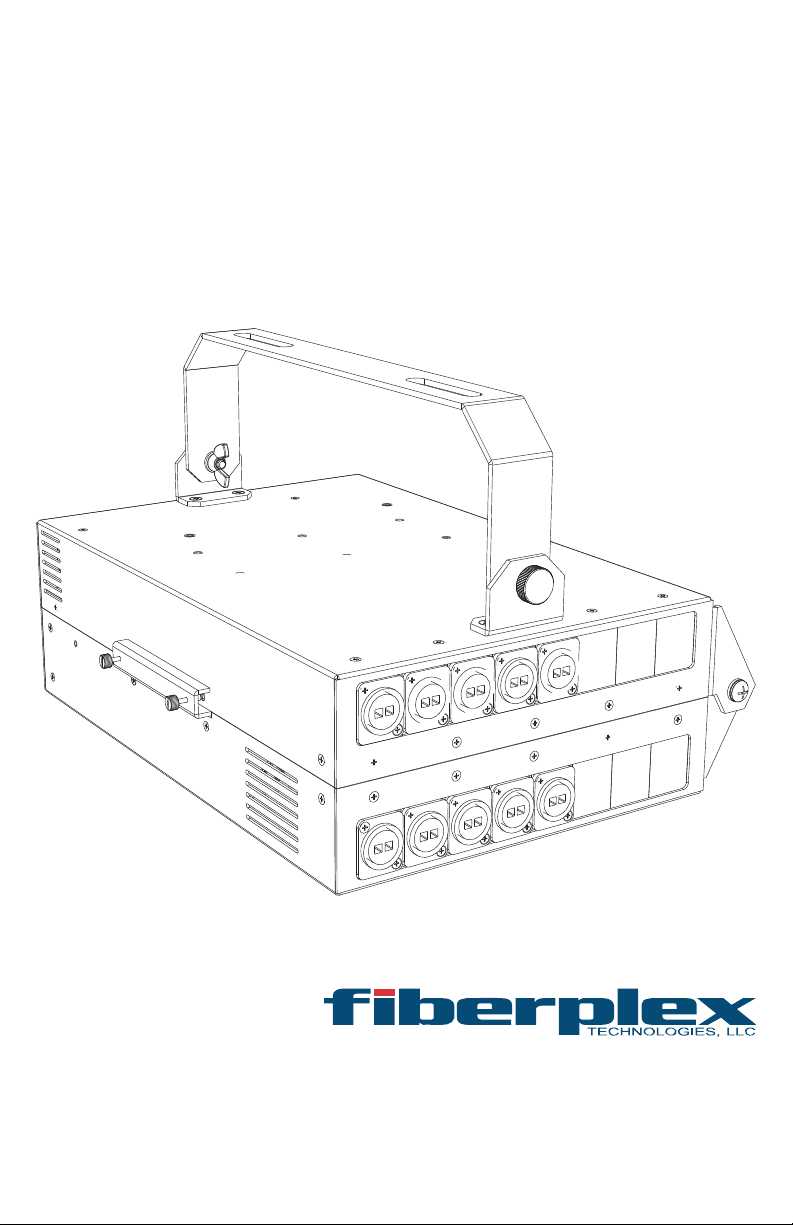

Fiberplex TTM User manual

USERMANUAL

6PositionTrussMountEnclosureforTDSeries

Moduleswith16ChannelModularFrontPanel

TTM

WarningforYourProtection

1.Readtheseinstructions.

2.Keeptheseinstructions.

3.Heedallwarnings.

4.Followallinstructions.

5.Donotusethisapparatusnearwater.

6.Cleanonlywithadrycloth.

7.Donotblockanyoftheventilationopenings.Installinaccordancewiththemanufacturer’sinstructions.

8.Donotinstallnearanyheatsourcessuchasradiators,heatregisters,stoves,orotherapparatus(includingamplifiers)thatproduceheat.

9.Donotdefeatthesafetypurposeofthepolarizedorgrounding‐typeplug.Apolarizedplughastwobladeswithonewiderthantheother.A

groundingtypeplughastwobladesandathirdgroundingprong.Thewidebladeorthethirdprongisprovidedforyoursafety.Iftheprovidedplug

doesnotfitintoyouroutlet,consultanelectricianforreplacementoftheobsoleteoutlet.

10.Protectthepowercordfrombeingwalkedonorpinched,particularlyatplugs,conveniencereceptacles,andthepointwheretheyexitfromthe

apparatus.

11.Onlyuseattachments/accessoriesspecifiedbythemanufacturer.

12.Useonlywiththecart,stand,tripod,bracket,ortablespecifiedbythemanufacturer,orsoldwiththeapparatus.Whenacartisused,use

cautionwhenmovingthecart/apparatuscombinationtoavoidinjuryfromtip‐over.

13.Unplugthisapparatusduringlightningstormsorwhenunusedforlongperiodsoftime.

14.Referallservicingtoqualifiedservicepersonnel.Servicingisrequiredwhentheapparatushasbeendamagedinanyway,suchaspower‐supply

cordorplugisdamaged,liquidhasbeenspilledorobjectshavefallenintotheapparatus,theapparatushasbeenexposedtorainormoisture,does

notoperatenormally,orhasbeendropped.

Theapparatusshallnotbeexposedtodrippingorsplashing.Noobjectsfilledwithliquids,suchasvasesordrinkcups,shallbeplacedonthe

apparatus.

“WARNING:Toreducetheriskoffireorelectricshock,donotexposethisapparatustorainormoisture.”

GeneralInstallationInstructions

Pleaseconsiderthesegeneralinstructionsinadditiontoanyproduct‐specificinstructionsinthe“Installation”chapterofthismanual.

Unpacking

Checktheequipmentforanytransportdamage.Iftheunitismechanicallydamaged,ifliquidshavebeenspilledorifobjectshavefallenintothe

unit,itmustnotbeconnectedtotheACpoweroutlet,oritmustbeimmediatelydisconnectedbyunpluggingthepowercable.Repairmustonlybe

performedbytrainedpersonnelinaccordancewiththeapplicableregulations.

InstallationSite

Installtheunitinaplacewherethefollowingconditionsaremet:

Thetemperatureandtherelativehumidityoftheoperatingenvironmentmustbewithinthespecifiedlimitsduringoperationofthe

unit.Valuesspecifiedareapplicabletotheairinletsoftheunit.

Condensationmaynotbepresentduringoperation.Iftheunitisinstalledinalocationsubjecttolargevariationsofambient

temperature(e.g.inanOB‐van),appropriateprecautionsmustbetaken.

Unobstructedairflowisessentialforproperoperation.Ventilationopeningsoftheunitareafunctionalpartofthedesignandmust

notbeobstructedinanywayduringoperation(e.g.‐byobjectsplaceduponthem,placementoftheunitonasoftsurface,or

improperinstallationoftheunitwithinarackorpieceoffurniture).

Theunitmustnotbeundulyexposedtoexternalheatsources(directsunlight,spotlights).

AmbientTemperature

UnitsandsystemsbyFiberPlexaregenerallydesignedforanambienttemperaturerange(i.e.temperatureoftheincomingair)of+5...+40°C.

Whenrackmountingtheunits,thefollowingfactsmustbeconsidered:

Thepermissibleambienttemperaturerangeforoperationofthesemiconductorcomponentsis0°Cto+70°C(commercial

temperaturerangeforoperation).

Theairflowthroughtheinstallationmustallowexhaustairtoremaincoolerthan70°Catalltimes.

Averagetemperatureincreaseofthecoolingairshallbeabout20C°,allowingforanadditionalmaximum10C°increaseatthe

hottestcomponents.

Ifthecoolingfunctionoftheinstallationmustbemonitored(e.g.forfanfailureorilluminationwithspotlamps),theexhaustairtemperaturemust

bemeasureddirectlyabovethemodulesatseveralplaceswithintheenclosure.

GroundingandPowerSupply

Groundingofunitswithmainssupply(classIequipment)isperformedviatheprotectiveearth(PE)conductorintegratedinthreepinPhoenix™

connector.Unitswithbatteryoperation(<60V,classIIIequipment)mustbeearthedseparately.Groundingtheunitisoneofthemeasuresfor

protectionagainstelectricalshockhazard(dangerousbodycurrents).Hazardousvoltagemaynotonlybecausedbydefectivepowersupply

insulation,butmayalsobeintroducedbytheconnectedaudioorcontrolcables.

Thisequipmentmayrequiretheuseofadifferentlinecord,attachmentplug,orboth,dependingontheavailablepowersourceatinstallation.If

theattachmentplugneedstobechanged,referservicingtoqualifiedpersonnel.

Warranty,ServiceandTermsandConditionsofSale

ForinformationaboutWarrantyorServiceinformation,pleaseseeourpublished‘TermsandConditionsof

Sale’.Thisdocumentisavailableonfiberplex.comorcanbeobtainedbyrequestingitfrom

[email protected]orcalling301.604.0100.

Disposal

DisposalofPackingMaterials

Thepackingmaterialshavebeenselectedwithenvironmentalanddisposalissuesinmind.Allpackingmaterial

canberecycled.Recyclingpackingsavesrawmaterialsandreducesthevolumeofwaste.Ifyouneedto

disposeofthetransportpackingmaterials,recyclingisencouraged.

DisposalofUsedEquipment

Usedequipmentcontainsvaluablerawmaterialsaswellassubstancesthatmustbedisposedof

professionally.Pleasedisposeofusedequipmentviaanauthorizedspecialistdealerorviathepublicwaste

disposalsystem,ensuringanymaterialthatcanberecycledhasbeen.Pleasetakecarethatyourused

equipmentcannotbeabused.Afterhavingdisconnectedyourusedequipmentfromthemainssupply,make

surethatthemainsconnectorandthemainscablearemadeuseless.

Disclaimer

Theinformationinthisdocumenthasbeencarefullycheckedandisbelievedtobeaccurateatthetimeof

publication.However,noliabilityisassumedbyFiberPlexforinaccuracies,errors,oromissions,norforlossor

damageresultingeitherdirectlyorindirectlyfromuseoftheinformationcontainedherein.

Introduction

ComplementingtheflexibilityoftheFiberPlex‘TDSeries’offiberopticmodules,theTTMprovidesconnection,

mounting,power,andcablemanagementforupto6frontfacingTDmodulesinacompactandruggedTruss

Mountablealuminumenclosure.Eachofthe16channelsofthemodularTTMfrontpanelcanaccommodate

anyNeutrik™DSeriesconnector,LCandSTbarrelconnectors,DB9connectors,etc.Theunusedpositionsare

simplyfilledbyinsertingblankpanels.Additionally,theTTMhas4additionalmodularchannelsontherearof

theunitforgreaterflexibility.Therearconnectorsallowforcableattachmentinopposingdirectionswithout

worryingaboutbendingthefiber‐opticcables,whilealsohelpingtokeepthecablingneatandorganized.The

integratedkey‐holemountingholesonthebottomoftheTDunitslocksecurelyonmatingstudswhilearear

retentionbarholdsthemsecurelyinplace.A6positionpowerwiringharnessandincludedpoweradapter

providepowerandapositiveearthgroundtothemodulesvia3positionPhoenix™lockingpowerconnectors.

Managingallthatcablingandfibercanbetedious;theTTMallowsasimplesolutiontoputmaximumcapacity

andflexibilityintoasingletrussmountedunit.

KeyFeatures

Providesmountingandpowerforupto6singlewideTDSeriesmodules,orupto2

doublewideand2singlewidemodules

Perfectforconnectingtotrussmountedequipment

Accommodatesupto16connectorpositions

PlatesavailableforstandardNeutrik™DSeriesconnectors,LCandSTbarrels,DE‐9,etc

Reconfigureinminutes

Securelyseatsmoduleswithpositiveretentionbar

IntegratedACpowersupplyandwiringharnessincluded

Convenientcabletrayforcleaninstallation

GettingStarted

InitialInspection

Immediatelyuponreceipt,inspecttheshippingcontainerfordamage.Thecontainershouldberetaineduntil

theshipmenthasbeencheckedforcompletenessandtheequipmenthasbeencheckedmechanicallyand

electrically.Iftheshipmentisincomplete,ifthereismechanicaldamage,oriftheunitfailstooperatenotify

FiberPlexandmaketheshippingmaterialsavailableforthecarrier'sinspection.

ChassisMounting

TheTTMcanbeopenedbyunscrewingthetwothumbscrewsalongthelatch,andswingingthechassisopen

aboutthehinges.Topreventpinchinginjury,keepfingersawayfromtheopenedgeswhenclosingthechassis.

Mountthechassistoanystandardtrusssectionusingtwotrussclamps,alsoknownasCheeseboroughclamps,

(notincluded)oftheappropriatesize.TheTTMmountingbracketisdesignedtoaccommodatetrussclamps

withM10mountingbolts.Theseclampsshallbeaffixedtotheswivelbracketofthechassis,withtheM10

mountingboltthrougheachslot.Therotationalalignmentcanthenbeadjustedbylooseningthetwowing

nutswherethebracketjoinsthechassis,movingtheTTMtothedesiredposition,andthentighteningthe

wingnutsandthetrussclampstoholditinplace.Thechassisshouldbelocatedinanenvironmentwherean

ambienttemperaturebetween0°and50°Ccanbemaintained,withallventsunobstructed.

PowerRequirements

Anycombinationof6FiberPlexTDSeriesModulescanbemountedinaTTM.EachTDmodulecandrawas

muchas6Watts,andtheventilationfancandrawupto1.5Watts,foratotalmaximumpowerconsumption

of37.5Watts.Powerissuppliedtotheindividualmodulesthroughapre‐wiredPowerHarnessthatconnects

theonboardpowersupplytothemodulesusing3pinPhoenix™connectors.PowerissuppliedtotheTTMas

ACmainspower(100to240V,universal)throughaNeutrikPowerCONTRUE1connectorontherearofthe

enclosure.

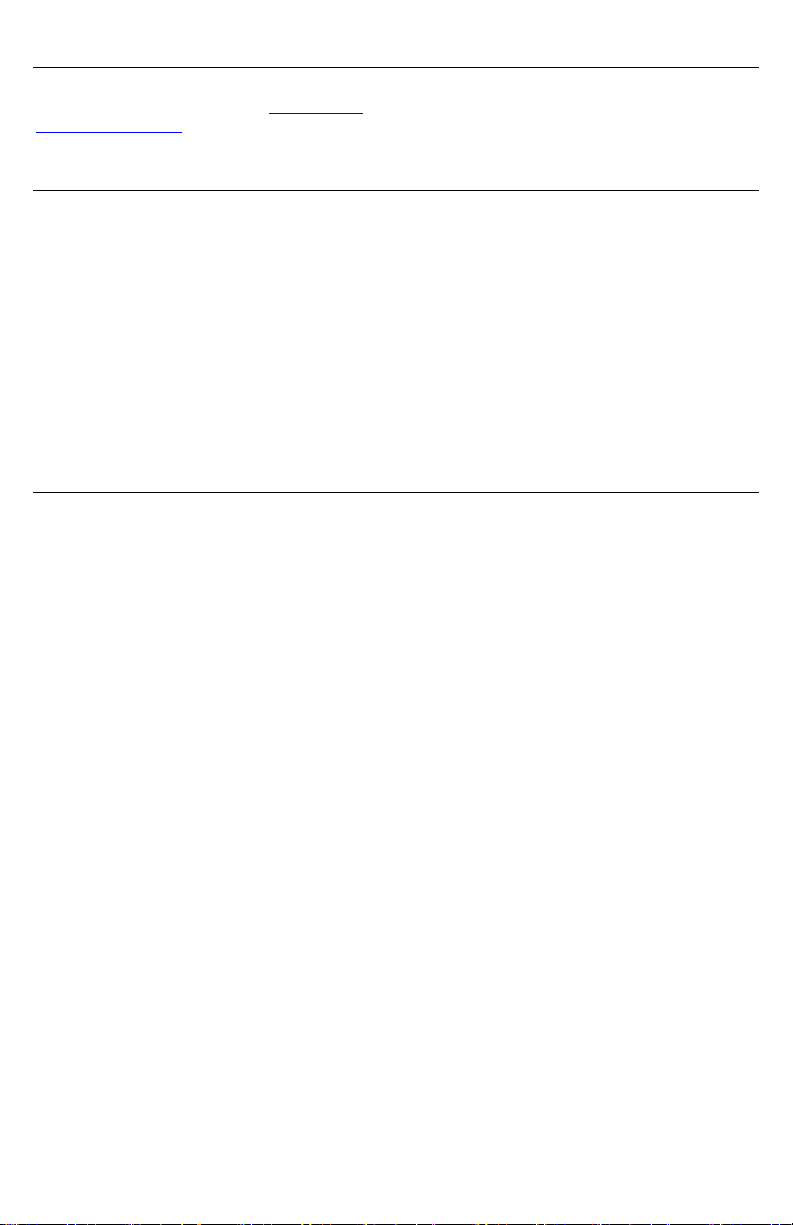

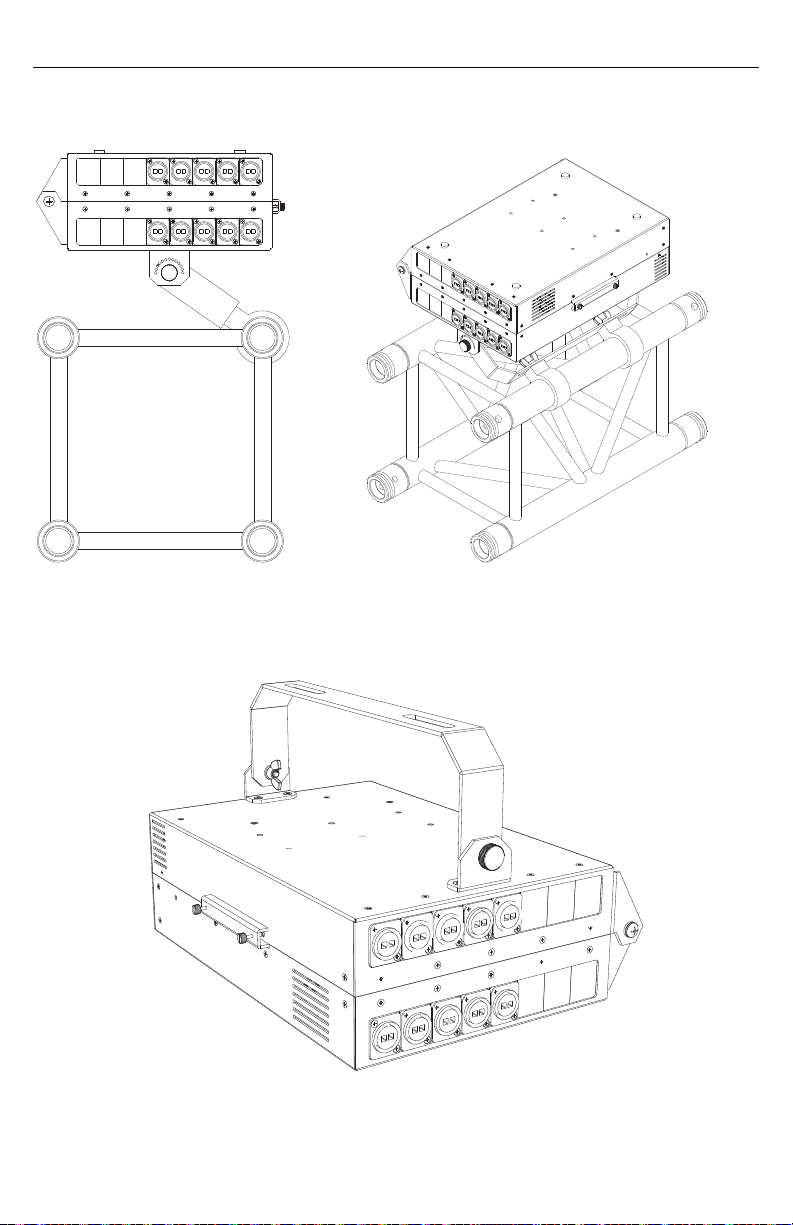

MountingOptions

Figure1TrussMountusingCheeseboroughClamps(notincluded)

Figure2Portable"DropBox"

Features

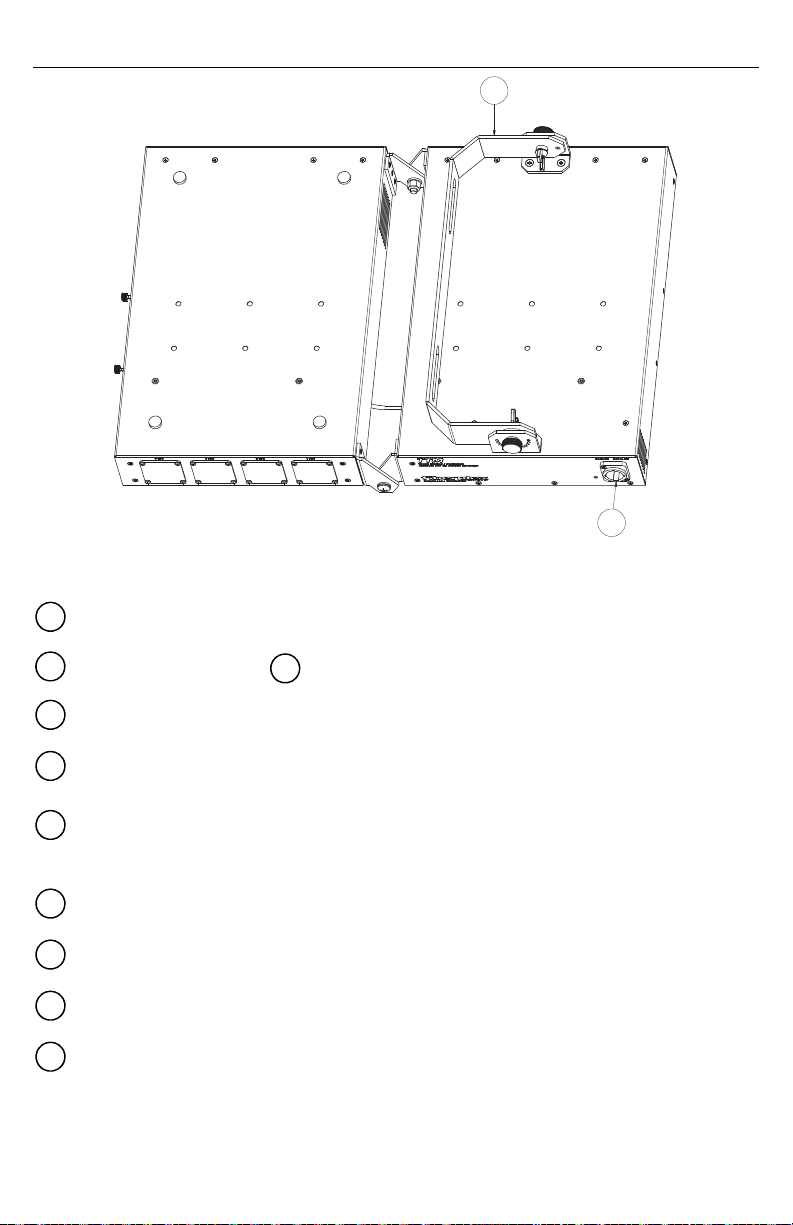

Figure3:TTMOpen

TTMEnclosure–ThehingedtraysoftheTTMaremadefromruggedaluminumandneatlyfoldclosed,

givingitalowprofilewhilemountedtoatruss.Theunithas6pairsofstudspressedintothebaseto

matewiththekeyholesonTD‐Seriesmodules.

FiberPlexTD‐SeriesModules(NotIncluded)–TheTTMcanaccommodateupto6TD‐Seriesmodulesor

twodouble‐widemodulesandtwoadditionalsingle‐widemodules.

RetentionBar& RetentionScrews–OncetheTD‐Seriesmodulesaresecurelyseatedonthe

pressedstuds, theretentionbarslidesinbehindthemtosecurethemodulestightlyinplace.

Tworetentionscrewsarethentightenedtoholdthebar.

CableTieDown–Sixtie‐wrapbasesareaffixedwithintheenclosuretoallowforcleanmanagementof

cablingtotheTD‐Seriesmodules.Tie‐wrapscanbeusedtosecurecablebundlesagainsttherearand

insidehingefacetopreventpinchingofthecablewhenclosingtheassembly.

BackShellRelief–ThebarprovidesclearancenotchesforthePhoenix™backshellsinstalledonthe

wiringharnessorindividualpowerconnections.Thesereliefcutsalsoeaseinsertionofthepower

connectionswhiletheretentionbarisinplace.

PowerSupplyBox–TheAC‐DCconverter,agroundpin,andtheACwiringarecompletelycontained

withinthepowersupplyboxtopreventelectrocution.Thishigh‐efficiencypowerunitcansupplyenough

powertorunallsixTDmodulesatfullloadandprovidesover‐current,over‐voltage,andshortcircuit

protection.

1

14

2

5

7

12 11

9

3

10

13 6

15 16

1

2

3 4

6

5

7

Figure4TTMOpen,Bottom

PowerCONTRUE1Connector–ACpowerentryfortheunit.Thisconnectormateswithastandard

PowerCONACplugtoreceiveinputpowerwithaflexiblevoltagerangeof100to240VAC.

PowerHarnesswith(6each) Phoenix™PowerConnectors–TheTTMcomesstandardwitha6‐

positionwiringharness.This harnessreceivesitspowerfromtheintegratedpowersupply.

ConnectorPositionBlankingPlates–Theseplatesfillunusedconnectorspaceinthefrontoftheunit.

I/OConnectorPositions–InputandOutputconnectorstotheTD‐Unitsareprovisionedhere.

RearConnectorPlates–Theunitcanbeequippedwithupto4I/Oconnectorsintherear,allowingfor

easybidirectionalconnection.Pleasenotethattheseplatesaredifferentlysizedandnotinterchangeable

withthefrontI/Oconnectorplates.

EnclosureLatch–Theunitissecurelyclosedscrewingthetwocaptivescrewsinthelatchbracketinto

holesontheoppositeenclosurehalf.

Hinge–Thereinforcedaluminumhingesallowtheunittosmoothlyswingopenforeasyserviceand

reconfiguration,andswingclosedforacompactprofileduringuse.

VentilationFan–Theunitcomesequippedwithaquietrunning50mmfantoremoveanyexceess

heatedairinsidetheenclosure.

Swivelbracket–Attachedtotheenclosureisaswivelablemountingbracket.Trussclampsaremounted

inthetwoslots.Theswivelpositionofthebracketcanbeadjustedbylooseningthethumbscrews,then

squeezingthetwosidestogethertofreethepositioningpins.Whilesqueezing,rotatethebracketintothe

desiredposition,thenletgoandtightenthethumbscrews.Optionally,wingnutscanbescrewedontothe

thumbscrewsandjammedagainstthemountingbracketthreadstoprovidevibrationresistance.

8

17

8

9 10

11

12

13

14

15

16

17

InstallingTDModules

1. OrienttheTDSeriesmodulewiththerear

(powerside)facingtherearoftheTTM

2. Alignthelargeopeningofthekeyholeonthe

bottomtotheTDmodulewiththepressed

studsontheMountingTray

3. LowertheTDmoduleoverthestudsuntilthe

moduleisflatonthetrayandslidetothefront

oftheMountingTrayuntilthemodulestops

4. Repeatsteps1‐3untilalldesiredmodulesare

installed.

5. LowertheRetentionBarflatonthetraysothat

itisontherear(power)sideoftheTDmodules

andstraddlesthethreadedstandoffs

6. PushtheRetentionBarforwarduntilitissecure

againsttheTDmodules,thereshouldonlybea

tinyshiftasittightensagainsttheunit.Tighten

theRetentionScrews.Repeatsteps5and6for

thethreemodulesontheotherhalfofthe

enclosure.

7. ConnectthePhoenix™powerconnector

fromthePowerHarnessatintoitsmating

connectorontheTDmoduleineach

position.

8. InstallloadedTTMontotrusswith

appropriateCheeseboroughclamps.

ReconfiguringFrontConnectors

1. Unscrewandremovetheupperpositioningand

holdingbracketsbyremovingthe7retainingscrews.

Notethatthescrewthatprotrudesthroughthehinge

bracketisslightlylongerthantheothers.

2. Slightlyloosenthe4screwsholdingthebottommountingplatetoreleasethe

modularconnectorplates.

3. Replaceandrearrangeconnectorplatesasneeded,

takingcaretoorientthechamferededgestowards

thefrontoftheenclosure.

4. Replaceandtheupperpositioningbracketusingtwoscrewsas

shown.

5. Tightendownthescrewswhichholdthelowerholdingbracket.

6. Replacetheupperholdingbracketandtightenall

screws.

Specifications

Figure5TTMDimensions,CaseOpen

20.65

[524.6]

21.48

[545.5]

2.78

[70.7]

1.81

[46.0]

14.28

[362.6]

Figure6TTMDimensions,CaseClosed

PHYSICALSPECIFICATIONS

Length Width Height Weight

CaseDimensions(Unloaded) 14.3in

(363mm)

11.4in

(290mm)

4.5in

(114mm)

6.5lb

(2.9kg)

ELECTRICALSPECIFICATIONS

Min Typ Max Units

PowerRequirement VoltageRange 100 110 240 VAC

PowerLineFrequency 50 ‐ 60 Hz

PowerConsumption ‐ 18 40 W

PowerConnector PowerCONTRUE1connectoronrear

14.28

[362.6]

6.46

[164.1]

11.48

[291.6]

4.65

[118.1]

14.29

[363.0]

10.91

[277.0]

18040-412 Guilford Rd. • Annapolis Junction, MD 20701

• 301.604.0100

UMTTM

161011

Table of contents