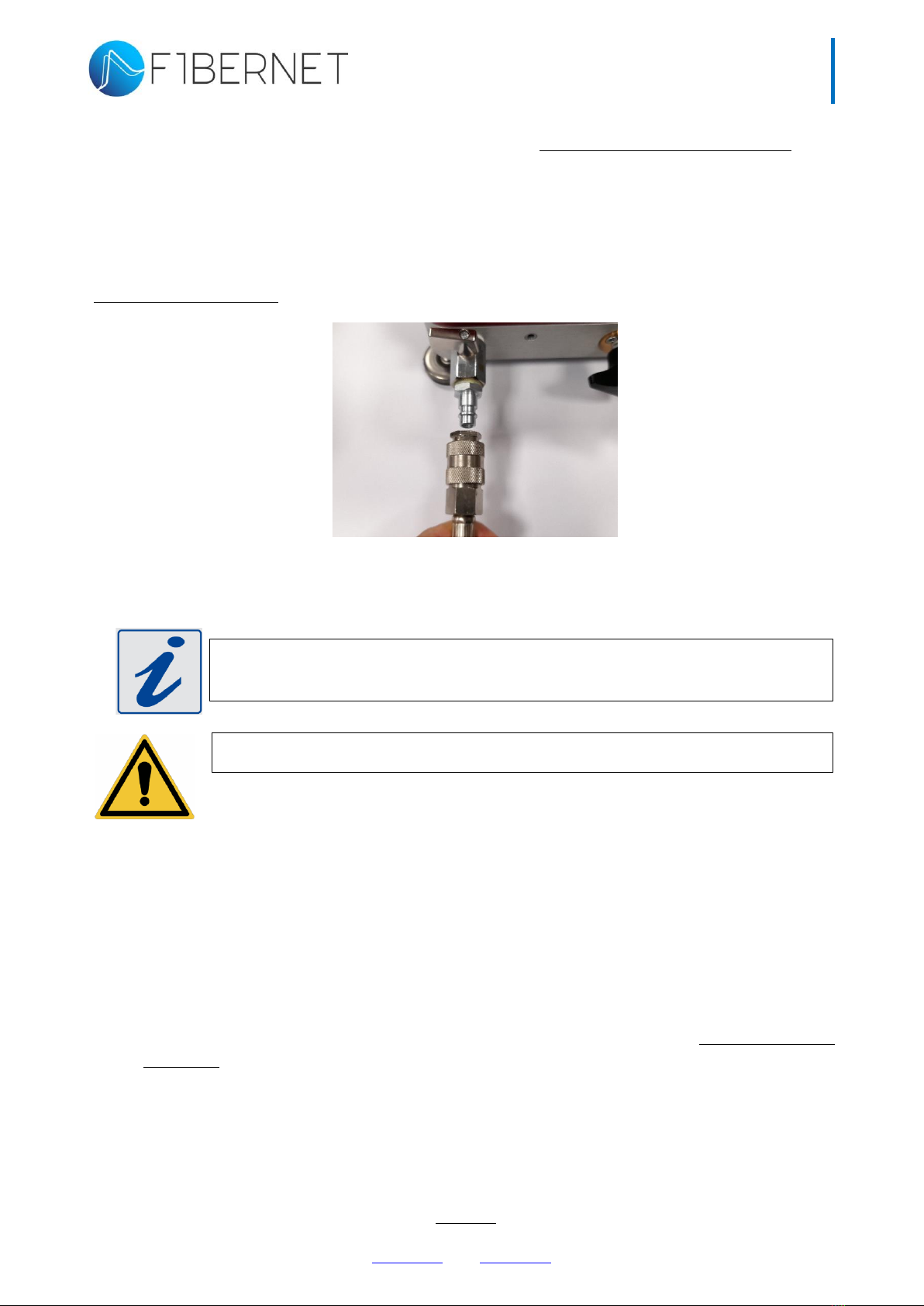

3.3.2. AIR COMPRESSOR CONNECTION

After having positioned the minitube, the cable and their gaskets, connect the air hose to the

“compressed air connector” (7).

Figure 15: connecting the air hose to the compressed air connector

3.4. CABLE POSING

After having connected all the above mentioned components, you can proceed by lighting up the

display by pushing the “ON/OFF” button (menu instructions are listed in paragraph 3.6)

To pose the cable:

•Connect the electric screwdriver spindle equipped with a clutch to the “electric screwdriver

connector” (8).

NOTE: Compressed air helps reduce friction inside the minitube. We recommend

to increase pressure gradually once you started the machine.

MAXIMUM AIR PRESSURE SHALL NOT EXCEED 16 BAR

FIBERNET SRL

Sede Operativa: Via degli Olmetti,18 –00060 Formello (RM) - Italia

Capitale € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

16

USER MANUAL

LADY

Figure 16: connecting the electric screwdriver.

NOTE: Lady can be actioned by an electric or pneumatic motor. Respective manuals are provided

according to the type of motor chosen.

Figure 17: Direction of rotation of the electric screwdriver spindle

•Start the electric screwdriver keeping an eye contact on the “LCD display” (2) while making sure

that the cable is properly moving between the drive belts.

ATTENTION: MAKE SURE THAT THE DIRECTION OF ROTATION OF THE

ELECTRIC SCREWDRIVER IS SET COUNTER-CLOCKWISE AS SHOWN ON THE

“ELECTRIC SCREWDRIVER CONNECTOR “

Direction of

rotation

ATTENTION: STOP THE DEVICE IF YOU SEE THAT THE CABLE IS NOT MOVING

TO AVOID POSSIBLE DAMAGE TO THE CABLE OR TO THE MACHINE

we recommend inserting a 10 mm male hex

socket in the electric screwdriver

FIBERNET SRL

Headquarters: Via degli Olmetti,18 –00060 Formello (RM) - Italy

Share Capital € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

17

USER MANUAL

LADY

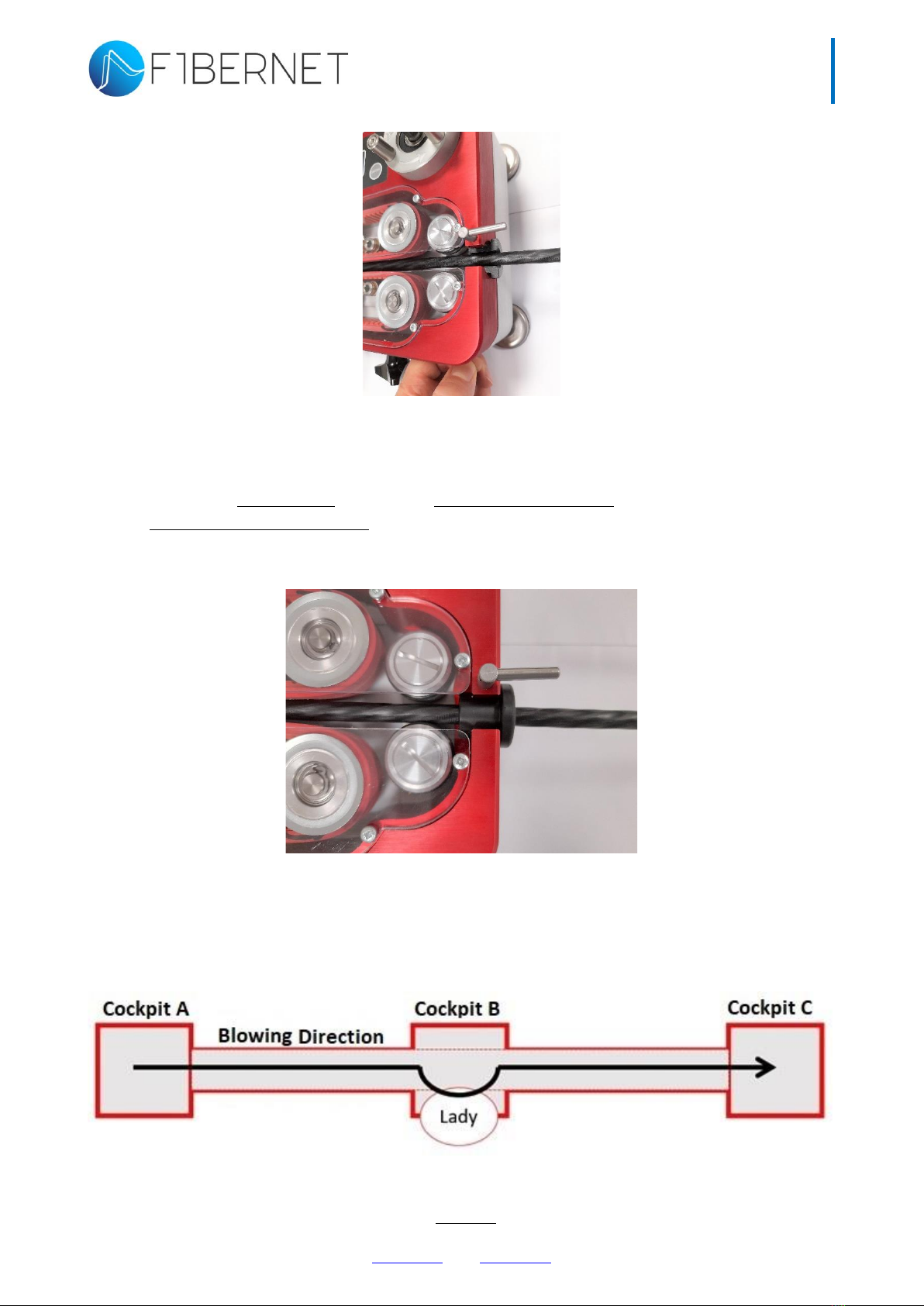

3.5. CABLE POSING IN AN INTERMEDIATE STOP

When the blowing operation stops between two cockpits a possible solution is to intervene in an

intermediate cockpit, intercepting the tube without interrupting cable’s continuity.

Figure 18: initial situation.

Lady set in proximity of cockpit A, blows cable toward cockpit C.

Figure 19: cable pose interrupted.

Passed the intermediate cockpit B, blowing operation stops before reaching cockpit C.

Figure 20: Open cockpit B, place lady in this intermediate cockpit and continue operation.

It is possible to resume the operation intercepting the tube and inserting the cable back again assuring

continuity.

FIBERNET SRL

Sede Operativa: Via degli Olmetti,18 –00060 Formello (RM) - Italia

Capitale € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

18

USER MANUAL

LADY

Inserting cable in continuity in the blowing machine:

•Extract the “upper cable entry adapter”(4.a) turning the “cable entry adapter fixing lever” (3).

Figure 21:Open the cable entry adapter kit turning the lever outwards

•Open the “air lid”(1) and the “minitube fixing clamp”(12).

•With a pair of scissors cut diagonally both cable and duct gasket.

Figure 22: cut gaskets diagonally.

FIBERNET SRL

Headquarters: Via degli Olmetti,18 –00060 Formello (RM) - Italy

Share Capital € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

19

USER MANUAL

LADY

•Now insert both gaskets on the corresponding component

Figure 23: inserting diagonally cut gaskets.

•Set cable and minitube inside the device, positioning the gaskets with cut facing down, for a

better fit, as shown in figure 24.

Figure 24: positioning the gaskets with cut facing down

•Set pressure between cable and drive belts using the “drive belts pressure regulation knob” (6).

•Insert the cable inside the “cable entry” (4) pulling the “meter counter wheel opening lever” (5).

FIBERNET SRL

Sede Operativa: Via degli Olmetti,18 –00060 Formello (RM) - Italia

Capitale € 100.000,00 - P.I. e C.F.: 06557181002 - Tel. +39 06 90405039, +39 06 90400349 –Fax +39 06 90409266

www.fibernet.it; E mail: info@fibernet.it

20

USER MANUAL

LADY

Figure 25: pulling the meter counter wheel opening lever to insert the cable

•Closing the “cable entry kit” (4): set the “upper cable entry adapter” (4.a) and fix it by turning the

“cable entry adapter fixing lever” (3) inward.

Figure 26: cable insetion inside cable adapter kit.

•Finish the operation following the above-mentioned steps.

Figure 27: operation completed.

Other manuals for LADY

1

Table of contents