EN

PETROL BRUSH CUTTER USER'S MANUAL

3

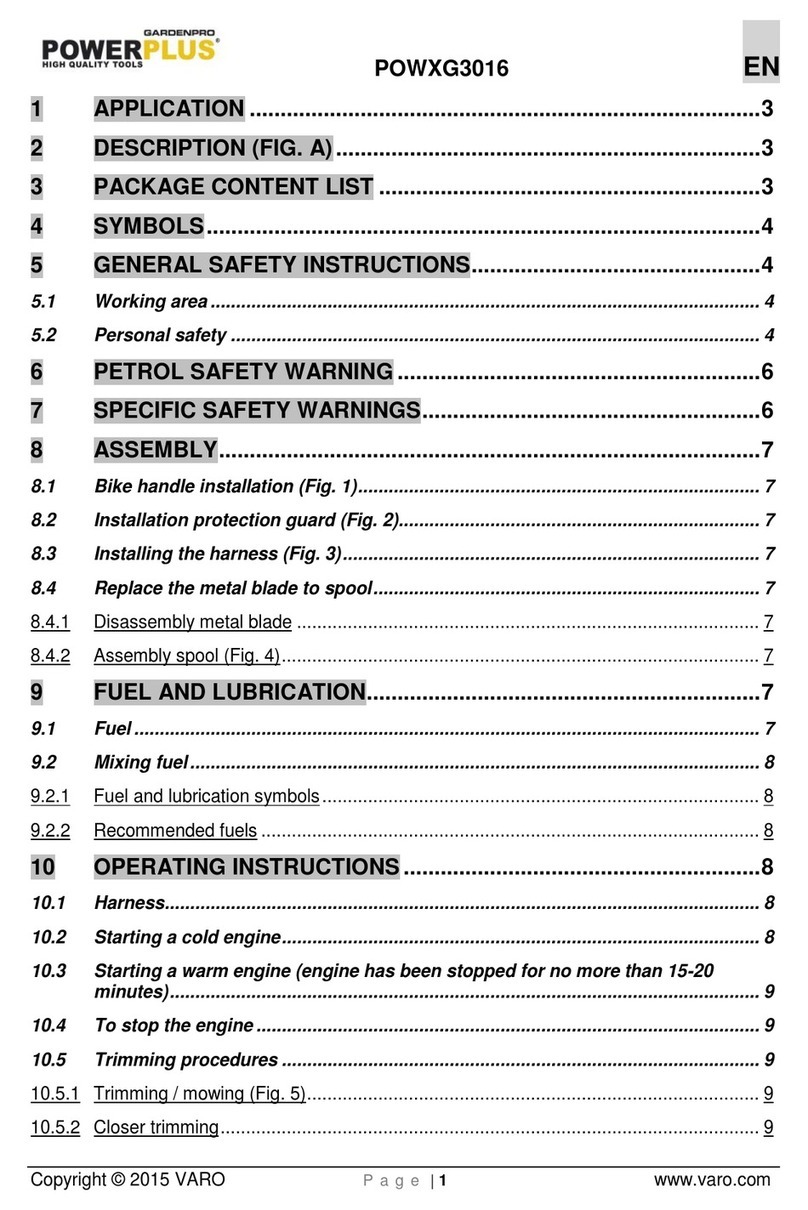

Table of Contents

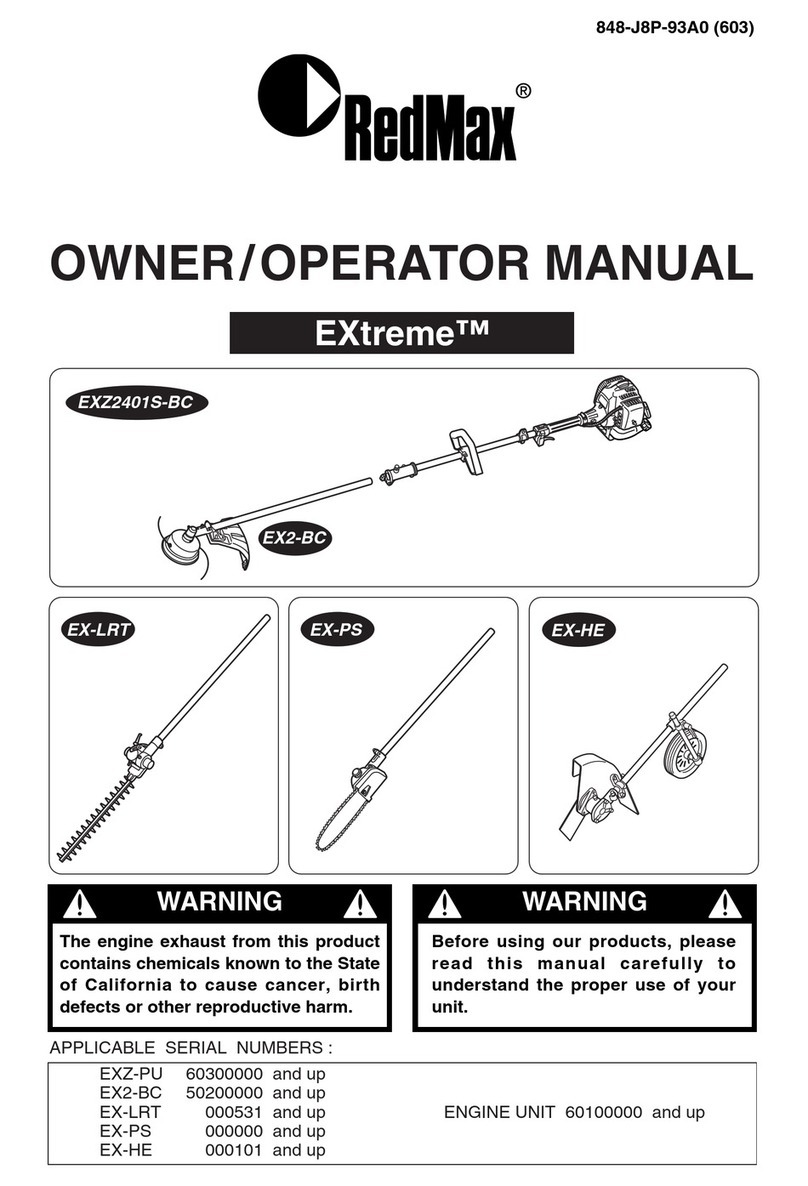

Petrol brush cutter

USER’S MANUAL

Thank you for purchasing this petrol brush cutter. Before you start using it, please

carefully read this user’s manual and save it for possible future use.

CONTENTS

1. GENERAL SAFETY INSTRUCTIONS..........................................................................................................................5

Important safety notice ............................................................................................................................................5

Packaging .......................................................................................................................................................................5

User’s Manual.................................................................................................................................................................5

2. EXPLANATION OF INSTRUCTION LABELS ON THE MACHINE...................................................................6

3. OPERATING INSTRUCTIONS......................................................................................................................................7

Safety instructions ........................................................................................................................................................7

Safety instructions ........................................................................................................................................................7

Safety instructions ........................................................................................................................................................8

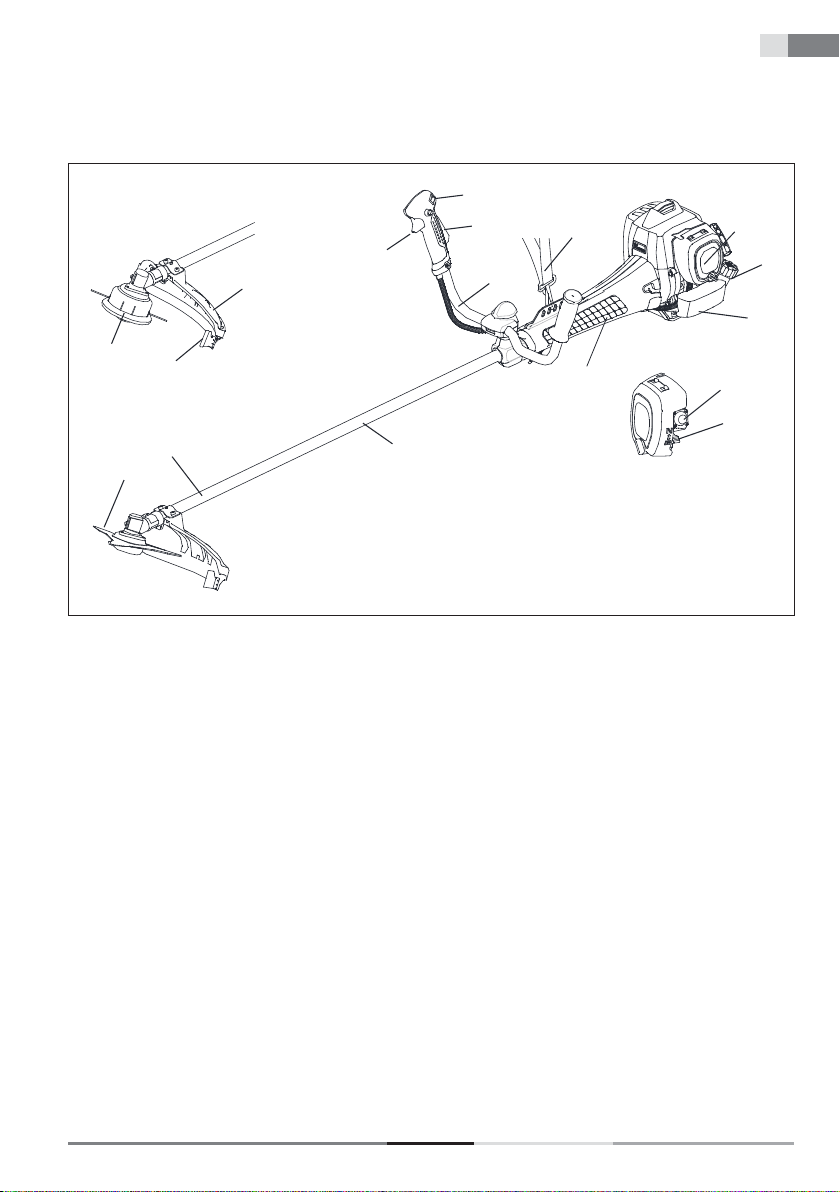

4. Description of the machine ..................................................................................................................................9

Included contents ....................................................................................................................................................10

5. ASSEMBLY........................................................................................................................................................................ 11

6. Mixing the fuel mix ...................................................................................................................................................14

Storing fuel.....................................................................................................................................................................14

7. OPERATION....................................................................................................................................................................14

8. PREPARING FOR OPERATION ...............................................................................................................................16

Points to check before starting work...............................................................................................................16

9. SAFETY WORKING WITH BRUSH CUTTER .........................................................................................................16

10. CUTTING ...........................................................................................................................................................................21

CUTTING WITH THE NYLON STRING TRIMMER HEAD .................................................................................21

Trimming grass.............................................................................................................................................................21

Clearing and trimming edges............................................................................................................................22

CUTTING USING THE BLADE...................................................................................................................................22

Cutting weeds ............................................................................................................................................................22

11. MAINTENANCE.............................................................................................................................................................24

12. TROUBLE SHOOTING GUIDE ..................................................................................................................................26