8

SAFETY INFORMATION

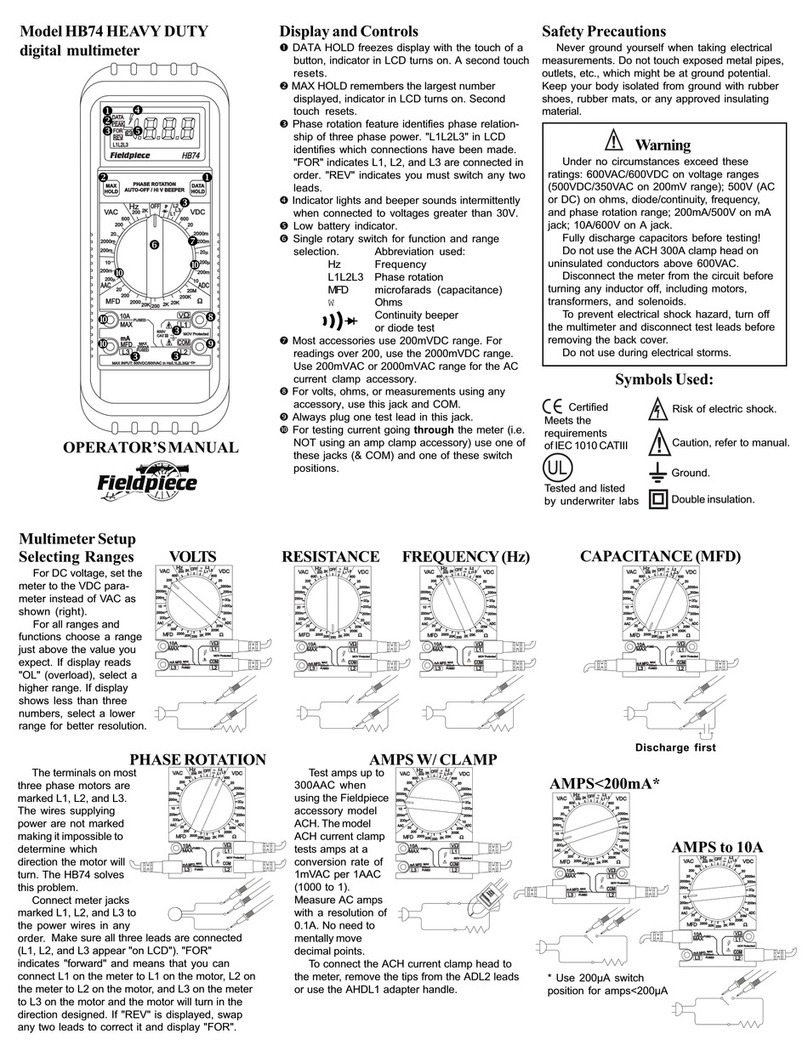

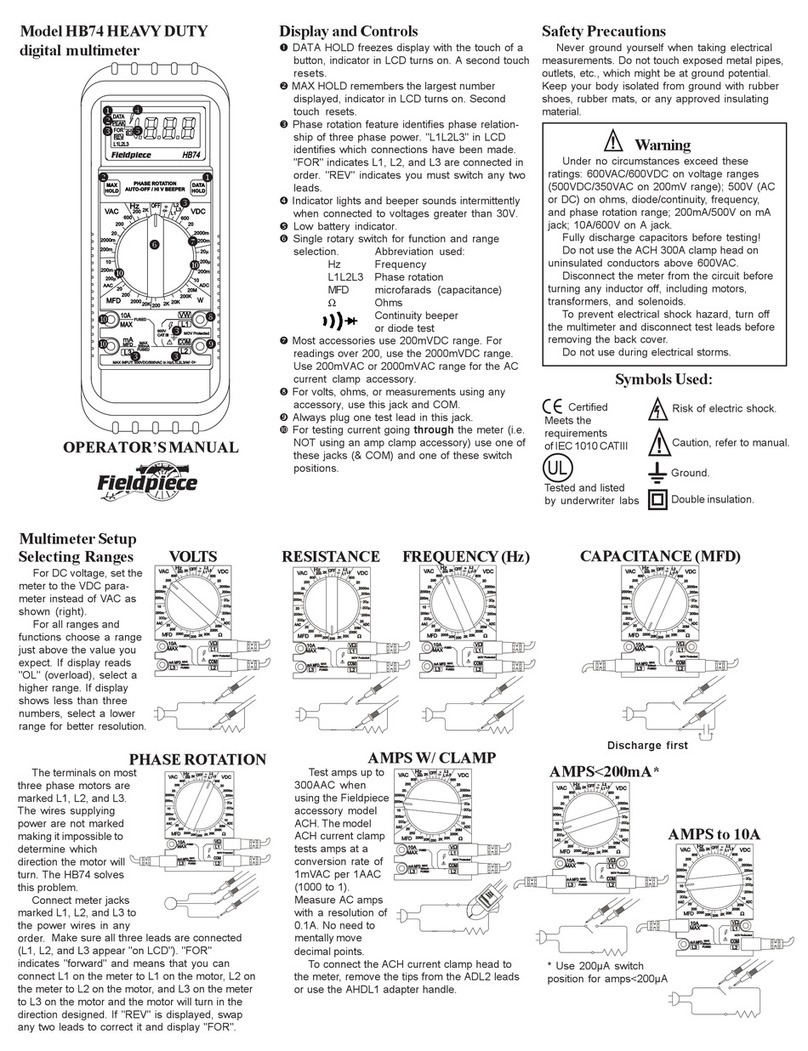

The Fieldpiece HB series was designed in accordance with IEC Publi-

cation 348, Class II, Safety Requirements for Electronic Measuring Appa-

ratus for use by trained professional technicians, and has been supplied in

a safe condition. Fire retardant plastics, metal oxide varistors (MOVs), and

"O" ring seals have been used for protection. Electricity can cause severe

injury or death even with low currents and voltages. The following safety

information must be observed to insure maximum personal safety during

operation of this meter

Do not use this meter if the meter or test leads look damaged, or if you

suspect that the meter is not operating properly.

Never ground yourself when taking electrical masurements. Do not

touch exposed metal pipes, outlets, fixtures, etc., which might be at ground

potential. Keep your body isolated from ground by using dry clothing,

rubber shoes, rubber mats, or any approved insulating material.

Turn off power to circuit under test before cutting, unsoldering, or

breaking the circuit. Small amounts of current can be dangerous.

All Voltage Measurements

To avoid electrical shock hazard and/or damage to the meter, do not

apply more than 1200VDC or 850VAC between earth ground and any

input terminal. Use caution when measuring high voltage.

AC Measurements

Measurement of AC power sources with inductive loads or AC power

sources during electrical storms may result in extremely high-voltage,

high-energy transients that could damage the meter and expose the user to

a dangerous shock hazard. Do not use during electrical storms.

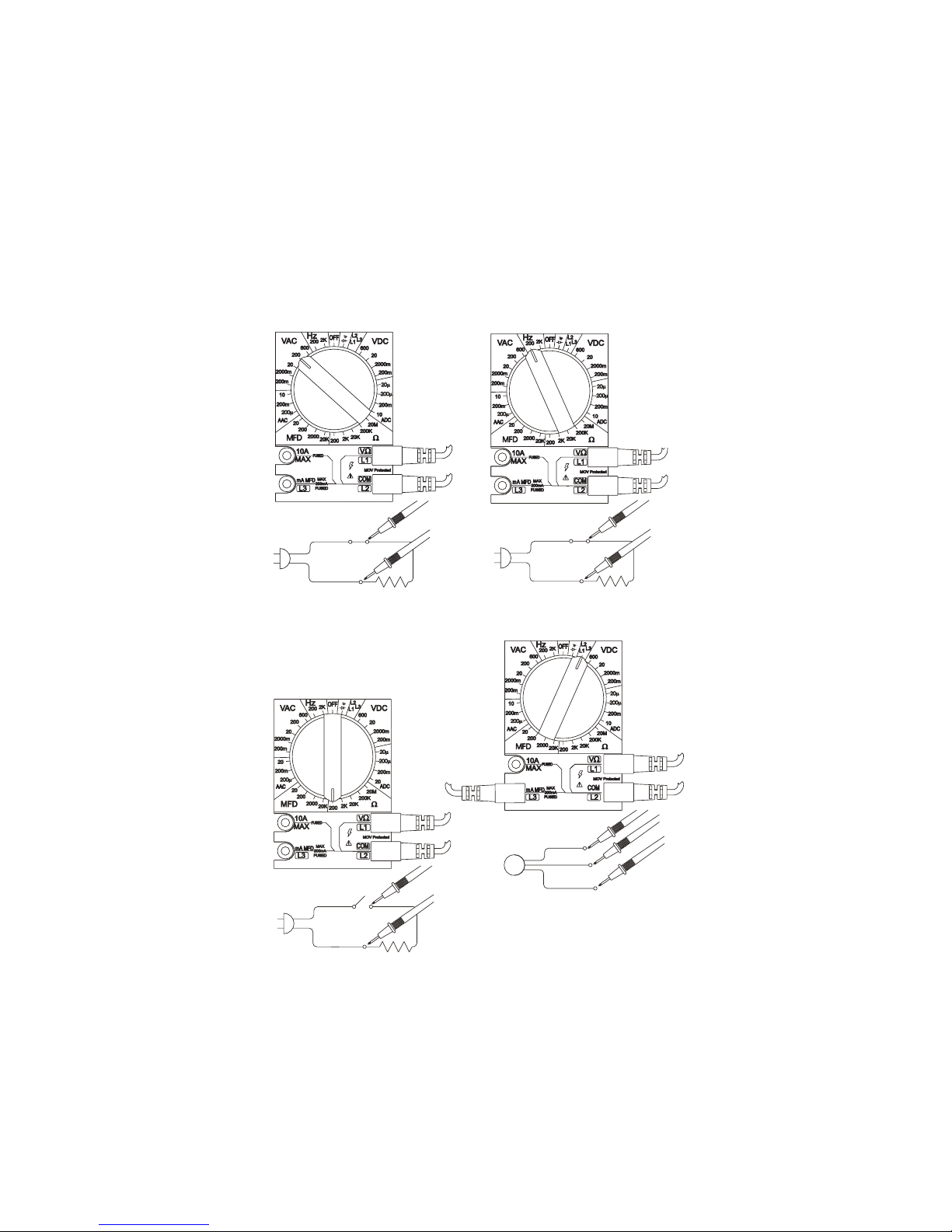

Resistance and Capacitance Measurements

Turn off the power to the circuit or device being measured before taking

measurements. Otherwise, damage may result. Fully discharge all capaci-

tors before testing.

General

Inspect the test leads for damage to the insulation or exposed metal.

Replace if suspect. When disconnecting from a circuit, disconnect the

"RED" lead first, then the common lead. Work with others. Use one hand

for testing.