FIELD ONE Force User manual

FIELD ONE PAINTB A L L - 34 De L U C A P L A CE - SUITE D - SAN R A F A E L - C A 9 4 9 01 - 415 - 324 - 4050 - FIELDONEPAINTBALL.COM

USER MANUAL

Thank you for purchasing the Field One Force. We at Field One Paintball truly appreciate your support in

purchasing and using this product.

This manual will serve as your guide to the Field One Force and should help to maintain a high level of

performance with your new marker while also increasing the overall experience of the user. Your Field One

Force paintball marker also comes with a Force Quick Start Guide to get you started with your Field One Force

marker and provide insight into the basic maintenance and operation of the marker. The Field One Force User

Manual, the Force Quick Start Guide as well as video tutorials and a section on FAQs (Technician Tips) are

available at www.fieldonepaintball.com. If you have questions about your Field One Force marker, please

contact your local retailer or service center or contact Field One Paintball directly at:

A list of Field One Authorized Service Centers can be found on our website or by clicking on the link here:

https://fieldonepaintball.com/pages/certified-dealers-and-technicians

.

• This marker is not a toy. Misuse/careless use may result in serious injury or death.

• Eye protection designed specifically for paintball and compliant with ASTM standards must be worn by the

user and all persons within range.

• READ OWNER'S MANUAL BEFORE USING.

• ALWAYS COVER BARREL with a barrel blocking safety device when not in use.

• You must comply with all local and federal rules and regulations.

• Eye protection in compliance with ASTM Specification F1776, with temple, ear and face protection must be

worn by anyone within range of the Force.

• Must be at least 18 years old to purchase, 14 years old to use or operate with adult supervision, 10 years or

older to operate on insured paintball fields meeting ASTM-standard F1777-97.

• This marker is designed to shoot .68 caliber paintballs.

• This marker is designed to operate with compressed air supplied by a compressed air tank(equipped with

regulator) designed specifically for paintball markers. DO NOT USE CO2.

• Only shoot your paintball marker in areas where people, animals and property are not at risk of being

damaged or hurt by paintball projectiles.

• Only shoot your paintball marker in areas where all people are wearing paintball approved eye and face

protection.

• Do not put your finger (or any other body part) in the breech or in any other area where there are moving

parts.

• Do not fire the marker near your ear or near the ear of another person or animal.

• Never operate your marker at chrono speeds in excess of 300 feet per second and always adhere to

chronograph speed limits and guidelines set forth by local rules and regulations.

• Thoroughly read entire operating manual before using this equipment.

SAFETY WARNING! READ THIS BEFORE HANDLING YOUR MARKER!

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

Introduction to the Field One Force Marker

SAFETY WARNING (READ THIS BEFORE HANDLING YOUR F1 PAINTBALL MARKER

Marker Setup- Getting Ready to Play with your Field One Force

Getting to Know your Field One Force Hardware

OLED Grip Frame Diagram

Force Electronics and OLED Screen

Rhino Regulator and Cam Drive ASA

Force KO Trigger, 4-C Eye System and Eye Assembly

Force Nucleus Engine

Lever Lock Feedneck, Foregrip and AA Battery Compartment

Field One Force Marker Diagram

Foregrip and Battery Compartment Diagram

Mainbody Diagram

Adjusting your Force Software Settings

Force Board- Adjustable Settings Explained

Field One Force Maintenance Schedule

O-ring Size and Location Chart

Nucleus Engine Maintenance

Grip Shift Instructions

Rhino Regulator Maintenance

Trigger Adjustment and 4-C Eye Maintenance

Changing Batteries and Power Select

Field One Paintball Warranty

Troubleshooting and FAQ

TABLE OF CONTENTS

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

Your Field One Force will come from the Field One Paintball factory with the latest software program and the

optimal board settings (referred to as “DEFAULT” or “FACTORY DEFAULT”) for marker performance under most

conditions. Before playing with your marker, you will need to chronograph the marker to ensure you are shooting

at a safe velocity and adhering to local rules and regulations. You may also need to adjust the rate of fire setting

and/or the fire mode setting to comply with local rules and safety regulations. Instructions for adjusting these

settings can be found here in the Field One Force User Manual or the Field One Force Quick Start Guide.

Introduction to the Field One FORCE Marker

The Field One Force is an open-bolt spool engine design that is meant to provide top level performance for all

paintball players at all levels of the game in a variety of playing formats. In this user's manual you will find

information about all of the different components and systems of the Field One Force. There will be diagrams

and links to videos which will help with maintenance and provide a better overall understanding of how the Field

One Force operates. We hope that this marker will increase your paintball enjoyment whether you are messing

around with friends on the weekend, lurking behind enemy lines at a scenario game or competing for the

Paintball World Cup. In this User’s Manual, you will find information about all of the different components and

systems of the Field One Force as well as diagrams and links to videos to help with maintenance and provide a

better understanding of how the Field One Force operates. While this manual has all of the information you

should need for set-up, maintenance and trouble-shooting for the Force, you may find it more convenient to use

and keep on hand the Field One Force Quick Start Guides, which come in the case with your new Force

marker.

To optimize the performance of your Field One Force, we recommend that you use high quality paintballs with a

motorized loader and a low output pressure compressed air tank (250 psi - 550 psi recommended). We also

recommend the use of high quality, name brand batteries in your marker and loader.

Your Field One Force marker is an electro-pneumatic paintball marker that combines electronic software and

components with mechanical parts and air/gas pressure. As with all electro-pneumatic paintball markers, some

simple guidelines will help to keep your marker working at the highest level of performance:

• Replace the battery in the marker with fresh “brand name” batteries at regular intervals

• Keep the marker and it’s electronic components free from moisture.Clean and dry the marker and any

of the electronic components after use in wet conditions

• Maintain adequate lubrication on o-rings and seals in the marker and replace o-rings and seals as

needed. Please read the Force Quick Start Guide or check out the Force Routine Maintenance video

tutorial for details on the upkeep required for your Force Marker.

• Use high quality paintballs (consistent in roundness, shape and size)

• Use a high quality motorized loader and high quality compressed air tank with your marker and perform

regular maintenance on these components as well

• Before you play, check the “paintball to barrel bore sizing” to ensure proper fit and chrono your marker,

staying under the recommended chrono speed limit. Never operate your paintball marker at chrono

speeds in excess of 300 feet per second.

MARKER SETUP Getting ready to play with your F1 FORCE

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

This section will take you through the basic process of getting your marker set up and ready to play. Keep in mind, once you have

assembled your marker and added air and paint, you will have to chronograph your marker before you play. You should

test/adjust the chronograph speed of your marker setup before each time you play to ensure safe operation.

is OFF. Before adding air or paintballs to the marker, be sure that you have a barrel cover or barrel blocking safety device secured

over the barrel. Always keep your marker pointed in a safe direction and be sure that people within range are wearing paintball

approved eye and face protection.

BARREL- Your Field One Force comes equipped with the Field One AccuLock Barrel

(fig A4)

. This is a 3 piece barrel system that

without breaking in the barrel.

Here is a simple method to determine a barrel bore size match to paint size match:

After selecting the appropriately sized AccuLock Barrel Bore, slide the

Barrel Back Sleeve over the insert (fig 1A) and allow the AccuLock

hooks to match up (fig 1B). Each of the AccuLock hooks on the Barrel

Back Sleeve should be engaged with an AccuLock peg on the Barrel

Bore (fig 1C). Once you have the “hooks” around the “pegs," you can

secure the barrel together by screwing the AccuLock Barrel Tip into

the AccuLock Barrel Back Sleeve. This will create a self aligning,

compression type fit between the 3 components of the AccuLock

Barrel System. The barrel components should be hand tightened. Do

not overtighten barrel components during assembly as this can cause

damage to the barrel and make it difficult to disassemble the

AccuLock Barrel System when you are done playing. Once you have

assembled your AccuLock Barrel, you can screw the barrel into your

Force marker.

• Remove barrel from marker or select barrel bore insert you would like to test.

• Drop a paintball into the barrel bore insert.

• The paintball should suspend itself at the beginning of the barrel bore insert. Any amount of force to the

paintball should free the paintball to move through the barrel.

• A barrel that is too tight will increase the chance of breaking the paintball as it is fired from the marker.

• A barrel that is too loose will cause the marker to lose air efficiency and chronograph speed and may allow

the ball to roll out of the barrel in closed bolt systems (Pump Guns).

• PRO TIP for barrel bore sizing: If you are shooting extremely fragile paint or paint that is inconsistent

in size or shape, it is recommended that you slightly oversize the barrel bore insert. This will allow

any inconsistencies in the paintballs to “sneak” through without putting additional pressure on the

paintball and possibly breaking it before it leaves the barrel.

C

AB

C

(fig 1A)

(fig 1B)

(fig 1C)

A

AB

C

Barrel Bore

Barrel Back Sleeve

Barrel Tip

(fig 1D)

(fig 1D)

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

BARREL COVER - A barrel cover or barrel blocking device must be

used before the Field One Force (or any other marker) is connected

to an air source. WARNING: The barrel cover should be used

whenever the marker is not in use or whenever the marker is around

people that are not wearing paintball approved eye and face

protection. To install the barrel cover, place the barrel cover over the

tip of the barrel and the cord around the rear of the marker

(fig 2A)

.

Make sure there is tension on the cover (by adjusting the cord lock)

and that the cord is resting in a secure place so the barrel blocking

device cannot slip free. You may then connect the barrel to the

marker by snugly screwing it in

(fig 2B)

.

AIR UP - The Field One Force is powered by high pressure

compressed air. Use of C02 may damage the marker and will void the

Field One Paintball Warranty. High pressure air systems for paintball

use with the capacity of 3000 to 4500 psi and the output pressure of

250psi to 550psi should be used with the Field One Force.If your Air

System output pressure exceeds 750psi it may damage the solenoid

or other components of your marker. If you have questions about the

safety of your compressed air tank or the capacity or output pressure

of your compressed air tank, consult with a certified technician or

airsmith. Before attaching the high pressure air system to your Field

One Force make sure the Cam Drive Knob located on the bottom of

the Cam Drive ASA is turned counter-clockwise until it stops (The

Cam Drive ASA should be in the OFF position)

(fig 3A)

. Once the high

pressure air system is filled, attach it to your Force marker by

screwing it into the Cam Drive ASA until it stops. Do not overtighten

the air system to the ASA but ensure that the air sytem is screwed all

the way in. Once the High Pressure Air System is attached to the

ASA, you can supply air to your Field One Force by turning the Cam

Drive Knob located on the bottom of the ASA clockwise until the knob

locks in place. You should hear the marker pressurize

(fig 3B)

.

POWER MARKER ON/OFF - The Field One Force is an electronic

paintball marker powered by two AA batteries located in the moveable

Force Foregrip or a rechargeable battery located in the Force Grip

Frame. Batteries are included from the factory. Batteries should be

changed about every 50,000 shots or when the Battery Level

Indicator on the OLED screen reads LOW. If you notice a drop off in

the performance of your marker, changing to fresh batteries should

be one of the first measures you should take to resolve the issue.

Always use high quality batteries. Rechargeable AA batteries are not

recommended for the Force marker. Low cost zinc/carbon batteries

should be avoided. The battery compartment and any electronic

connectors or terminals should be kept dry and free from debris.

Make sure the battery door is secured in place after changing

batteries and that the batteries and battery door are oriented

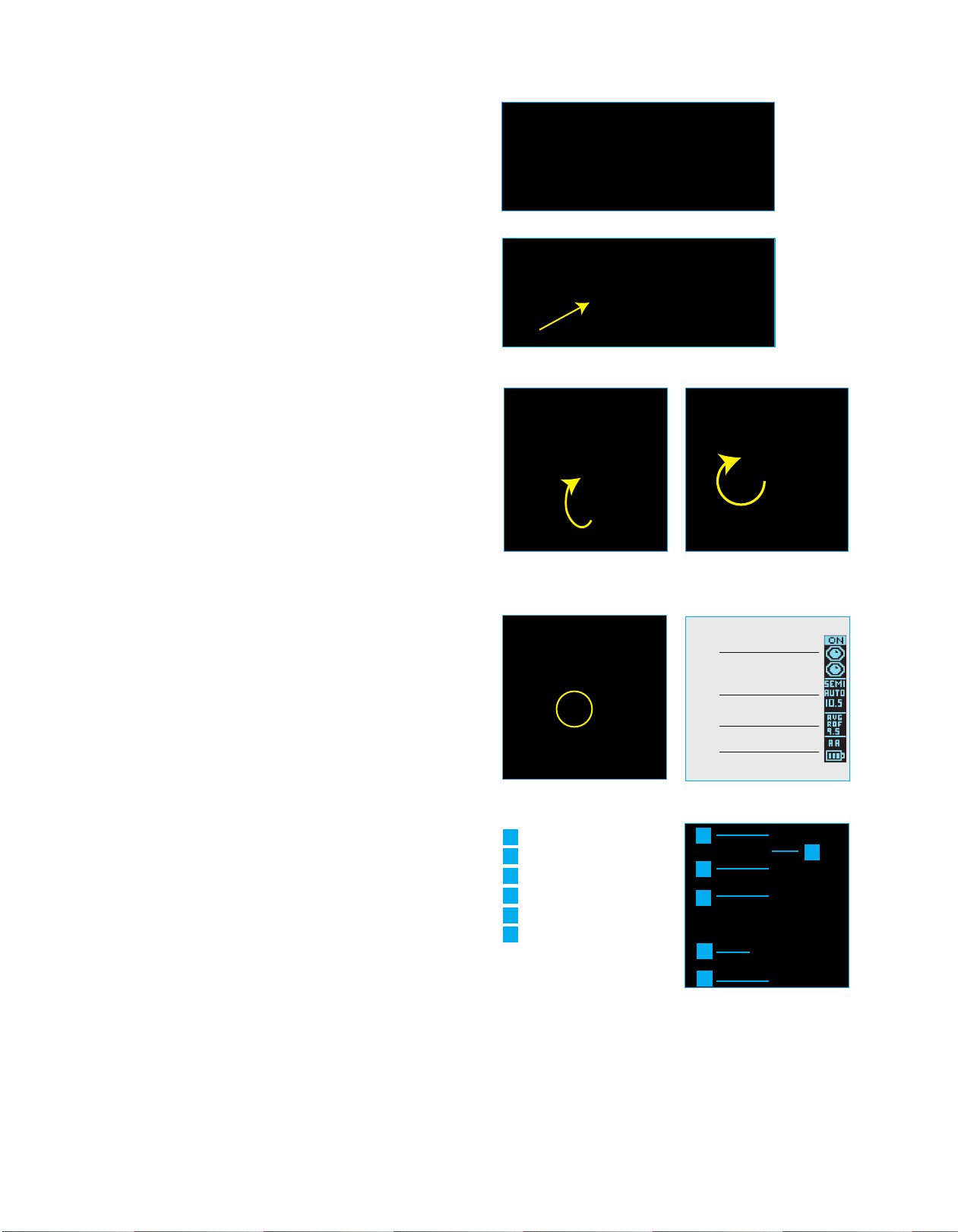

correctly. To POWER ON your Force marker press the power button

located on the rear of the grip frame below the OLED

(fig 4A)

screen.

The OLED screen will illuminate displaying a brief “STARTUP

SCREEN.” After a moment, the HOME SCREEN will appear and give

you information about the FIRE MODE, Battery Life, 4C-ES Status,

ROF CAP and ROF of the last 10 shots

(fig 4B)

. The Force is ready

to shoot once you see the Home Screen. The electronic eyes will

default to EYES ON every time you POWER ON the marker. To

POWER OFF the marker- press and hold the power button for 4

seconds. A “...3..2..1..0..OFF” countdown will appear on the OLED

screen then the marker will shut down. When the OLED screen has

gone blank, the marker is OFF. It is still highly recommended that you

use a barrel blocking safety device even when you have the marker

powered OFF.

A

AB

C

D

E

F

Grip Frame

Bezel

OLED Screen

Power button

ASA

Cam Drive Knob

Grip Frame Rear View (fig 4C) (fig 4C)

(fig 2A)

(fig 2B)

(fig 3A)

(fig 4A) (fig 4B)

(fig 3B)

EYE INDICATOR

FIRE MODE INDICATOR

RATE OF FIRE INDICATOR

BATTERY LEVEL AND

SOURCE INDICATOR

A

AB

C

D

E

F

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

LOAD UP - Attach your loader into the Lever Lock Feedneck by

opening the lever

(fig 5A)

. You may loosen the locking lever if

necessary by turning either the lever or the stainless steel thumb

screw

(fig 5B)

. Insert the loader into the feedneck and lock the lever

securing the loader in place

(fig 5C)

. The Lever Lock is designed to

hold the loader snug in the feedneck but should not be overtightened.

Overtightening the feedneck lever can cause damage to the feedneck

or loader neck. Once your loader is in the feedneck, adjust the thumb

screw to reach the desired level of tension. The Field One Force is

capable of high rates of fire. It is recommended that you use a high

performance motorized loader to get the most consistent rate of fire

and the highest possible performance from your Field One Force.

Make sure your barrel blocking safety device is in place before loading

your paintballs into the loader.

ADJUST YOUR VELOCITY - You must test your velocity at the start of

each paintball session or when you change paintball size or barrel

bore size. Make sure that your loader is filled with paintballs and

turned on. Whenever operating your marker, you must wear eye

protection specifically designed for paintball and compliant with ASTM

standards. Once in a safe area to fire your marker, remove the barrel

cover. Pull the trigger to fire the paintball marker over the chronograph

to measure the velocity. To adjust your velocity insert a ⅛ inch allen

wrench into the velocity adjustment screw

(fig 6A)

located on the

bottom of the Cam Drive ASA just forward of the Cam Drive ASA Knob

(fig 6B)

. To increase the velocity turn the screw clockwise

(facing you). To decrease the velocity turn the screw counter clockwise

(facing you). The range of adjustment is about 15 feet per second

(FPS) per quarter turn. Shoot 2 shots in between each adjustment to

stabilize the pressure. Only adjust the velocity adjustment screw by ¼

turn between chronograph measurements as this adjustment can be

sensitive. WARNING: DO NOT adjust the velocity of your Force

marker in excess of 300 FPS. Check with your local field or

tournament organization for the recommended maximum velocity

setting.

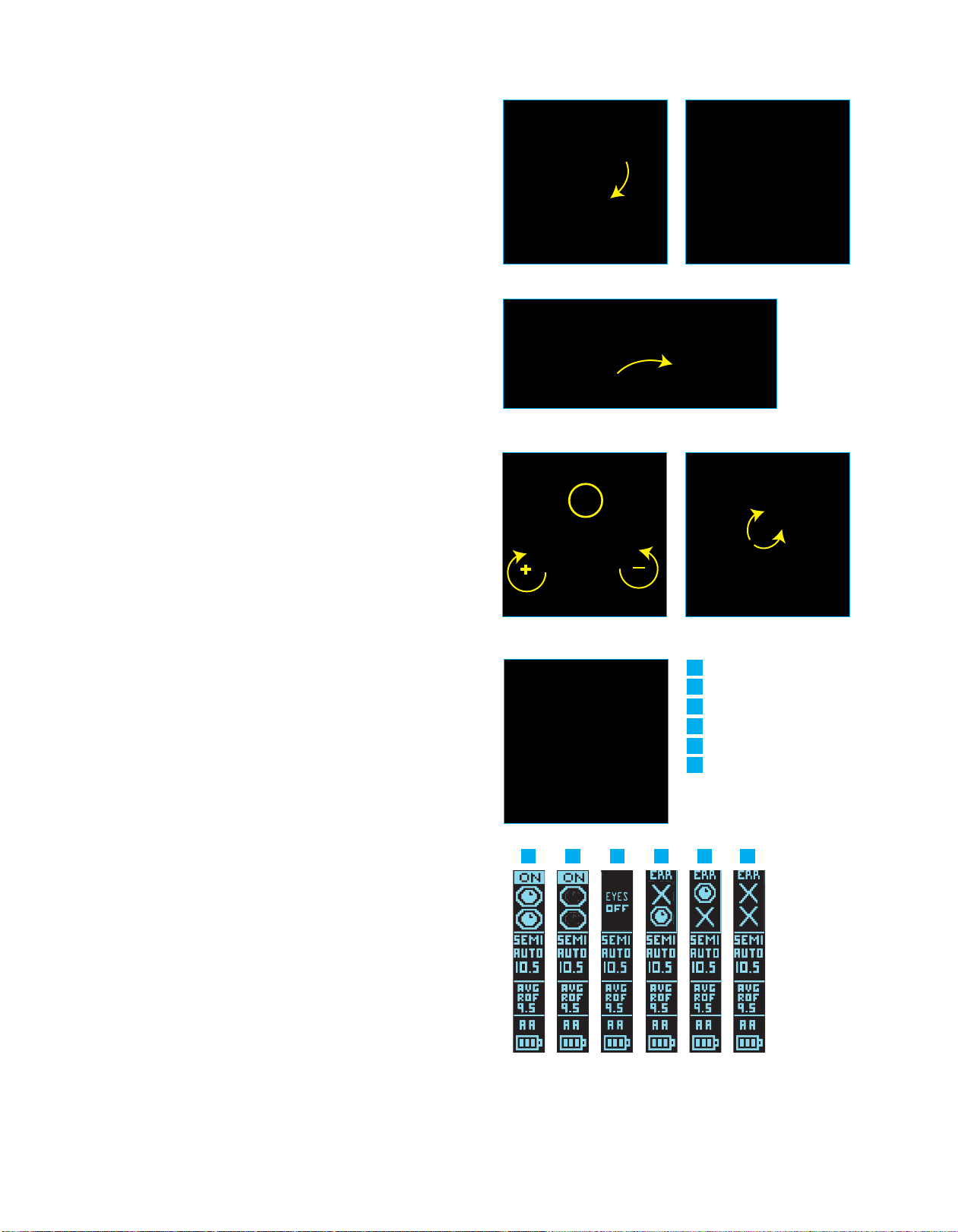

4C ILLUMINATE EYE SYSTEM (4C-ES) - Your Field One Force is

equipped with the 4C Illuminate Eye System consisting of 2 sets of

break-beam eyes (upper and lower)

(fig 7A)

, this feature allows the

Force to achieve maximum rates of fire without chopping paint. Even

with a high performance motorized loader, the Force needs proper eye

operation to avoid breaking/chopping paintballs in the breech. The eye

indicator located on the upper portion of the OLED HOME SCREEN

will display the status of the 4C-ES

(fig 7B)

. When your Force marker

is powered ON the 4C-ES system is active (ON) by default. When the

4C-ES is active and working properly the marker will not shoot unless

there is a ballt present in the breech (breaking the invisible beam

between the eyes). To turn the 4C-ES OFF tap the power button twice

within 1 second. You will notice that the OLED display indicates that

the 4C-ES status is OFF. You must turn off the 4C-ES in order to fire

your marker without paintballs (dry fire). It is not recommended that

you dry fire your marker excessively. To toggle between “EYES ON”

and “EYES OFF,” tap the power button twice within 1 second. Playing

with your 4C-ES “OFF” will greatly increase your chances of breaking

paint. If the eye indicator on your OLED screen shows that the eyes

are blocked/eye malfunction (ERROR), you may have to clean the

eyes to restore proper function.

A

AB

C

D

E

F

Eyes on Ball Loaded

Eyes on breach empty

Eyes off

Top eye fault (clean eyes)

Bottom eye fault

Both eyes fault (clean eyes)

Eye function HUD (fig 7B)

AAB C D E F

(fig 5A) (fig 5B)

(fig 5C)

(fig 6A)

+

(fig 6B)

-

(fig 7A)

(fig 7C)

+

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

TOURNAMENT/BOARD LOCK - Your Force marker has a lock

function that insures that the settings cannot be adjusted without tools

when the lock is on. When the lock is ON, the lock indicator icon will

display if you attempt to enter “settings adjustment mode.” To turn the

lock OFF, turn on the marker and use your 5/64 allen wrench to

remove the 3 screws that hold the left grip panel to the grip frame

(fig 8A)

. Open the grip panel and press the button labeled “LOCK” on

the main board

(fig 8B)

. To toggle between Lock ON and OFF, repeat

these steps. When the marker is on and the LOCK button is pressed,

the OLED screen will display whether the board has been locked or

unlocked. Some tournaments will require you to play with the

tournament/board lock ON (settings are locked).

(fig 8A) (fig 8B)

PLAY!- Once you have followed and understood the steps listed above, you are now ready to take your

Field One Force out to play. HAVE FUN, BE SAFE AND SHOOT STRAIGHT!

• Be sure to adhere to all paintball safety guidelines and local rules/regulations

• If you have questions about safety or local regulations, contact your local paintball store or field

• Always wear paintball approved eye protection and face protection when operating your Field One Force

• Always use a barrel blocking safety device with your Field One Force whenever you are not operating

your marker

• Only shoot your paintball marker in areas where people, animals and property are not at risk of being

damaged or hurt by paintball projectiles

• Only shoot your paintball marker in areas where all people are wearing paintball approved eye and face

protection

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

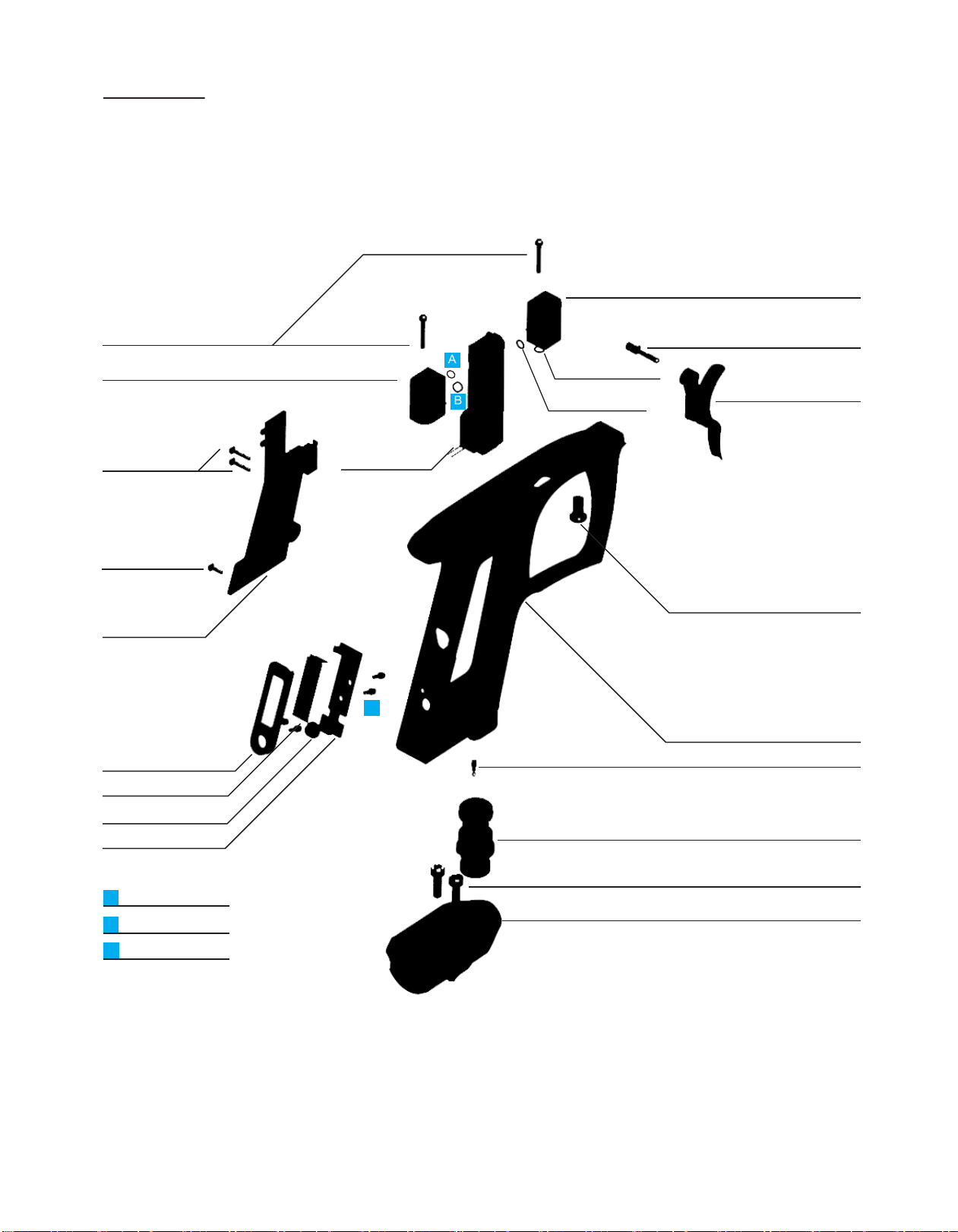

A

AB

Force Grip Frame

The Force grip frame houses the main board (Force Mainboard) for the Force, the OLED screen and Power Button, the HPR (Rhino

Regulator), velocity adjustment screw, trigger assembly and provides the mounting point for the Cam Drive ASA. Custom overmolded dual

durometer rubber grips protect the internals of the grip frame while providing the perfect amount of tactile function for the user to change

hands while operating and keep a firm grip when needed. The grip frame does not need to be removed during normal maintenance of the

Field One Force. Keeping the grip frame and the electronics within the grip frame free of moisture and debris is important and can be

maintained by removing both sides of the rubber grip panels. Access to the TOURNAMENT/BOARD LOCK button on the Force BLU18

Board can be had by removing the left-side grip panel. The Rhino Regulator can be accessed by removing the Cam Drive ASA from the

bottom of the grip frame.

C

Manifold Mounting Screws

Drive Manifold

Top Mainboard

Mounting Screws

Bottom Mainboard

Mounting Screw

Mainboard

C

AB

A

Bezel

OLED Screen

Power Button

PCB Board

1x3 Drive Manifold to Solenoid

1x4.5 Drive Manifold to Solenoid

PCB and Bezel Mounting Screws

Cam Drive ASA

Rhino Regulator

Downstream Bleed Valve

Gripframe

Front Gripframe to Body

Mounting Screw

1x3.5 Input

Manifold to Gripframe

1x3 DInput

Manifold to Solenoid

Input Manifold

KO Trigger

ASA Mounting Screws

Solenoid

Trigger Mounting Screw

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

Force Electronics and OLED Screen

The electronics in the Field One Force serve as the “central nervous system” for the Force marker.

There are 5 board types in the Force

• Force Main Board

• Force Bridge Board (connects the eyes (4C-ES), batteries (power source and the Jumper Board)

• 4C-IS Boards (2)

• Force Jumper Board (allows the user to separate the body from the grip frame without disconnecting wires).

• Force Power Control and OLED Board

To eliminate the use of long wire harnesses and delicate wire harness connectors, the Force makes use of spring loaded pin connectors and

low profile ribbon connectors to keep power and communication going to and from the different electronic components of the marker. The

Force Mainboard comes equipped with a capacitor as a failsafe in case of temporary disconnect between the battery and the electronics in

the marker due to vibration or a hard impact with the ground. It is important to keep the Force and the electronic components in the Force

free from moisture, paint and debris. Never submerge the Force in water and always perform proper maintenance after using the Force in

wet conditions. Cleaning and drying the electronic components of the Force with a dry soft cloth and dry cotton swab will help to prolong

their life after using in wet conditions. If there is built up paint or dirt residue, you can use rubbing alcohol on a swab to clean electronics and

hard to reach cavities. Make sure electronic components and connectors are dry and clean before reassembly. Changing out wet batteries

and drying out the battery compartment will also help to prolong the life of the electronic components.

Battery Board

Battery Harness

Bridge Board

Left Eye

Jumper Harness

Jumper Board

Main Board

PCB Board

OLED Screen

Right Eye

Solenoid Connector

Solenoid

Tournament Lock Button

Microswitch

Power Select Switch LiPo Battery Connector

Speaker

LiPo Rechargeable Battery

LiPo Battery Connector

Power Button

AA Batteries

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

Rhino Regulator

The Field One Force’s main air supply is regulated by the Rhino Regulator, which is mounted in the top of the ASA and housed within the

Force Grip Frame. Once you have connected an air source to the ASA, the air travels through the Rhino Regulator (and is regulated down to

about 145-155 psi) and directed to the solenoid and the Force Engine. The Force Rhino Regulator requires minimal maintenance and

should only be serviced if there is a decline in performance. Cleaning the piston, the reg seat and the reg housing and applying lube to all

regulator seals will help to keep the regulated air flow consistent.

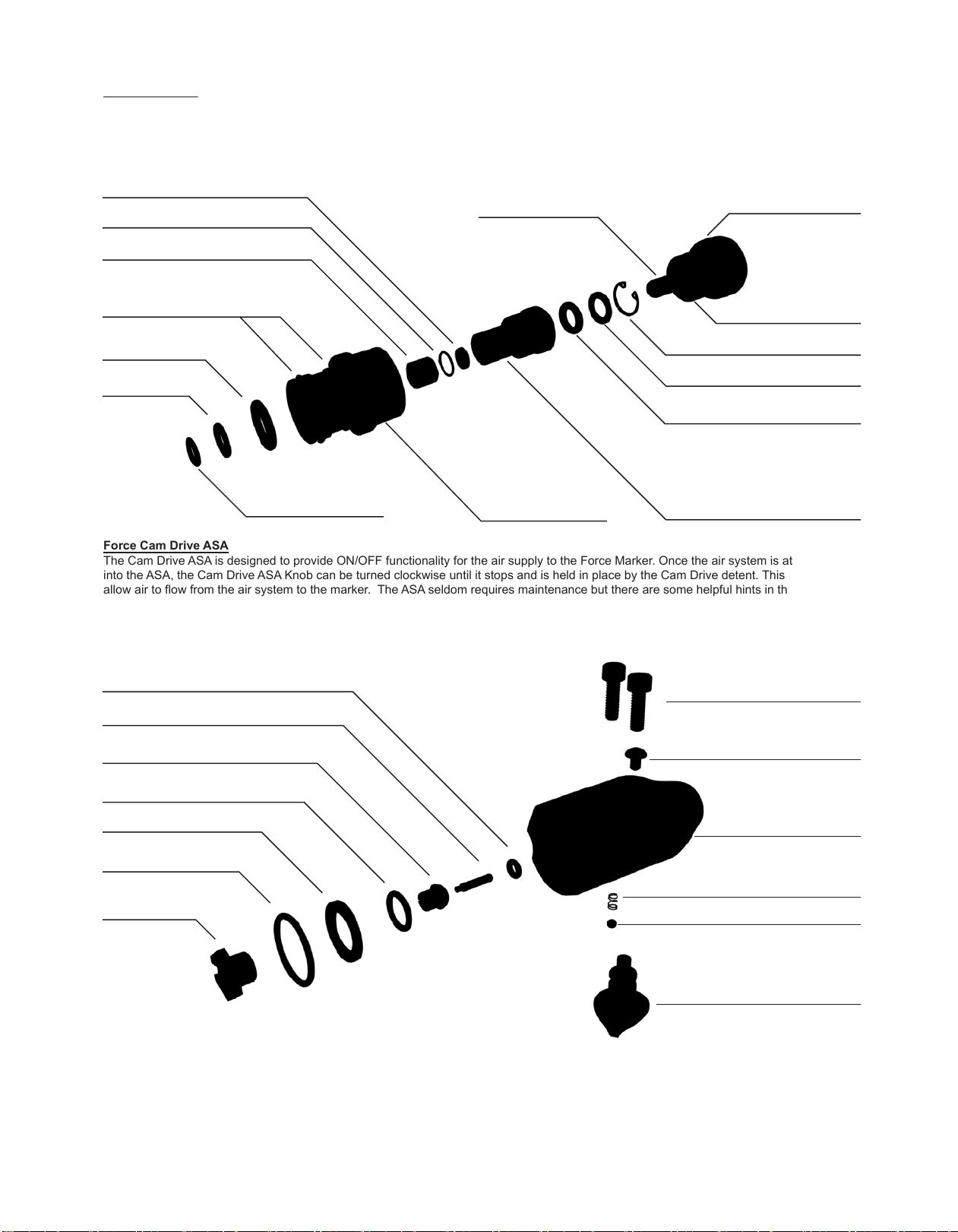

Force Cam Drive ASA

The Cam Drive ASA is designed to provide ON/OFF functionality for the air supply to the Force Marker. Once the air system is attached fully

into the ASA, the Cam Drive ASA Knob can be turned clockwise until it stops and is held in place by the Cam Drive detent. This action will

allow air to flow from the air system to the marker. The ASA seldom requires maintenance but there are some helpful hints in the

TROUBLESHOOTING section of this manual if you detect a leak coming from the ASA or ASA knob. Before attaching your air system to the

Cam Drive ASA, it is recommended that you clear any dirt or debris from the opening of the ASA, the ASA threads and the pin or ball valve

on your air system regulator. WARNING: Once you have turned your Cam Drive ASA to the OFF position and removed all paintballs from

your marker, take a clearing shot by holding down the trigger for one second to ensure there is no gas stored in the marker.

ASA Cam Drive Knob

Cam Detent Bearing

Cam Detent Spring

ASA Body

Cam Drive Knob Retaining Screw

ASA to Grip Frame Mounting Screws

005 ASA Main Seal

ASA Cam Activation Pin

Main Seal Support

011 ASA Outside Main Seal Retainer

ASA Filter

017 Outside ASA Filter

Main Seal Retainer

Reg Seat

Reg Adjuster

.237 OD Between Reg Seat and Reatiner

1x12 Outside Reg Adjuster Housing

12 U-Cup Inside Top Reg

Adjuster Housing

011 Inside Bottom Reg

Adjuster Housing

4.5x 1.5 90D Bottom Reg

Between Reg Adjuster and

ASA Reg Adjuster Reg Seat Retainer

008 Inside Reg Seat Housong

Under Washer and C- Clip

C-Clip

O-Ring Retaining Washer

Between O-ring and C-Clip

Spring Stack

Reg Piston 014 Top Reg Piston

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

Force KO Trigger Assembly

The Force comes equipped with the KO magnetic trigger and offers a wide range of adjustability by using three different adjustments. To

adjust trigger pull length, use your 1/16th inch allen wrench and insert into the bottom hole in the KO trigger face. Turning the Trigger

Stopper Screw clockwise will shorten the trigger pull length. To adjust the activation point, use the same 1/16th inch allen wrench in the

middle hole in the trigger face. Turning the Trigger Activation Adjustment Screw clockwise will make the trigger activate earlier in the trigger

pull. Turning the screw counter clockwise will make the trigger activate later in the trigger pull. You can also adjust the trigger tension or

magnet tension behind the trigger by using your 1/16th inch allen wrench in the top hole in the KO trigger face and turning the Trigger

Tension Screw clockwise to get more resistance behind the trigger and counter clockwise to get less resistance behind the trigger pull. The

F1 factory trigger setting will keep close to equal trigger travel in front and behind the trigger activation point. This will help to avoid “runaway

trigger” or “trigger bounce.”

4C Illuminate Eye System, Eye Covers and Ball Detents

The eye system in the breech of the Field One Force is called the 4c IlluminateEye System. This system uses two sets of break beam eyes

to detect whether or not a paintball has settled in the breech and is ready to fire. The upper set of eyes communicates that a ball is moving

into the firing position so there is less delay required when the lower set of eyes reads that the paintball has arrived and allows the firing

sequence to take place. This combination of eyes and technology allows for the fastest read rate and produces incredibly high rates of fire

with the eyes fully functional. If a paintball cracks in the breech or is chopped by the bolt (shooting with eyes OFF) the eyes will need to be

cleaned to ensure that the “break beam” is unimpeded and the eyes are fully functional. To inspect or clean the eyes and ball detents, simply

remove the eye covers with your 5/64 allen wrench and wipe with a soft cloth or cotton swab until the eyes/eye boards/detents are free from

paint or debris. Do not use water to clean the eye boards as this may cause a short or malfunction in the eye board. Carefully place the eye

board back in the recessed area of the body and make sure the rubber ball detents are fully seated in the appropriate hole. When reattaching

the eye cover, make sure to not crush the eye board. The eye cover mounting screw should be snug but not overtightened. The eye cover

should sit flush with the body when properly installed. You can verify proper eye function by turning on the marker and checking the OLED

readout for eye function.

Trigger Mounting Screw

Trigger Spacer

Roller Bearings

Trigger Activation Adjustment Screw

Trigger Stopper Screw

A

A

Trigger Tension Adjustment Screw

Trigger Tension Magnet

KO Trigger

Eye Cover

Mounting Screw

Left Eye Cover

Ball Detent

Left 4-C Eye

Bridge Board

Ball Detent

Right Eye Cover

Eye Cover

Mounting Screw

Right 4-C Eye

Top Eye

Bottom Eye

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

A

A

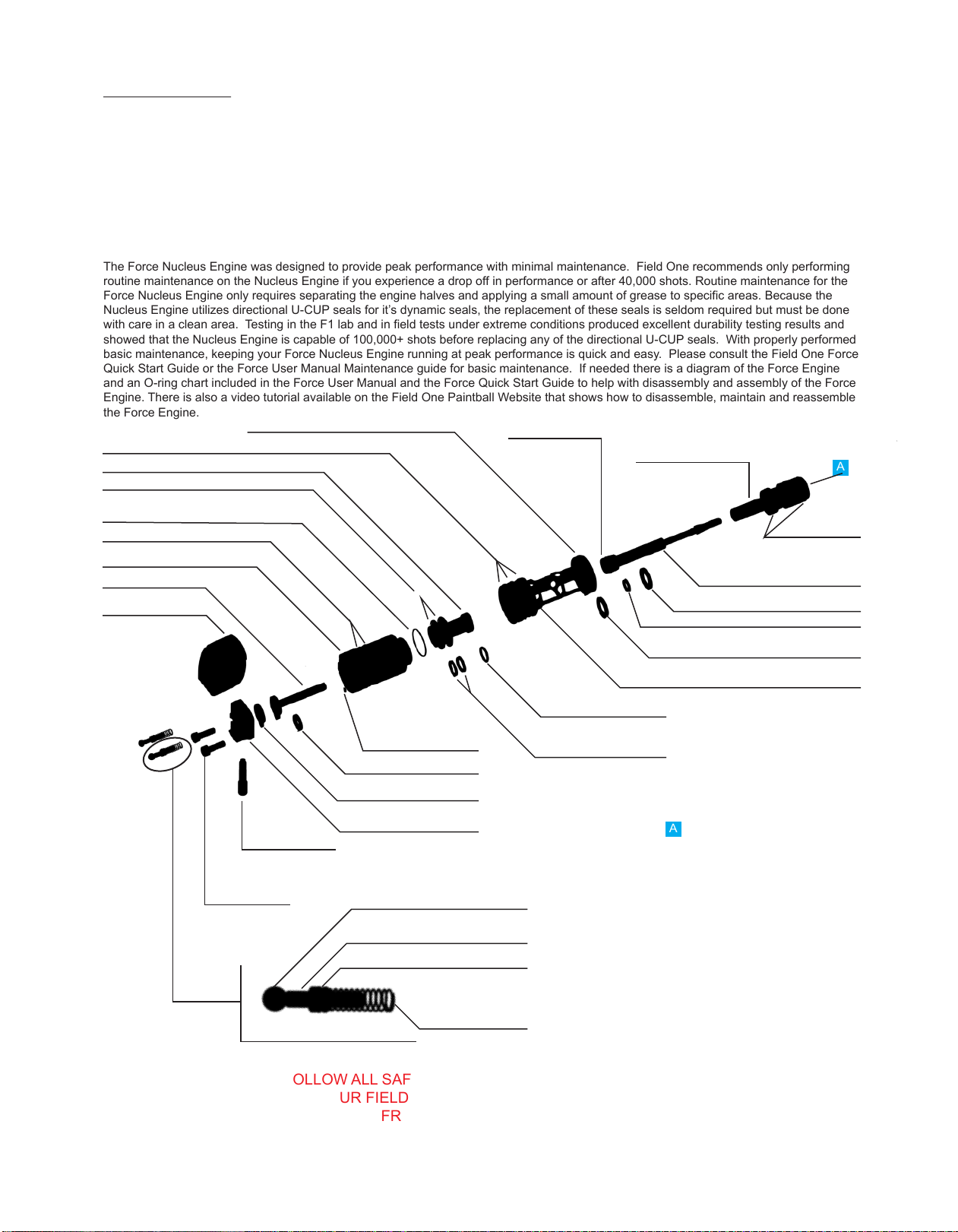

Force Nucleus Engine

The Force Nucleus Engine is a Spool Valve type engine that works by moving air from the volume chamber through the bolt tip to propel the

paintball through the barrel at consistent velocities. With each shot cycle, the Force solenoid provides a measured amount of air to the

engine, moving the ram and bolt forward and back to open and close the different chambers of the Force Nucleus Engine. The Nucleus

Engine is made up of 7 main components:

• Bolt Tip

• Ram Shaft

•Reduction Shaft

• Volume Chamber

•Brass Shut Off

• Ram Housing

• Back Block and Back Cap Assembly

The Force Nucleus Engine was designed to provide peak performance with minimal maintenance. Field One recommends only performing

routine maintenance on the Nucleus Engine if you experience a drop off in performance or after 40,000 shots. Routine maintenance for the

Force Nucleus Engine only requires separating the engine halves and applying a small amount of grease to specific areas. Because the

Nucleus Engine utilizes directional U-CUP seals for it’s dynamic seals, the replacement of these seals is seldom required but must be done

with care in a clean area. Testing in the F1 lab and in field tests under extreme conditions produced excellent durability testing results and

showed that the Nucleus Engine is capable of 100,000+ shots before replacing any of the directional U-CUP seals. With properly performed

basic maintenance, keeping your Force Nucleus Engine running at peak performance is quick and easy. Please consult the Field One Force

Quick Start Guide or the Force User Manual Maintenance guide for basic maintenance. If needed there is a diagram of the Force Engine

and an O-ring chart included in the Force User Manual and the Force Quick Start Guide to help with disassembly and assembly of the Force

Engine. There is also a video tutorial available on the Field One Paintball Website that shows how to disassemble, maintain and reassemble

the Force Engine.

Magnetic Back Cap Detaining Ball

Gas Interlock Magnet Post

Gas Interlock Piston

Gas Interlock Spring

Gas Interlock Assembly

Back Cap

Pillow Tip Insert

Back Block Screw

Back Block Pin

Back Block

Reduction Shaft Support Pad

Retraction Bumper (on reduction shaft)

1x2 between Ram Housing

and Reduction Shaft

Reduction Shaft

Ram Housing

021 Outside Ram Housing

1x15 between Ram Housing and

Volume Chamber

017 Inside Volume Chamber

Brass Shut O

021 Outside Volume Chamber

020 Outside Volume Chamber front 011 U Cup Outside Ram (opening faces front)

Bolt

015 outside

Bolt

Ram

Extension Bumper (on Ram)

009 U Cup inside Ram (opening faces front)

110 U Cup inside Volume Chamber front

(opening faces back)

Volume Chamber

011 inside Brass Shut Off front

011 U Cup inside Brass Shut Off rear

(openings face away from each other)

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

A

AB AB

LeverLock Feedneck

The Field One Force comes equipped with the new LeverLock clamping feedneck. This feedneck is adjustable without tools and allows for

the use of a variety of different motorized loaders and ensures a snug fit. Do not overtighten the clamping lever screw as this may cause

damage to the feedneck or the clamping lever bolt. If the lever ever becomes too tight to manipulate with your fingers, you can use a 1/8th

inch allen wrench to loosen the LeverLock assembly.

Force GRIP SHIFT (Dual Position) Foregrip (Battery Compartment)

The Force Foregrip is designed to provide 2 different mounting points so the user can choose the foregrip stance or distance that is most

comfortable for their playing style. The Force Foregrip position change involves separating the foregrip (also the AA(2) battery compartment)

from the reversal plate and then switching the orientation of the Force Foregrip Reversal Plate before reinstalling the foregrip. This

adjustment operation is not meant to be performed while playing or operating the marker. It is highly recommended that this adjustment

operation is done where there is a clean flat surface to work with and all of the separate components of the marker are removed (REMOVE

loader, tank, barrel). The foregrip (battery compartment) will remain connected to the marker with the power supply wire harness. Excessive

pressure or tension on this wire harness while changing foregrip positions will cause power failure or damage the electronic components in

the marker. Please refer to the Grip Shift instructions or the Grip Shift Video Tutorial before starting this process

A

A

Reversal Plate Mounting Screws

Reversal Plate

Foregrip Housing

Foregrip Mounting Screws

Battery Board

Foregrip Core

AA Batteries

Battery Door

Feedneck

Cam Pivot

Lever

Adjuster Nut

Adjuster Knob

Locking Screw

Adjuster Bolt

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

Force Body

The Force Body is the shell that holds the Force together. There are only three o-rings in the force body that seal between both manifolds

and the underside of the body. The Jumper board screws into the mainbody and connects to the main board by way of pressure contact

pads. The Jumper harness connects the jumper board to the Bridge Board which relays information to and from the eyes and power from the

AA batteries in the foregrip to the mainboard. The Force Bridge holds the Bridge Board in place and creates a mounting point for the

gripframe.

A

Rear Gripframe Mounting Screw (insert from inside the body)

A

Leverlock Feedneck

Eye Cover

Mainbody

005 Mainbody to Drive

Manifold

007 Mainbody to Input

Manifold

Jumper Harness

Bridge

Bridge Board (under Bridge)

Battery Harness

Jumper Board

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

Adjusting your FORCE Software Settings (Force Main Board Version 1.0)

The Field One Force comes equipped with the Force Main Board. The Force Main Board allows the user to manually adjust board settings

with the OLED interface on the Force grip frame.

Your Field One Force will come from the Field One Paintball Factory with the latest program code and the optimal board settings (referred to

as “DEFAULT” or “FACTORY DEFAULT”) for the highest marker performance under most conditions. Once board settings have been

changed, board settings can be adjusted back to “FACTORY DEFAULT” at anytime by activating “Factory Reset” in PROGRAMMING

MODE. Depending on local rules and regulations you may need to adjust the RATE OF FIRE setting and/or the FIRING MODE setting for

your Force Marker before playing with your Force Marker. Instructions for adjusting these settings can be found here in the Field One Force

User Manual or the Field One Force Quick Start Guide.

TOURNAMENT/BOARD LOCK

Your Force marker has a lock function that insures that the programmable settings cannot be adjusted without tools when the lock is ON.

When the lock is ON, the lock indicator icon will display if you attempt to enter “settings adjustment mode." To turn the lock OFF, turn on the

marker and use your 5/64 allen wrench to remove the 3 screws that hold the left grip panel to the grip frame. Open the grip panel and press

the button labeled “LOCK” on the main board. To toggle between Lock ON and OFF, repeat these steps. When the marker is on and the

LOCK button is pressed, the OLED screen will display whether the board has been locked or unlocked. Some tournaments will require you

to play with the tournament/board lock ON (settings are locked).

Once the tournament/board lock is off you may adjust the software settings by using the grip frame OLED. The marker will not fire while in

programming mode but we highly suggest you remove the air source and paintballs from the marker before entering PROGRAMMING

MODE and adjusting settings. WARNING: Always keep barrel blocking device in place while adjusting board settings.

Using the OLED to Adjust Settings

To access the settings menu

1 Hold down the trigger while powering the marker ON. The OLED screen will flash with the current software version and then enter

PROGRAMMING MODE.

2 Once in PROGRAMMING MODE, you can cycle through the settings by pulling the trigger until you reach the desired setting. (By

scrolling through the different settings, you will also be able to see the current value for each setting.)

3 To adjust a setting scroll to the desired setting by pulling the trigger then tap the power button to enter ADJUSTMENT MODE for that

particular setting.

4 Use the trigger to adjust the setting to your satisfaction.

5 Tap the power button once more to exit the ADJUSTMENT MODE for that setting. The setting has now been changed.

6 If you wish to return to the factory settings (DEFAULT), enter programming mode, scroll to the FACTORY RESET setting and adjust

to “RESET YES.”

You may adjust more settings while you are in PROGRAMMING MODE by following steps 3 through 5 listed above turn the marker OFF by

pressing and holding the power button for 3 seconds to save your new settings. The gun will retain the new settings until they are changed or

the software is updated. Below is a list of adjustable settings and their functionality.

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

Force Board - Adjustable Settings Explained

FIRE MODE - This setting determines the type of FIRE MODE your Force will use. The Maximum Rate of Fire and the Rate of Fire Cap

will be determined by the ROF CAP setting.

Modes Available:

•NXL Ramp - (World Paintball League current ramping rules). This fire mode is specific to the type of ramp and ramp settings

allowed by the NXL. The ROF Cap will have to be set separately once the FIRE MODE is set to “NXL Ramp."

•Custom Ramp - Adjustable ramp settings. This is the only fire mode that will allow

adjustability of the three ramp settings (RAMP START, RAMP KICK IN ROF, and RAMP

SUSTAIN ROF)

• Semi-Auto - one shot cycle per trigger pull

• 3 Shot Burst - 3 shot cycles per trigger pull (single shot before 3 shot burst engages)

• Full Auto - holding the trigger down will cycle the marker (single shot before full auto engages)

From the NXL Rulebook.

RATE OF FIRE (ROF) CAP - This setting will determine the limit on RATE OF FIRE. This setting will not override the FIRE MODE setting if

using an uncapped FIRE MODE. UNCAPPED RATE OF FIRE will allow the Force to shoot as fast as the marker will mechanically cycle

(EYES OFF) or as fast as the loader can feed paintballs to the marker (EYES ON).

Range of Adjustment: 2 BPS - 20 BPS

Default: 10.5 BPS (NXL)

EYES OFF RATE OF FIRE (ROF OFF) - This setting allows the user to set a separate RATE OF FIRE CAP if the eyes are toggled to “eyes

OFF” or if there is an eye malfunction.

PRO TIP for EYES OFF ROF setting: Setting the EYES OFF RATE OF FIRE lower than RATE OF FIRE CAP is recommended to reduce

paintball breakage in the event the eyes become dirty or disabled. 8 BPS is a good default setting in case the eyes are no longer functioning

and you must continue to play before addressing the issue.

Range of Adjustment: 2 BPS - 25 BPS- UNCAPPED

Default: 8.5 BPS

DWELL - The amount of time the solenoid is energized each time the marker is fired. Too low of a dwell setting may lead to inconsistency or

drop off. Too high of a dwell can cause bad air efficiency.

Default: 16

BALL IN PLACE (BIP) DELAY - This setting is referred to as the “bounce detector” setting and is designed to help prevent chopping in the

breech as the last paintballs in the loader “bounce” in the breech. PRO TIP for BIP DELAY setting: If you commonly break or chop the last ball

or two in your loader, raise your BD DELAY setting higher than the factory DEFAULT setting.

Default: MID HI

EYE POWER - The Eye Power setting adjusts the intensity of the eye beam. The higher the setting is set the more resistance the eye puts on

the beam. If your marker reads that there is a ball in the breach but will not fire you should increase this setting.

Default: Mid Lo

DEBOUNCE - This setting controls the read-rate of your trigger pull and can be thought of as trigger bounce sensitivity. Lowering your

D-BOUNCE setting can result in higher rates of fire (trigger/micro-switch bouncing), especially in SEMI-AUTO/UNCAPPED fire mode. Raising

your D-BOUNCE setting can help to eliminate “runaway trigger” or excessive “trigger/micro-switch bouncing”

Range of Adjustment:

Default: 2

RAMP START - The number of trigger pulls required to start ramping.

RAMP KICK IN (ROF) - The rate of fire that must be achieved to begin ramping.

RAMP SUSTAIN (ROF) - The rate of fire needed to sustain ramping.

ANTI BOLT STICK (ABS) - This setting will increase the dwell setting when the gun is left for a certain amount of time (adjustable in “ABS

time”. This setting should be set at a higher dwell time than the current dwell setting. If you experience first shot drop off and basic engine

maintenance does not fix it try increasing this setting. This setting will not affect the velocity.

Default:4

ANTI BOLT STICK (ABS Time) - This setting controls the amount of time the gun can rest before the ABS Dwell kicks in.

Default: 30 seconds

Chirp- This setting controls weather the speaker is ON or OFF.

Default: ON

CHIRP - This setting controls whether the speaker is ON or OFF.

Default: ON

SHOT COUNTER - This keeps track of the amount of shots the gun has fired with or without paint. You can reset the counter by selecting it in

the settings menu.

GAME TIMER - The Field One Force comes with a game timer built into the Force BLU18 board. The user will be able to set the timer to a

specified amount of time and then start the timer with a trigger pull at the beginning of a game or match. To access the TIMER SCREEN

before a game or match, press and hold the power button for 1.5 seconds. Once TIMER SCREEN is displayed on the OLED screen, you can

start the timer by pulling the trigger once. Once the timer has been started, the time remaining will be displayed on the OLED screen on the

grip frame. To reset the GAME TIMER, press and hold the power button for 1.5 seconds. This will also return you to the HOME screen.

TEXT ORIENTATION - This setting will allow right-handed and left-handed users to switch the orientation of the OLED text to best suit how

they like to hold the gun while adjusting settings.

Default: Right Hand text

FACTORY RESET - This will restore the Field One Factory settings.

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR

ATTEMPTING ANY WORK ON YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY

POINT, STOP AND GET HELP FROM A FIELD ONE PAINTBALL CERTIFIED TECHNICIAN.

F1 Force Maintenance

Your Field One Force marker was designed to require minimal maintenance. However, to keep the Force working at the highest performance

level, it is recommended that a regular maintenance schedule be kept. In this section, we will discuss the tools needed to maintain the Force

marker and layout a maintenance schedule that will help to keep the Force working at it’s best.

Tools needed to perform regular maintenance on the Force:

• Standard Allen Wrench set.

• Maintenance Kit included with the Field One Force (7/32, 1/8, 5/64, 1/16 Standard Allen Wrenches).

• Field One approved marker lube (comes with your Force Marker).

• Barrel cleaning squeegee.

• Spare O-ring Kit (comes in the Force Maintenance Kit).

• AA Batteries or Force Rechargeable Battery Charger.

• These items are also helpful for performing routine maintenance:

○Small Soft bristle brush (for cleaning small spaces and electronics.

○Cotton swabs (for applying grease to engine and regulator components).

○Long “T Handle” 1/8th allen wrench (for adjusting the position of the Force GRIP SHIFT adjustable foregrip).

○Vice Grips with soft jaws (to separate Bolt from Ram if they get overtightened).

Field One Force Maintenance Schedule:

This schedule is designed to prevent failure during play and promote peak level performance. As with any paintball marker,

maintenance works on an “as needed” basis but is best performed on a “preventive schedule." Maintenance involving cleaning the

eyes, breech and barrel will be required any time you break paintballs in that area and it is hindering the performance of the marker.

•Before you play Check/clean barrel and breech area. Make sure the ASA is clean from debris/dirt/moisture before attaching your

air system. Chrono your marker. Check/change/charge battery if battery meter is showing “LOW.”

•”Once Month/ Before Event (Approximately 40K shots from last routine maintenance)- clean and inspect eyes and detents- replace

detents if they look heavily worn, perform routine engine maintenance if there is a decline in performance (See “Engine Quick Start

Guide” or Page (X) of the Force User Manual).

•Once a year/ Season rebuild engine o-rings and seals only if there is a decline in performance, rebuild regulator o-rings only if

there is a decline in performance.

•Before you put your marker away after playing wipe off external surfaces of your marker to prevent corrosion/damage. Check

and clean breech area. Ensure there is no more pressure stored in the marker. Turn marker off. Store in a clean and dry area.

Avoid storing your marker in extreme temperatures to avoid damage to the electronic components and seals.

Please visit Fieldonepainball.com and the Filed One Paintball YouTube Channel for more information on tech tips and maintenance.

CAUTION: READ AND FOLLOW ALL SAFETY GUIDELINES AND WARNINGS BEFORE HANDLING OR ATTEMPTING ANY WORK ON

YOUR FIELD ONE PAINTBALL MARKER. SHOULD YOU BE UNSURE AT ANY POINT, STOP AND GET HELP FROM A FIELD ONE

PAINTBALL CERTIFIED TECHNICIAN.

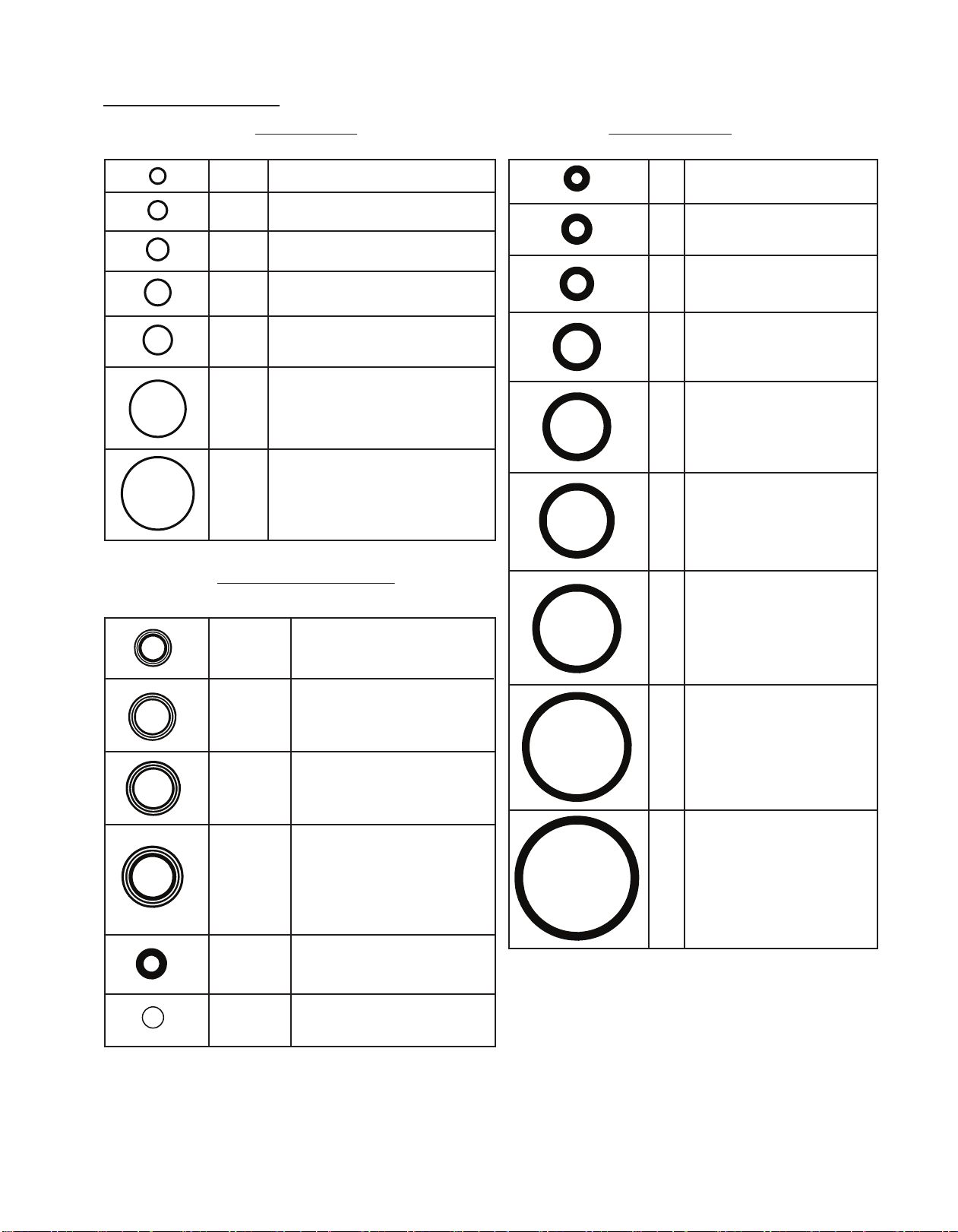

O-ring Size Chart.

x1 inside ram shaft

U- CUP 011

x1 Inside front of Volume

Chamber (opening faces rear)

011

1x12

1x15

1x2 005

007

1x3

1x3.5

1x4.5

1x5

008

014

015

021

020

017

x1 Outside front

Volume Chamber

x3 Outside rear

Voulme Chamber

x2 Outside ram housing

4.5x1.5 90D

x1 Ram Housing rear to reducton shaft

x1 Input Manifold, x1 Drive

Manifold, x2 Interlock Plungers

O-ring Size Location(s)

O-ring Size Location(s)

O-ring Size Location(s)

METRIC O-RINGS

U-CUPs and CUSTOM ORINGS

STANDARD O-RINGS

x1 Gripframe to bottom Input

manifold

x1 Drive Manifold to Solenoid

x1 Spring Stack Retainer

x2 Outside Rhino Reg

Adjuster Housing

x2 Body botttom to Drive Manifold

x1 ASA Main Seal Retainer

x1Body botttom to Input

Manifold

x1 inside Reg Seat Housing

under C-clip and washer

x1 inside bottom Rhino Reg

Adjuster Housing

x1 Inside front Brass Shut Off

x1 ASA Outside Mainseal Retainer

x1 Outside Rhino Reg Piston

x2 Bolt Tip

x2 inside rear Volume

Chamber to Brass Shut Off

x1 ASA Filter

U- CUP 009

1x outside ram shaft

2x Inside shut off

U- CUP 110

x1 bottom Rhino Reg between

reg Adjuster and ASA

x1 Ram Housing between

engine halves.

U- CUP 012 x1 Inside top Rhino Reg Adjuster

Hosing. (opening faces down)

.237 OD

Rhino Reg Seat

Retainer (between reg

seat and Reg Seat Retainer)

Table of contents