Contents

4 / 56 EN-US · 30.30.01.02196 · 01 · 11/20

5.11 Output and Input Signals.................................................................................................................. 22

5.11.1 Signal Inputs .............................................................................................................................. 22

5.11.2 Signal Outputs ...........................................................................................................................22

5.11.3 Signal Type................................................................................................................................. 23

5.12 Activating a Freedrive Request......................................................................................................... 23

5.13 Switch-Off Delay [0x004B] ................................................................................................................ 24

5.14 Device Functions................................................................................................................................ 24

5.14.1 Restricting Access Using Device Access Locks [0x000C] ........................................................... 24

5.14.2 Restricting Extended Access with Extended Device Access Locks [0x005A] ........................... 24

5.15 Resetting the Device to the Factory Settings................................................................................... 24

5.16 Counter(s) .......................................................................................................................................... 25

5.17 Displaying Errors and Warnings ....................................................................................................... 26

5.17.1 Displaying Errors........................................................................................................................ 26

5.17.2 Display of Warnings .................................................................................................................. 27

5.17.3 Temperature Display [0x0044] .................................................................................................. 27

5.17.4 Monitoring the Supply Voltages [0x0042] ............................................................................... 28

5.18 Energy and Process Control (EPC)..................................................................................................... 28

5.18.1 Condition Monitoring (CM) [0x0092] ....................................................................................... 28

5.18.2 Energy Monitoring (EM) [0x009D]............................................................................................ 31

5.18.3 Predictive Maintenance (PM) ................................................................................................... 31

5.19 Production Setup Profiles ................................................................................................................. 32

5.20 Device Data........................................................................................................................................ 32

5.21 User-Specific Localization ................................................................................................................. 32

5.22 Robot-specific Device Data ............................................................................................................... 33

5.23 Device Status...................................................................................................................................... 33

6 Transport and Storage..................................................................................................................................34

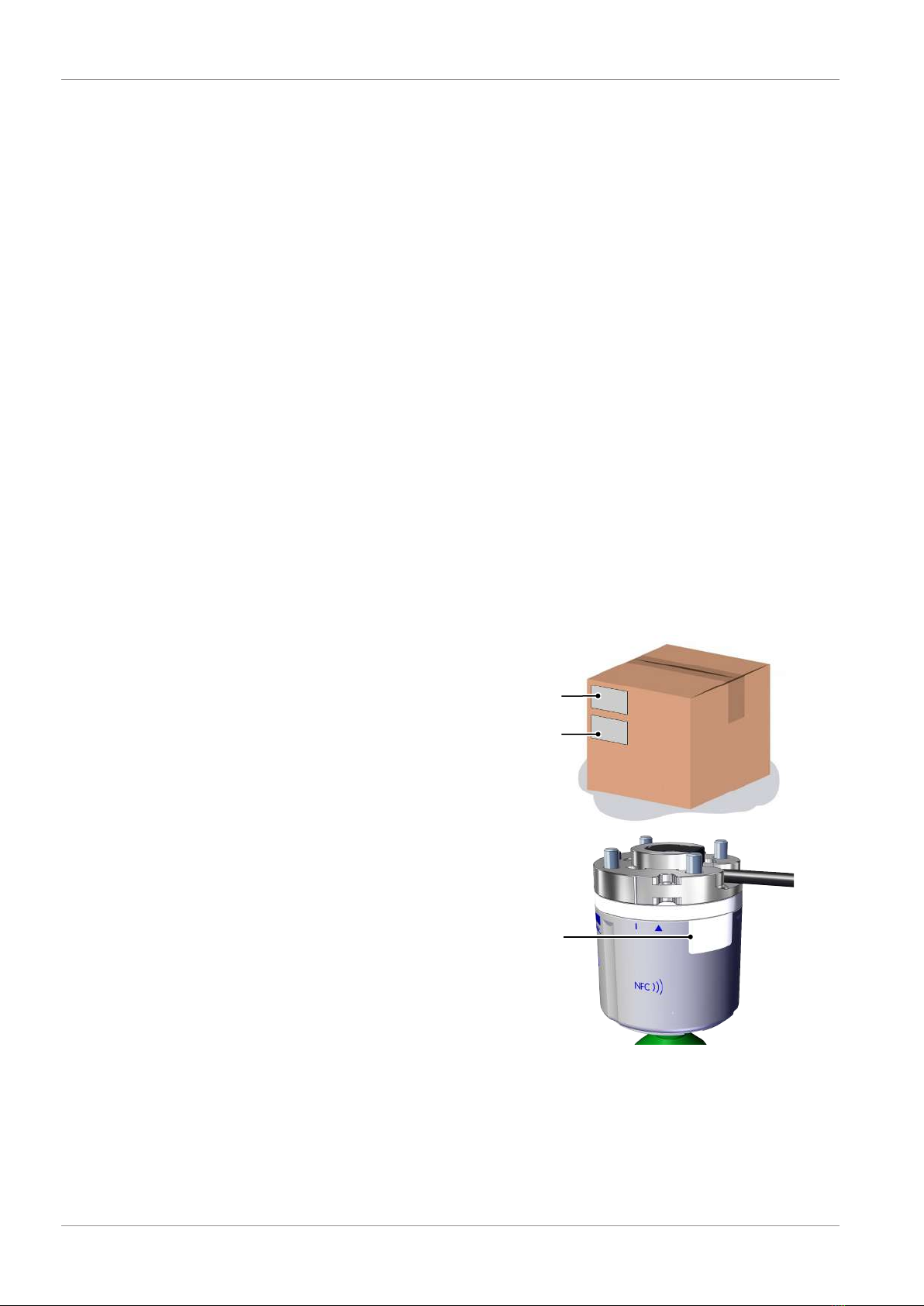

6.1 Checking the Delivery ....................................................................................................................... 34

7 Installation.....................................................................................................................................................35

7.1 Installation Instructions..................................................................................................................... 35

7.2 Mechanical Attachment.................................................................................................................... 35

7.3 Compatibility ..................................................................................................................................... 36

7.4 Description of the Electrical Connection ......................................................................................... 37

7.5 Start of Operations............................................................................................................................ 40

8 Operation ......................................................................................................................................................41

8.1 Hazard during Operation ................................................................................................................. 41

8.2 Preparations....................................................................................................................................... 41

8.3 Operating Modes .............................................................................................................................. 41

8.3.1 SIO Operating Mode ................................................................................................................. 42

8.3.2 IO-Link Operating Mode ........................................................................................................... 42

8.3.3 Operating Mode RS-485............................................................................................................ 42

9 Maintenance..................................................................................................................................................43

9.1 Safety ................................................................................................................................................. 43

9.2 Cleaning the Device .......................................................................................................................... 43

9.3 Cleaning the Sieve Insert .................................................................................................................. 43

9.4 Replacement of the Device with a Parameterization Server.......................................................... 43

10 Warranty........................................................................................................................................................44

11 Troubleshooting............................................................................................................................................45