Fife MAXCESS SE-26B User manual

FIFE GUIDING SOLUTIONS

FIFE SE-26B

Operating Instructions

Line Guide Sensor

MI 1085 1

EN

ICONTENTS

SE-26B www.maxcess.euMI 1085 1

INSTRUCTION 1-1

About these operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

SAFETY INSTRUCTIONS 2-1

Important information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Information about safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Preventing hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installation and commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

INSTALLATION 3-1

Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

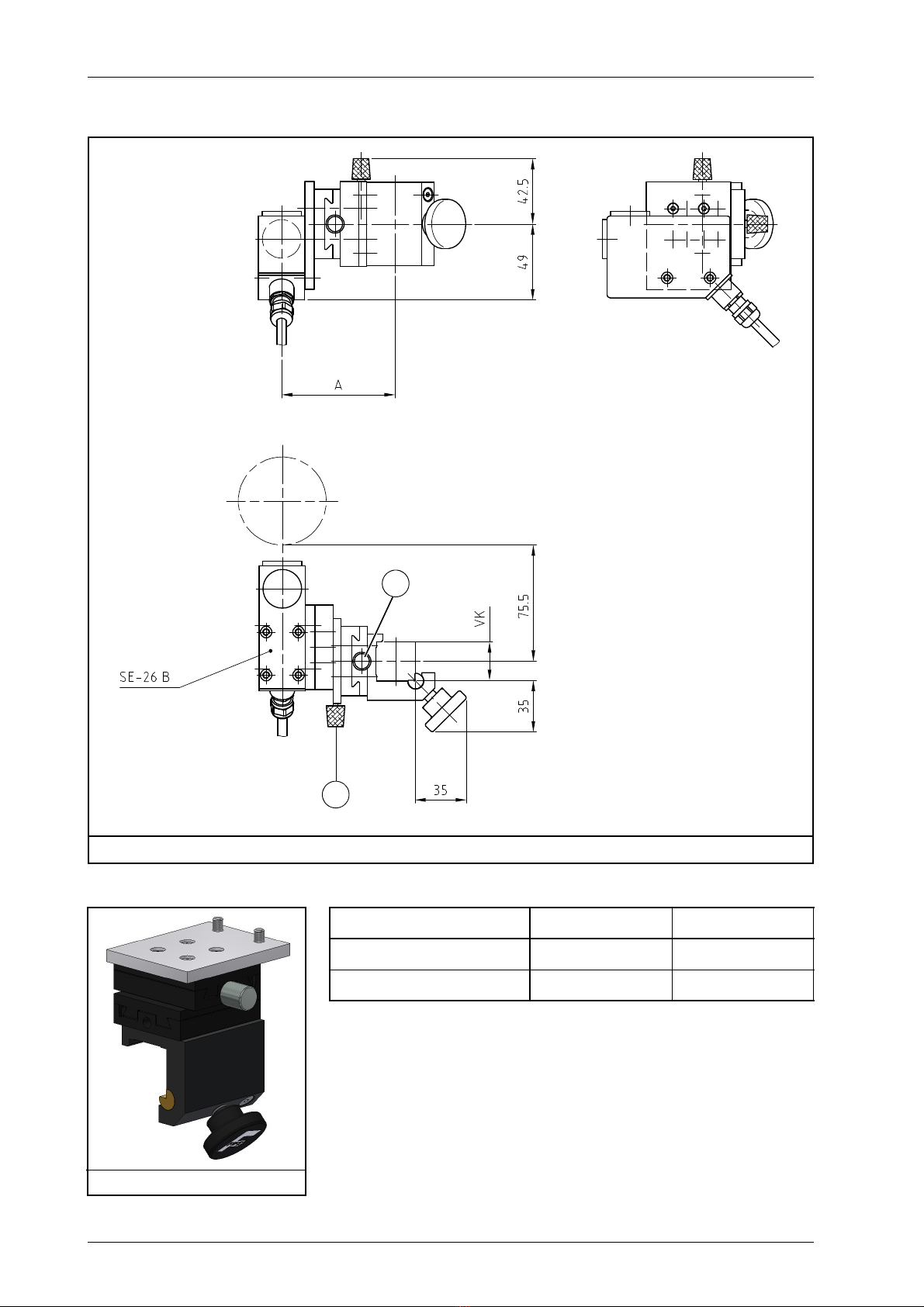

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mounting location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mechanical fastening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

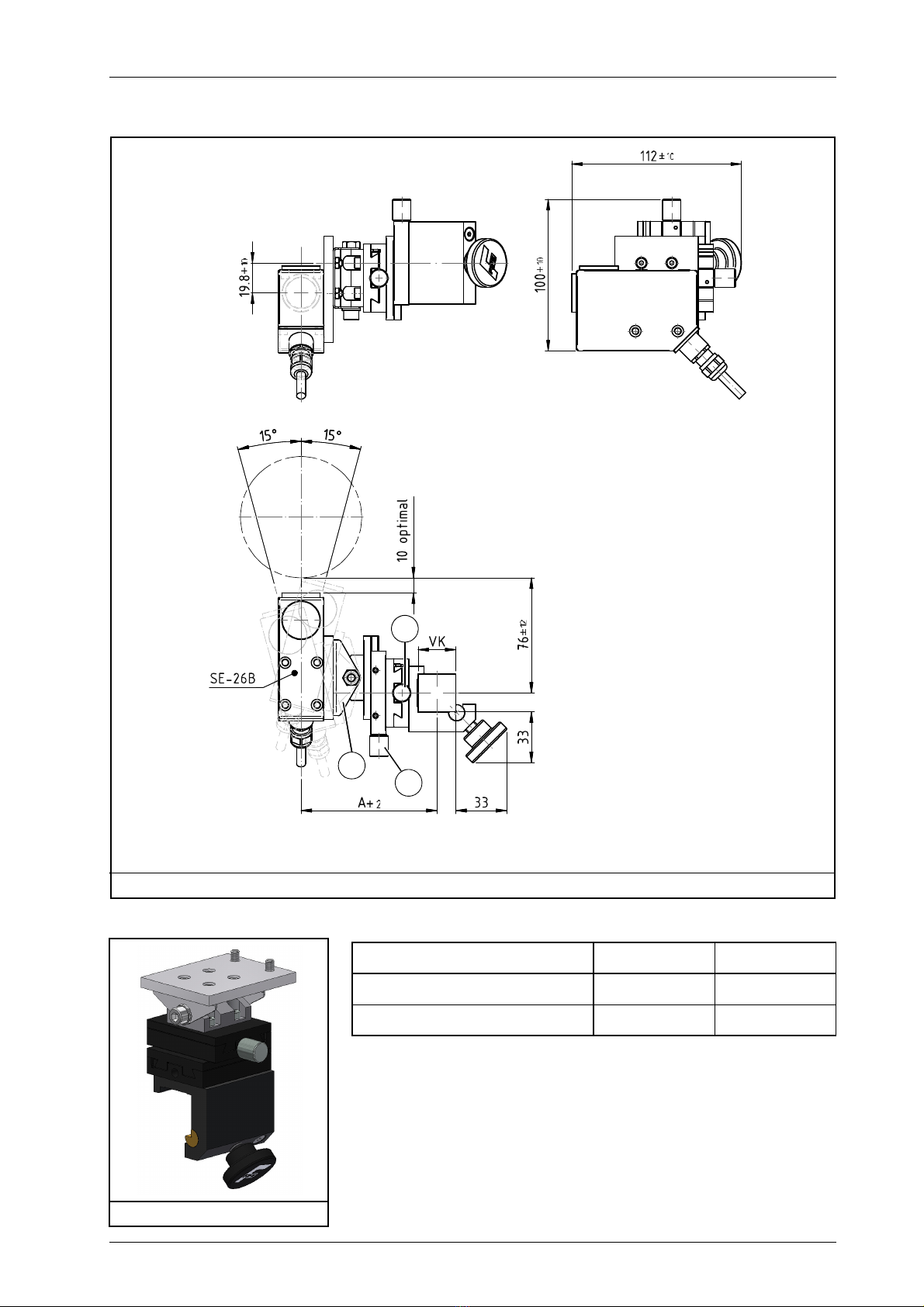

Fine adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Changing the sensor alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Mounting arrangement with different materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

COMMISSIONING 4-1

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Preparation of the web guide controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

OPERATION 5-1

Selecting suitable references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Edge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Setting up references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Preconditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

D-MAX(E) WITH OPERATOR INTERFACE OI-TS 6-1

Preparing the controller for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Select sensor type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Selecting a reference type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Setting up the ASC function with broken line/edges . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Setting up references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Setting up a (broken) line as a reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Setting up a (broken) material or print edge as a reference . . . . . . . . . . . . . . . . . . . 6-5

D-MAX(E) WITH OPERATOR INTERFACE OI-N 7-1

Preparing the controller for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Select sensor type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Selecting a reference type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Setting up the ASC function with broken line/edges . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Setting up references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Setting up a (broken) line as a reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Setting up a (broken) material or print edge as a reference . . . . . . . . . . . . . . . . . . . 7-5

IICONTENTS

SE-26Bwww.maxcess.eu MI 1085 1

MI10851-IVZ.fm

DP-20/DP-30 8-1

Preparing the controller for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Select sensor type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Selecting a reference type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Setting up the ASC function with broken line/edges . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Setting up references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Setting up a (broken) line as a reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Setting up a (broken) material or print edge as a reference . . . . . . . . . . . . . . . . . . 8-5

FIFE-500 9-1

Preparing the controller for use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Select sensor type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Selecting a reference type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Setting up references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Setting up a (broken) line as a reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Setting up a (broken) material or print edge as a reference . . . . . . . . . . . . . . . . . . 9-5

MAINTENANCE 10-1

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

TROUBLESHOOTING 11-1

TECHNICAL DATA 12-1

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Optical properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

SERVICE 13-1

Requests for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Adresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

INSTRUCTION1 - 1

SE-26B www.maxcess.euMI 1085 1

1 INSTRUCTION

About these operating

instructions These operating instructions describe the installation,

commissioning, operation and maintenance of the SE-26B line

sensor and provide important instructions for proper use.

These operating instructions are intended for both the system

construction master as well as the operator who uses the

SE-26B sensor in production. The Operating Instructions must

be read and applied by everyone who is responsible for

installation, commissioning, operating or maintaining the

SE-26B sensor.

The Operating Instructions must be carefully kept and must

always be available throughout the service life of the SE-26B

sensor.

Translation of the original Operating Manual:

This Operating Manual is a translation. The original Operating

Manual was composed in German.

Proper use The SE-26B line sensor is intended for use on machines or

systems. It is used for no-contact measurements of the lateral

offset of a material web that is being guided. The SE-26B sensor

is suitable for

– center guiding on a thin printed line.

– edge guiding on a printed line.

– guiding on a material edge.

Guiding is also possible with dashed lines, discontinuous

pattern or discontinuous edges. The free spaces between the

lines or pattern must not be too large, since guiding is blocked

during that time.

The SE-26B works reliably with smooth, rough, dull or glossy

material surfaces. This sensor can also be used with low color

contrast between the background and printed line.

The SE-26B sensor must only be used in accordance with its

intended purpose and in a technically flawless conditions.

INSTRUCTION 1 - 2

SE-26Bwww.maxcess.eu MI 1085 1

Einführung.fm

Improper use – Operation outside of the technical specifications is not

permitted.

– Operation in areas where there is a danger of explosions is

prohibited.

– Outdoor operation is not permitted.

– The SE-26B sensor may not be used as a support, handle or

step.

– Any use other than the designated use is not permitted.

Operating principle The SE-26B line sensor works with white LED light.

The light emitter in the SE-26B sensor generates a light spot on

the surface of the material being scanned. Differences in

contrast in this area will be sensed by the receiver. The

difference in contrast could be produced for example by a

printed line. In this case the line is the reference for control.

The lens and cover can be screwed off and replaced to change

the scanning direction.

Note:

The explanation in the sections on commissioning and

operation also apply to sensors SE-26 and SE-26A.

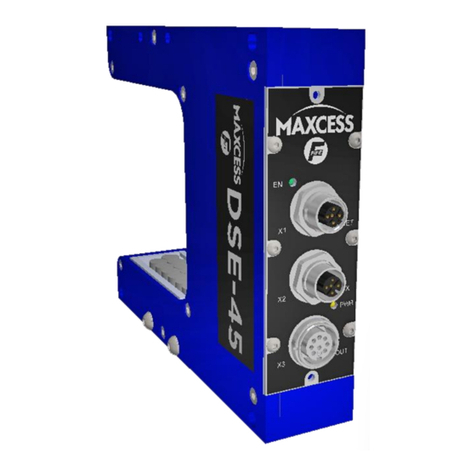

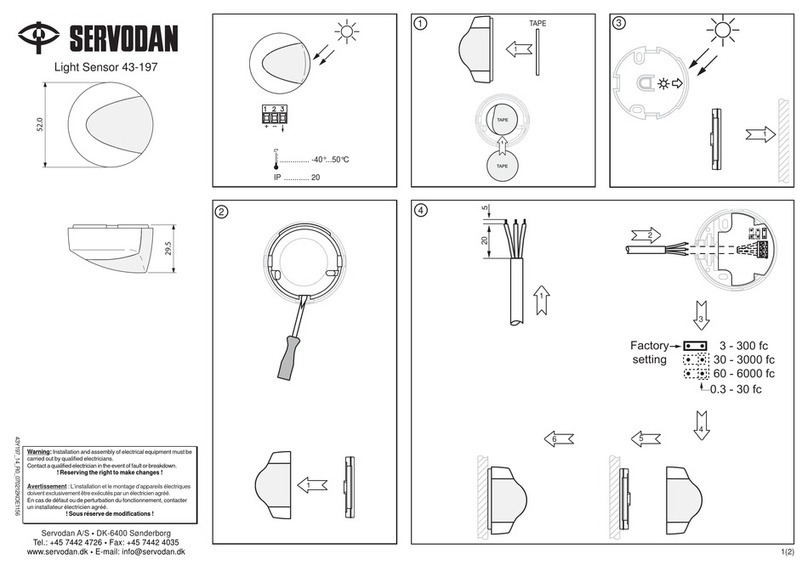

1Lens

2Cover

3Nameplate

4 Thread for sensor bracket

5 Connection cable to a

Fife controller

Figure 1.1: Line guiding sensor SE-26B

1

2

4

3

5

SAFETY INSTRUCTIONS2 - 1

SE-26B www.maxcess.euMI 1085 1

2 SAFETY INSTRUCTIONS

Important information Problem-free and reliable operation of the SE-26B requires that

the sensor

– properly shipped and stored,

– properly mounted and placed in operation,

– properly used and carefully maintained.

Proper operation and careful maintenance will ensure a long

service life for the sensor.

Only persons who are acquainted with the installation,

commissioning, operation and maintenance of the sensor and

who possess the necessary qualifications for their activities may

work on the sensor.

Please note the following:

– The content of these operating instructions

– The safety instructions printed on the unit

– The requirements of the machine manufacturer

– National, state and local requirements for accident

prevention and environmental protection

Information about

safety instructions The safety instructions and symbols described in this section

are used in these Operating instructions. They are used to avoid

possible dangers for users and to prevent material damage.

SIGNAL WORD

Source of danger and its results.

Avoiding dangers

The signal word WARNING refers to the danger of moderate to

sever bodily injuries.

The signal word CAUTION refers to the danger of slight to

moderate bodily injuries or material damage.

SAFETY INSTRUCTIONS 2 - 2

SE-26Bwww.maxcess.eu MI 1085 1

Sicherheit.fm

Symbols

Warning/caution - dangerous area

Reference to general hazards that may result in bodily injuries

or damage to the device

Warning/caution - danger due to crushing

Refers to danger of injury caused by crushing

Warning/caution - danger due to cutting

Refers to danger of injury caused by cutting

Additional symbols

– This endash is followed by an enumeration.

∙This dot is followed by a prompt to do something.

Note:

Reference to important information.

Preventing hazards ∙The SE-26B sensor may not be used as a support, handle or

step. There is a danger that the sensor will become damaged

(breaking off/snapping), resulting in personal injury.

Installation and

commissioning ∙A damaged sensor must not be installed or placed in

operation.

∙Assembly work must be performed while the machine is

stopped and protected against being turned on again.

∙All assembly tasks must only be performed when there is no

electrical power in the system.

∙The sensor must not be placed in operation unless it has

been securely mounted.

∙Electrical connections should always be made or

disconnected on the sensor while there is no electrical power

in the system. Failure to observe these instruction may result

in damage to the sensor.

SAFETY INSTRUCTIONS2 - 3

SE-26B www.maxcess.euMI 1085 1

∙The parameters specified in Section

Technical Data

must be

observed.

∙Only replacement parts that have been approved by

Fife-Tidland may be used.

∙No changes must be made to the sensor.

∙Electrical lines must not be subjected to any mechanical

loads.

Operation

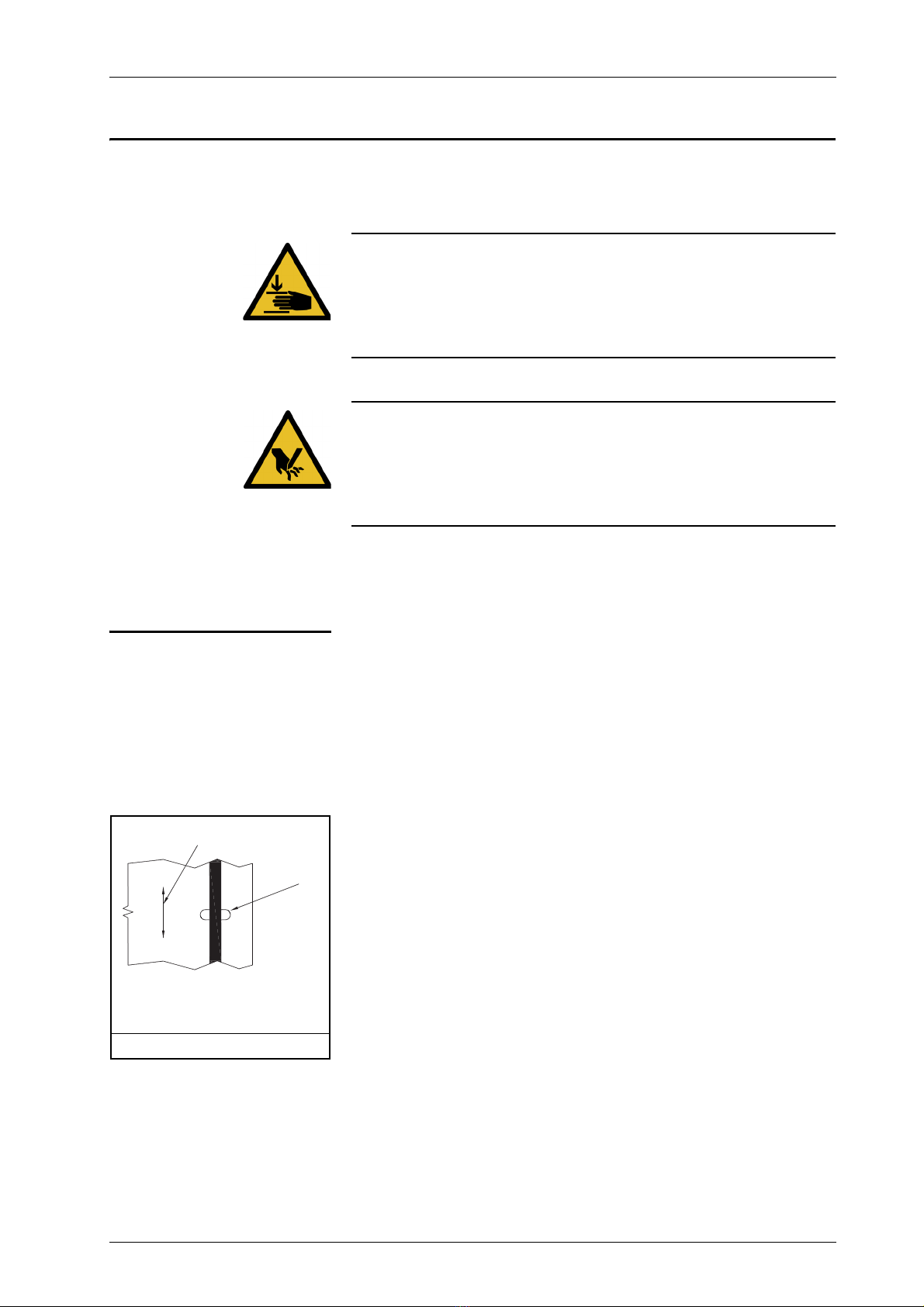

∙Danger of injury by crushing

Do not place your hands on or near moving parts (rollers,

material web, etc.) during operation.

∙Danger of injury due to cutting on the edge of the material

web

Do not place your hands on the edge of the (moving)

material web during operation.

Maintenance

∙Danger of injury by crushing

Maintenance work must only be performed on the sensor

when the power is turned off, the machine is stopped, and it

is protected against being turned back on.

INSTALLATION 3 - 1

SE-26Bwww.maxcess.eu MI 1085 1

Montage.fm

3 INSTALLATION

Transport and storage – The sensor and/or the unit on which the sensor is mounted

must be secured against slipping during transport.

– The sensor must be stored in a cool, dry place.

– The sensor must not be stored in the vicinity of powerful

magnetic fields. The electronic components of the sensor

may be damaged.

Scope of delivery –SensorSE-26B

The model designation and the serial and part number are on

the nameplates on the housing.

see item 3 in

Figure 1.1, page 1-2

– Operating Instructions

Mounting

WARNING

All assembly tasks on the sensor must be performed when

there is no electrical power in the system.

Assembly tasks and mechanical settings must only be

performed when the machine has been stopped and has been

secured from being turned on again.

INSTALLATION3 - 2

SE-26B www.maxcess.euMI 1085 1

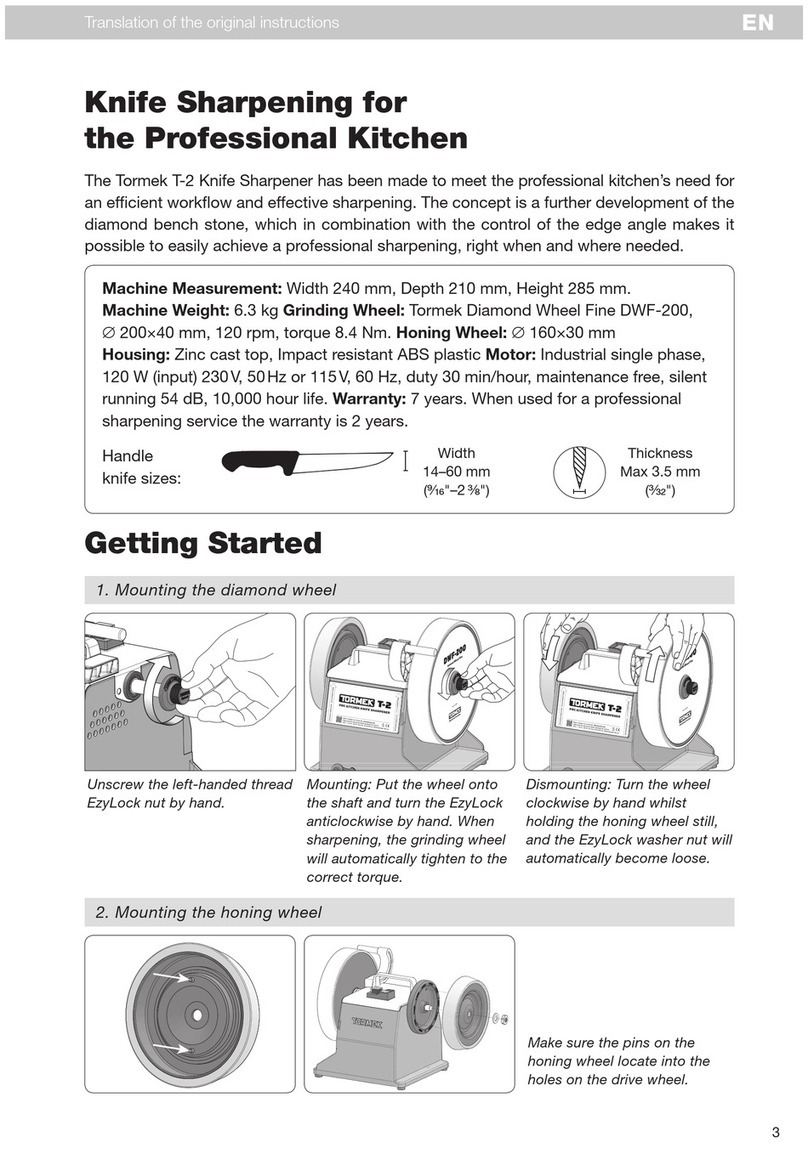

Dimensions

Mounting location –ProtectionClass:IP65

– Operating temperature: 0°C ... 50°C

– Relative humidity: 5% to 85%

–Protectfromvibrations

– Not in the vicinity of strong magnetic fields

The electronic components may be damaged.

– Not in places where there is a risk of explosions

– Distance between lens and material being scanned:

approx. 10mm

– The material web must be guided in the area where the light

spot appears (guide point) by a support rod or support roller.

A plane change is not permitted.

– Protect the lens of the sensor against extraneous light.

72.73

53.3

40.3

25.3

99.4

24

39

28

80

3

M5-6 tief/deep

18.7

58

30

21

(4.5)

28

28

43

M5-6 tief/deep

39

28

1525.3

15

24

M5-6 tief/deep

A Cable length plus connector about 300 mm

Figure 3.1: SE-26B Dimensions

A

INSTALLATION 3 - 3

SE-26Bwww.maxcess.eu MI 1085 1

Montage.fm

Mechanical fastening Holes with M5 threads are available on the housing for

mounting the sensor (

Figure 3.1

). A large variety of assembly

options are possible in connection with the various sensor

mountings.

CAUTION

Using long bolts introduces the risk of a short-circuit and

destroying the electronics that are located inside the housing.

Please note when assembling sensor that only the original M5*6

bolts or similar ones should be used.

INSTALLATION3 - 4

SE-26B www.maxcess.euMI 1085 1

Sensor bracket type MAMB

C

B Fine positioning C Fine adjustment for focus

Figure 3.2: SE-26B with sensor bracket MAMB

B

Type A VK

MAMB-25 smooth 74 25

MAMB-30 smooth 78 30

Figure 3.3: MAMB

INSTALLATION 3 - 5

SE-26Bwww.maxcess.eu MI 1085 1

Montage.fm

Sensor bracket type MAMB SE-26B, pivoting

B Fine positioning

C Fine adjustment for focus

D Pivot point for angle setting

Figure 3.4: SE-26B with sensor bracket MAMB, pivoting

B

D

C

Type A VK

MAMB-25 SE-26B smooth 89,5 25

MAMB-30 SE-26B smooth 93,5 30

Figure 3.5: MAMB SE-26B

INSTALLATION3 - 6

SE-26B www.maxcess.euMI 1085 1

Fine adjustment Fine positioning

This setting allows for precise positioning of the light spot on

the line/material edge being scanned.

Fine adjustment for focus

The fine adjustment of the distance between sensor and

material web must be made so that the light spot appears well

focused on the material web.

Changing the sensor

alignment ∙Unscrew the lens and cover

∙Replace the parts and screw them back in again

Note:

When screwing the parts in, make certain there is an

O-ring under each of them.

See

Figure 3.6

Mounting arrangement

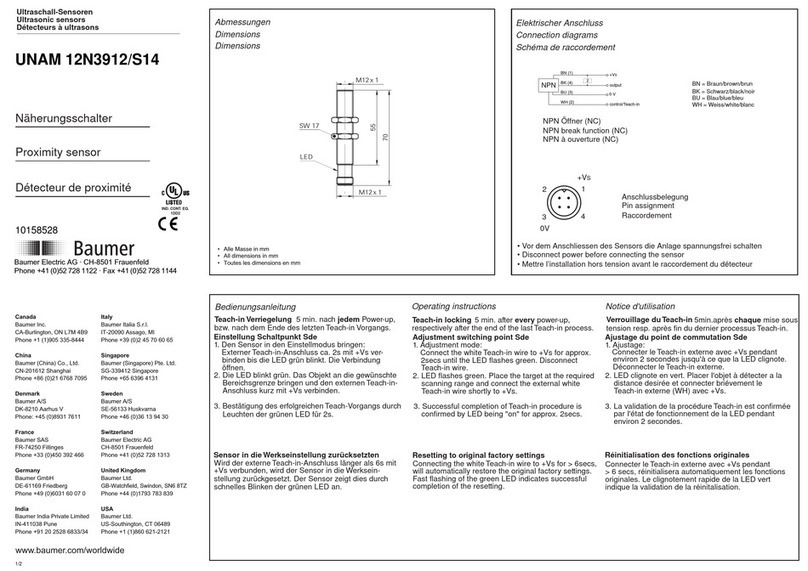

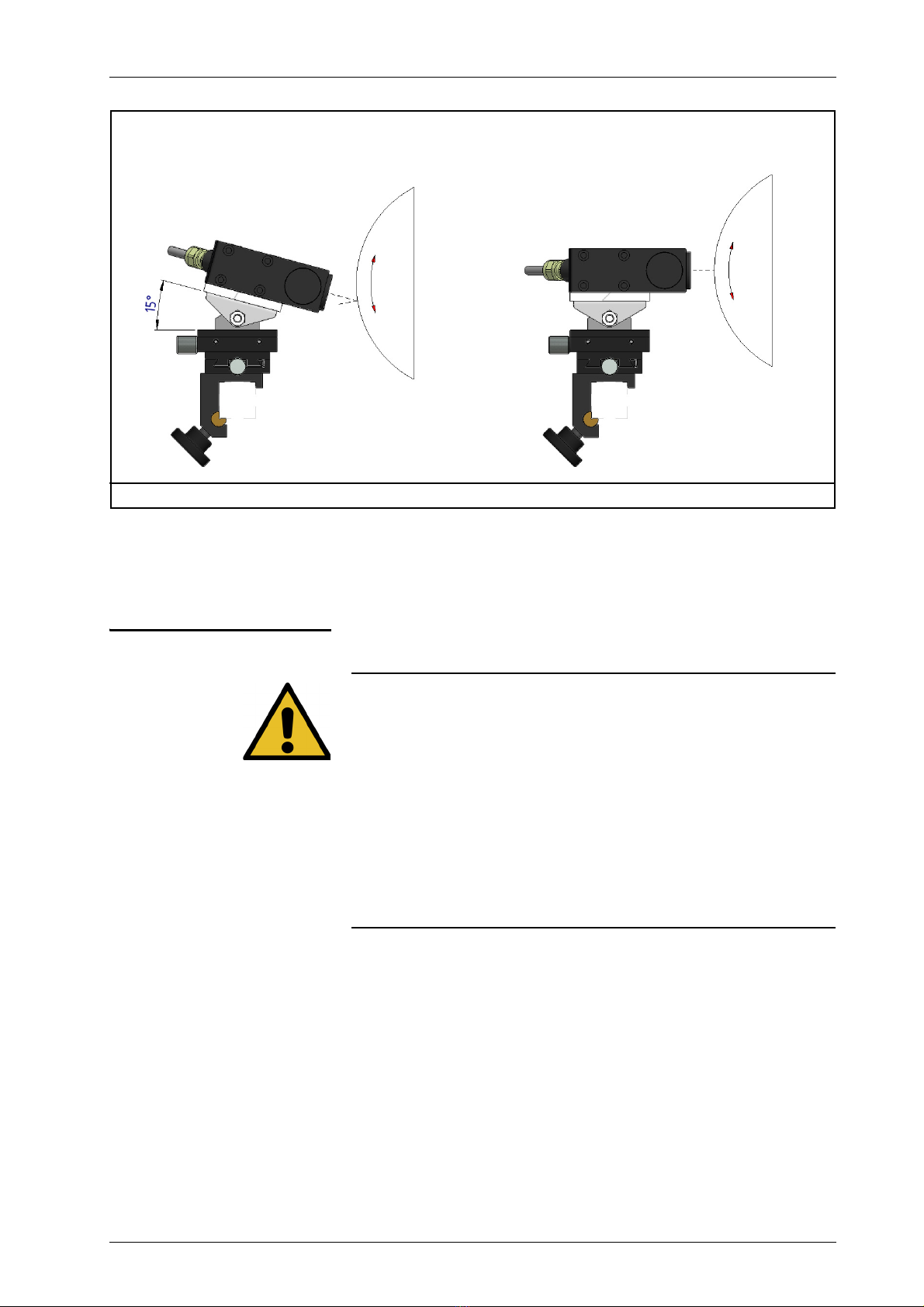

with different materials Smooth non-reflective materials

∙Mount the sensor perpendicular to the material web so that

all of the light from the sensor is reflected into the lens

Glossy reflective materials

Examples:

Glossy laminates, metallic materials, glossy films

∙Mount the sensor at an angle of 15° from perpendicular

This will cause a portion of the sensor light to be reflected

away from the lens.

see

Figure 3.7

Figure 3.6: Sensor alignment

INSTALLATION 3 - 7

SE-26Bwww.maxcess.eu MI 1085 1

Montage.fm

Electrical connection

CAUTION

The sensor could be damaged.

Electrical connections should always be made or disconnected

on the sensor while there is no electrical power in the system.

Electrical lines must not be subjected to any mechanical

loads.

The entire wiring, for which the installer is responsible, must

meet the fundamental requirements of the relevant standard(s).

The sensor must be connected to the web guide controller

according to the system diagram in the system documentation.

Figure 3.7: SE-26B and different material types

Assembly with glossy materials Assembly with smooth materials

COMMISSIONING4 - 1

SE-26B www.maxcess.euMI 1085 1

4 COMMISSIONING

WARNING:

Before commissioning, ensure that:

Commissioning of the sensor is performed while the web is

stopped.

No one is in the danger zone of the moving parts.

WARNING:

There is a risk of crushing and cutting injuries on the web

material itself and/or due to the motion of the web.

Do not grasp moving parts (rollers, web, etc.) or anything

close to them during commissioning.

Do not touch the edges of the material web.

Commissioning Once all assembly and connection tasks have been checked and

are in proper condition, the sensor system can be placed in

operation.

Preparation of the web guide

controller The web guide controller must be prepared for use with a line

sensor.

See the

Commissioning

section in the section describing the

relevant web guide controller:

- D-MAXE with Operator Interface OI-TS (

Page 6-1

)

- D-MAXE with Operator Interface OI-N (

Page 7-1

)

- DP-20/DP-30 (

Page 8-1

)

- Fife-500 (

Page 9-1

)

-CDP-01

Sensor Calibration with Line Sensor SE-26

can

be found in the "CDP-01 Operating Manual."

Note:

When a complete system is delivered, the web guide controller

has already been mostly calibrated in the factory. The same is

not true for deliveries of individual parts or replacement parts,

however.

OPERATION 5 - 1

SE-26Bwww.maxcess.eu MI 1085 1

Betrieb.fm

5 OPERATION

WARNING:

Danger of injury by crushing

Do not place your hands on or near moving parts (rollers,

material web, etc.) during operation.

WARNING:

Danger of injury due to cutting on the edge of the material web

Do not place your hands on the edge of the (moving) material

web during operation.

Selecting suitable

references The operator must select a suitable reference (a line or an edge)

that can be found again unambiguously within the sensor field

of view on the material web.

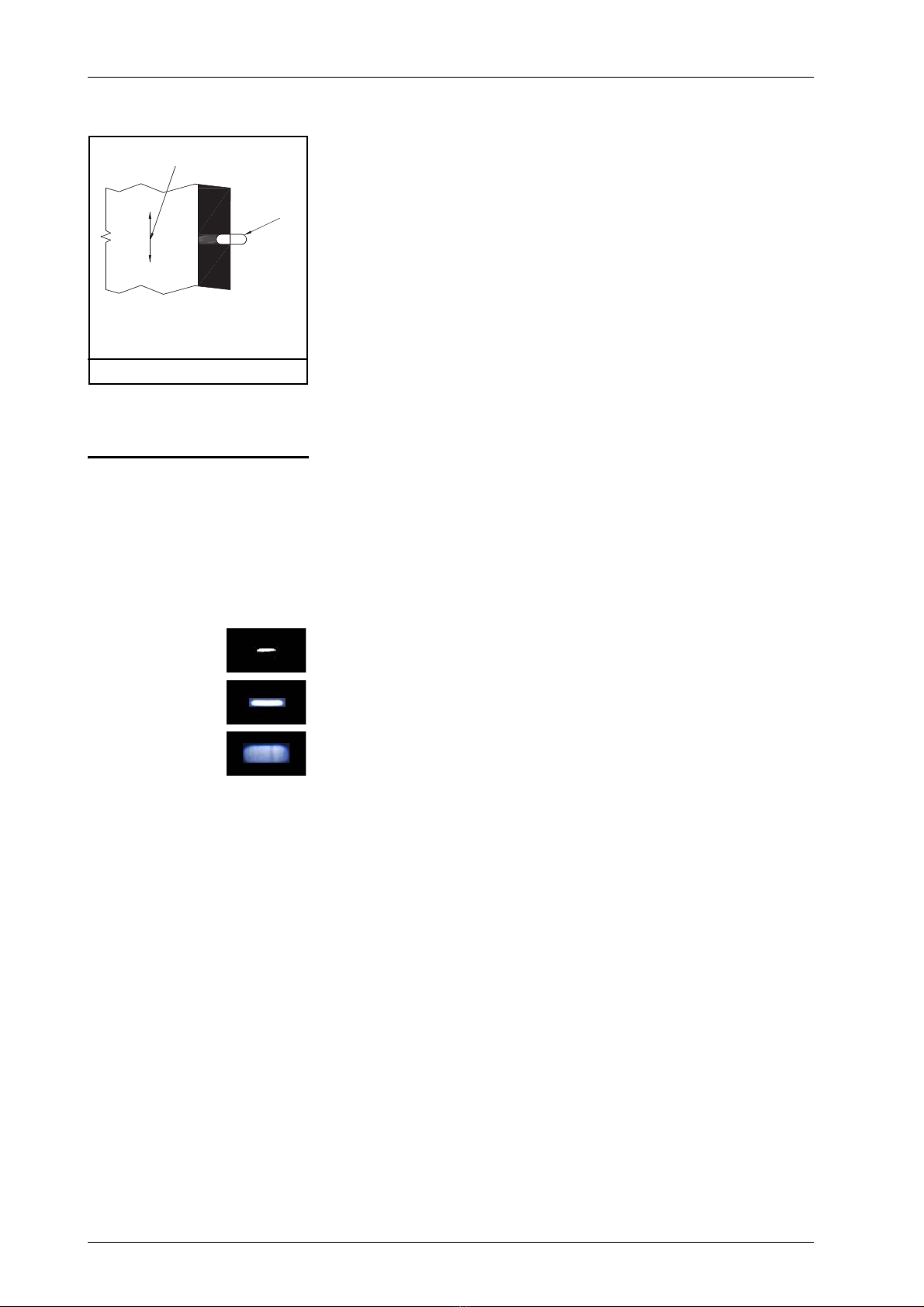

Line The material web is guided to the center of a printed line.

– Line width between 1.3mm and 2.5mm

– Distance of at least 2.5mm on both sides of the line from

other edges or printing

– Thin lines very rich in contrast, even up to 0.25mm can be

used

– Lines can be continuous or broken

1 Direction of motion of the

material web

2Lightspot

Figure 5.1: Line

1

2

OPERATION5 - 2

SE-26B www.maxcess.euMI 1085 1

Edge The material web is guided to

– the edge of a material on a roller or support plate.

– the edge of a continuous printed sample.

– the edge of a line that is wider than 2.5mm and has a

continuous background.

Setting up references The reference is set up on the web guide controller to which the

setup menu is connected.

Preconditions – Position the sensor so that the desired reference is centered

in the sensor field of view.

– The reference must be set up while the material web is

stopped.

– The light spot of the line sensor must appear clearly and

unambiguously on the material web.

1 - No light spot, distance too small

2 - Light spot well focused, distance correct

3 - No light spot, distance too great

– There must be no plane change of the material web in the

area of the light spot.

Set-up Setting up the reference depends on the web guide controller in

use.

See section

Setting up a reference

in the section describing

the relevant web guide controller:

- D-MAXE with Operator Interface OI-TS (

Page 6-3

)

- D-MAXE with Operator InterfaceOI-N

(Page 7-3

)

- DP-20/DP-30 (

Page 8-3

)

- Fife-500 (

Page 9-3

)

-CDP-01

Sensor Calibration with Line Sensor SE-26

can

be found in the "CDP-01 Operating Manual."

1 Direction of motion of the

material web

2Lightspot

Figure 5.2: Edge

1

2

1

2

3

D-MAX(E) WITH OPERATOR INTERFACE OI-TS 6 - 1

SE-26Bwww.maxcess.eu MI 1085 1

Bedienung OITS.fm

6 D-MAX(E) WITH OPERATOR INTERFACE OI-TS

Preparing the controller

for use

Note:

Detailed information about sensor calibration is available in the

"D-MAX Operating Instructions". "Supplementary Operating

Instructions“ may also be available.

Precondition:

The SE-24B sensor is connected to the D-MAX(E) controller as

specified in the system diagram to X5 or X9.

Placeholder y:

These places in the menu IDs depend on the currently selected

job.

Select sensor type

∙Press the Manual key to set the "Manual" operation mode

∙Select menu 1y.5.1.1.2

Type

(Press the 6 button and hold it for 2sec. Button 5:

Hardware Button 1: Sensors Button Sensor S1 .. Sensor

S4: select the desired sensor Button 2: Type)

∙Set the

Type

to SE-26

Selecting a reference type Depending on the selected reference type, a distinction is made

in set-up for:

– a (broken) line

or

– a material edge or (broken) print edge.

D-MAX(E) WITH OPERATOR INTERFACE OI-TS6 - 2

SE-26B www.maxcess.euMI 1085 1

The properties of a reference are described in section

Selecting

suitable references, page 5-1

.

∙

Select job:

Press the 4 key until the suitable controller type for

- Line center (menu ID J or K)

or

- Material edge or print edge (menu ID L or M)

is selected

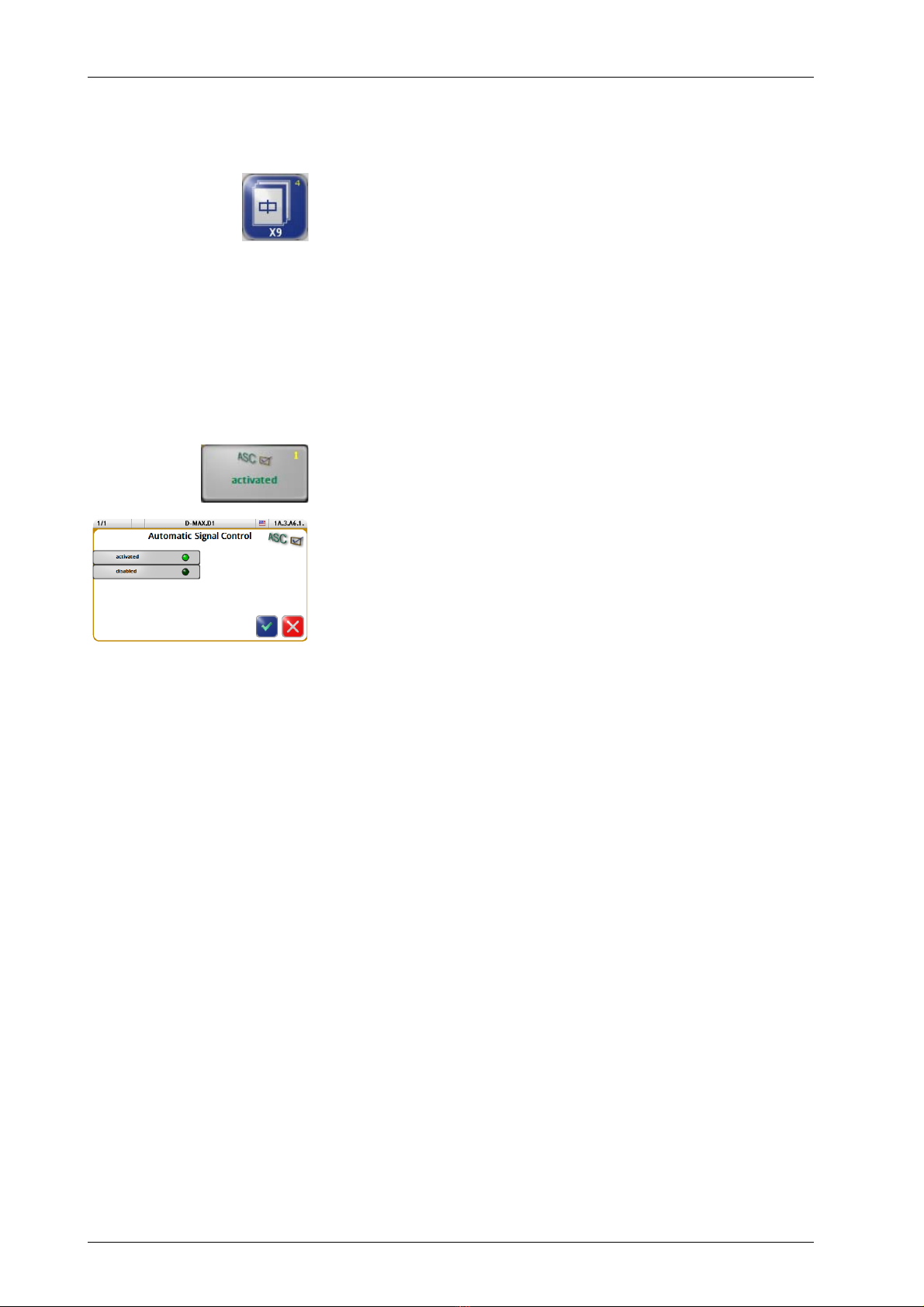

Setting up the

ASC

function

with broken line/edges

Turning on ASC blocking

∙Select menu 1y.3.y6.1

ASC Automatic Signal Control

(Button 6 Button 6: ASC Button 1: ASC)

∙Activate the

ASC

parameter

Table of contents

Other Fife Accessories manuals