Figaro TGS5141-P00 Manual

Revised 11/18 1

TECHNICAL INFORMATION FOR TGS5141-P00

Technical Information for Carbon Monoxide Sensors

Figaro’s TGS5141 is a battery operable

electrochemical sensor which uses a unique

electrolyte that eliminates the need for a water

reservoir. By eliminating the water reservoir used

in TGS5042, the comparative size of TGS5141 is

reduced to just 10% of TGS5042. With its ultra

compact size, this sensor is the ideal choice for

size oriented applications such as portable CO

detectors, small residential CO detectors, and

multi-sensor fire detectors. OEM customers

will nd individual sensor data printed on each

sensor in bar code form, enabling users to skip

the costly gas calibration process and allowing

for individual sensor tracking.

Specifications Page

Features..................................................................................................2

Applications...............................................................................................2

Structure...........................................................................................2

Basic Measuring Circuit...........................................................................2

Operating Conditions & Specications...................................................3

Dimensions...................................................................................................3

Operation Principle......................................................................................................4

Basic Sensitivity Characteristics

Sensitivity to Various Gases............................................................5

Temperature and Humidity Dependency.............................................5

Gas Response Pattern.................................................................................6

Repeatability.............................................................................6

Inuence of Storage...................................................................................6

Normal Operation Test.....................................................................................7

Sensitivity Test...................................................................................7

Reliability

InterferenceGasTest......................................................................................8

Long-Term Stability................................................................................9

Corrosion Test...........................................................................................9

Variable Ambient Temperature Test................................................................9

Humidity Test.............................................................................................10

Stability Tests..................................................................................................11

Dust Test................................................................................................12

Marking..........................................................................................................................12

Cautions.......................................................................................................13

Appendix - Lead conguration............................................................................14

an ISO9001 company

IMPORTANT NOTE: OPERATING CONDITIONS IN WHICH FIGARO SENSORS ARE USED WILL VARY

WITH EACH CUSTOMER’S SPECIFIC APPLICATIONS. FIGARO STRONGLY RECOMMENDS CONSULT-

ING OUR TECHNICAL STAFF BEFORE DEPLOYING FIGARO SENSORS IN YOUR APPLICATION AND,

IN PARTICULAR, WHEN CUSTOMER’S TARGET GASES ARE NOT LISTED HEREIN. FIGARO CANNOT

ASSUME ANY RESPONSIBILITY FOR ANY USE OF ITS SENSORS IN A PRODUCT OR APPLICATION FOR

WHICH SENSOR HAS NOT BEEN SPECIFICALLY TESTED BY FIGARO.

TGS5141 is a UL recognized component in accordance with the

requirements of UL2034. Please note that component recognition

testing has conrmed long term stability in 15ppm of carbon monoxide;

other characteristics shown in this brochure have not been conrmed by

UL as part of component recognition.

Revised 11/18 2

TECHNICAL INFORMATION FOR TGS5141-P00

1. Specications

1-1 Features

* Ultra compact size

* Battery operable

* High repeatability/selectivity to carbon monoxide

* Linear relationship between CO gas concentration

and sensor output

* Simple calibration

* Long life

* UL recognized component

* Meets UL2034, EN50291, and EN54-31 requirements

1-2 Applications

* Residential and commercial CO detectors

* Fire detection

1-3 Structure

Figure 1 shows the structure of TGS5141. The gas sensing

layer is sandwiched between a stainless steel washer

(counter electrode) and a stainless steel cap (working

electrode), together with gas diffusion control stainless

lm and backing layers. This assembly is placed in the

compartment of the stainless steel can. A charcoal lter is

installed inside the stainless steel cap.

1-4 Basic measuring circuit

Figure 2 shows the basic measuring circuit of TGS5141.

The sensor generates a minute electric current which is

converted into sensor output voltage (Vout) by an op-amp/

resistor (R1) combination.

Figaro recommends the following electrical parts:

R1 : 1MΩ

C1 : 1µF

IC : AD708

An additional resistor or FET is required to prevent

polarization of the sensor when circuit voltage is off.

NOTE:When voltage is applied to the sensor output

terminal, the sensor may be damaged. Voltage applied to

the sensor should be strictly limited to less than ±10mV.

1-5 Operating conditions & specications (Table 1)

Figure 1 - Sensor structure

Figure 2 - Basic measuring circuit

(Including equivalent circuit)

Gasket

Washer

Can / Counter

electrode terminal

Cap / Working electrode terminal

Gas inlet

Gas inlet

Active charcoal filter

Gas sensing layer

Gas diffusion control film

TGS5141

Working

Counter

-

+

R1

C1

Vout

1MΩ

1µF

IC

NOTE 1: Represents sensor output in air under operating conditions

Table 1 - Operating conditions and specications

Item Specication

Model number TGS5141-P00

Target gases Carbon monoxide

Typical detection range 0 ~ 5,000ppm

Output current in CO 1.2~3.2nA/ppm

Baseline offset(*1) <±10ppm equivalent

Operating temperature -10˚C ~ +50˚C (continuous)

-20˚C ~ +60˚C (intermittent)

Operating humidity 10 ~ 95%RH (no condensation)

Response time (T90) within 60 seconds

Storage conditions -10˚C ~ +50˚C (continuous)

-20˚C ~ +60˚C (intermittent)

Weight approx. 2.5g

Standard test conditions 20±2˚C, 40±10%RH

Revised 11/18 3

TECHNICAL INFORMATION FOR TGS5141-P00

1-6 Dimensions (see Fig. 3)

Figure 3 - Dimensions

All sensor characteristics shown in this brochure

represent typicalcharacteristics. Actualcharacteristics

vary from sensor to sensor and from production lot

to production lot. The only characteristics warranted

are those shown in the Specication.

5.0±0.4

Top view

Gas inlet

Side view

Bottom view

Working electrode

8.5±0.2

unit: mm

13.9±0.4 Counter electrode

Revised 11/18 4

TECHNICAL INFORMATION FOR TGS5141-P00

2. Operation Principle

The operation principle of TGS5141 is basically

identical to that of a fuel cell. When CO passes

through the gas permeable diffusion membrane

and reaches the working electrode, protons and

electrons are generated as part of a CO oxidization

reaction (see equation 1). By creating a short circuit

between the working and counter electrodes with

external wiring, electrons and protons on the

working electrode move to the counter electrode

through the external wiring and through the proton

conductor respectively. The proton then reacts

with oxygen on the counter electrode as shown in

equation 2. The total reaction is expressed as shown

in equation 3.

A linear relationship exists between the sensor's

electric current and CO concentration (see equation

4). By calibrating the sensor with a known

concentration of CO gas, the output current of the

sensor can then be used to quantitatively determine

CO concentration.

Since, unlike conventional dry batteries, there is no

consumption of active materials or of the electrodes,

TGS5141 possesses excellent long-term stability

for its output signal and enables maintenance-free

operation. Furthermore, the sensor's self-generating

output current makes it ideal for usage in battery-

operated CO detectors.

Figure 4 - Operation principle

Figure 5 - Schematic diagram of TGS5141

operating principle

Air

Gas

H+

e-

A

Working electrode

Counter electrode

Proton exchange membrane

Working electrode (Anodic reaction)

CO + H2O →CO2 + 2H+ + 2e- (equation 1)

Counter electrode (Cathodic reaction)

2H+ + 1/2 O2 + 2e- → H2O (equation 2)

Total reaction

CO + 1/2 O2→ CO2 (equation 3)

Theoretical output current value

I = F x (A/σ) x D x C x n (equation 4)

where:

F : Faraday constant

A: Surface area of diffusion lm

D: Gas diffusion co-efcient

C: Gas concentration

σ: Thickness of diffusion lm

n: Number of reaction electrons

Revised 11/18 5

TECHNICAL INFORMATION FOR TGS5141-P00

3. Basic Sensitivity Characteristics

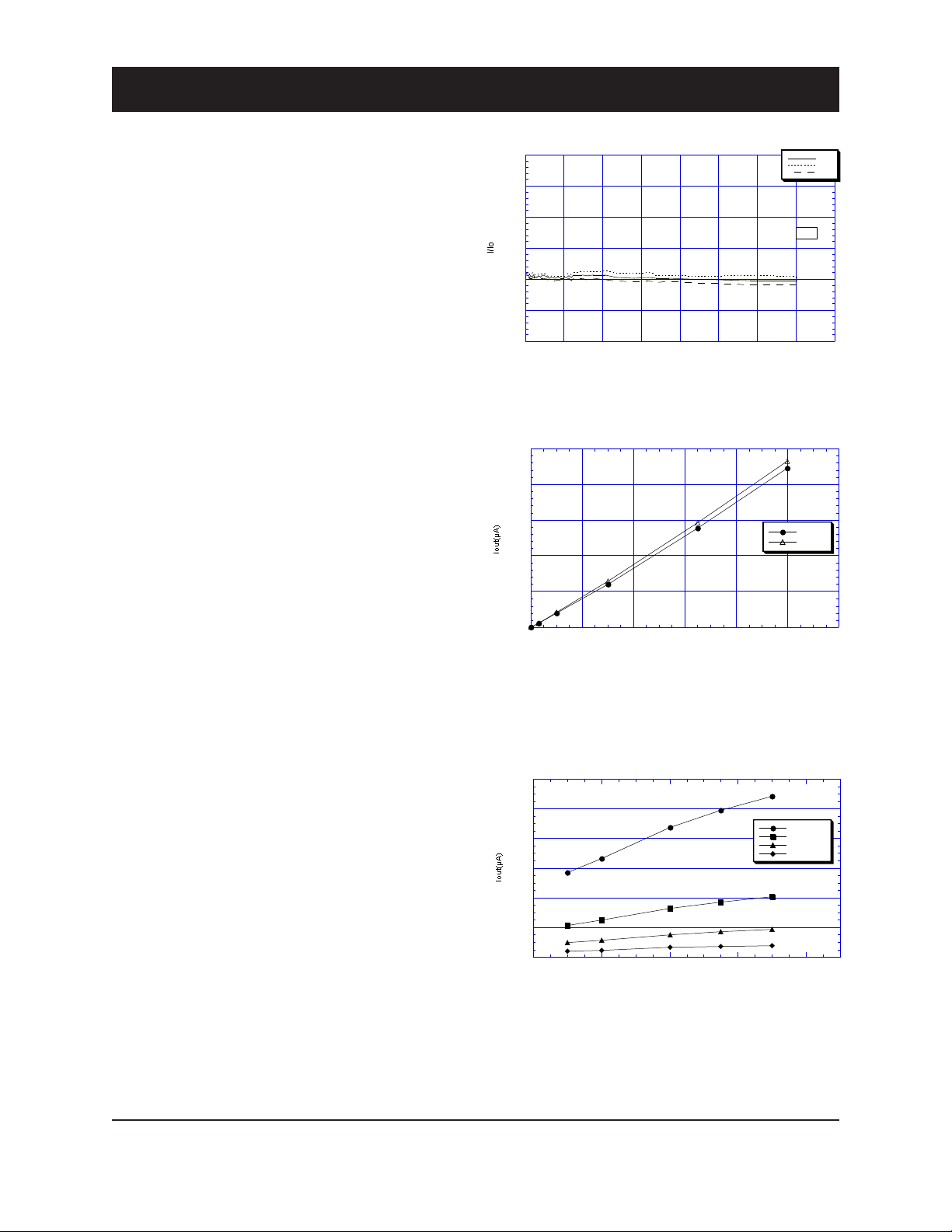

3-1 Sensitivity to various gases

Figure 6 shows the sensor’s sensitivity to various

gases. The Y-axis shows output current (Iout/µA) in

each gas. The output current is linear to CO concen-

tration, with a deviation of less than ±5% in the range

of 0~500ppm. Cross sensitivity data for other gases

than those in Figure 6 are tabulated in Table Y.

3-2 Temperature and humidity dependency

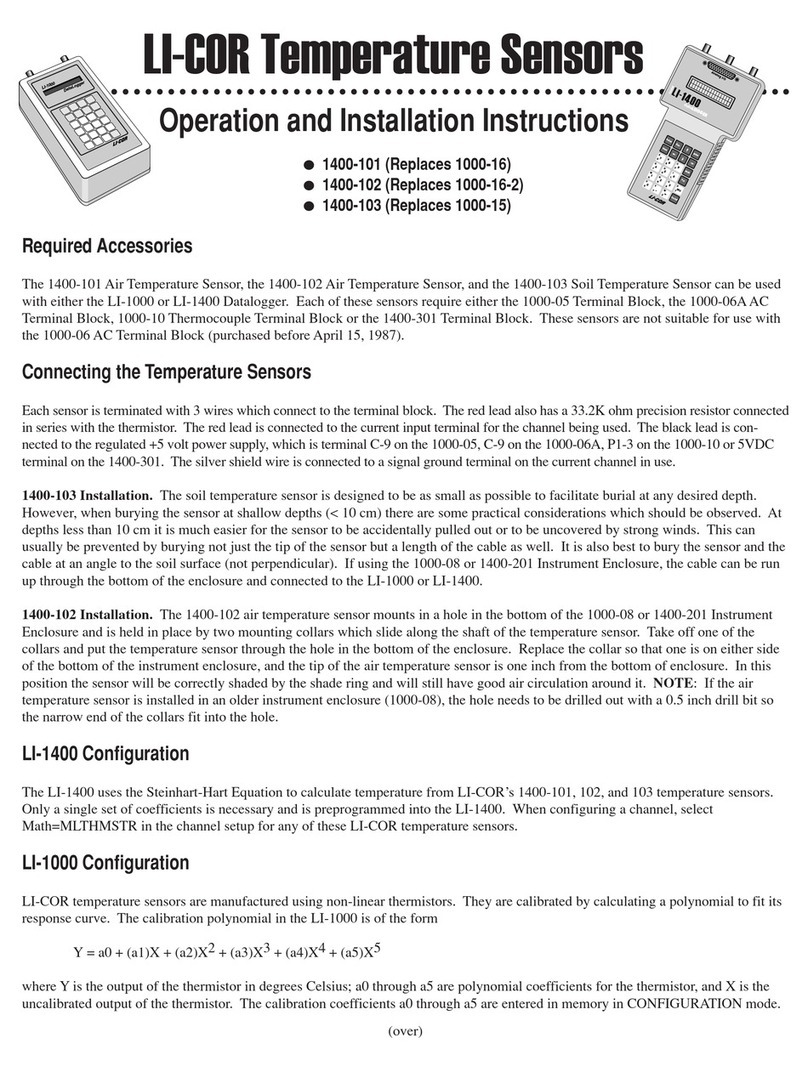

Figure 7a shows the temperature dependency of

TGS5141 under a constant humidity of 50%RH. The

Y-axis shows the ratio of output current in 400ppm

of CO at various temperatures (I) to the output

current in 400ppm of CO at 20˚C/50%RH (Io).

Temperature dependency is based on the difference

in the catalytic reaction rate on the electrodes,

and it can be simply compensated by utilizing a

thermistor. This linear relationship between I/

Io and CO concentration is constant regardless of

CO concentration range, according to the sensor's

operating principle.

Figure 7b shows the humidity dependency of

TGS5141 under constant temperatures of 20˚C and

50˚C. The Y-axis shows the ratio of output current

in 400ppm of CO at various relative humidities

(I) to the output current in 400ppm of CO at

20˚C/50%RH (Io). This data demonstrates that

humidity dependency is negligible as temperature

varies.

Figure 6 - Sensitivity to various gases

Figure 7a - Temperature dependency at 400ppm CO/50%RH

(Io=sensor output current at 20˚C)

Figure 7b - Humidity dependency at 400ppm CO

(Io=sensor output current at 50%RH)

0.0

0.5

1.0

1.5

2.0

0 20 40 60 80

100

20˚C

50˚C

I/Io

Relative Humidity (%)

Note: The gures in this table are typical values and should not be used

as a basis for cross calibration. Cross sensitivity for various gases may

not be linear and should not be scaled. All data based on a 4 minute

exposure. For some gases, lter saturation and gas breakthrough may

occur if gas is applied for a longer time period.

0.0

0.5

1.0

1.5

2.0

-10 0 10 20 30 40 50

I/Io

Temperature (˚C)

-0.5

0.0

0.5

1.0

1.5

2.0

2.5

0 200 400 600 800 1000

CO

H2

Ethanol

CH4

Iso-butane

Iout(µA)

Gas concentration (ppm)

Gas Concentration CO equivalent

Hydrogen 1000ppm 500ppm

Methane Heptane

1000ppm <30ppm

Butane IPA

Ethanol Freon R22

HMDS (Si vapor) Acetone

Toluene Cyclohexane

Trichloroethane CO2

NO2Ethylene

200ppm <30ppm

Formaldehye Ammonia

Xylene SO2

Acetic acid Ethyl acetate

Acetylene 200ppm 360ppm

Revised 11/18 6

TECHNICAL INFORMATION FOR TGS5141-P00

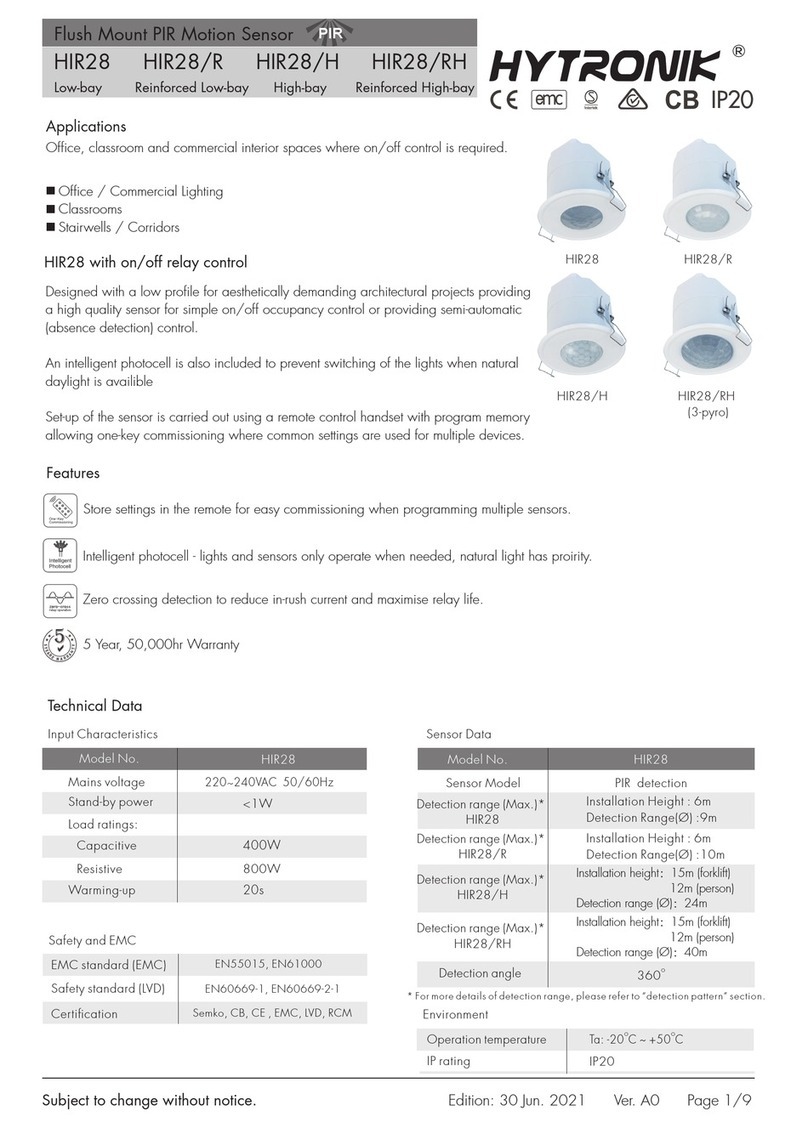

3-3 Gas response pattern

Figure 8 shows the gas response pattern of the

output signal when the sensor is placed into 30, 70,

150 and 400ppm of CO and then returned to normal

air. The response time to 90% of the saturated signal

level is within 60 seconds, and the recovery of the

signal back to 90% of the base level is within 120

seconds. This data demonstrates that TGS5141

possesses sufcient response speed for meeting UL

requirements for CO detectors.

3-4 Repeatability

Figure 9 shows the pattern of the output signal

when the sensor is repeatedly exposed to 400ppm

of CO at a constant interval of 240 seconds. The data

demonstrates extremely high reproducibility of the

output signal, the deviation being less than ±5%.

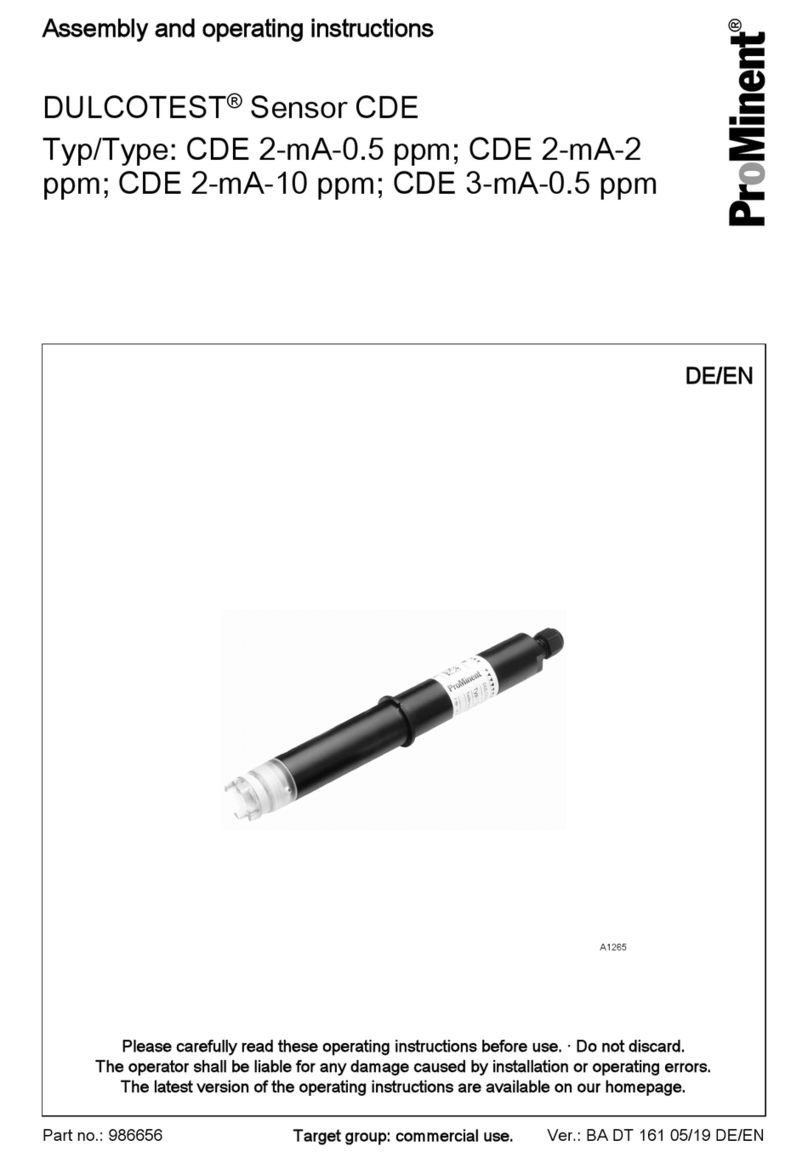

3-5 Inuence of storage

Figure 10 shows the initial action of the sensor's

output current signal in fresh air. For the purpose

of this test, sensors were stored for more than six

months under two separate conditions between the

working and counter electrodes: in short-circuited

condition, and in open-circuited condition. The

chart illustrates the behavior of sensor output

current for each group just after installation into

the operating circuit. The output current signal of

sensors stored in a short-circuited condition reaches

its saturated level quickly, while those stored with

an open-circuit exhibit much slower behavior.

Since sensors are shipped in an open-circuit

condition, stabilization time of one hour (typical) is

recommended after mounting on a PCB that includes

an anti-polarization circuit (see Item 2-4 in Application

Notes for TGS5xxx Series). If no antipolarization circuit

is used, it is necessary to wait for about one hour after

powering the circuit. One hour of powering is

required, regardless of when the sensor is placed into

the detector circuit.

Figure 8 - Response pattern

Figure 9 - Repeatability (in 400ppm of CO)

0.0

0.2

0.4

0.6

0.8

1.0

0 500 1000 1500 2000

Iout(µA)

Time (sec.)

CO 30ppm

CO 70ppm

CO 150ppm

CO 400ppm

-0.2

0.0

0.2

0.4

0.6

0.8

1.0

0 500 1000 1500 2000

Iout(µA)

Time (sec.)

-100

-50

0

50

100

0 10 20 30 40 50 60 70

Short

Open

Iout(nA)

Time (min.)

Figure 10 - Inuence of storage

(in fresh air)

Revised 11/18 7

TECHNICAL INFORMATION FOR TGS5141-P00

3-6 Normal operation test

Figure 11a shows the result of the “Normal Operation

Test” required by UL2034 where the sensor is exposed

to 600ppm of CO for 12 hours at 20˚C/40%RH. Stable

output current signal can be seen throughout the

exposure.

In addition, Figure 11b shows the CO sensitivity

characteristics of the sensor before, during, and

after the Normal Operation Test, demonstrating that

TGS5141 is hardly inuenced by exposure to high

concentrations of CO.

3-7 Sensitivity test

Figure 12a shows the results of the “Sensitivity Test”

as required by UL2034. Under this test, the sensor

was exposed to 30, 70, 150 and 400ppm of CO at

20˚C/40%RH. The period of exposure was varied

by concentration, corresponding with the maximum

time in which a CO detector should generate an

alarm for the subject concentration. Throughout the

test exposures, TGS5141 displayed a reasonable and

stable output current signal.

Figure 11a - Normal operation test

(CO 600±30ppm for 12 hours at 20˚C/40%RH)

0.0

0.5

1.0

1.5

0 5 10 15 20

Iout(µA)

Time (hrs.)

CO 600ppm

Figure 11b - Normal operation test

(20˚C/40%RH)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

0 100 200 300 400 500 600 700

Before

During

After

Iout(µA)

CO concentration (ppm)

0

0.2

0.4

0.6

0.8

1

0 200 400 600 800 1000 1200 1400

Iout(µA)

Time (min.)

CO 30ppm

CO 70ppm

CO 150ppm

CO 400ppm

Figure 12a - Sensitivity test

(20˚C/40%RH)

Revised 11/18 8

TECHNICAL INFORMATION FOR TGS5141-P00

In addition, Figure 12b indicates the CO sensitivity

characteristics of the sensor before, during, and

after the Sensitivity Test, demonstrating the

excellent reproducibility of TGS5141's CO sensitiv-

ity characteristics.

4. Reliability

Tests conducted in this section demonstrate that TGS5141

can meet the requirements of various testing standards

without incurring adverse long term effects from such

tests.

4-1 Interference gas test

Figure 13a shows the results of testing the TGS5141

sensor for durability against various interference

gases as specied by UL2034. The test was conducted

by exposing the sensor to each gas shown in Figure

13a (starting with CO 30ppm) for two hours, then

removing the sensor to fresh air for just one hour,

and followed by inserting the sensor into the next

gas. This procedure was repeated for the full range

of gases shown in Figure 13a.

Because the sensor is exposed to each of the test

gases consecutively, to some small extent the effect

of the previous test gas may affect subsequent tests

for a short period. However, despite the short-term

effects of such gases remaining after exposure, the

sensor still shows signicantly less sensitivity to

each test gas when compared to 30ppm of CO, and

CO sensitivity remains unaffected.

In addition, Figure 13b shows the CO sensitivity

characteristics of the sensor before and after this test,

further demonstrating the excellent reproducibility

of the CO sensitivity characteristics of TGS5141,

demonstrating its durability against the interference

gases listed in the requirements of UL2034.

Fig. 12b - Sensitivity test

(20˚C/40%RH)

Figure 13a - Interference gas test

(20˚C/40%RH)

0.0

0.2

0.4

0.6

0.8

1.0

0 100 200 300 400 500

Before

During

After

Iout(µA)

CO concentration (ppm)

0

0.01

0.02

0.03

0.04

0.05

0.06

Iout(µA)

Air

CO 30ppm

Methane 500ppm

Butane 300ppm

Heptane 500ppm

Ethyl acetate 200ppm

IPA 200ppm

CO2 5000ppm

NH3 100ppm

Ethanol 200ppm

Toluene 200ppm

Trichloroethane 200ppm

Acetone 200ppm

CO 30ppm

0

0.1

0.1

0.2

0.2

0.3

0.3

0.4

0 20 40 60 80 100 120 140 160

Before

After

Iout(µA)

CO concentration (ppm)

Figure 13b - Interference gas test

(20˚C/40%RH)

Revised 11/18 9

TECHNICAL INFORMATION FOR TGS5141-P00

4-2 Long-term stability

Figure 14 shows long-term stability data for

TGS5141. Test samples were stored in natural clean

air under a short-circuit condition and measured at

various intervals as dictated by the standard test

conditions of UL2034. The Y-axis shows the ratio of

output current in 300ppm of CO at any point in time

(I) over output current in 300ppm of CO on the rst

day of the test (Io). This chart demonstrates very

stable characteristics for more than 700 days.

4-3 Corrosion test

To demonstrate the durability of TGS5141 against

corrosion, samples were subjected to test conditions

called for by UL2034-Corrosion Test. Over a three-

week period, a mixture of 100ppb of H2S, 20ppb of

Cl2, and 200ppb of NO2was supplied to the sensors

at a rate sufcient to achieve an air exchange rate

of ve times per hour. Figure 15 shows the CO

sensitivity characteristics before and after exposure

in the above conditions, demonstrating that TGS5141

is hardly inuenced by such corrosive gases. In

addition, the sensor's stainless steel housing did not

show any sign of corrosion as a result of this test.

4-4 Variable ambient temperature test

To demonstrate the ability of TGS5141 to withstand

the effects of high and low temperature, the

“Variable Ambient Temperature Test” of UL2034

was conducted.

(1) Operation in high and low temperature test

Figure 16a shows the results for the “Operation in

High and Low Temperature Test” of UL2034. The

sensor was exposed to environments of 0˚C/15%RH

and 49˚C/40%RH for at least three hours each,

with measurements taken before and during the

exposure in accordance with the test conditions

of UL2034. By plotting the output current values

from these test measurements atop the data taken

prior to this test at a constant 50%RH (representing

standard temperature dependency), it can be seen

that the test data are still in line with data taken

at a constant RH. The conclusion which can be

drawn is that, regardless of exposure to extremes

of temperature and humidity, the sensor's output

is not affected by humidity. As a result, TGS5141

can meet the requirements of UL2034 by utilizing a

simple temperature compensation method.

Figure 14 - Long term stability

Figure 15 - Durability against corrosion

Figure 16a - Operation in high and low temperature

(all data at 50%RH except test points)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

0 100 200 300 400 500 600 700 800

ave.

min.

max.

I/Io

Time (days)

N=10

0.0

0.5

1.0

1.5

2.0

2.5

0 200 400 600 800 1000 1200

Before

After

Iout(µA)

CO concentration (ppm)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

-20 0 20 40 60

CO 400ppm

CO 150ppm

CO 70ppm

CO 30ppm

Iout(µA)

Temperature (˚C)

Revised 11/18 10

TECHNICAL INFORMATION FOR TGS5141-P00

0.0

0.5

1.0

1.5

2.0

2.5

0 200 400 600 800 1000 1200

Before

After

Iout(µA)

CO concentration (ppm)

(2) Effect of shipping and storage

To verify the effects of shipping and storage, the

sensor was tested under the conditions of UL2034.

Test samples in a short-circuited condition were

subjected to 70˚C for 24 hours, allowed to cool to

room temperature for 1 hour, subjected to -40˚C

for 3 hours, and then allowed to warm up to room

temperature for 3 hours. Figure 16b shows the CO

sensitivity characteristics before and after the test,

demonstrating that TGS5141 meets the requirement

of UL2034.

4-5 Humidity test

Figure 17a shows the results of testing the sensor

under UL2034. The sensor was exposed in an

atmosphere of 52±3˚C/95±4%RH for a period of 168

hours,returnedtonormalairfor2days,thenfollowed

by 168 hours exposure at 22±3˚C/10±3%RH. The

data demonstrates the stable characteristics in both

low and high humidity conditions.

Figure 17b shows data taken prior to the above test

at a constant relative humidity of 50%. These curves

represent the typical temperature dependency of

the sensor. When plotting measurements taken at

the environmental extremes specied on UL2034

(52±3˚C/95±4%RH and 22±3˚C/10±3%RH) onto the

temperature dependency curves, it can be seen that

measurements taken at these extreme conditions still

fall in line with the temperature dependency curve

derived prior to testing. The conclusion which can

be drawn is that, regardless of exposure to extremes

of temperature and humidity, the sensor's output

is not affected by humidity. As a result, TGS5141

can meet the requirements of UL2034 by utilizing a

simple temperature compensation method.

Figure 16b - Effects of shipping and storage

Figure 17a - Humidity test

Figure 17b - Humidity test

(all data at 50%RH except test points)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 5 10 15 20

400ppm

150ppm

70ppm

30ppm

Iout(µA)

CO concentration (ppm)

52˚C/95%RH

20˚C/7%RH

0.0

0.2

0.4

0.6

0.8

1.0

1.2

-20 0 20 40 60

CO 400ppm

CO 150ppm

CO 70ppm

CO 30ppm

Iout(µA)

Temperature (˚C)

Revised 11/18 11

TECHNICAL INFORMATION FOR TGS5141-P00

4-6 Stability test

(1) False alarm test

To show the sensor’s behavior under continuous

low level exposure to CO, samples were tested

against the procedure detailed in UL2034--Stability

Test. Test samples were exposed to 30ppm of

CO continuously for a period of 30 days under

standard circuit conditions. Figure 18 shows the

CO sensitivity characteristics before and after the

exposure test, demonstrating that detectors using

TGS5141 will not give a false alarm as a result of

continuous low level CO exposure.

(2) Temperature cycle test

In accordance with UL2034--Stability Test, test

samples were exposed to ten cycles (<1 hour and

>15 minutes) of temperature from 0˚C/100%RH

to 49˚C/40%RH. Figure 19 shows CO sensitivity

characteristics before and after the cycle test,

demonstrating that TGS5141 is hardly inuenced by

the extreme conditions of the temperature cycle test.

Figure 18 - False alarm test

Figure 19 - Temperature cycle test

Revised 11/18 12

TECHNICAL INFORMATION FOR TGS5141-P00

4-7 Dust test

To judge the effect of dust contamination on TGS5141,

approximately 2 ounces (0.06 kg) of cement dust, capable

of passing through a 200 mesh screen, was circulated for

1 hour by means of a blower, enveloping the sensor in the

test chamber. Air ow was maintained at an air velocity of

approximately 50 fpm (0.25 m/s) at 20˚C/40%RH.

Figure 20 shows the sensor's CO sensitivity characteristics

before and after the dust exposure test. This data

demonstrates that the dust test of UL2034 has a negligible

effect on CO sensitivity.

5. Marking

The two-dimensional bar code indicates the following

information:

xxxxYYMMDDnnnnnnnnnnnnnnnnnn

xxxx = sensor's sensitivity (slope) in numeric value as

determined by measuring the sensor's output in

300ppm of CO (Ex.1827=1.827nA/ppm)

YYMMDD = sensor's sensitivity measuring date in year-

month-day format (Ex.150401=1st April 2015)

nnnnnnnnnnnnnnnnnn = 18-digit manufacturer's serial

number

0.0

0.5

1.0

1.5

2.0

2.5

0 200 400 600 800 1000 1200

Before

After

Iout(µA)

CO concentration (ppm)

Figure 20 - Dust test

Two-dimensional bar code

Figure 21 - TGS5141 markings

Revised 11/18 13

TECHNICAL INFORMATION FOR TGS5141-P00

6. Cautions

6-1 Situations which must be avoided

1) Disassembling the sensor

Under no circumstances should the sensor be disassem-

bled, nor should the sensor can and/or cap be deformed.

2) Contamination by alkaline metals

Sensor characteristics may be signicantly changed when

the sensor is contaminated by alkaline metals, especially

salt water spray.

3) Exposure to high concentration of basic (non-acidic) gases

Sensor characteristics may be irreversibly changed by

exposure to high concentrations of basic gases such as

ammonia. Avoid long term exposure to or use of packing

materials that may generate basic gases.

4) Exposure to certain VOCs

Avoid prolonged exposure to certain VOCs such as

styrene (commonly used in blister packs and packing

trays) and a-pinene (found in some kinds of printing

inks). Off-gassing from such VOCs may cause irreversible

changes to sensor characteristics. Avoid packing the sensor

or products incorporating the sensor in a tightly closed

container in which such VOC gases may be present. It is

strongly recommended to conduct a test to see if there would

be any adverse inuence by packing materials on sensor

characteristics. If the sensor is excessively exposed to other

organic vapors such as alcohols or acetone, these gases may

cause temporary change of cross sensitivity characteristics.

5) High temperature exposure

At temperatures of 80˚C or higher, the sensing membrane

may deteriorate, resulting in irreversible change of sensor

characteristics.

6) Contact with water

Sensor characteristics may be changed due to soaking or

splashing the sensor with water.

7) Application of excessive voltage

If higher than specied voltage is applied to the sensor,

breakage may occur or sensor characteristics may drift,

even if no physical damage or breakage occurs. Do not

use the sensor once excessive voltage is applied.

6-2 Situations to avoid whenever possible

1) Exposure to silicone vapors

Avoid exposure of sensor where silicone adhesives, hair

grooming materials, or silicone rubber/putty may be

present. Silicone vapors may cause clogging of the gas

diffusion route.

2) Dew condensation

If severe dew condensation occurs for a long period

inside of the sensor or on the sensor surface, it may cause

clogging of gas diffusion route or deterioration of the

sensing membrane. Mild dew condensation which occurs

in normal indoor air would not cause any signicant

damage.

3) Exposure to hydrogen sulde or sulfuric acid gas

If the sensor is exposed to hydrogen sulde or sulfuric acid

gas, sensor components such as the gas diffusion lm, can,

and cap may be corroded, resulting in the sensor damage.

4) Vibration and shock

Vibration and shock may cause an open or short circuit

inside the sensor.

5) Dust and oil mist

Extremely high concentrations of dust or oil mist

may cause clogging of the sensor's internal structure.

When such conditions are expected to be encountered,

installation of an external air lter is recommended.

6) Flux for soldering

Manual soldering is recommended since high concen-

trations of ux may affect sensor characteristics when

the sensor is soldered by wave soldering. When wave

soldering is used, a test should be conducted before

production starts to see if there would be any inuence to

sensor characteristics. Please refer to Item 7-3 of Application

Notes for TGS5xxx Series for advice on manual soldering

conditions.

6-3 Additional cautions for installation

This sensor requires the existence of oxygen in the

operating environment to function properly and to exhibit

the characteristics described in this brochure. The sensor

will not operate properly in a zero oxygen environment.

Figaro USAInc. and the manufacturer, Figaro Engineering

Inc. (together referred to as Figaro) reserve the right to make

changes without notice to any products herein to improve

reliability, functioning or design. Information contained in

this document is believed to be reliable. However, Figaro

does not assume any liability arising out of the application

or use of any product or circuit described herein; neither

does it convey any license under its patent rights, nor the

rights of others.

Figaro's products are not authorized for use as critical

components in life support applications wherein a failure

or malfunction of the products may result in injury or

threat to life.

Revised 11/18 14

TECHNICAL INFORMATION FOR TGS5141-P00

APPENDIX

TGS5141-P00 Lead Conguration

Leads are connected to sensor electrodes when the

sensors are shipped.

Stainless steel (SUS) pin version (Fig. 22)

Solid SUS pins enable the sensor to be more easily

mounted and/or directly soldered onto a PCB.

The height from the PCB to the sensor should be 0.6 mm

or more to ensure sufcient electrical insulation from the

PCB.

Figure 22 - Dimensions (w/lead pins)

4.15±0.40

13.9±0.4

Top View

Side View

Bottom View

Unit : mm

Side View

3.75±0.40

0.80±0.05

7.5±0.2

0.80±0.05

4.0±0.1

14.65±0.40

0.20±0.050.20±0.05

11.65±0.60

10.8±0.2

1.40±0.05

7.7±0.4

4.15±0.40

Working electrode

Counter electrode

Ni-plated SUS304

0.8

0.8

2.2

2.0

A

B

6.5±0.1

11.6±0.1

0.8

1.8

2.0

0.8

1.8

2.0

2.0

3.0

3.2

2.2

3.2

3.4

Note:

・Unspecified tolerance: ±0.05

Enlarged view of “A” Enlarged view of “B”

Unit : mm

Figure 23 - Recommended footprint

Revised 11/18 15

TECHNICAL INFORMATION FOR TGS5141-P00

FIGARO GROUP

HEAD OFFICE

Figaro Engineering Inc.

1-5-11 Senba-nishi

Mino, Osaka 562-8505 JAPAN

Tel.: (81) 72-728-2561

Fax: (81) 72-728-0467

email: garo@garo.co.jp

www.garo.co.jp

OVERSEAS

Figaro USA Inc.

121 S. Wilke Rd. Suite 300

Arlington Heights, IL 60005 USA

Tel.: (1) 847-832-1701

Fax.: (1) 847-832-1705

email: garousa@garosensor.com

Figaro Sensor (Shanghai) Co., Ltd

Room No. 1003-1004A 511 Weihai Road

Shanghai 200041 CHINA

Tel.: (86) 21-6253-1501

Fax.: (86) 21-6251-2166

email: garo@garo-china.com

Table of contents

Other Figaro Accessories manuals

Popular Accessories manuals by other brands

Hytronik

Hytronik HIR28 quick start guide

Endress+Hauser

Endress+Hauser Condumax CLS15 operating instructions

ProMinent

ProMinent DULCOTEST CDE Series Assembly and operating instructions

Kramer

Kramer KRT-3 user manual

Honeywell

Honeywell Fire-Lite Alarms AD365A Installation and maintenance instructions

SICK

SICK deTec4 C4C-EV03030A10000 operating instructions