Figaro KE Series Manual

Revised 09/22 1

TECHNICAL INFORMATION FOR KE-SERIESTECHNICAL INFORMATION FOR KE-SERIES

Technical Information for Maxell Oxygen Sensor KE-Series

The Maxell Oxygen Sensor

KE-Series is a unique galvanic

cell type oxygen sensor which

provides a linear output voltage

signal relative to percent oxygen

present in a particular atmosphere.

The sensor features long life

expectancy, excellent chemical

durability, and it is not inuenced

by CO2, making it ideal for

oxygen monitoring.

Page

Introduction...............................................................................................2

Basic Information and Specications

Features...............................................................................................2

Applications.......................................................................................2

Structure and Operating Principle.................................................2

Specifications.........................................................................2

Absolute Maximum Operating and Storage Conditions............3

Dimensions.................................................................................3

Typical Sensitivity Characteristics

Sensitivity to Oxygen...........................................................................4

Response Speed..............................................................................4

InuencefromVariousGases...........................................................4

Eects of Pressure Change......................................................5

Humidity Dependency...........................................................5

Temperature Dependency..................................................................6

Reliability

Inuence of Organic Solvents.....................................................6

Life Expectancy.................................................................................6

RelationshipofExpectedLifeandO2Concentration..............6

RelationshipofExpectedLifeandStorageTemperature.........6

Long Term Stability...........................................................................7

Cautions.................................................................................................7

Limited Warranty and Limitation of Liability..........................................9

an ISO9001 company

Revised 09/22 2

TECHNICAL INFORMATION FOR KE-SERIESTECHNICAL INFORMATION FOR KE-SERIES

1. Introduction

The Maxell Oxygen Sensor KE series (KE-25 and KE-50) is

a unique galvanic cell type oxygen sensor. Its most

notable features are a long life expectancy, excellent

chemical durability, and it is not inuenced by CO2.

The KE series oxygen sensor is ideal to meet the

ever-increasing demand for oxygen monitoring in

various elds such as combustion gas monitoring, the

biochemical eld, domestic combustion appliances,

etc.

2. Basic Information and Specications

2-1 Features

* Long life (KE-25 - 5 years / KE-50 - 10 years)

* Virtually no inuence from CO2, CO, H2S, NOx, H2

* Low cost

* Operates in normal ambient temperatures

* Stable output signal

* No external power supply required for sensor

operation

* No warm-up time is required

2-2 Applications

* Biotechnology - Oxygen incubators

* Food industry - Refrigeration, greenhouses

* Safety - Air conditioners, oxygen detectors, re

detectors

2-3 Structure and operating principle

The KE series sensor is a lead-oxygen battery which

incorporates a lead anode, an oxygen cathode made of

gold, and a weak acid electrolyte. Oxygen molecules

enter the electrochemical cell through a non-porous

uorine resin membrane and are reduced at the gold

electrode with the acid electrolyte. The current

which ows between the electrodes is proportional

to the oxygen concentration in the gas mixture

being measured. The terminal voltages across the

thermistor (for temperature compensation) and

resistor are read as a signal, with the change in

output voltages representing the change in oxygen

concentration.

The following chemical reactions which take place

in KE sensors:

Cathodic reaction: O2 + 4H++ 4e-→ 2H2O

Anodic reaction: 2Pb + 2H2O → 2PbO + 4H++ 4e-

Total reaction: O2+ 2Pb →2PbO

A small volume air bubble is contained inside the sensor

body in order to compensate for internal inuence from

pressure changes. The sensor's electrolyte is primarily

composed of acetic acid with a pH of approximately 6.

The sensor's body is made of ABS resin.

Both the KE-25 and the KE-50 sensors are based on

identical design and performance principles. The

basic difference between these two models is in the

thickness of the uorine resin membrane. This affects

the diffusion speed of oxygen molecules and, as a

result, the response speed and life of the sensor. Each

model shows basically the same performance in the

various conditions described in the technical data, e.g.

inuence by other gases, pressure dependency, etc.

2-4 Specications

Table 1 (see following page) shows the specications

of the KE series oxygen sensors.

Notes:

1)

Whencalibratedatboth0%and100%ofO2,accuracy

in the range from 0-100% O2shall be within ±1% of

full scale for KE-25 and ±2% of full scale for KE-50.

2) Va = output voltage at 21% O2

V0= output voltage at 0% O2

V100 = output voltage at 100% O2

3) Va = output voltage at 25˚C

VH = output voltage at 40˚C

VL = output voltage at 5˚C

4) Sensors should be used under conditions where

the air exchange is greater than 200~300ml per

minute in order to obtain the response speed as

specied in Table 1.

2-5 Absolute maximum operating and storage conditions

Fig. 1 - Structure of KE-25/KE-50

Bottom Lid

Compensating

Resistor

Air Bubble

Electrolyte

Lead Electrode

(Anode)

Lead Wire (-)

Lead Wire (+)

Thermistor

Titanium

Lead Wire

Current

Collector

O-Ring

Inner Lid

Outer Lid

Oxygen Permeable

Membrane

Gold Electrode

(Cathode)

Revised 09/22 3

TECHNICAL INFORMATION FOR KE-SERIESTECHNICAL INFORMATION FOR KE-SERIES

The accumulated total duration of exposure to the

absolute maximum conditions listed in Table 2

should be limited to no more than 24 hours.

Cautions:

1) Beneath the lower pressure limit, sensor life may

become shorter due to excessive evaporation of the

liquid electrolyte.

Table 1 - Specications of KE-25/KE-50

Table 2 - Absolute maximum operating and storage conditions

of KE-25/KE-50

2) At pressure in excess of the upper limit, sensor

output may become unstable due to excessive air

entering through the o-ring.

3) In the range -10~-20˚C, the electrolyte will freeze

and the sensor will not function, but KE sensors

would not be damaged by freezing of the electrolyte

and will resume functioning after the electrolyte

thaws to a liquid state. Below -20˚C, the sensor may

be damaged by freezing of the electrolyte, resulting

in possible leakage of the electrolyte.

4) At temperatures in excess of the upper limit, the

ABS resin casing may deteriorate.

5) If used for a long period in an extremely dry

environment, sensor life may be shortened due to

excessive evaporation of the liquid electrolyte.

2-6 Dimensions (see Fig. 2)

Figure 2 - Dimensions of KE-25/KE-50

OXYGEN

KE-

NO.18

ø28±0.5

22.5±0.3

80±5

4±2

47.3±0.5

5

ø23.2±0.5

15

ø5

ø9

M16 x P1.0

81.5

4.5 2.5

15

Lead wire

47.3±0.5

5

ø23.2±0.5

15

ø5

ø9

ø23.2±0.5

ø9

ø9

ø16

ø16.6

50±0.5

57±0.5

Unit = mm

22.7±0.5

ø23±0.5

KE-12/KE-25/KE-50 standard version KE-25F1 (w/o flange) KE-25F3 (threaded top) KE-25F4 (O-ring top)

13

13

22.7±0.5

ø23±0.5

22.7±0.5

ø23±0.5

Item Model

KE-25 KE-50

Measurement range 0~100% O2

Accuracy (Note 1)±1% full scale ±2% full scale

Operating conditions

Atmospheric pressure 811hPa~1216hPa

Temperature 5˚~40˚C

Relative humidity 10~90%RH (no condensation)

Response time (90%) (Note 4)14±2 seconds 60±5 seconds

Initial output voltage under factory test conditions 10.0~15.5mV 47~65mV

Factory test conditions

Test gas 21% O2

Atmospheric pressure 1013hPa

Temperature 25˚±5˚C

Linearity (Va-V0)/(V100-V0)

(Note 2)0.21±0.02

Oset voltage V0≤0.5mV ≤6.0mV

Temperature

characteristics (Note 3)

VH/Va 0.91~1.09

VL/Va 0.91~1.09

Item Lower limit Upper limit

Pressure 507hPA (Note 1) 1520hPA (Note 2)

Temperature -20˚C (Note 3) 60˚C (Note 4)

Relative humidity 0%RH (Note 5) 100%RH

KE-25/KE-50 standard version

Revised 09/22 4

TECHNICAL INFORMATION FOR KE-SERIESTECHNICAL INFORMATION FOR KE-SERIES

3. Typical Sensitivity Characteristics

3-1 Sensitivity to oxygen

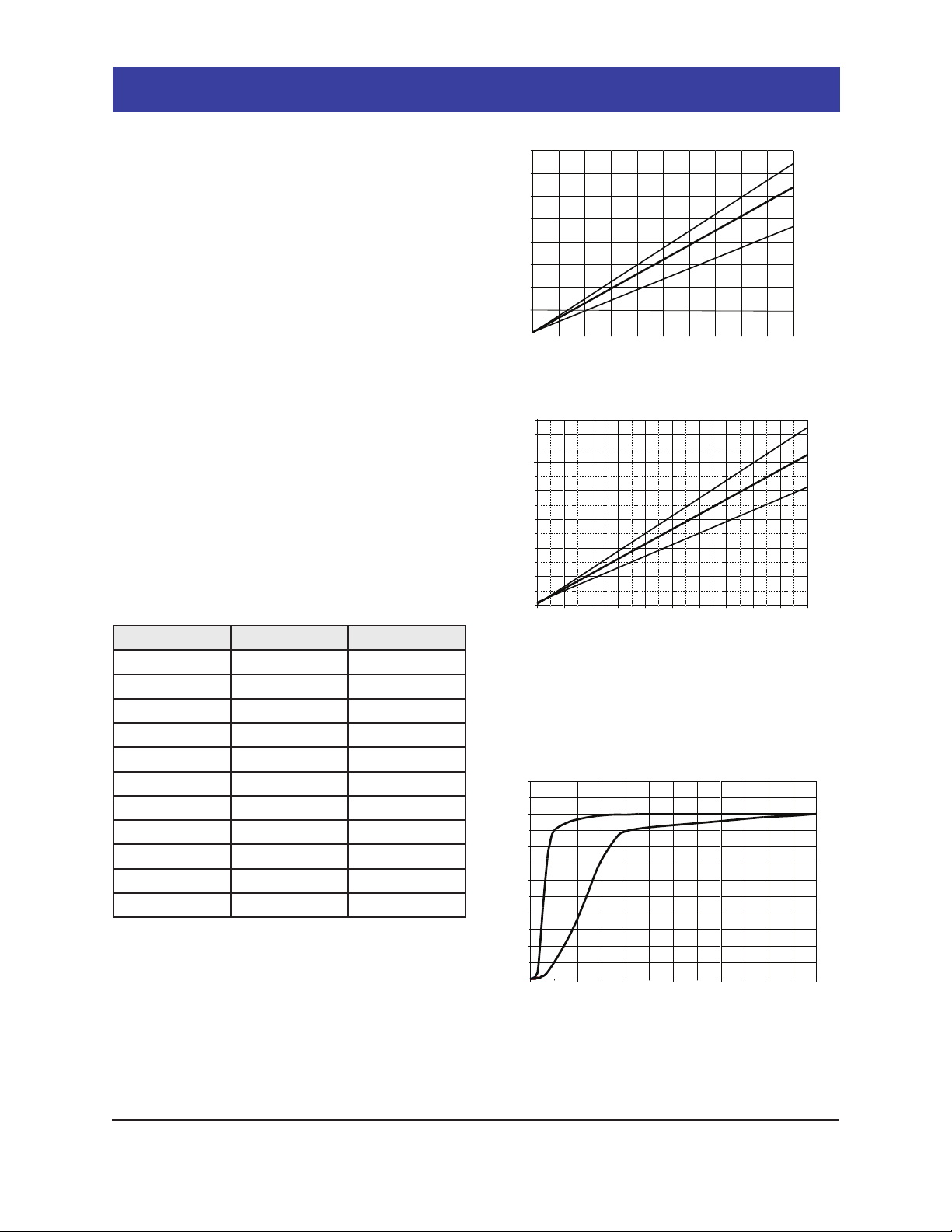

Figures 3a and 3b show the sensitivity characteristics

of the KE sensors. The Y-axis indicates the output

voltage of the sensor.

3-2 Response time

Figure 4 demonstrates the response pattern of the

sensor's output voltage. The Y-axis indicates the

output voltage ratio(%) to saturated voltage. Typical

response time to 90% of saturated response is 14

seconds for KE-25 and 60 seconds for KE-50.

3-3 Inuence of various gases

The inuence on KE sensors from various gases is

shown in Table 3. The 'interference level' shown in

the table indicates the change ratio between sensor

output in an air (20.7% O2) and gas mixture compared

to sensor output in normal air (20.7% O2). For

example, if the interference level of SO2is considered

to be 3%, that would indicate that the sensor's output

voltage in normal air (20.7% O2) would correspond

to a concentration of 21.3% O2 (20.7% x 1.03).

Fig. 3b - KE-50 sensitivity characteristics

Fig. 3a - KE-25 sensitivity characteristics

0

20

40

60

80

100

120

0 30 60 90 100 110 120

Time (sec.)

Output ratio (%)

KE-25

KE-50

Fig. 4 - Response speed of KE sensors to oxygen

Table 3 - Inuence of various gases on KE-series sensors

0

0

Oxygen concentration (%)

Output voltage (mV)

300

250

200

150

100

50

10 20 30 40 50 60 70 80 90 100

max.

min.

typ.

Gas Concentration Interference Level

Carbon monoxide 0-100% no eect

Carbon dioxide 0-100% no eect

Nitric monoxide 0-1% no eect

Nitrogen dioxide 0-1% no eect

Sulfur dioxide 0-3% 3%

Hydrogen sulde 0-3% no eect

Ammonia 0-3% 1%

Hydrogen 0-100% no eect

Hydrogen chloride 0-3% 1%

Benzene 0-100ppm 1%

Methane 0-100% no eect

Oxygen concentration (%)

Output voltage (mV)

0

70

60

50

40

30

20

10

010 20 30 40 50 60 70 80 90 100

80

max.

min.

typ.

Revised 09/22 5

TECHNICAL INFORMATION FOR KE-SERIESTECHNICAL INFORMATION FOR KE-SERIES

3-4 Effects of pressure change

The pressure dependency of KE-50 can be seen in

Figure 5. In this range of atmospheric pressure, sensor

output voltage maintains a linear relationship when

compared with atmospheric pressure. This same

tendency can be seen in all models of KE sensors.

3-5 Humidity dependency

Figure 6 displays an example of humidity dependency

for KE-50. The Y-axis shows sensor output voltage. The

sensor itself is not inuenced by humidity, but its output

voltage may show some variation to the extent that O2is

displaced by humidity, as indicated in Figure 7.

Fig. 5 - KE-50 response of output voltage to

ambient pressure changes

(at 25˚C/60%RH)

Fig. 6 - KE-50 effect of humidity on output voltage

(at 25˚C in ambient air)

Fig. 7 - Effect of humidity on O2concentration

0 20 40 60 80 100

Humidity (%RH)

O2concentration (%)

21.0

20.5

19.5

19.0

20.0

5oC

15oC

40oC

35oC

30oC

25oC

�20oC

10oC

30

45

60

75

90

800 900 1000 1100 1200 1300

Sensor output (mV)

Atmospheric pressure (hPa)

max.

min.

typ.

30

40

50

60

70

20 40 60 80

Sensor output (mV)

Humidity (%RH)

max.

min.

typ.

100

This manual suits for next models

6

Table of contents

Other Figaro Accessories manuals