FieldServer ProtoNode RER Manual

Eective: 12-31-21

Replaces: 09-01-15

P/N 241515 Rev. 3

INSTALLATION & OPERATING

INSTRUCTIONS

ProtoNode RER and ProtoNode LER

For Interfacing Raypak heating products equipped with the VERSA IC® control platform to Building Automation

Systems: BACnet MS/TP, BACnet IP, Modbus TCP, Metasys N2, and LonWorks

(FPC N34)

B-85

(FPC N35)

B-86

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

2

Revision 3 reects the following changes:

Reformatted to reect latest I&O template. Paragraph added to bottom of page 4. Figures 1, 6, 7 & 9 revised. Text revised following

Figure 8. Section 4 verbiage and gures revised. Figures 14, 15, 16, 19 & 24 revised. " Instructions to Upload XIF" section revised.

Appendix A "Troubleshooting:" section revised. Appendix B table "Point Name" descriptions updated.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

3

TABLE OF CONTENTS

1. INTRODUCTION..................................................... 4

BTL Mark – BACnet Testing Laboratory ................. 4

LonMark Certication .............................................. 4

2. INTERFACING THE PROTONODE TO RAYPAK

PRODUCTS............................................................. 5

ProtoNode RER (FPC-N34) and LER (FPC-N35)

showing connection ports .............................. 5

3. BACNET/LONWORKS SETUP FOR

PROTOCESSOR PROTONODE RER/LER......... 6

Installation steps for the customer ..........................6

Record Identication Data ....................................... 6

Congure Raypak VERSA IC Modbus

COM Settings ................................................ 6

Select the Desired Field Protocol – for ProtoNode

RER (FPC-N34) ............................................. 7

Using S0 – S3 bank of DIP Switches ..................... 7

BACnet MS/TP, BACnet/IP, Modbus TCP, and

Metasys N2 Settings for ProtoNode RER

(FPC-N34) .................................................... 7

Setting the Device Instance (Node-ID) for BACnet

MS/TP and BACnet/IP on ProtoNode RER

(FPC-N34) ..................................................... 7

Setting the Node-ID for Metasys N2 and Modbus

TCP on ProtoNode RER (FPC-N34) ............. 7

Setting the MAC Address for BACnet MS/TP for the

ProtoNode RER (FPC-N34) ........................... 8

Set Field RS-485 Baud Rate for BACnet MS/TP on

ProtoNode RER (FPC-N34) .......................... 8

Setting the Serial Baud Rate (DIP Switch B0 – B3)

for BACnet MS/TP ........................................ 8

Wiring Connections to ProtoNode RER (FPC-N34

BACnet) and ProtoNode LER (FPC-N35

LonWorks) ..................................................... 9

Connecting the VERSA IC Modbus port to the

ProtoNode’s Phoenix 6 pin connector. ........... 9

Wiring the ProtoNode RER to RS-485 Field Protocol

(BACnet MS/TP or Metasys N2) .................. 11

Wiring the ProtoNode LER (FPC-N35) Field Port to a

LonWorks network ....................................... 11

Power-Up the ProtoNode RER (FPC-N34 BACnet)

or ProtoNode LER (FPC-N35 LonWorks) .... 12

4. CONNECT TO THE PROTONODE’S WEB

CONFIGURATOR TO SETUP THE RAYPAK

PRODUCTS (PROFILES) CONNECTED TO THE

PROTONODE RER OR LER .............................. 12

Connect the PC to the ProtoNode via the Ethernet

port ............................................................... 12

Congure Proles in the ProtoNode’s Web

Congurator ................................................. 13

Selecting the Raypak proles that will be connected

the ProtoNode .............................................. 13

Changing BN_Node_Oset via the ProtoNode’s Web

Congurator ................................................. 15

Set IP Address for BACnet/IP via GUI .................. 15

5. COMMISSIONING THE PROTONODE LER ON A

LONWORKS NETWORK..................................... 16

Commissioning the ProtoNode LER on a LonWorks

network ........................................................16

Instructions to Upload XIF File From the ProtoNode

LER Using FS GUI Web Server ................... 16

6. CHIPKIN AUTOMATION’S CAS BACNET

EXPLORER FOR VALIDATING THE

PROTONODE IN THE FIELD.............................. 17

Downloading Chipkin Automation’s CAS Explorer

and Requesting an Activation Key .............. 17

CAS BACnet Setup ............................................... 18

CAS BACnet MS/TP Setup ................................... 18

CAS BACnet BACnet/IP Setup ............................. 18

7. APPENDIX A. TROUBLESHOOTING................ 18

Check Wiring and Settings .................................... 18

Take Diagnostic Capture With the FieldServer

Utilities .........................................................18

Setting the Network Number for BACnet IP .......... 20

LED Diagnostics for Modbus RTU Communications

between the ProtoNode and Raypak VERSA

IC .................................................................20

8. APPENDIX B. PICS STATEMENT...................... 21

Raypak VERSA IC Modbus RTU Mappings to

BACnet MS/TP, BACnet/IP, Metasys N2 and

LonWorks ..................................................... 21

Address DIP Switch Settings ................................24

9. APPENDIX C. REFERENCE ............................... 26

Specications ........................................................ 26

Compliance with UL Regulations .......................... 26

10. LIMITED 2 YEAR WARRANTY ........................... 27

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

4

LonMark Certication

LonMark International is the recognized authority for

certication, education, and promotion of interoperability

standards for the benet of manufacturers, integrators and

end users. LonMark International has developed extensive

product certication standards and tests to provide the

integrator and user with condence that products from

multiple manufacturers utilizing LonMark devices work

together. FieldServer Technologies has more LonMark

Certied gateways than any other gateway manufacturer,

including the ProtoCessor, ProtoCarrier and ProtoNode

for OEM applications and the full featured, congurable

gateways.

Oered Congurations

Part No. Option Protocols

014691 B-85 BACnet MS/TP, MS/IP, Modbus TCP,

Metasys N2

014692 B-86 LonWorks

Table A. Oered Congurations

The wired conguration may be installed inside of the

cabinet ,or at a convenient location outside of the cabinet.

The wireless conguration must be installed outside of the

cabinet.

1. INTRODUCTION

ProtoNode is an external, high performance building

automation multi-protocol gateway that is congured to

allow communication between Raypak heating products

equipped with the VERSA IC® control platform to various

building automation protocols. These protocols include

BACnet MS/TP, BACnet/IP, Modbus TCP, Metasys N2,

and LonWorks.

• All Raypak products using VERSA IC control platform

support ProtoNode.

Through the ProtoNode Web GUI Congurator, the user

selects how many VERSA IC Master units are connected

to the ProtoNode as well as sets the Modbus Node-ID for

each VERSA IC Master. A Versa IC Master Unit can have

up to 169 Modbus points for up to 4 connected Versa IC

equipped units. Once the Raypak products are selected,

the ProtoNode Automatically builds and downloads the

Conguration for the desired protocol.

• The total number of VERSA IC Master units attached

to the ProtoNode RER (FPC-N34) cannot exceed 8

Master units or 1400 Modbus registers for BACnet

MS/TP, BACnet IP, Modbus TCP or Metasys N2.

• The total number of VERSA IC Master units attached

to the ProtoNode LER (FPC-N35) cannot exceed 6

Master units or 1000 Modbus registers for LonWorks.

This document provides the necessary information to

facilitate installation of the ProtoNode.

Raypak Videos

Go to www.youtube.com/RaypakChannel to watch

the latest videos on our products and how you can

troubleshoot/service them.

BTL Mark – BACnet

Testing Laboratory

The BTL Mark on the ProtoNode RER is a symbol that

indicates that a product has passed a series of rigorous

tests conducted by an independent laboratory which

veries that the product correctly implements the BACnet

features claimed in the listing. The mark is a symbol

of a high-quality BACnet product. Go to http://www.

bacnetinternational.net/btl/ for more information about the

BACnet Testing Laboratory.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

5

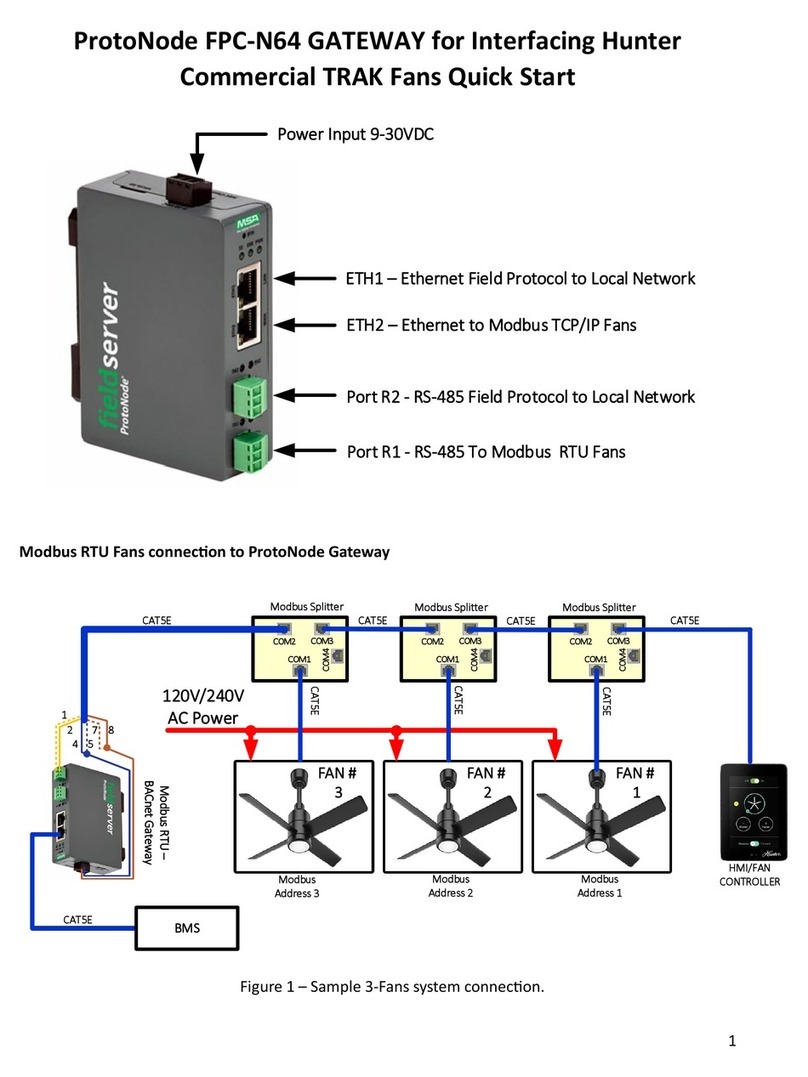

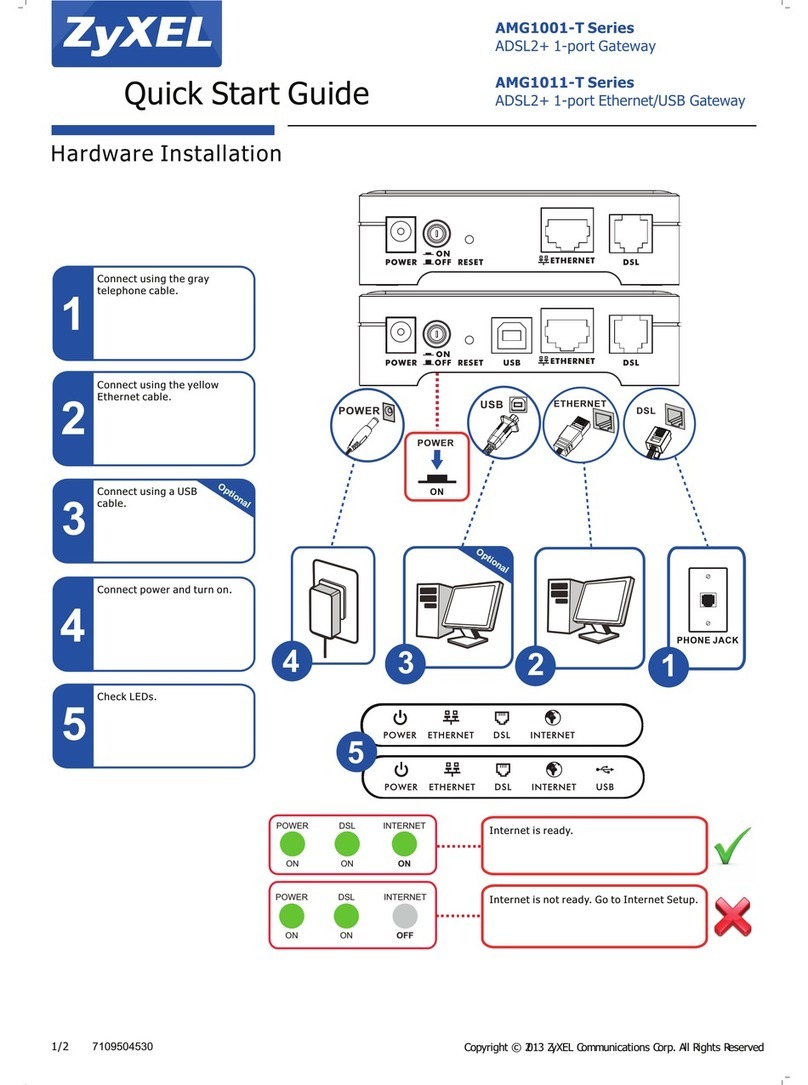

ProtoNode RER (FPC-N34) and LER (FPC-N35) showing connection ports

Figure 1. ProtoNode BACnet RER (BACnet) and ProtoNode LER (LonWorks)

RER Configuration:

B-85

BACnet, Modbus, Metasys

To Controller

To Controller

LER Configuration:

B-86

LonWorks

2. INTERFACING THE PROTONODE TO RAYPAK PRODUCTS

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

6

3. BACNET/LONWORKS

SETUP FOR

PROTOCESSOR

PROTONODE RER/LER

Connects only to a master unit, not a follower. Follow these

instructions step-by-step for successful commissioning of

the device.

Installation steps for the customer

1. Record identification data. (See page 5)

2. Set the Raypak VERSA IC Modbus RTU serial

settings (i.e. baud rate, parity, stop bits) and Modbus

Node-ID’s for each VERSA IC Master that will be

connected to the ProtoNode FPC-N34 or FPC-N35.

(See Table A)

3. Select the Field Protocol (BACnet MS/TP, BACnet

IP, Modbus TCP or Metasys N2) on the S Bank Dip

Switches on the FPC-N34-0636. (See Figure 2)

4. Set BACnet device address for the ProtoNode RER

(FPC-N34). (See "Setting the MAC Address for

BACnet MS/TP for the ProtoNode RER (FPC-N34)"

on page 8)

5. Set Metasys N2 Node-ID. (See

"Configure Raypak VERSA IC Modbus

COM Settings" on page 6)

6. If using BACnet MS/TP, Set B bank of DIP switches

to set the baud rate on ProtoNode RER (FPC-N34).

(See Figure 4 & Table D)

7. Connect the ProtoNode’s 3 pin RS-485 port to the

Field Protocol cabling. (See Figure 8)

8. Connect each of the Raypak devices to the RS-

485 Modbus RTU port to the ProtoNode’s RS-485

interface which is located on the 6 pin connector of

the ProtoNode (FPC-N34 and FPC-35). (See Figure

5 through Figure 7)

9. Connect Power to the ProtoNode RER or LER.

(See Figure 11) Raypak recommends a dedicated

power supply be used to power the ProtoNode.

10. Follow instructions on page 12 to use web

configurator.

11. Use Web-Configurator to select the Raypak

products that will be attached to the ProtoNode

and set the current Modbus Node-ID for each these

products. Once the Raypak products are selected,

the ProtoNode Automatically builds and downloads

the Configuration for the specific application. (See

"Selecting the Raypak profiles that will be connected

the ProtoNode" on page 13).

12. Where the Field protocol is BACnet/IP or Modbus

TCP, run the ProtoNode web GUI utility program

to change the IP address. No changes to the

configuration file are necessary. (See "Set IP Address

for BACnet/IP via GUI" on page 15)

13. Commission the ProtoNode on the LonWorks

Network. This needs to be done by the LonWorks

administrator using a LonWorks Commissioning

tool. (See "Commissioning the ProtoNode LER on a

LonWorks network" on page 16)

Record Identication Data

Each ProtoNode has a unique part number located on the

underside of the unit. The numbers are as follows:

• FieldServer part # FPC-N34-0636:VERSA IC

to BACnet MS/TP, BACnet/IP, Modbus TCP,

Metasys N2.

• FieldServer part # FPC-N35-0637: VERSA IC to

LonWorks.

This number should be recorded, as it may be required for

technical support.

Congure Raypak VERSA IC Modbus

COM Settings

• All Raypak VERSA IC Master units connected to the

ProtoNode MUST ALL have the same Baud Rate,

Data Bits, Stop Bits, and Parity. (See Figure 2)

These settings have no impact on the BMS portion

of the Protonode communication and only are used

to connect between the Versa IC Master and the

Protonode.

• Set Modbus Node-ID’s (Address) for each of the

Raypak VERSA IC Master units attached to the

ProtoNode. The Modbus Node-ID’s need to be

uniquely assigned between 1 and 127.

• The Modbus Node-ID’s that are assigned for

each Raypak VERSA IC Master unit needs to be

noted for later use when assigning Node-ID’s in

the web configurator. (See Figure 18)

• The Metasys N2 and Modbus TCP Node-ID

will be set to same value as the Node-ID of the

Modbus RTU device.

Serial Port Setting VERSA IC

Baud Rate 19K2 (19200)

Data Bits 8

Stop Bits 1

Parity Even

Table B. Modbus RTU COM settings for the Raypak

VERSA IC control platform

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

7

Select the Desired Field Protocol

– for ProtoNode RER (FPC-N34)

Using S0 – S3 bank of DIP Switches

• The S bank of DIP switches, S0 – S3 are used to

select the BACnet MS/TP, BACnet/IP, Modbus

TCP, or Metasys N2 on the ProtoNode RER

(FPC-N34-0636).

• The S bank of DIP switches on ProtoNode LER

(FPC-N35-0637 - LonWorks) is disabled.

S Bank DIP Switches

Figure 2. S0 through S3 DIP Switches

BACnet MS/TP, BACnet/IP, Modbus

TCP, and Metasys N2 Settings

for ProtoNode RER (FPC-N34)

Installation Steps for the Customer

The following chart describes S0 - S3 DIP switch

conguration settings for the Raypak products to support

BACnet MS/TP or BACnet/IP on a ProtoNode RER (Part

# FPC-N34-0636).

• When the S bank of switches are all off (default

setting) BACnet IP is enabled.

ProtoNode RER

FPC-N34-0636

ProtoNode S

Bank DIP Switches

Prole SO S1 S2 S3

BACnet IP O O O O

BACnet MS/TP On O O O

Modbus TCP O On O O

Metasys On On O O

Table C. “S” Bank DIP Switch Settings

Setting the Device Instance (Node-

ID) for BACnet MS/TP and BACnet/

IP on ProtoNode RER (FPC-N34)

• BACnet IP/BACnet MSTP addressing: The BACnet

device instances will be set by taking the BN_

Node_Offset found in the Web Configurator (See

page 13) and added to each Modbus RTU device

address set on the Raypak VERSA IC Master units,

attached to the ProtoNode.

• 50000 is the default.

• If one of the Raypak VERSA IC Master units

Modbus RTU node addresses were set for 10,

then the device instance would be 50010.

• If the 2nd Device is Modbus address set 2, then

the device instance will be set to 50002.

• To change the BN_Node_Offset (See page

15). The node offset can be changed from

50000 to some other number via the Web

Configurator.

Setting the Node-ID for Metasys

N2 and Modbus TCP on

ProtoNode RER (FPC-N34)

• Metasys N2 and Modbus TCP Node-ID Addressing:

Metasys N2 and Modbus TCP Node-ID’s range from

1-127. The Metasys N2 and Modbus TCP Node-ID

will automatically set to the same value as the Node-

ID (Address) of the Raypak VERSA IC Master units.

Do not use ID values over 127.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

8

Setting the MAC Address

for BACnet MS/TP for the

ProtoNode RER (FPC-N34)

• Only 1 MAC address is set for the ProtoNode

regardless of how many Raypak devices are

connected to the ProtoNode.

• Set the BACnet MS/TP MAC addresses between 1 to

127. This is so that the BMS Front End can find the

ProtoNode.

• Addresses from 128 to 255 are Slave Addresses

and cannot be discovered by BMS Front Ends that

support auto discovery of BACnet MS/TP devices.

Never set a BACnet MS/TP MAC Address from 128

to 255.

• Set DIP switches A0 – A7 to assign MAC Address for

BACnet MS/TP for the first Raypak device attached

to the ProtoNode.

• Please refer to "Address DIP Switch Settings" on

page 24 for the full range of addresses to set

Node-ID/Device Instance.

• When using Metasys N2 and Modbus TCP, the A

Bank of DIP switches are disabled and not used.

They should be set to OFF.

Figure 3. A0 through A7 DIP Switches

NOTE: When setting DIP switches, please ensure that

power to the board is OFF.

Set Field RS-485 Baud

Rate for BACnet MS/TP on

ProtoNode RER (FPC-N34)

The serial baud rate setting between the BMS and the

Protonode has no impact on the communication baud

rate between the Versa IC Master and the Protonode. The

serial baud rate and Versa IC baud rate are not required

to match for communication to take place. The Versa IC

Master baud rate must always be set for 19K2 (19200)

to allow communication between the Versa IC Master and

the Protonode.

Setting the Serial Baud Rate (DIP

Switch B0 – B3) for BACnet MS/TP

• DIP Switches B0 – B3 can be used to set the serial

baud rate to match the baud rate provided by the

Building Management System for BACnet MS/TP.

• DIP Switches B0 – B3 are disabled on ProtoNode

LER (FPC-N35 LonWorks).

• The rate on the ProtoNode for Metasys is set for

9600. DIP Switches B0 – B3 are disabled for Metasys

N2 on ProtoNode RER (FPC-N34).

Figure 4. B0 through B3 DIP Switches

Baud B0 B1 B2 B3

9600 On On On O

19200 O O O On

38400 On On O On

57600 O O On On

76800 On O On On

Table D. “B” Bank DIP Switch Settings

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

9

Wiring Connections to ProtoNode RER (FPC-N34 BACnet)

and ProtoNode LER (FPC-N35 LonWorks)

Figure 5. Power and RS485 pin outs

(Tx/+)

(Rx/-)

Connecting the VERSA IC Modbus port to the

ProtoNode’s Phoenix 6 pin connector.

• Connect VERSA IC Modbus pin A (RS485+) to the ProtoNode’s pin 1 (RS485+) on the Phoenix 6 pin connector.

• Connect VERSA IC Modbus pin B (RS485-) to the ProtoNode’s pin 2 (RS485-) on the Phoenix 6 pin connector.

• Connect VERSA IC Modbus pin GND (Ground) and the ProtoNode’s pin 3 (Signal Ground) on the Phoenix 6 pin

connector.

Figure 6. VERSA IC Modbus RS485 pin outs to the ProtoNode’s Modbus port

Raypak Pin # ProtoNode Pin Assignment

MODBUS A (+) Pin 1 RS-485 +

MODBUS B (-) Pin 2 RS-485 -

MODBUS GND Pin 3 RS-485 GND

Power In (+) Pin 4 V +

Power In (-) Pin 5 V -

Frame Ground Pin 6 Frame GND

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

10

RS-485

Cable

Raypak

VERSA

Master Unit 1

Master Unit 2

Raypak

VERSA

( + )

( - )

Tx/+

Rx/-

Tx/+

Rx/-

Figure 7. Multiple VERSA IC Masters

NOTE: Multiple Master conguration requires each

Master to have dierent ID’s.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

11

Wiring the ProtoNode RER to RS-485 Field

Protocol (BACnet MS/TP or Metasys N2)

• Connect BMS BACnet MS/TP or Metasys N2 RS485 port to the 3-pin RS485 connector on ProtoNode RER as

shown below.

Figure 8. Connection from ProtoNode to RS-485 Field Protocol –BACnet MS/TP

• If the ProtoNode is the last device on the trunk, then the end of line (EOL) termination switch needs to be

enabled, as shown below:

* The default setting from the factory is OFF (switch position = right side).

* To enable the EOL termination, turn the EOL switch ON (switch position = left side)

Figure 9. End-of-line termination on from ProtoNode to RS-485 Field Protocol – BACnet MS/TP

Figure 10. LonWorks Terminal

Wiring the ProtoNode LER (FPC-N35) Field Port to a LonWorks network

• Connect the ProtoNode to the field network with the LonWorks terminal using a twisted pair non-shielded cable.

LonWorks has no polarity.

BMS RS-485 Wiring ProtoNode Pin # Pin assignment

RS-485 + Pin 1 RS-485 +

RS-485 - Pin 2 RS-485 -

- Pin 3 RS-485 GND

+ – G

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

12

Power-Up the ProtoNode RER (FPC-N34 BACnet)

or ProtoNode LER (FPC-N35 LonWorks)

Figure 11. Power pin outs to the ProtoNode

• Apply power to the ProtoNode. Ensure that the power supply used complies with the specifications provided in

Appendix C. Ensure that the cable is grounded using the “Frame-GND” terminal. The ProtoNode is factory set to

accept both 9-30 VDC and 12-24 VAC. Raypak recommends using a dedicated power supply for the Protonode

in lieu of unit power.

Voltage Pin outs

4. CONNECT TO THE PROTONODE’S WEB CONFIGURATOR

TO SETUP THE RAYPAK PRODUCTS (PROFILES)

CONNECTED TO THE PROTONODE RER OR LER

Connect the PC to the ProtoNode via the Ethernet port

For BACnet IP only. For all others, use RS485 connection.

Figure 12. Ethernet port location of ProtoNode

• Connect a Cat-5 Ethernet cable (straight through or

cross-over) between the PC and ProtoNode.

• The default IP Address for the ProtoNode is

192.168.1.24, Subnet Mask is 255.255.255.0. If the

PC and ProtoNode are on different IP networks,

assign a static IP Address to the PC on the

192.168.1.xxx network.

For Windows 10:

• Find the search field in the local computer’s

taskbar (usually to the right of the windows

icon and type in “Control Panel”.

Power to the ProtoNode ProtoNode

Pin # Pin Assignment

Power In (+) Pin 4 V +

Power In (-) Pin 5 V -

Frame Ground Pin 6 FRAME GND

• Click “Control Panel”, click “Network and Internet”

and then click “Network and Sharing Center”.

• Click “Change adapter settings” on the left side of the

window.

• Right-click on “Local Area Connection” and select

“Properties” from the drop down menu.

• Highlight

and then click the Properties button

• Select and enter a static IP Address on the same

subnet. For example:

Figure 13. Local Area Connection Properties

• Click the OK button to close the Internet Protocol

window and the Close button to close the Ethernet

Properties window.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

13

Congure Proles in the ProtoNode’s Web Congurator

• Open PC web browser; enter the default IP address of the ProtoNode 192.168.1.24.

• When the S bank of DIP switches are set for BACnet you will see all the Raypak Profiles supporting BACnet listed

in the Configurator.

• When the S bank is set for BACnet MS/TP, all Raypak profiles supporting BACnet MS/TP will appear.

Selecting the Raypak proles that will be connected the ProtoNode

• When you open the Web Configurator, you will see Active Profiles on the left side of the screen. There is a pull

down box under Current Profiles that will list all the profiles available to select from.

• To add an active profile to the ProtoNode, select Add under Active Profiles. For every Raypak VERSA IC Master

Unit that will be added to the ProtoNode, you will need to add the Active Profile (on the left of the screen) and the

Modbus Node Address that the device is assigned to. Each Versa IC Master unit must have a unique Modbus

Node Address selected in the Versa adjust menu. Note: Modbus Node Address must match the Node ID

selected when commissioning the Protonode from the Web Configurator shown below.

Figure 14. Web Congurator showing the active proles to select from

• Once the Profile and Modbus Node Address have been selected, press the Add button to add the Profile to be

configured.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

14

Figure 15. Web Congurator showing a prole selected

Figure 16. Web Congurator showing a completed prole added

• Continue this process until all the Raypak VERSA IC Master units have been added.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

15

Changing BN_Node_Oset via the ProtoNode’s Web Congurator

• The BACnet Device Instance is equal to the Modbus Node ID plus the BN_Node_Offset.

• To change the BN_Node_offset, enter the new values for the offset in web configurator.

• And click to update new values.

Set IP Address for BACnet/IP via GUI

• Open a PC web browser, enter the default IP address of the ProtoNode 192.168.1.24 and connect to the Protonote.

• The Default GUI landing page is the Web Configuration.

• Press the Diagnostics and Debugging button at the bottom right corner of the page to go to FSGUI utility.

Figure 17. Web Congurator showing multiple completed proles added

• Click on setup and then Network Settings to enter the Edit IP Address Settings menu.

Figure 18. ProtoNode Network Settings Tab

• Type in a new Subnet Mask

• If necessary, change the IP Gateway (Default Gateway field)

• Type in a new IP Gateway

• Note: If the ProtoNode is connected to a router, the IP Gateway of the ProtoNode should be set to the IP address

of the router that it is connected to

• Reset ProtoNode

• Unplug Ethernet cable from PC and connect it to the network hub or router

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

16

5. COMMISSIONING THE

PROTONODE LER ON A

LONWORKS NETWORK

Commissioning may only be performed by the

LonWorks administrator.

Commissioning the ProtoNode

LER on a LonWorks network

To commission the ProtoNode LER LonWorks port, insert

a small screwdriver in the commissioning hole on the face

of the LER’s enclosure to access the Service Pin. See

the illustration on the ProtoNode LER as to which way to

toggle the screw driver during commissioning.

Figure 19. ProtoNode LER Commissioning Hole Location

• If an XIF file is required, see Figure 27 to generate

XIF.

Instructions to Upload XIF

File From the ProtoNode LER

Using FS GUI Web Server

• Connect a Cat-5 Ethernet cable (straight through or

cross-over) between the PC and ProtoNode.

• The default IP Address for the ProtoNode is

192.168.1.24, Subnet Mask is 255.255.255.0. If the

PC and ProtoNode are on different IP networks,

assign a static IP Address to the PC on the

192.168.1.xxx network.

For Windows 10:

• Find the search field in the local computer’s taskbar

(usually to the right of the windows icon and type in

“Control Panel”.

• Click “Control Panel”, click “Network and Internet”

and then click “Network and Sharing Center”.

• Click “Change adapter settings” on the left side of

the window.

• Right-click on “Local Area Connection” and select

“Properties” from the dropdown menu

• Highlight > and

then click the Properties button.

• Select and enter a static IP Address on the same

subnet. For example.

• Click the OK button to close the Internet Protocol

window and the Close button to close the Ethernet

Properties window.

• Open a web browser and go to the following address:

[IP Address of ProtoNode]/fserver.xif.

o Example: 192.168.1.24/fserver.xif

• If the web browser prompts to save the file, save the

file onto the PC. If the web browser displays the .xif

file as a web page, save the file onto the local PC as

“fserver.xif”.

Figure 20. Sample of Fserver.XIF le being generated.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

17

6. CHIPKIN AUTOMATION’S CAS BACNET EXPLORER FOR

VALIDATING THE PROTONODE IN THE FIELD

Chipkin Automation has extended to Raypak and their customers a free complementary 2 week fully functional copy of

CAS BACnet Explorer that can be used to validate BACnet MS/TP and/or BACnet/IP communications of the ProtoNode

in the eld without having to have the BMS Integrator on site. A Serial or USB to RS-485 converter is needed to test

BACnet MS/TP.

Downloading Chipkin Automation’s CAS Explorer

and Requesting an Activation Key

• To request a 2-week complementary BACnet CAS key, go to http://app.chipkin.com/activation/twoweek/ and fill in

all the information. Enter Vendor Code “Raypak2012”. Once completed, the key will be sent to the email address

that was submitted. From this email from Chipkin Automation, the long key will need to be copied and pasted into

the CAS key activation page.

• Go to Chipkin Automation’s web site, download, and install the CAS BACnet Explorer to your PC http://www.

chipkin.com/technical-resources/cas-bacnet-explorer/.

• In the CAS Activation form, enter the email address and paste the CAS key that was sent from Chipkin Automation.

Once completed, select Activation.

Figure 21. Chipkin Account Activation

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

18

CAS BACnet Setup

These are the instructions to set CAS Explorer up for the

rst time on BACnet MS/ST and BACnet/IP.

CAS BACnet MS/TP Setup

1. Using the Serial or USB to RS-485 converter,

connect it to your PC and the 3 Pin BACnet MS/TP

connector on the ProtoNode RER.

2. In CAS Explorer, do the following:

a. Click on settings.

b. Check the BACnet MSTP box and uncheck the

BACnet IP and BACnet Ethernet boxes.

c. Set the BACnet MSTP MAC address to 0.

d. Set the BACnet MSTP Baud Rate to 38400.

e. Click OK.

f. On the bottom right-hand corner, make sure that

the BACnet MSTP box is green.

g. Click on discover.

h. Check all 4 boxes.

i. Click Send.

CAS BACnet BACnet/IP Setup

1. Set the IP address and subnet of the PC that will be

running the CAS Explorer.

2. Connect a straight through or cross Ethernet cable

from the PC to the ProtoNode.

3. In CAS Explorer, do the following:

a. Click on settings.

b. Check the BACnet IP box and uncheck the

BACnet MSTP and BACnet Ethernet boxes.

c. In the “Select a Network Device” box, select the

network card of the PC by clicking on it.

d. Click OK.

e. On the bottom right-hand corner, make sure that

the BACnet IP box is green.

f. Click on discover.

g. Check all 4 boxes.

h. Click Send.

7. APPENDIX A.

TROUBLESHOOTING

Check Wiring and Settings

1. No COMS on Modbus RTU side. If the Tx/Rx LEDs

are not flashing rapidly then there is a COM issue. To

fix this, check the following:

o Visual observations of LEDs on ProtoNode

(Section 8)

o Check baud rate, parity, data bits, stop bits.

o Check device address.

o Verify wiring.

o Verify the device was listed in the Web

Congurator (Section 6).

• Field COM problems:

o Visual observations of LEDs on the ProtoNode

o Verify IP Address setting

o Verify wiring

NOTE: If the problem persists, a Diagnostic Capture

needs to be taken and sent to support. (Section A)

Take Diagnostic Capture With

the FieldServer Utilities

NOTE: When there is a problem on-site that cannot

easily be resolved, perform a Diagnostic Capture

before contacting support. Once the Diagnostic

Capture is complete, email it to technical support. The

Diagnostic Capture will accelerate diagnosis of the

problem. Once the Diagnostic Capture is complete,

email it to support@protocessor.com. The Diagnostic

Capture will allow us to rapidly diagnose the problem.

If the FieldServer bios is updated/released on November

2017 or later, then the Diagnostic Capture is performed via

the gateway’s on-board system.

• Access the FieldServer Diagnostics page via one of

the following methods:

o Open the FieldServer FS-GUI page and click on

Diagnostics in the Navigation panel.

o Open the FieldServer Toolbox software and click the

diagnose icon of the desired device.

Figure 22. Full Diagnostics Screen

• Go to Full Diagnostic and select the capture period.

• Click the Start button under the Full Diagnostic

heading to start the capture.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

19

o When the capture period is nished, a Download

button will appear next to the Start button.

Figure 23. Capture Download Button

• Click Download for the capture to be downloaded to

the local PC.

• Email the diagnostic zip file to technical support.

NOTE: Diagnostic captures of BACnet MS/TP

communication are output in a “.PCAP” le extension

which is compatible with Wireshark.

Taking a Capture with

Older Firmware

If the FieldServer rmware is from before November 2017,

the Diagnostic Capture can be done by downloading the

FieldServer Toolbox software but network connections

(such as Ethernet and Wi-Fi) cannot be captured (if a

network diagnostic is needed take a Wire Shark capture).

NOTE: Once the Diagnostic Capture is complete,

email it to technical support. The Diagnostic Capture

will accelerate diagnosis of the problem.

• Ensure that FieldServer Toolbox is loaded onto

the local PC. Otherwise, download the FieldServer

Toolbox.zip via the MSA Safety website.

• Extract the executable file and complete the

installation.

Figure 24. Ethernet Port Location

• Connect a standard Cat-5 Ethernet cable between

the PC and ProtoNode.

• Double click on the FS Toolbox Utility.

• Step 1: Take a Log.

• Click on the diagnose icon for the desired

device.

Figure 25. Device Options Screen

o Select “Full Diagnostic" from the drop down menu.

NOTE: If desired, the default capture period can be

changed.

o Click on the Start Diagnostic button.

o Wait for the capture period to nish and the

Diagnostic Test Complete window will appear.

• Step 2: Send Log.

o Once the diagnostic test is complete, a .zip le

is saved on the PC.

o Choose “Open” to launch explorer and have it

point directly at the correct folder.

o Send the Diagnostic zip le to technical support.

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

20

Setting the Network Number for BACnet IP

On the main Web-Congurator screen, update the Network Number in the BN_Network_Nr and hit Submit. Please note

that the default value is 5.

Figure 26. Setting the Network Number for BACnet IP

LED Diagnostics for Modbus RTU Communications

between the ProtoNode and Raypak VERSA IC

ProtoNode RER (B-85) and LER (B-86) LED Locations:

Light Description For ProtoNode RER and LER

RTC Unused

RUN The RUN LED will start ashing 20 seconds after power indicating normal

operation.

ERR

The SYS ERR LED will go on solid 15 seconds after power up. It will turn

o after 5 seconds. A steady red light will indicate there is a system error on

the ProtoNode. If this occurs, immediately report the related “system error”

shown in the error screen of the GUI interface to FieldServer Technologies for

evaluation.

RX The RX LED will ash when a message is received on the Modbus RTU.

TX The TX LED will ash when a message is sent on the Modbus RTU.

PWR This is the power light and should show steady green at all times when the

ProtoNode is powered.

Figure 27. Diagnostic LEDs Location and Description

APPROVED

UNCONTROLLED DOCUMENT IF PRINTED

This manual suits for next models

2

Table of contents

Other FieldServer Gateway manuals

Popular Gateway manuals by other brands

HMS

HMS Netbiter EasyConnect EC220 Get started

Uponor

Uponor Smatrix Base PRO R-147 KNX Installation and operation manual

Arris

Arris Touchstone DG1680 user guide

NetComm

NetComm HS800 Specifications

bintec elmeg

bintec elmeg be.IP 4isdn manual

Johnson Controls

Johnson Controls MAP Series installation instructions

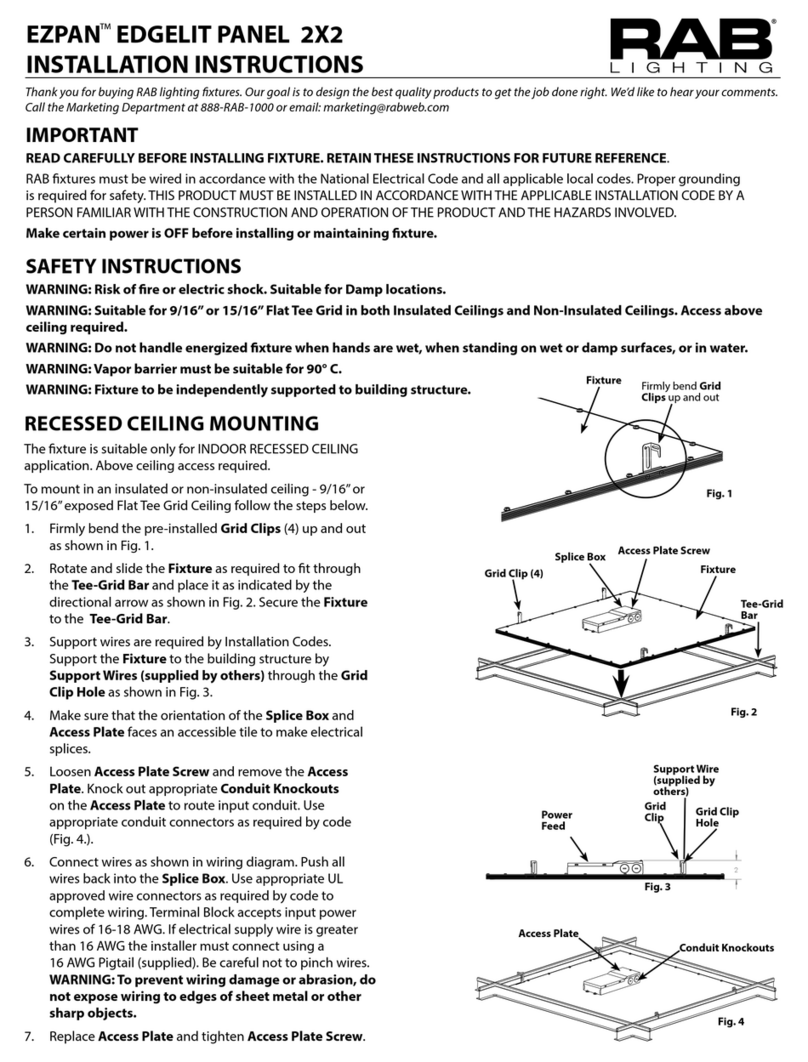

RAB

RAB Lightcloud LCGATEWAY manual

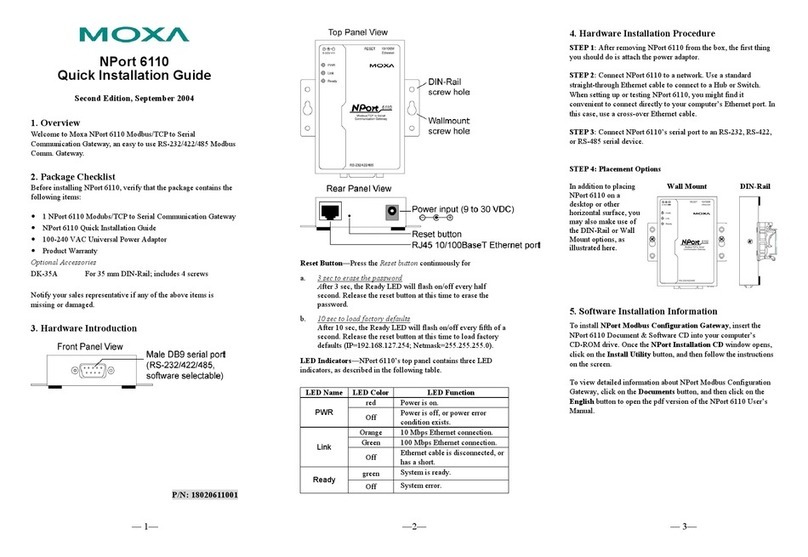

Moxa Technologies

Moxa Technologies NPort 6110 Quick installation guide

NetComm

NetComm CloudMesh NS-01 Getting started

ZyXEL Communications

ZyXEL Communications P-660H-TX V2 - VERSION 3-40 user guide

Aastra

Aastra BusinessPhone installation instructions

Bticino

Bticino FC80GT installation manual