Chziri ZVFG7 series User manual

ZVFG7 SERIES

ϵÁÐ

ZVFP7 SERIES

ϵÁÐ

³¬Ì©µçÆ÷

INVERTER USER'S MANUAL

ÉϺ£³¬Ì©µçÆ÷ÓÐÏÞ¹«Ë¾

INVERTER

Foreword

Thank you very much for your purchase of ZVFG7

and ZVFP7 series of inverters.

This manual introduces the installation, operation,

function setting, trouble shooting and etc. of inverters.

Ensure that this manual is made available to the final

user and keep it handy for future reference.

If there is any doubt or question, please contact the

Technical Service Center of Company.

Incorrect installation or use may result in damage or other

accidents. Do read all instructions in detail before installing

or operating.

Directory

Article 1.Safety Instruction 4

1.1 The indication of safty symbol 5

1.2 Caution of electric 5

1.3 Caution of Installation and connection item 5

1.4 Caution of Operation 6

1.5 Caution of enviroment 7

Article 2 Introduction to Products 8

2.1 Checking after you got the Inverter 9

2.2 Symbol andtype reference 9

2.3 specification 10

2.4 standard technique 11

Article 3 Installation and Connection 12

3.1 Installation of Inverter 13

3.2 Connecting of Inverter 14

Article 4 Control panel and display 21

4.1 Control panel 22

4.2 Operation of control panel 24

4.3 The content of dispay 27

Article 5 Run-in test 28

5.1 Run-in test 29

5.2 Operation of run 30

Article 6 Reference on Function Data 31

6.1The fleet of function data 32

6.2Detail reference of function data 39

Article 7 Trouble diagnosis and treatment 58

7.1Trouble and the reason 59

7.2 Familiar trouble diagnosis and treatment 60

7.3Motor abnormity and treatment 64

Article 8 Repairing and Maintenance 66

8.1Repair and maintain 67

8.2 Transport and deposited 68

Article 9 Exterior dimension and installing dimension

69

9.1 Exterior dimension and installing dimension 70

Directory

Article 10 Quality guarantee 72

10.1Quality guarantee 73

Appendix

Appendix AOperation panel 74

Appendix B Trig unit .brake resistance 75

Appendix C Reference of surrounding equipment 76

1.1

1.2

1.3

1.4

1.5

1.1

1.2

1.3

Indications of Safety Symbols 5

Cautions for Electrical Work 5

Cautions for Installing and Wiring 5

Cautions for Operation 6

Cautions for Working Ambient 7

Article 1

This article mainly introduces cautions for installation, wiring,

operation, operating conditions and electrical work. To avoid

any errors that may result in damage to equipment or injury to

personnel, do read carefully all of the instructions in this article.

Indications of Safety Symbols

To use and operate the inverter correctly, do read and clearly understand

the following symbols in this manual before installing and operating it, and

follow the instructions exactly.

WARNING: This symbol callsyour attention toavoid any incorrect

operation that can result in serious damage to the

equipment or death to personnel.

CAUTION:This symbol callsyour attention toavoid any incorrect

operation that can result in damage to the inverter or

other equipment.

Caution of electric

The ground terminal must be reliably, properly and independently grounded

to ensure security.

The electronic components inside the inverter arevery sensitive to static.

Do keep your hands off thecircuit board and never put foreign matter inside

the inverter before taking antistatic measures. Otherwise, there is an

equipment failure.

Do not touch any active components in the inverter, for high voltage remains

in it when the indicator light isON after the power cut.

Cautions for Installation and connection

The installation and connection of inverter should be operated by qualified

electricians. Read this instruction manual in detail before installing and wiring.

Wait at least five (5) minutes after turning OFF the power supply before wiring.

Otherwise, there is the danger of electricshock.

Be sure that the main circuit iscorrectly wired. Three-phase 200V or 400VAC

input power must be connected to the terminals labeled R, S and T. Single

phase input power must be connected to terminals labeled L1 and L2. The

output power should be connected to terminals marked U, V and W. Otherwise,

there is serious damage to the inverter.

The output terminals (U, V, W) should be connected to the motor directly. Do

not install electromagnetic contactor, switch, capacitor or surge suppressor

between the terminal and the motor.Otherwise, it may result in inverter failure

and device damage.

Be sure to install the inverter on flame-resistant material such as a steel plate,

for heat will be produced during the running ofinverter. The surfaceof plate must

be flat or even. Otherwise, the base of inverter might be easily broken.

Be sure to install an exhaust fanor other ventilation equipment in the casein

which the inverter is installed, so as to keepthe ambient temperature less

than +40 .

Safety Instruction

Article 1 Safety Instruction

1.4 1.5

Cautions for Operation

Be sure to turn ON the input power supply only after closing the case. While

the inverter is energized, be sure not to open the case. Otherwise, there is the

danger of electric shock.

Be sure not to operate the inverter with wet hands. Otherwise, there is the

danger of electric shock.

Be sure not to disconnect power or install an electromagnetic contactor between

inverter and power to start or stop the inverter. Otherwise, it could reduce the

service life of inverter.

If the Retry Mode is set, please put a warning sign like KEEP CLEAR in

an eye-catching place before the equipment to avoid sudden restart of the

equipment after a trip stop that may result in injury to personnel.

Set an appropriate status of forward orreverse according to your specific

requirements. Otherwise, the motor may counter rotate.

Do not modify the set parameter value for inverter if there is no special

requirement, for the factory default setting has been done properly. Otherwise,

it may cause damage to the inverter or equipment due to error parameter.

The heat sink base, the braking resistanceand other heating elements will

have high temperature in running. Be carefulnot to touch them.

The operation of inverter can be easily changed from low speed to high speed.

Be sure to check the capability and limitations of the motor before operating the

inverter. Otherwise, the motor may get burned.

Cautions for operating ambient

It is strongly recommended not to use the

inverter in the following places that have:

direct exposure

to sunlight

corrosive gas

and liquid

Salt

gasoline and air mist

high humidity with relative

humidity>90% or dew

condensation

iron dust or foam

strong vibration extreme cold

over heat

Electromagnetic

wave (i.e., Welding

machine)

radioactive material

flammable material

Article 1 Safety InstructionArticle 1 Safety Instruction

2.1

2.2

Z VF 7

G

P

2 022

4

015

015=1.5kw

Introduction to Products

Article 2

Check the inverter immediately after you get it 9

Instruction on the nameplate and type 9

Product Specifications 10

Standard Technical Specifications 11

2.2.1 Instruction on the nameplate 9

2.2.2 Instruction on the nameplate 9

This article is a brief introduction of Inverter,main items

are name plate reference.type reference,the gerneral technique

and the checking item after you got the Inverter.

Checking after you got the Inverter

The Inverter has been inspected strictly and keep the Inverter

shock resistent.crash resistent ,maybe the accident happened in the

transport,so please open the carton and check it as soon as you got the

products.

Checking item:

1. check theInverter destroied or not.

2. Packing box concluding a piece of Inverter,a brochure.

3. Check the name plate ,be sure that the Inverter is your ordered.

The reference of name plate and type

2.2.1 Reference ofname plate

MODEL: ZVFG7-4015 1.5KW 2HP

INPUT: 3PH 400V 50/60Hz

OUTPUT: 3PH 0-400V 3.7A

Freq. Range: 0-400Hz

S / N: 0408001

AC Motor Drives Model.

Input Spec.

Output Spec.

Freq .Range.

Seri No. Bar Code.

2.2.2 Reference oftype

Maimum motoradapter power:022=2.2k w

Voltage ofinput:2=200v

4=400v

The code ofdesign

G means typeof ventilating(constant angular force)

P means typeof fan drive .water pump(square angularforce)

Converter adjustment

Code of enterprise

Article 2 Introduction to Products

S stands for single phase input, and

T stands for three-phase input.

S/T

INVERTER

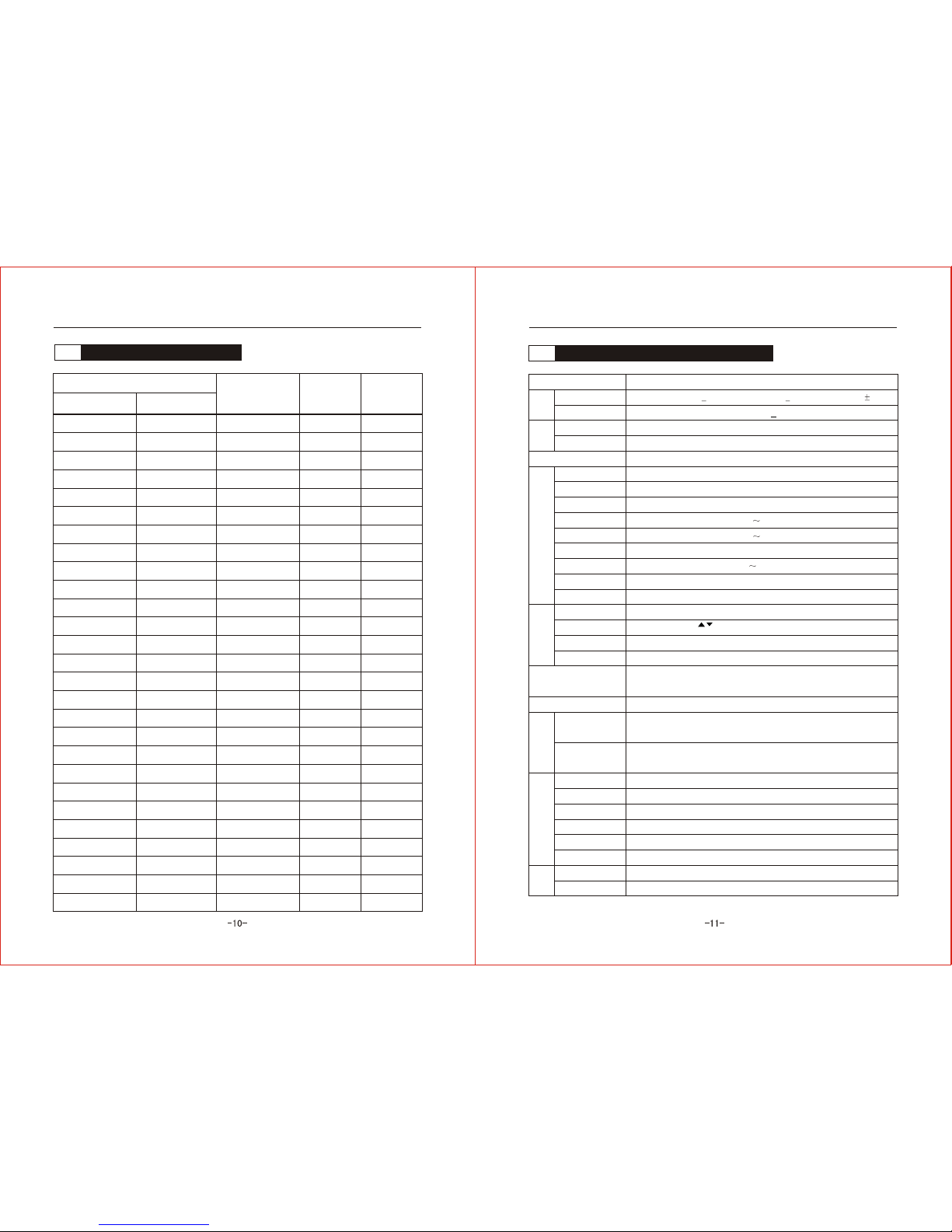

2.3

ZVFG7-2015T/S

ZVFG7-2022T/S

ZVFG7-4007T

ZVFG7-4015T

ZVFG7-4022T

ZVFG7-4037T

ZVFG7-4055T

ZVFG7-4075T

ZVFG7-4110T

ZVFG7-4150T

ZVFG7-4185T

ZVFG7-4220T

ZVFG7-4300T

ZVFG7-4370T

ZVFG7-4450T

ZVFG7-4550T

ZVFG7-4750T

ZVFG7-4930T

ZVFG7-41100T

1.5

2.2

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

93

110

7

10

2.5

3.7

5

8.5

13

18

24

30

39

46

58

75

90

110

150

170

210

2.4

0 30%

0.0 5.0 Hz

1 12KHz

IP20

Product Specifications

220

Standard Technical Specifications

Input

Item Reference

Input voltage

Input frequency

Output voltage

Output frequency

Single phrase 200V +15% three phrase 400V+20%

50/60 Hz+5%

Three phrase 0~inputvoltage

0.1~400Hz

Campacity of overload

ZVF-G7:150%rated current one minute ZVF-P7:

120%Rated current one minute

Control function

Adjustment

Output Accuracy

Space voltage complexor SVPWM control

Max output frequency +0.1%

Output frequency

resolution factor

Data setting:0.1Hz analog setting:Max frequency *0.1%

angular force lifting

angular force

compensation

Speed/release time

PWM carrier frequency

V/F curve line

Mutistep run

Straight and S curve line .eight section

speed/release the time.set range 0.1~999.9s

Set the V/F curve arbitrarily

DC brake frequency 0.0~25.0Hz.torque 0~30%.time 0.0~25.0S

Run function

Run control

Frequency setting

Input signal

Output signal

Panel control .terminal control exterior

Panel key ,analog voltage or potentiometer .

analog current .terminal exterior lift/down

Positive. Reverse command,multi speed command,run command,

accident input,reset command,count input and so on.

Accident warning output (250V/2A contact),open electric pole output

Other function Diagram run.PID.restart after transient stop,restart after accident,

frequency down up,data locking.crawl function.absorbing function and so on.

Protection function

Overcurrent protection.over voltage protection.under voltage protection.

overload protection.over heat protection.output short circuit protection

Dispaly

Run

accident

Output frequency.output current.output voltage.DC bus bar voltage.speed .

PID feedback.PID aim data.counter data

Overc urrent.over voltage.under voltage.overload.over heat.output shirt

circuit.system abnormality.fault of diagram code.accident exterior.depsoit

fault.data fault and so on

Enviroment

Exterior connecting meter

Work place

altitude

Temperature.humidity

shake

Deposit temperature

Analogue frequency teller.analogue ammeter(ImA).analogue volmeter(DC10V)

Indoor,avoid the sunshine,without dust ,without combustible and corrosion gas

Below 1000 meters

Temperature:-10 degree~+40 degree humidity:20%~90%RH(with water drip)

Below 0.5G

-20 degree~+60 degree

Force fan cold

Function

Protect grade

Manner of cooling

ZVFP7-4110T

ZVFP7-4150T

ZVFP7-4185T

ZVFP7-4220T

ZVFP7-4300T

ZVFP7-4370T

ZVFP7-4450T

ZVFP7-4550T

ZVFP7-4750T

ZVFP7-4930T

ZVFP7-41100T

ZVFG7-2037T/S

ZVFG7-2055T

ZVFG7-2075T

ZVFG7-2110T

ZVFG7-2150T

ZVFG7-2185T

ZVFG7-2220T

3.0 13

Output

Article 2 Introduction to ProductsArticle 2 Introduction to Products

Three-phase 200V 15%

220

220

220

Type of Inverter

Input Voltage

(v)

Max Adapter

Moter(kw)

Rated output

current(A)

ZVFG7-2007T/S 0.75 4

220

means type of

ventilating

means type of fan

drive .water pump

220

220

220

220

220

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

380

5.5

7.5

11

15

18.5

22

33

65

75

90

49

25

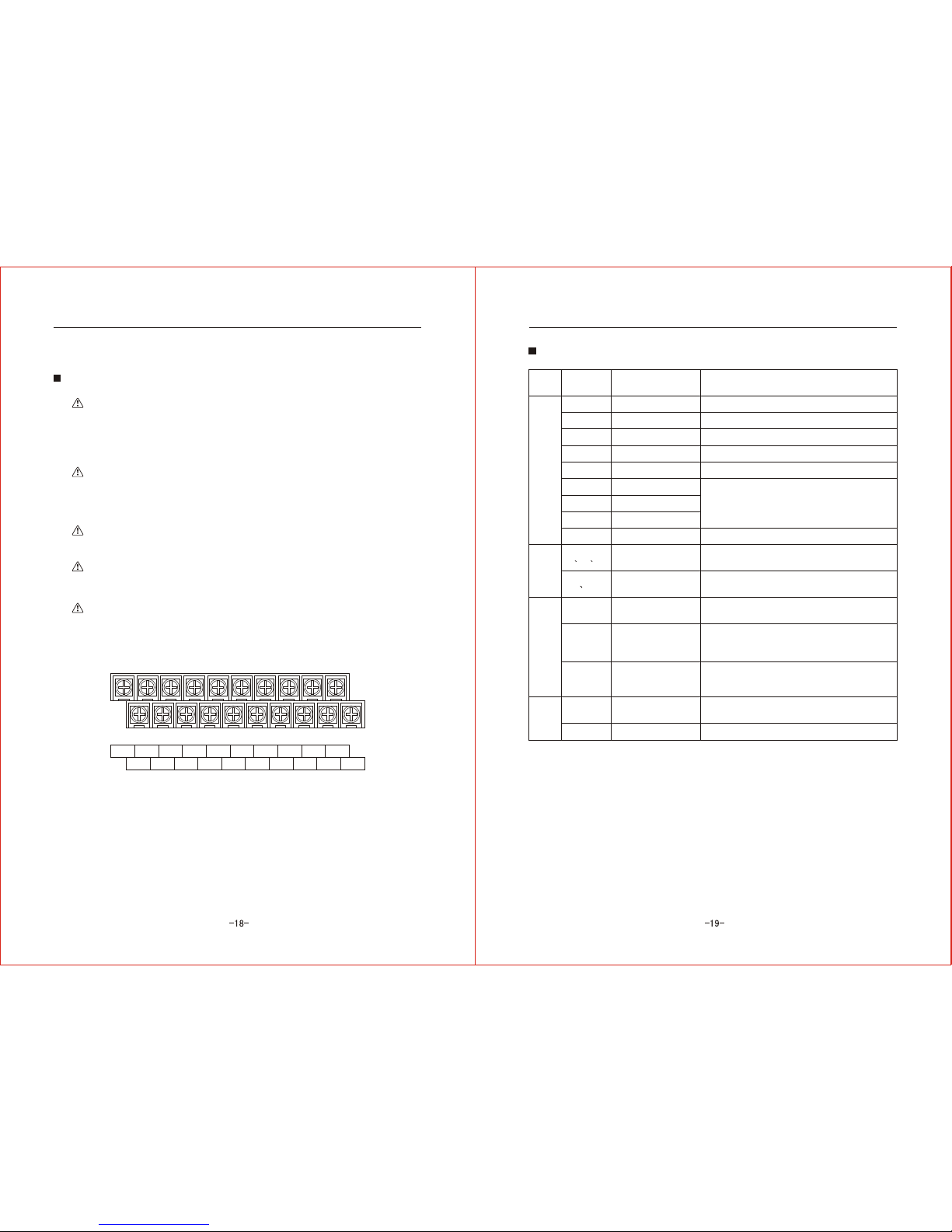

3.1.1

3.1.2

3.1.3

3.2.1

3.2.2

3.2.3

3.2.4

3.1

3.2

3.1

150mm above

150mm above

50mm above 50mm above

1 2 3

Installation and Connection

Article 3

Installation of Inverter 13

Caution of enviroment 13

Caution of installation 13

Install space and direction 13

Connecting of Inverter 14

Standard connecting diagram 14

key electric way connecting 15

connecting of control 18

The listof complement electricity 20

Good or badenviroment is theneccessory item for the Inverter.

In that case,be sure to install it correctly.The installation job are charge

for the electrician.Pleasepay attention tothe caution item.

Installation of Inverter

3.1.1 Caution ofenviroment

Under the 1000meters of altitude

Temperature.humidity: Temperature:-10 degree ~+40 degree h umidity:

20%~90%RH(with water drip)

Without dirct sun shine.no water drip .noevapour.dust and oil place

Indoor,avoid t he sunshin e,without dust ,without combustible and corrosion

gas

No granule of metal or foam ofmetal place

No shake .no electro magnetic interference place

3.1.2 Caution ofinstallation

The board must be plat,otherwise it will make the base breaken

off .

There will be heat when the Inverter run,so it is better to install

the Inverter on the steel board and other fire-resisted material.

If you install the Inverter in the cabinet,please install the pan

in additional,be sure to keep the enviroment below+40degree;

Caution:

Caution:

Caution:

3.1.3 Install spaceand direction

In order to keep cool the Inverter well and maintainwell,you would

better keep the enough space for the Inverter and install it vertically.

If you install two piececs in a cabinet ,please install it in horiz ontal

dioposition (No.2 picture);if itis neccessory to install together up and

down,in order to avoid the overheat,please add a division board(No.3

picture)

Article 3 Installation and Connection

Wind output Wind output

Wind input Wind input

Wind input

Wind input

Wind output

Wind output

3.2

DC-

DB P

DC+

U

V

W

TA

TB

TC

Y1

Y2

COM

R

S

T

COM

STF

STR

EMS

RST

X1

X2

X3

X4

COM

10V

VRC

+ I

Braking resistance

AFM

COM

+12

DC0-10V or 0-1mA

+12V output

Inverter connecting

3.2.1 Standard connecting diagram

brakeing unit electric reactor

Motor

Three phrase

Input

Power

Potentiometer input

or analogue voltage

input(DC0-10V)

Analogue current input

(4~20mA)

accident relay output

(AC250/2A)

muti light rootoutput 1

muti light rootoutput 2

Public terminal

Positive rotation/stop

Reverse rotation/stop

Accident exterior

Reset after accident

Muti speedX1

Muti speedX2

Muti speedX3

Crawl

Analogue signal output

Note: The factory set the connecting diagram;

Indicate the key terminal, indicate the control terminal

3.2.2 Key electricconnecting

Caution of the key electric conneting

Dangerous: Be sure the key electirc connecting correct.Three-phase

200V or 400V input have to connect R.S.T terminal blocks,

(single phrase 220V input have to connect the terminal block

L1.L2),output have to connect the terminal block U.V.W,

otherwise it will destroy the Inverter.

Dangerous: It is forbidden to connect the wire when the Inverter is in

use.Be sure to operate it when cut off the power after five

minutes .

The terminal block for output (U.V.W) must be connect to

the motor directly,do not install magnetic starter .switchgear.

power capacitor and surge protetsive device with it.other

wise it will destroy the Inverter;

Attention:

It only switching the motor or power after the Inverter stoped.

Attention:

Attention:

Attention:

It is forbidden earth other currentloaded equipment.Be sure

earth seprately and the wire must be as short as possible.

It must be earth well,avoid the electric shock . the fire or

reduce the sound.It is forbidden that it connect a circuit with

many Inverter earth.

Attention:

Attention:

Attention:

Earth has match the international requirement.

Be sure to connect the wire with the press terminal, keep the

connecting contact.

After comp leted the connecting ,please check it whether

impurity in it,and be sure that the connecting cor rect. No le akage

and wrong connecting.No circuit between the terminal and the

connector.

Article 3 Installation and ConnectionArticle 3 Installation and Connection

WrongRight Wrong

ZVFG7 4075T 4110T

GND R ST U V P

WDB

ZVFG7 4185T 4300T

ZVFP7 4220T 4370T

R ST V WU

DC-

DB P

RST

UVW

DB¡¢P

P¡¢DC-

P¡¢DC+

ZVFG7 4300T 41100T

ZVFP7 4450T 41320T R ST DC+ DC-

PW

U V

ZVFG7 2007S 2022S

GND L1 L2 V P

WDB

U

ZVFG7 4115T 4150T

ZVFP7 4150T 4185T R ST V WU

DC-

DB

P

earth single phrase input connecter brake resisitance

The key terminal

three phrase input

earth connecter brake resisitance

three phrase input

earth brake unit connecter

three phrase input

earth brake unit connecter

three phrase input

earth connecterreactor

Main circuit terminal reference

Mark Title of terminal Function reference

Input terminal of Inverter Connect the Three-phase

Output terminal of Inverter

Connect the three

phrase motor

Brake terminal

Connect exterior

resistence of braking

DC bus bar terminal Connect external braking unit

External reactor terminal Connect the DC reactor external

Earth terminal earth

Reference of main circuit connecting

Three phrase input terminal (R.S.T) connect freely,

Output terminal (U.V.W) connect the three phrase motor,if you find the

rotating reverse ,please adjust the two phrase arbitrary,

The Inverte r below 15KW concluding the brake unit,if you need to

connect the brakeing resistance,please connect the it between DBand Por

+ -;

BR and BR

The Inverte r with out the int ernal brake unit,in order to increase the

braking ability ,it can be incraese a braking unit between terminal Pand DC+.

If the wire between the motor and the Inverter is too long,especiall y the

low frequency out put,the rotate torque will fall down or the accident will

happened in the condition of the component s act error.So it would better

that the length no exceeding 50 meters(200V is 30 meters),other wise

please consider plus output side ACreactor.

The connecting which between Inverter and the motor would better put

in metal pipe.

brake resistance

brake resistance

Article 3 Installation and ConnectionArticle 3 Installation and Connection

L1 L2 Input terminal of Inverter Connect the singlephase

BR+ BR- Brake terminal

Connect exterior

resistence of braking

P DB

P DC-

P DC+

ZVFG7 4007T 4040T

ZVFG7 2007T 4055T

ZVFG7 2075T 2110T

ZVFG7 2150T 2220T

COM

STF

STR

EMS

RST

X1

X2

X3

X4

TA¡¢TB¡¢TC

Y1¡¢Y2

10V

VRC

+I

AFM

-----

+12V

TA TB TC X1 X2 X3 X4 EMS RST +12V

Y1 Y2 STF COM STR 10V VRC COM +I AFM

3.2.3 Connecting of the control circuit

Caution of the connecting circuit

Control circuit must be absorb creen wire and twisted

pair wire,and it must be connect to the key circuit .stav ing

circuit separatly.If the control circuit line must be cross

the the key circuit and other control line , it mustbe

vertical cross connecting.

Attention:

Attention:

Attention:

Attention:

Attention:

Control circuit is easily disturbed by the enviroment,

so the distancemust be short ( Generally no exceeding

30 meters).Analogue voltage .Ampere and potentiometer

input no exceeding20 meters.

In the condition of contact ,please use the reliable

contact point.

Be sure to install the surgue absorbing between the magnetic

coil which is occuring voltage surge ,it eliminates the voltage

surge that avoid the error action.

2

The wire for control circuit used to 0.75mm

Reference for the terminal of control circuit

Type Mark Title of terminal Reference of function

Input singnal

Public terminal

Positive rotata/stop

Reverse/stop

Accident exterior

Accident reset

Multi-speed 1

Multi-speed 2

Multi-speed 3

Crowl function

Positive rotate after connecting COM,break stop

Reverse rotate after connecting COM,break stop

Connecting COM,Inverter quick output

Connecting COM,accident reset

Connect or break X1.X2.X3with the COM,

can realizate switch run of eight section

Connecting COM,crowl run

Output signal

Accident relay output

Multi light output

TA-TB close when the accident protecting,TA-TB

breaking(Rated contact campacity AC250V 2A)

Look at "F098.F099"about the multi light input

chioce(light output DC24V 50MA)

Analogue input

Reactor input

Analogue signal input

Analogue signal input

Connect the potentionmeter and terminal of VRC.

COM,can Set frequency(potentionmeter 5-10k)

Connect analogue input voltage with the terminal

COM,can set frequency(analogue voltage signal

DC0-10V)

Connect analogue input voltage with the terminal

COM,can set frequency(analogue Ccurrent signal

4~20mA)

Connect voltmeterDC0~10v or Ampmeter0~1mA,

corresponding output 0~Max frequency

Output +12V power between terminal of COM

Power output

Analogue signal input

Analogue

output

Note: the list are the factory set

Article 3 Installation and ConnectionArticle 3 Installation and Connection

TATBTC

Y1 Y2

-4007T

-4015T

-4022T

-4037T

-4055T

-4075T

-4110T

-4150T

-4185T

-4220T

-4300T

-4370T

-4450T

-4550T

-4750T

-4930T

-41100

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

93

110

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

0.75

10A

10A

10A

16A

32A

32A

50A

63A

80A

100A

125A

160A

200A

200A

250A

315A

400A

10A

10A

16A

16A

25A

40A

40A

63A

63A

100A

160A

160A

160A

250A

250A

400A

400A

1.5

2.5

2.5

4

6

6

10

10

16

16

25

25

35

35

50

50

70

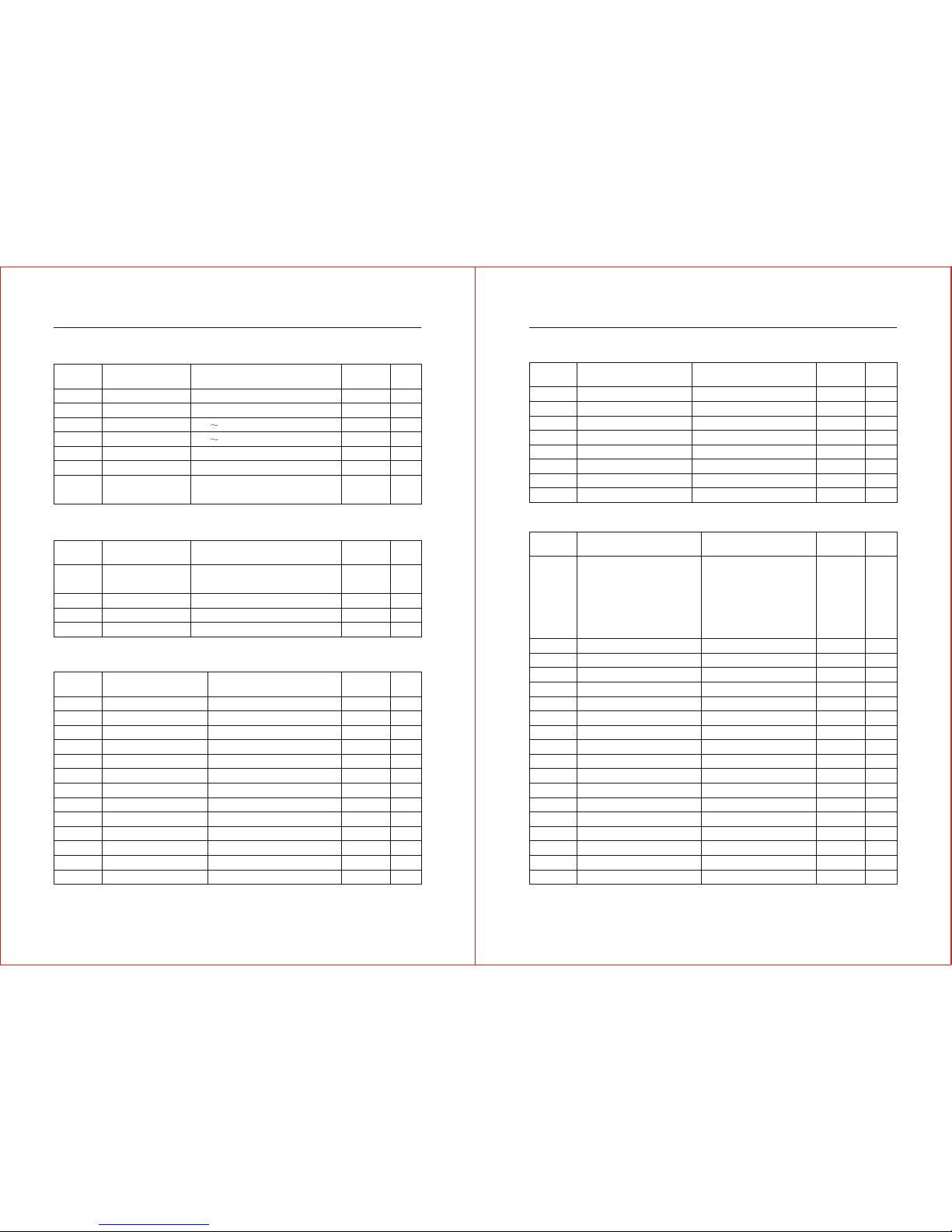

3.2.4Directory of complementelectric

Complement of circuit breaker.magnetic starter and the width of wire with the

Inverter

Article 3 Installation and Connection

-2015T/S

-2022T/S

1.5

2.2

0.75

0.75

16A

20A

16A

25A

Title

Max adapter

Motor(KW)

Key circuit

wire(mm2)

Control line

(mm2)

Circuit breaker

(A)

Contactor

(A)

-2007T/S 0.75 0.75 10A 10A2.5

2.5

4

-2037T/S

-2055T

-2075T

-2110T

-2150T

-2185T

-2220T

3.0

5.5

7.5

11

15

18.5

22

0.75

0.75

0.75

0.75

0.75

0.75

0.75

32A

50A

63A

100A

125A

160A

200A

40A

40A

63A

100A

160A

160A

160A

6

10

10

16

25

25

35

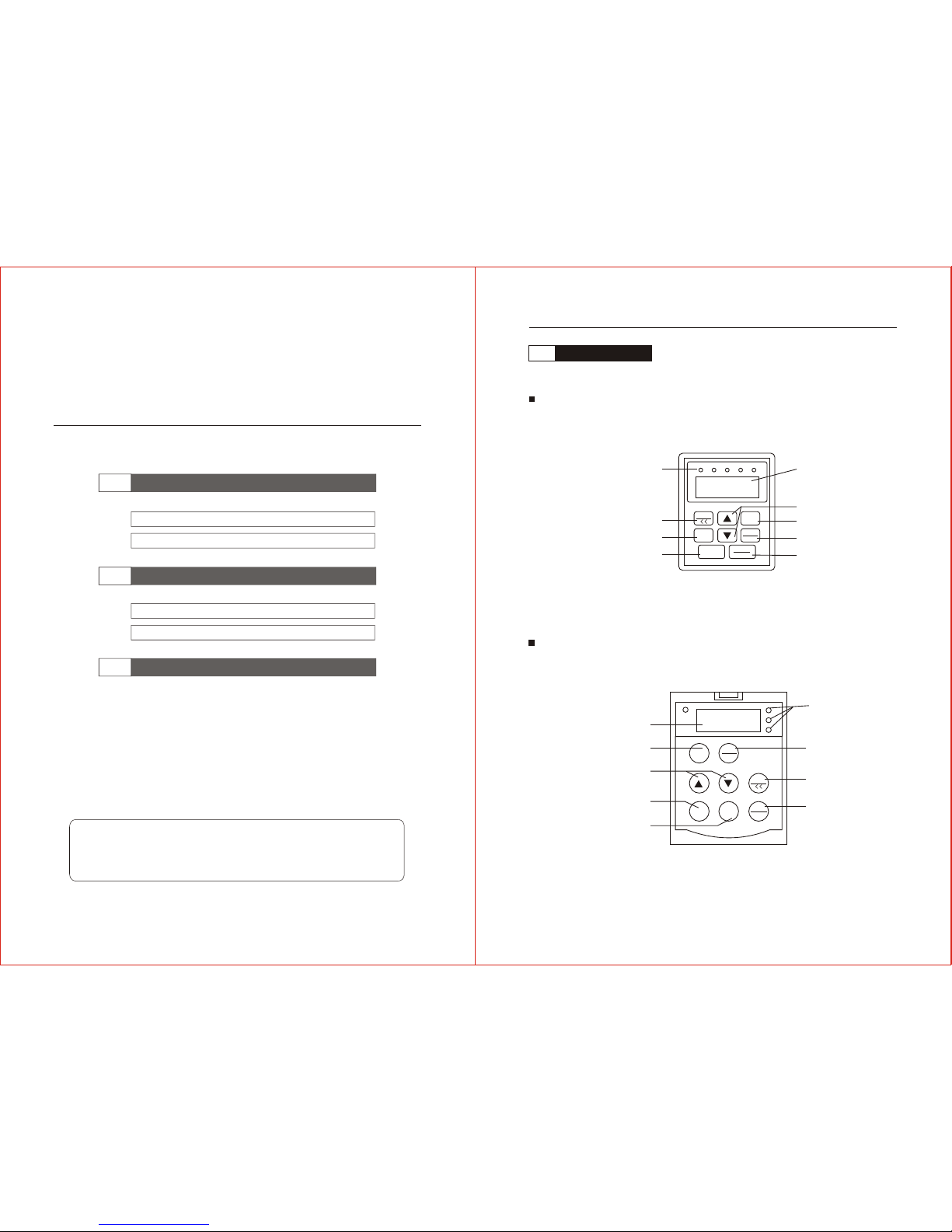

4.1

4.2

4.3

-21- -22-

4.1

Article4

Control panel and display

Control panel 22

4.1.1Figure of panel 22

4.1.2Reference of key on panel 23

Operation of control panel 24

4.2.1Data modify method 24

4.2.2Example of data modify 25

The content of dispay 27

This article are main introduce the figure of panel .key.

operation and the display,the user can understand the control

panel ,it is suitable for you operate it correctly.

4.1.1 Figure of panel

Control panel(1)

Control panel(2)(with potentIometer)

RLN STOP JOG FWD REV

JOG

PRGM

REV

FUNG

DATA

RUN

STOP

RESET

JOG

PRGM

REV

FUNG

DATA

RUN

STOP

RESET

FWD

REV

JOG

STOP

LED display area

Display current status:run.stop.

crowl.positive.reverse

crowl/remove

reverse

run

LED desplay Area

Display freguency out put.

power.setted parameter

inerease/introduce

program

function/informa

stop/reset

LED display Area

Display out put frequency.electrie.

setted parametr

program

introduce/increase

run

reverse

Display Area

Displuy current status

run.stop.croue.

positive and reverse

function/information

crowt/remove

stop/reset

Article4 Control panel and display

Control panel

-23-

4.2

-24-

1

2

3

4

5

6

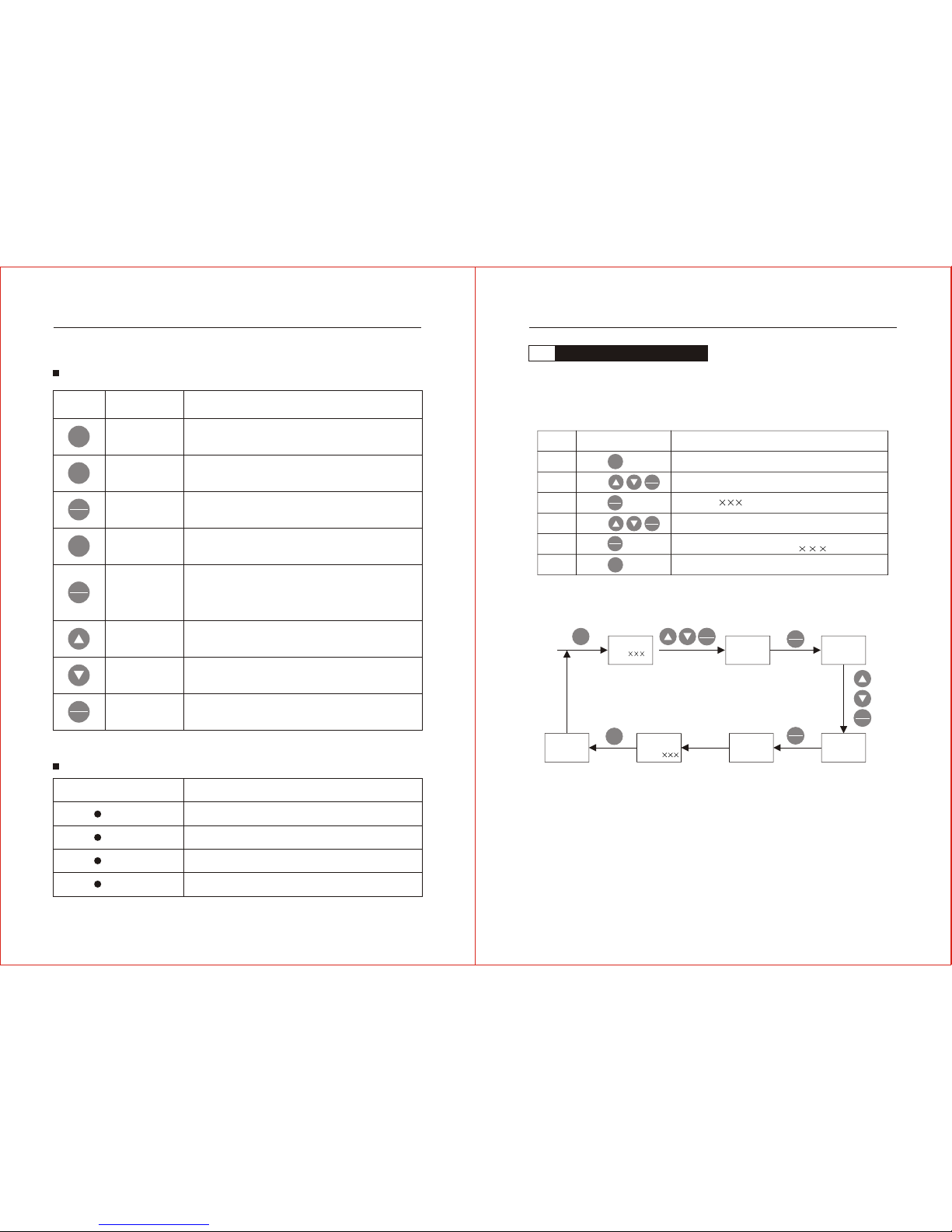

4.1.2 Illustration of key

Illustration of panel

Symbol Title Reference of function

Start reverse rotate

Stop/reset

Set

Function/display

Increase

Reduce

Crawl

Press it start run(If set F001 asthe exterior control,

it is expiry)

Press it start reverse run(If set F001 as the exterior

control or F004 is 1,it is expiry)

Press it stoprun(If set F001 as the exteriorcontrol,it

is expiry).After accidentwarning,press this can reset.

Press this enter into the setting situation,after you

completed modify,press this can recede from the

setting situation.

In theconditionof setting,press it as theconfirm code,

after completed thedata modify,pressit as the deposit

of the data.In the conditionof run,press thisas display,

such asoutput frequency.speed.output current andso on.

In the settingcondition,press this can increase code

of function .dataof parameter.In run or stand-by,press

this can increasethe frequency of run.

In the setting conditio n,press this can reduce code of

function .data ofparameter.In run or stand-by ,press

this can reducethe frequency of run.

In the condition of stand-by(F021=1),press this operate

crawl action.In the condition of setting,when you want

to modify the data,press this can choose the position

of modify data.

Illustration of indicator

Title of indicator

Illustration

Stop

Positive

Reverse

Crawl

After the Inverterconnect the powerand it is

not start theindicator is lighting.

After the Inverterconnect the power and press

the positive key,the indicator is lighting.

After the Inverter connect the power and

press the reversekey,the indicator is lighting.

After the Inverterconnect the power and press

the crawl key,the indicator is lighting.

Control panel operation

4.2.1 Method of the data modify

If you need to modify the data,first enter into the function code which

will be modified,then reset the data,the process as following:

Subsequence

Operation Illustration

Display F000,enter intothe function setting.

Adjust to the function data which will be modified.

Display = ,enter the data setting situation

Reset the parameter value according

your requirement.

Display the END quickly,deposit the data,then

display the function code F

Recede the setting condition,turn back to the

stand by or run condition.

Display function

code F

Display modify

code

Display

parameter

Display the

modified

parameter

Deposit,

display END

code F

display

function

Recede

from setting

condition

Article4 Control panel and displayArticle4 Control panel and display

RUN

REV

STOP

RESET

PRGM

FUNC

DATA

JOG

<<

RUN

setpress

press JOG

<<

FUNC

DATA

press

press JOG

<<

FUNC

DATA

press

setpress

set JOG

<<

FUNC

DATA

JOG

<<

FUNC

DATA

set

1

2

3

4

5

1

2

3

4

5

6

7

8

9

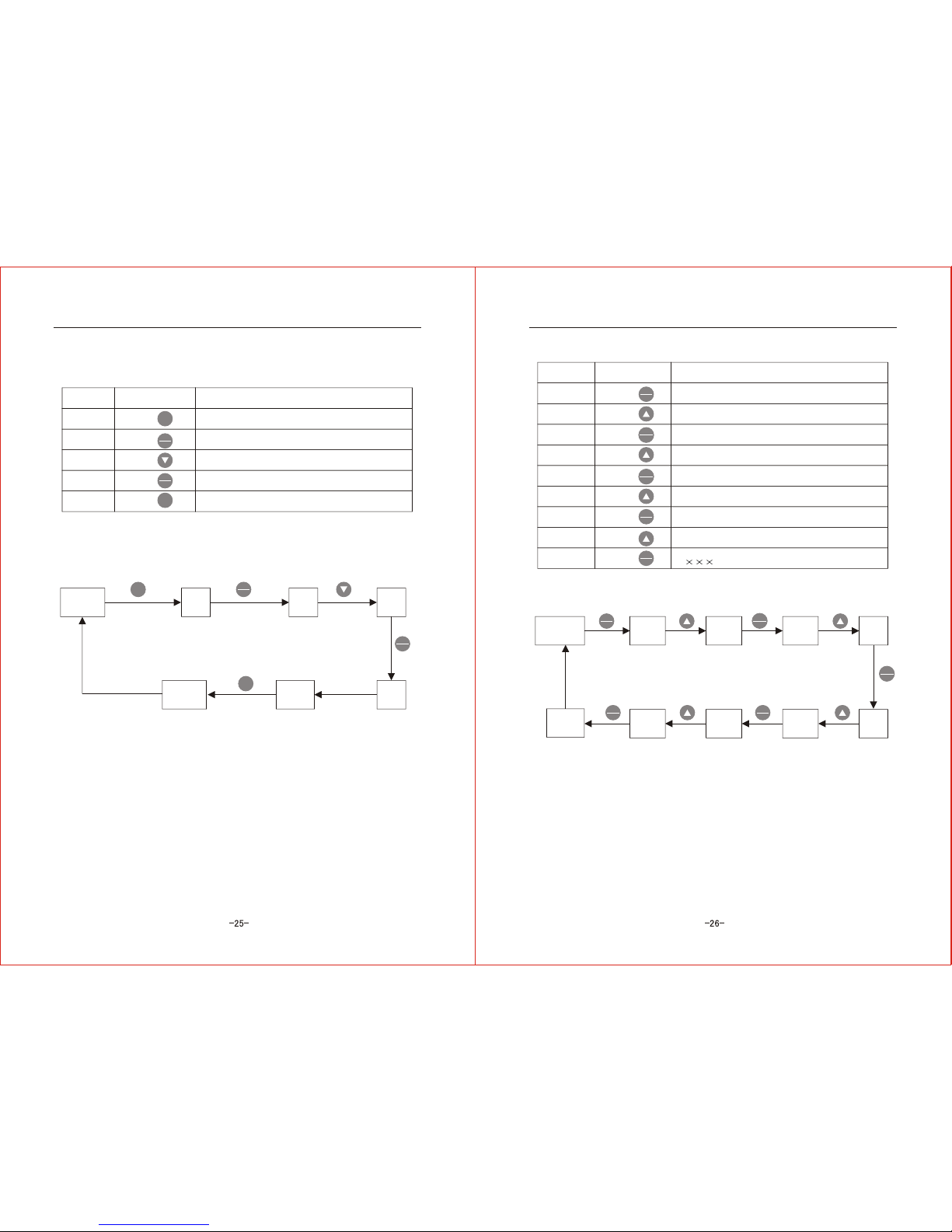

4.2.1 Example of the data modify

No.1Example :Change output frequency 50HZ to 25HZ

Subsequence

Operation Illustration

Display F000,enter intothe function setting.

Display=500,enter into parametermodified.

Continue press thisuntill display=25.0

Display the END quickly,deposit the data,then

display the function code F000

Recede the setting condition,turn back to the

stand by,display H25.0

Display H50.0

stand by

Display

F000

Display

=50.0

Display

=25.0

Display

END

display

F000

Completed

setting

frequency

Recede from

setting condition

No.2Example :Recovery the factory data(data initialize)

Subsequence

Operation Illustration

Display F000,enter intothe function setting.

Press four times,displayF004.

Press one time,0 in thebetween is flashing

Press one time,displayF014.

Press one time,theforward 0 isflashing

Press one time,displayF114.

Display=0,enter into settingstatus

Press one time,display=1

All display data flashing one time,then display

H ,completed recover factory data

Stand by

display H50.0 Display

F000

Display

F004

Display

F004 Display

F014

Display

F014

display

F114

display

=0

display

=1

Recover

factory

data

Recede from

setting condition

Article4 Control panel and displayArticle4 Control panel and display

set

FUNC

DATA

FUNC

DATA

set

press

press

press

press

press

set FUNC

DATA

FUNC

DATA

set

FUNC

DATA

press

press

JOG

<<

press JOG

<<

press

press JOG

<<

press

FUNC

DATA

press

press

FUNC

DATA

press

FUNC

DATA

JOG

<<

FUNC

DATA

FUNC

DATA

4.3

5.1

5.2

H

P

C

U

D

N

Content of display on the control panel

Inverter in the stand by status,when you press "Display"key,display

cycle as follows.

Stand by or

run status

H50.0 or P50.0

display

d XXX

display

C XXX

display

U XXX

display

n XXX

Display

b XXX

Display

L XXX

Display

o XXX

Illustration

Code

Inverter in the status of stand by,display frequency of it

Inverter in the status of run,display frequency of it

Display the outputcurrent of therun

Display the outputvoltage of therun

Display theAC voltage ofbus bar wire

Display the presentspeed of theInverter

Display the feedbackdata when PIDrun

Display the datasetted when PIDrun

Display the dataof the counter

Display the temperatureof the module

Run-in test

Article 5

Run-in test 29

5.1.1Caution of the safty 29

5.1.2Checking before the Run-in test 29

5.1.3Run-in test 29

Operation of run 30

5.2.1Caution of the safty run 30

5.2.2Operation of run 30

This article are introducing the caution of operation,it is

including the checking item before run .the process of Run-in

test and the several operation method.

Article4 Control panel and display

J

b

L

o

5.1

1

3

4

5

6

7

5.2

2

Run-in test

5.1.1 Caution of the safty before Run-in test

Install well the shell when it run,do not dismount the shell

when it runs,avoid the electric shock.

Before run-in test ,it must be unload run,avoid the destroy

by the error action.

Dangerous:

Attention:

5.1.2Checking before run-in test

Be sure tocheck and confirmbefore run-in test:

5.1.3 Run-in test

After checking and confirm by the clause 5.1.2,you can run-in test .You

would better choose key control the the run manner.Run-in test

in process as follows:

Subsequence

Operation Illustration

Close the switch,

Inverter run

In status of electric ,Inverter is in status,

display H ,interior fan start work

Press key untill

frequency display P5.0

If itdisplay H5.0 ,ignore this process

Press start key

Motor start ,Inverter display inrease from

P0.0 to 5.0

Check :

1.Whether motor run well;

2.Whether noise and

abnormality;

3.whether the correct

direction

If abnormality happened,please stop the run

and cut off the electric ,then check the accident,

restart it after repair it.If you found the motor

run reverse against your requirement,change

each two of connection U.V.Wis ok.If everything

is ok,operate the next step.

Press Up key

continously untill frequency

display is P50.0

Press Up key

continously untill frequency

display is P0.0

Press stop key

Motor speed up ,frequency display increase from

P5.0 to P50.0;if everything is ok,operate the next

step.

Motor speed down ,frequency display reduce from

P50.0 to P0.0;if everything is ok,operate the next

step.

Inverter stop to output,motor stop rotate,run-in test

finish.Gernerally,please repeat servral times. from the

first step to the seventh step

Run operate

5.2.1 Cautions inruning status

Install well the shell when it run,do not dismount the shell

when it runs,avoid the electric shock.

Do not operate the Inverter by the damp hand,avoid

electric shock.

When the Inverter set the function of restart after power

off,please put a warning sign "Do not approach" beside it.

Otherwise it will prevent the human after the start abruptly.

The Inverter has install the radiator and exterior brake

resistance,so please do not touch it.It is heat.

If the Inverter set in high speed status,please confirm

it is able before.

Attention:Do not change the setted parameter if you have

not special requirment, because it is been fixed by the

factory.Avoid the distroy by the change.

Dangerous:

Dangerous:

Dangerous:

Dangerous:

Attention:

Attention:

5.2.2Run operation

In the status of run,setting frequency can adjust directly on the line.

All function of Inverter depend on the the parameter setted,this style of

Inverter is make up by function code 001~116,detail as directory 6.1.The

parameter displayed is the factory parameter,user can adjust it by the

private requirement.Because the parameter are relevant

parameter,when user modify some parameter,it better modify the related

parameter.If user modify error or disorder the parameter,please initialize

parameter according examples 2 by clause 4.2.2.(Initialize factory

parameter)

Article 5 Run-in testArticle 5 Run-in test

STOP

RESET

RUN

RUN

STOP

RESET

-31-

6.1

6.2

6.1

-32-

F000

F001

F002

F003

5.0Hz

0

0

0

50.0Hz

220V

380V

50.0 Hz

25.0 Hz

50%

0.0 Hz

1%

F011

F012

F013

0 100%

0 100%

50.0 110%

100%

1%

100%

F004

F005

F006

F007

F008

F009

F010

200V 160.0V 240.0V

400V 320.0V 480.0V

(F007) 400.0Hz

0.0 10.0 Hz

Article6

Function parameter illustration

Function parameter directory 32

Detail illustrationof functionparameter 39

This article express the function parameterof Inverter.

When user set the function parameter,please read it carefully,

in that case,user can avoidthe error setand the accident.

Directory of function parameter

Function of control

Function

code Title of function Range of set Factory

parameter Note

Run frequency 0.0~max frequency(F004)

Choice of

runing control

0: panel control (positive start,reverse

start,stop)

1: ExteriorTerminal control (positive

start/stop, reverse/stop)

2: ExteriorTerminal control (positive

start/stop, reverse/positive)

3: ExteriorTerminal control (positive

start, reverse start,stop)

Choice of

frequency setting

Choice of stop

0: panel up/down

1: Panel reactor

2: Exterior reactor or exterior

voltage 0~10VDC

3: Exterior input current4~20mA

4: Exterior up or down

0: reduce stop

1: free stop

2: immediate AC brake

3: Exterior free stop

V/F curve setting

Function

code Title function Range of setting Factory

parameter Note

Highest frequency Lowest frequency~400.0HZ

High voltage

Rated motor frequency

Medium frequency

Lowest frequency(F009)~

Highest frequency(F004)

Medium voltage

Lowest frequency

Lowest voltage

Lowest voltage(F010)~99% rated voltage

0~10%rated voltage

Basic function

Function

code Title of function Range of setting

Factory data

Note

Highest frequency

corresponding input

Lowest frequency

corresponding input

Rated current of

Article6 Function parameter illustration

-33- -34-

F014

F015

F016

F017

F018

F019

0.0 10.0Hz

0.0 60.0S

50.0 Hz

1.0 Hz

1.0 Hz

0.5S

F025

F026

F027

F028

F029

F030

F031

F032

F033

F034

F035

F036

F037

F020 0

F022

F023

F024

F021

F038

F039

F040

F041

F042

F043

F044

F045

1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

F047

F048

F049

F050

F051

F052

F053

F054

F055

F056

F057

F058

F059

F060

F061

F062

F063

F046 0

Basic function(continous upstair)

Function

code Title function Range of setting

Factory

parameter

Note

Toplimitfrequency

Lowlimit frequency

start frequency

Start delay time

Speed time

Reduce time

Increase/reduce

curve

Lowlimit frequencyF015~400HZ

0.0~ toplimit frequency(F014)

0: straight line

1: S curve

0.1~999.9S

0.1~999.9S

10.0S

10.0S

Crawl function

Function

code Title function Range of setting

Factory

parameter

Note

Choice crawl

crowl frequency

Time speed up

Time speed down

0:the function expiry

1:the function validity

Lowest frequency (F009)

0.1~999.9S

0.1~999.9S

0

5.0Hz

5.0s

5.0s

Multi speed run

Function

code Title function Range of setting

Factory

parameter

Note

Second frequency

Second speed up time

Second speed down time

Third frequency

Third speed up time

Third speed down time

Fourth frequency

Fourth speed up time

Fourth speed down time

Fifth frequency

Fifth speed up time

Fifth speed down time

Sixth frequency

Highest frequency(F004)

0.1~999.9S

0.1~999.9S

Highest frequency(F004)

0.1~999.9S

0.1~999.9S

Highest frequency(F004)

0.1~999.9S

0.1~999.9S

Highest frequency(F004)

0.1~999.9S

0.1~999.9S

Highest frequency(F004)

5.0Hz

10.0S

10.0S

10.0Hz

10.0S

10.0S

20.0Hz

10.0S

10.0S

30.0HZ

10.0S

10.0S

40.0HZ

Multi speed run

Function

code Title function Range of setting

Factory

parameter

Note

0.1~999.9S

0.1~999.9S

Highest frequency(F004)

0.1~999.9S

0.1~999.9S

Highest frequency(F004)

0.1~999.9S

0.1~999.9S

sixth speed downtime

Seven frequency

Seven speed uptime

Seven speed downtime

Eighth frequency

Eighth speed uptime

Eighth speed downtime

Sixth speed uptime 10.0S

10.0S

50.0HZ

10.0S

10.0S

50.0HZ

10.0S

10.0S

Program run

Function

code Title function Range of setting

Factory

parameter

Note

Mode of

program run

0: expiry

1: Stop after single cycle run

2: Run cycle

3: Maintain the last frequency

after single cycle run

1~100

0~999.9S

0:positive 1:reverse

0~999.9S

0:positive 1:reverse

0~999.9S

0:positive 1:reverse

0~999.9S

0:positive 1:reverse

0~999.9S

0:positive 1:reverse

0~999.9S

0:positive 1:reverse

0~999.9S

0:positive 1:reverse

0~999.9S

0:positive 1:reverse

Program run coefficient

Program run at1 temporal

Program run at1 direction

Program run at2 temporal

Program run at2 direction

Program run at3 temporal

Program run at3 direction

Program run at4 temporal

Program run at4 direction

Program run at5 temporal

Program run at5 direction

Program run at6 temporal

Program run at6 direction

Program run at7 temporal

Program run at7 direction

Program run at8 temporal

Program run at8 direction

Article6 Function parameter illustrationArticle6 Function parameter illustration

1000

100%

0

0

1.00

1.0

1.0

100%

F067

F068

F069

F070

F071

F072

F073

F074

0 9999

0 100%

0 9999

0 100%

0.00 99.99

0.0 99.9S

0.0 99.9S

0 200%

-35- -36-

F075

F076

F077

F078

F079

0

1

0 9999

F064

F065

F066

0

0

1

F080 0 9999 1

F081 0

F082

F083

F084

F085

F086

F087

F088

F089

F090

F091

F092

0 30%

0.0 5.0Hz

1 12K Hz

0.0 400.0Hz

0.0 200%

50 150%

0.01 99.99

1

4%

0.0 Hz

5

0

0.0 Hz

100%

0

100%

0

30.00

PID function

Function

code Title function Range of setting

Factory

parameter

Note

PID mode choice

PID aim parameter

PID original parameter

PID max aimparameter

Max parameter feedback

PID minimum parameter

Min parameter feedback

Proportion gain

Integral time

Differential time

Feedback coefficient

0:PID function expiry

1: PID validityexpiry

0: Panel key

1: Panel reactor

2: Exterior reactor or anologue

voltage 0~10v

3: Exterior anologue

current 4~20mA

4: Exterior lift/fall lift

0: Exterior voltage

1: Exterior current

Ac brake function

Function

code Title function Range of setting

Factory

parameter

Note

AC brake time

AC brake frequencystarting

AC brake torque

0.0~25.0S

0.0~25.0HZ

0~30%

0.3 s

3.0HZ

4%

Counter funtion

Function

code Title function Range of setting

Factory

parameter

Note

Counter mode

Counter parameter

0:Expiry

1:Mode of upcounter

2: Mode ofdown counter

Function

code Title function Range of setting

Factory

parameter

Note

Counter coefficient

Counter dealing

0:Stop count ,close output

1: Stop count ,continous output

2: Restart count,close output

3: Restart count,continous output

Special function

Multi-speed run (Continous)

Function

code Title function Range of setting

Factory

parameter

Note

AVR founction

Torquelift

Slip compensation

Carrier wave frequency

Restart after

Instant stop

Frequency arrive setting

Analogue input gain

Analogue

output choice

Analogue output gain

Starting

display

choice

Speed coefficient

0:Expiry

1:validity

0:Expiry

1: Quick run after electric recover

2: Quick start after electric recover

0:Analogue cymometer

1: Analogue Ammeter

2: Analogue Volmeter

0:Output frequency

1: Output current

2: Output voltage

3:AC bus barvoltage

4:Motor speed

5:PID parameter feedback

6:PID aim parameter

7:Parameter of count

8:Temperatureof module

Article6 Function parameter illustrationArticle6 Function parameter illustration

This manual suits for next models

1

Table of contents

Other Chziri Inverter manuals

Popular Inverter manuals by other brands

WEG

WEG CFW-11 Series user manual

Champion Power Equipment

Champion Power Equipment 100246 Owner's manual & operating instructions

INSBUD

INSBUD IB-INV-CSI manual

MULTIQUIP

MULTIQUIP WHISPERWATT DCA150USJ3CAN Operation and parts manual

Tronic

Tronic TSW 150 A1 operating instructions

Mitsubishi Electric

Mitsubishi Electric FR-F862 instruction manual