Fife Maxcess DSE-45 Series User manual

DSE-45

Wideband Ultrasonic Sensor

User Manual

EN

MI 2-315 1 A

FIFE GUIDING SOLUTIONS

CONTENTS

www.maxcessintl.com

DSE-45

MI 2-315 1 A

INTRODUCTION 1.1

About these operating instructions .............................................................................. 1.1

Target groups ....................................................................................................... 1.1

Read operating instructions .................................................................................. 1.1

Proper use.................................................................................................................... 1.2

Improper use ............................................................................................................... 1.2

Definition of terms ....................................................................................................... 1.4

SAFETY 2.1

Important safety information ....................................................................................... 2.1

Signal words ................................................................................................................ 2.1

Symbols used............................................................................................................... 2.2

Personnel requirements ............................................................................................... 2.3

Qualified electrician ..................................................................................................... 2.3

Preventing hazards ...................................................................................................... 2.4

INSTALLATION 3.1

Transport and storage.................................................................................................. 3.1

Mounting ..................................................................................................................... 3.1

Mounting location ................................................................................................. 3.1

Product dimensions............................................................................................... 3.2

Mounting the sensor .................................................................................................... 3.3

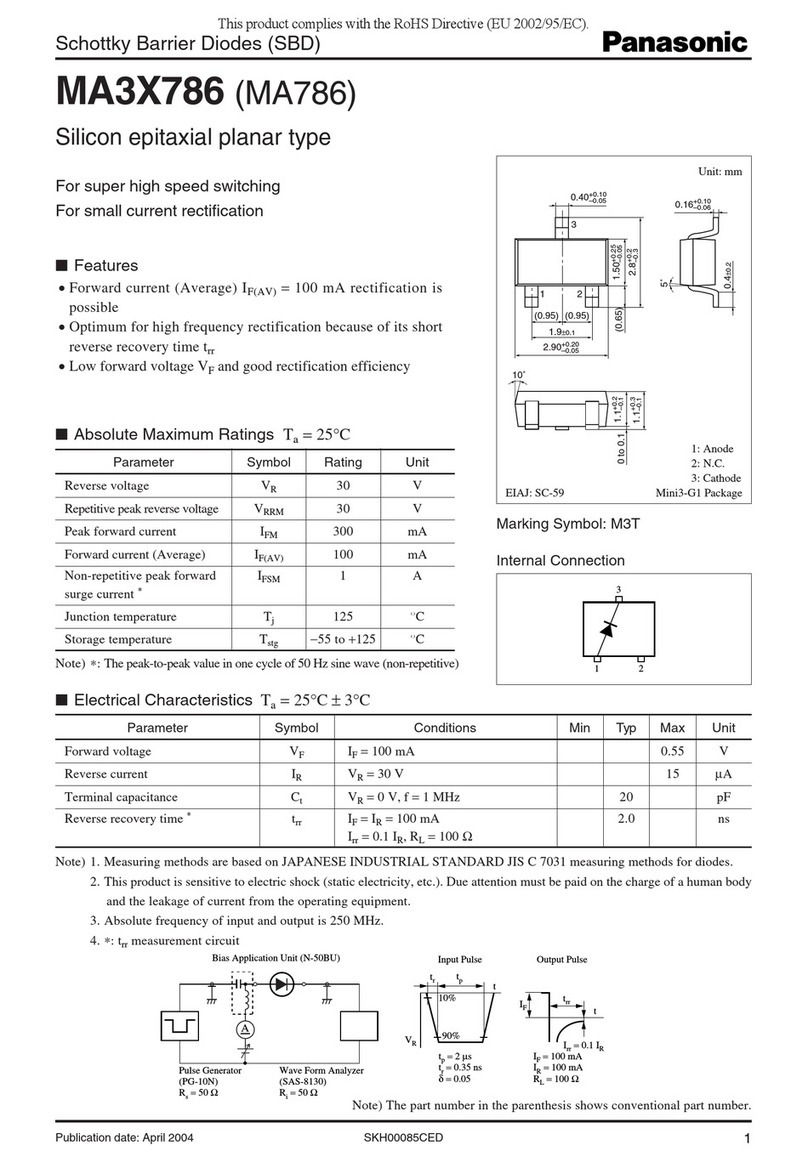

DSE-45 sensor connections ......................................................................................... 3.4

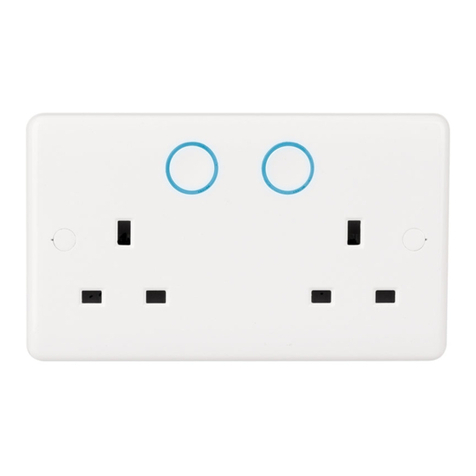

Power connection .................................................................................................. 3.4

Network connection .............................................................................................. 3.5

Optional network communication settings ..................................................... 3.5

OPERATION OVERVIEW 4.1

DSE-45 Sensor ............................................................................................................. 4.1

Analog outputs ..................................................................................................... 4.1

Digital outputs ...................................................................................................... 4.2

Sensor jobs ........................................................................................................... 4.2

Operation modes .................................................................................................. 4.3

Single proportional band mode ...................................................................... 4.3

Multiple proportional band mode ................................................................... 4.4

MODBUS/TCP INTERFACE 5.1

Default signals ............................................................................................................. 5.1

Default data ................................................................................................................. 5.2

Remote control ............................................................................................................ 5.4

WEB PAGE ACCESS 6.1

DSE-45 web page tab descriptions............................................................................... 6.2

Home .................................................................................................................... 6.2

Info ....................................................................................................................... 6.3

Network ................................................................................................................ 6.4

CONTENTS

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Analog output configuration ................................................................................. 6.5

Analog output parameter descriptions ........................................................... 6.6

Calibration ............................................................................................................ 6.7

OPERATOR INTERFACE 7.1

DSE-45 home screen.................................................................................................... 7.1

Key (button) definitions......................................................................................... 7.2

Menu navigation.................................................................................................... 7.4

JOB SETTINGS 8.1

Setting up a job............................................................................................................ 8.1

Set sensor mode .......................................................................................................... 8.2

Single proportional band....................................................................................... 8.2

Multiple proportional band.................................................................................... 8.3

Proportional band size ................................................................................... 8.4

Edge learning ................................................................................................. 8.4

Virtual sensor linking ..................................................................................... 8.4

Select job ..................................................................................................................... 8.5

Select job menu structure ..................................................................................... 8.5

Calibrate transducers ............................................................................................ 8.6

Control options ............................................................................................................ 8.7

Configuration............................................................................................................... 8.8

Network ....................................................................................................................... 8.9

SPECIFIC PROCEDURES 9.1

Jog virtual sensors ....................................................................................................... 9.1

Application filtering ..................................................................................................... 9.2

MAINTENANCE 10.1

SPECIFICATIONS 11.1

SERVICE 12.1

CONTENTS

www.maxcessintl.com

DSE-45

MI 2-315 1 A

TABLE OF FIGURES

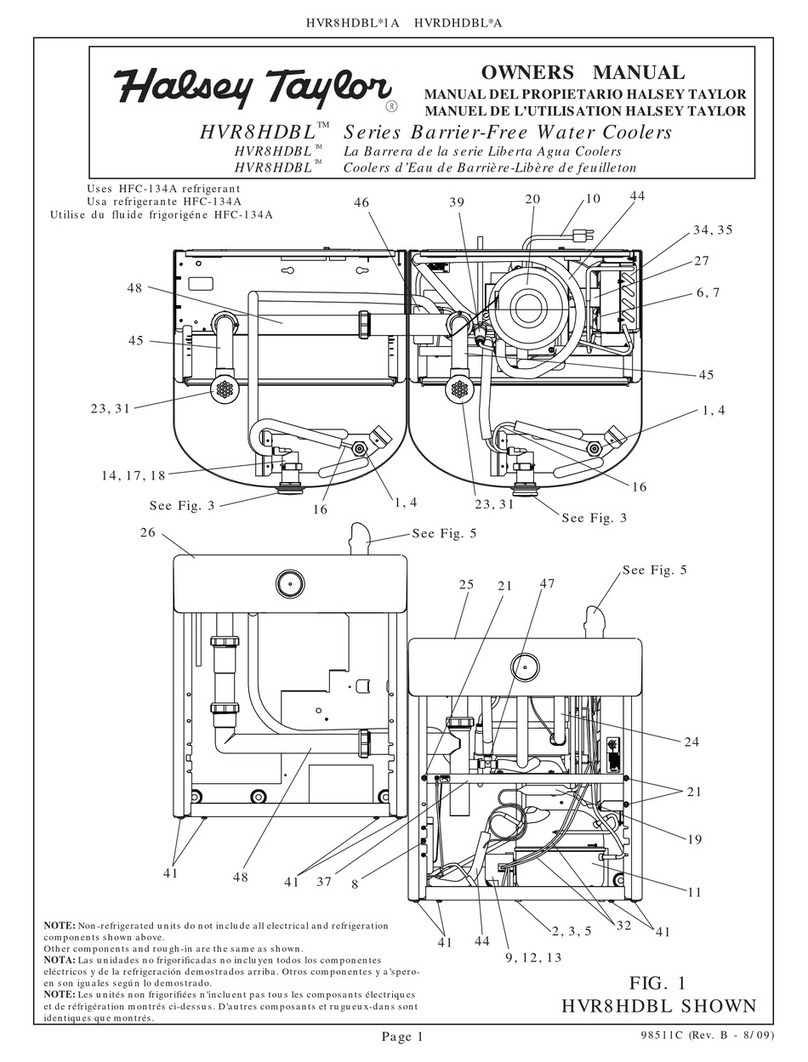

Figure 1. Product dimensions.............................................................................................. 3.2

Figure 2. Sensor offset to web pass line .............................................................................. 3.3

Figure 3. DSE-45 sensor connections ................................................................................. 3.4

Figure 4. Single proportional band ...................................................................................... 4.3

Figure 5. Multiple proportional band................................................................................... 4.4

Figure 6. Modbus/TCP default signals ................................................................................ 5.1

Figure 7. Modbus default data ............................................................................................ 5.3

Figure 8. DSE-45 web page tabs ......................................................................................... 6.1

Figure 9. DSE-45 home screen............................................................................................ 7.1

Figure 10. Job setting menu structure................................................................................. 8.1

Figure 11. Select job menu structure .................................................................................. 8.5

Figure 12. Hardware settings menu structure ..................................................................... 8.6

Figure 13. Control options menu structure ......................................................................... 8.7

Figure 14. Configuration menu structure ............................................................................ 8.8

Figure 15. Network menu structure .................................................................................... 8.9

Figure 16. Service menu structure..................................................................................... 8.11

Figure 17. Jog menu structure............................................................................................. 9.1

1.1

INTRODUCTION

www.maxcessintl.com

DSE-45

MI 2-315 1 A

About these operating instructions

These operating instructions describe the installation,

commissioning, operation, and maintenance of the DSE-45 and

provide important instructions for proper use.

Additionally, where applicable, instructions are included for

communications with Fife Controllers/Processors, such as the

Fife D-MAX Web Guide Controller. These instructions are to be

used in addition to those instructions provided with the

controller/processor.

All of the information herein is the exclusive proprietary

property of Maxcess International, and is disclosed with the

understanding that it will be retained in confidence and will

neither be duplicated nor copied in whole or in part nor be

used for any purpose other than for which disclosed.

Copyright 2020. All rights reserved.

Periodically there will be updates to this manual. The latest

version is available on our website or by calling the number on

the back page of this publication.

The operating instructions must be carefully stored and must

always be available at or near the customer's system during the

service life of the sensor.

The original instructions were written in English.

Target groups

These operating instructions are directed to both the system

construction master as well as the operator who uses the

sensor in production line.

Read operating instructions

The operating instructions must be read and used by all

persons who have the responsibility of installing,

commissioning, operating and maintaining the sensor.

1.2

INTRODUCTION

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Proper use

The DSE-45 is used for non-contact measurement of the

lateral offset of a material web being guided in a customer

system. The sensor is suitable for

- Web edge guiding,

- Web center guiding, and

- Web width or edge position measurement.

The sensor can be used to control or measure both opaque and

transparent materials.

The sensor must only be used in accordance with its intended

purpose and in a technically flawless condition.

The sensor must not be changed or opened.

Improper use

Operation outside of the technical specifications is not

permitted.

Operation in areas where there is a danger of explosions is

prohibited.

The sensor may not be used as a support, handle or step.

Any use other than the designated use is not permitted.

1.3

INTRODUCTION

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Operation principle

The DSE-45 Ultrasonic Sensor utilizes scanning technology to

detect on-web and off-web transition edges of web material

that is located within the sensor field of view. This allows new

edges to be detected at any time. The scanning orientation is

from the closed end of the sensor to the open end of the

sensor. The position of the detected edges in relation to either

the sensor default proportional band or the user configured

proportional band is then applied to the output signals of the

sensor. Both analog and digital output signals are provided.

The DSE-45 Ultrasonic Sensor can be used in conjunction with

the Fife Controllers/Processors as a guiding system. If the

sensor is connected to a D-MAX Operator Interface via an

Ethernet connection, multiple menus are available for

configuring the sensor. It can also be used as a "stand-alone"

for web width monitoring or edge position monitoring.

1.4

INTRODUCTION

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Definition of terms

Controller/Processor –The electronics processing unit that

controls and drives the actuators that are attached to it, in

response to position feedback from the sensors.

MAC Address –(Media Access Control). This is the factory

assigned hardware address of a DSE-45. MAC Address is also

referred to as MAC-ID.

MAXNET –This is the Fife proprietary Ethernet protocol that is

used for communications between DSE-45 and D-MAX devices.

This is a deterministic protocol. Therefore, the MAXNET

network must be isolated from other Ethernet networks that do

not follow this protocol.

Polarity –The direction of movement in response to a

command or error signal.

Strip/Web –The user material that is being guided.

Virtual Sensor –This is a term adopted to describe the way the

DSE-45 handles web edges. A virtual sensor simply defines a

range within the sensor field of view which represents the

signal scaling to be applied to the edge tracked within the

defined range. Each virtual sensor is also polarity-aware so

that it only tracks the edge with the configured polarity. Virtual

sensor sizes can be the entire field of view or can be as small

as 10.2 mm [0.4 in], and since they are just mathematical

ranges, they can overlap in any conceivable manner.

2.1

SAFETY

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Important safety information

To ensure safe and problem-free operation of the DSE-45 it

must be

-properly shipped and stored,

-properly mounted and placed in operation,

-properly used and carefully maintained.

Proper operation and careful maintenance will ensure a long

service life for the sensor.

Please note the following:

-The content of these operating instructions

-Any safety instructions that are printed on the unit

-The requirements of the machine manufacturer

-Applicable national, state and local requirements for

accident prevention and environmental protection

Information about safety instructions

The safety instructions and symbols described in this section

are used in these Operating instructions. They are used to

avoid possible dangers for users and to prevent material

damage.

SIGNAL WORD

Source of danger and its results.

Avoiding dangers

Signal words

The signal word DANGER indicates an immediate danger of

serious injury or death.

The signal word WARNING indicates a possible danger which

could lead to serious injury or death.

The signal word CAUTION refers to a possible danger which

could lead to slight to moderate injury.

The signal word ATTENTION refers to a possible danger which

could lead to material damage.

2.2

SAFETY

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Symbols used

Reference to general hazards that may result in bodily

injuries

Refers to danger of injury caused by crushing

Refers to danger of injury caused by cutting

Refers to general hazards that will result in damage to the

device or system

Qualified electrician

The electrical components may only be connected and

disconnected by a qualified electrician!

Read operating instructions

Follow these operating instructions for proper and safe use.

Keep for future use.

Other markings

Reference to important information

2.3

SAFETY

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Personnel requirements

The tasks listed in these operating instructions may only be

carried out by appropriately qualified personnel commissioned by

the operator. The responsibilities of the personnel for the work on

the system must be clearly defined by the operator.

Transport, assembly, maintenance, troubleshooting, disassembly

Specialized staff

-Mechatronics engineer, industrial mechanic, etc.

Electrical connection or disconnection

Specialized staff

-Only by a qualified electrician

Control during operation

Specialized staff

-Machine and system operators, etc.

-Personnel or trainees trained and supervised by the system

operator

Repair

Specialized staff

-Service technician of Fife-Tidland GmbH

Qualified electrician

A qualified electrician is a person whose specialist training,

knowledge and experience, as well as knowledge of the relevant

standards, enable him to assess and perform the work assigned to

him and to recognize and avoid possible hazards.

The electrician is specially trained for the field in which he or she

works and is familiar with the relevant standards and regulations.

2.4

SAFETY

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Preventing hazards

-No changes may be made to the sensor.

-Electrical lines must not be subjected to any mechanical

loads.

-The parameters specified in

Section 11.1, Specifications

must

be observed.

-Only accessories and replacement parts that have been

approved by Fife Tidland may be used.

-The sensor may not be used as a support, handle or step.

There is a danger that the sensor will become damaged

(breaking off/snapping), resulting in personal injury.

The DSE-45 can be remotely controlled via a network connection.

As with any network-controlled device, when remote control of

the device is implemented, there is the possibility of movement

of the guiding structure when remote commands are issued.

Therefore, any time personnel are near the guiding structure, it is

recommended that standard safeguards be taken to prevent

injury. During servicing of the equipment, to prevent injury to

personnel, it is recommended that standard Lockout/Tagout

procedures be used.

3.1

INSTALLATION

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Transport and storage

-The sensor and/or the unit on which the sensor is mounted

must be secured against slipping during transport

-The sensor must be stored in a cool, clean, and dry place;

see

Ambient Conditions, page 11.1

-The sensor must not be stored in the vicinity of powerful

magnetic fields. The electronic components of the sensor

may be damaged.

Mounting

The DSE-45 Ultrasonic Sensor can be mounted to a square

bar using the optional mounting brackets, or by using the

incorporated mounting holes near the far corners of the

sensor housing. For complete details, refer to the

installation drawings and instruction sheets included with

your shipment.

WARNING

-If a sensor is damaged, it must not be installed or placed

in operation.

-All assembly tasks on the sensor must only be performed

when there is no electrical power in the system.

-Assembly tasks and mechanical settings must only be

performed when the machine has been stopped and

secured from being turned on again.

Mounting location

-Protection Class: IP65

-Operating temperature: 5°C ... 60°C [40°F ... 140°F]

-Relative humidity: maximum 85%

-Operating altitude above sea level:

maximum 5000 meters [16,000 feet]

-Protected from vibrations

-Do not place close to strong magnetic fields;

the electronic components may be damaged.

-Do not place close to strong electrostatic fields;

the electronic components may be damaged.

-Do not mount in places where there is a risk of explosions.

3.2

INSTALLATION

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Product dimensions

1 - Sensor gap (typical for all sensors)

2 - M5 x 20 mm SHCS with lock washer

3 - The minimum bend radius of the optional Ethernet cable is 90 mm [3.54 in].

The minimum bend for output and auxiliary cables is less.

Figure 1. Product dimensions

Sensor model

A

Bandwidth

B

Bandwidth center

C

D

E

DSE-45-7

66.2 [2.606]

59.75 [2.351]

193.2 [7.606]

n/a

175.2 [6.898]

DSE-45-11

107.0 [4.213]

80.0 [3.149]

234.0 [9.213]

n/a

216 [8.504]

DSE-45-18

178.4 [7.024]

115.69 [4.555]

305.0 [12.024]

105.0 [4.134]

287.4 [11.315]

DSE-45-31

311.0 [12.244]

181.98 [7.164]

438.0 [17.244]

210.1 [8.272]

420.0 [16.535]

DSE-45-52

515.0 [20.276]

283.96 [11.179]

642.0 [25.276]

420.0 [16.353]

624.0 [24.567]

3.3

INSTALLATION

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Mounting the sensor

Remove the plastic dust covers from the

connectors that will be in use for your

application.

For complete details, refer to the

installation drawings and instruction

sheets included with your shipment.

4 -

Center line of sensor should be offset

15 degrees or more of perpendicular

to the web pass line.

5 -

Web pass line

6 -

Mounting screws can be relocated in

the sensor as needed for your

installation.

Figure 2. Sensor offset to web pass line

3.4

INSTALLATION

www.maxcessintl.com

DSE-45

MI 2-315 1 A

DSE-45 connections

Disconnect power from the DSE-45 before connecting or

disconnecting any cables.

All cable connectors must be tightened sufficiently to provide

the required connection for the cable shielding.

X1 –

ETHERNET

X2 –

AUXILIARY

Auxiliary power (+10.5 to +51 VDC)

Analog output (web width)

X3 –

OUTPUT

-Connection to controller (default)

-Power input (+10.5 to +28 VDC)

-Analog outputs (edge1, edge2, web width)

-RS-485

Figure 3. DSE-45 connections

Power connection

Power to the DSE-45 should be supplied to either the X2 or X3

Connector, but not to both connectors.

-When used as a ‘stand-alone’ sensor, power should be

applied to the X2 Connector. Follow the voltage

guidelines in Figure 3.

-When used as part of a Fife system, the Controller/

Processor generally supplies power to the X3 connector.

If alternate power is to be supplied, refer to the system

drawings for information on power supply requirements.

Verify that the supply is within the above listed limits.

3.5

INSTALLATION

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Network connection

Optional network communication

settings

-The IP address of each Ethernet device in a network must be

unique to each device in the network. All DSE-45 sensors are

shipped from the factory with the same IP address (10.0.0.150).

If it is necessary to change the IP address of the DSE-45, see

Web Access Network; page 6.1.

-MAXNET is a Fife proprietary protocol used to communicate

between the DSE-45 and other network devices, such as the Fife

D-MAX Controller and D-MAX Operator Interface.

-The MAXNET address of each Ethernet device in a network must

be unique (Address 1-31). The address must not be 0 (zero). If

using the optional Ethernet connection on the DSE-45, you will

need to set the MAXNET address of the sensor. see

Web Access

Network; page 6.1.

4.1

OPERATION OVERVIEW

www.maxcessintl.com

DSE-45

MI 2-315 1 A

DSE-45 outputs

The DSE-45 Ultrasonic Sensor provides analog outputs for

backward compatibility and an Ethernet digital interface for

advanced functions.

The DSE-45 Ultrasonic Sensor can be used in conjunction with

the Fife Controllers/Processors as a guiding system. If the

sensor is connected to a D-MAX Operator Interface via an

Ethernet connection, multiple menus are available for

configuring the sensor.

It can also be used as a "stand-alone" for web width

monitoring or edge position monitoring.

The following sections describe the default and optional

settings for available sensor parameters.

Before changing any of the sensor parameters, verify that the

controller that is using this sensor as a signal source is in

either Manual Mode or Servo Center Mode. Otherwise, there is

the possibility of movement of the guiding structure.

4.1

OPERATION OVERVIEW

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Analog outputs

There are four configurable analog outputs, controlled by three

configurable signal sources. The analog outputs can be

independently configured to produce any combination of the

following signal ranges. The analog output mapping can be

configured for each of the sensor jobs. An Ethernet connection

to the sensor is required for configuration changes.

0 to 10 mA (default)

0 to 20 mA

4 to 20 mA

OFF

Two of the four analog outputs, by default, provide edge

position (the first on-web edge and the first off-web edge

detected in the scan direction).

The other two outputs, by default, provide web width

measurement and are common to each other in function, but

are located on two separate connectors for accessibility in

various applications.

The function assigned to the analog outputs is configurable.

Any signal produced by the DSE-45 can be mapped to the

analog outputs up to and including duplicating the same signal

on all outputs, if desired. An Ethernet connection to the sensor

is required for configuration changes.

The default mode maps the analog channels as follows:

Analog Channel 0 (Analog Output 1) = VS1(Virtual Sensor 1)

Analog Channel 1 (Analog Output 2) = VS2(Virtual Sensor 2)

Analog Channel 2 (Analog Outputs 3 and 4) = WW1(web width)

4.2

OPERATION OVERVIEW

www.maxcessintl.com

DSE-45

MI 2-315 1 A

Digital outputs

The digital outputs are transmitted via a proprietary Fife

MAXNET Serial Protocol over Ethernet, which requires an

optional Ethernet cable connected to a network device.

For more information about the available signals;

see

DSE-45 Web Page, page 6.6.

Sensor jobs

The DSE-45 supports storage for up to eight different jobs. A

job contains the sensor operation mode (single or multiple

proportional bands), the proportional band size, and all

learned virtual sensor parameters.

The DSE-45 default has only a single job enabled and is

configured as a single proportional band.

Recalling a stored job immediately activates the position and

proportional bands for all virtual sensors.

Select job; page 8.5

.

In order to use more than one job, additional configured jobs

must first be enabled;

Control Options, page 8.7.

This manual suits for next models

5

Table of contents

Other Fife Accessories manuals