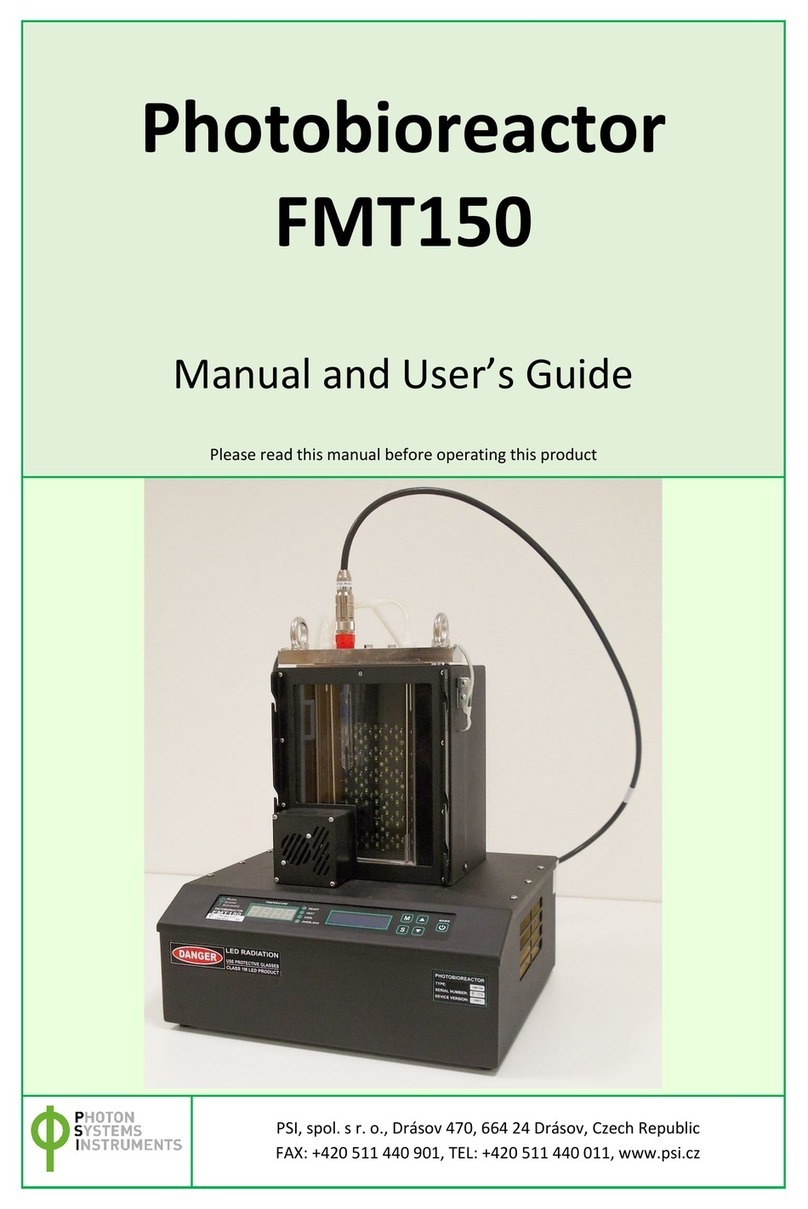

Fike Clean Agent System Instruction Manual

Design, Installation & Maintenance Manual

for

Fike Clean Agent Systems

w/ FM-200™, GCA and DOT / TC Containers

P/N 06-215 (Rev G)

Revision Date: January, 2010

REVISION HISTORY

Manual P/N: 06-215

Document Name: DESIGN, INSTALLATION, AND MAINTENANCE MANUAL

FOR ENGINEERED HFC-227ea SYSTEMS

Original Release Date..........................................................................................................................February, 2001

Revision / Description of Change Revision Date

Revision A................................................................................................................................................... April, 2002

1) Added reference to 4BW500 containers to Section 1

2) Moved details on 4BA500 containers to Appendix B

Revision B....................................................................................................................................................July, 2003

1) Add low pressure switch to Section 1 & 4

2) Add back to back 180° nozzles to Section 2

Revision C ................................................................................................................................................March, 2004

1) Changed minimum design concentration in Section 2 for Class A hazards

2) Revised sample problem in Section 3

Revision D ...................................................................................................................................................May, 2005

1) Updated 10, 20 & 35-lb container information in Section 1 and 4

Revision E...................................................................................................................................................June, 2006

1) Add notes to par 2.7.4 on page 15 and par 2.8.5 on page 22, of Design Section regarding 10 pipe dia.

limitation for back to back 180 degree nozzles

Revision F...................................................................................................................................................June, 2009

1) Added 3/8” Sch 40 & Sch 80 pipe to paragraph 4.4, Section 4

2) Changed Mounting Bracket information in Section 1 & 4

3) Removed 10 lb. Container from Manual

4) Removed Notes (Class C energized hazards) under paragraph 2.2.2 in Section 2

5) Added reference to ULC and TC to manual

6) Updated information on 1” & 2” Check Valves in Section 1 & 2

7) Reformatted Nozzle information

8) Removed reference to 4B500/4BM500 in paragraph 1.5.2, Section 1

Revision G.............................................................................................................................................January, 2010

1) Added threaded valve information to Sections 1, 2 and 4

This page intentionally left blank

TABLE OF CONTENTS

Manual P/N: 06-215 (Rev G)

INTRODUCTION............................................................................................................................................ 1 PAGE

SECTION 1 – EQUIPMENT.......................................................................................................................25 PAGES

1.1 AGENT..........................................................................................................................................................1

1.2 PERFORMANCE ..........................................................................................................................................1

1.3 PHYSICAL PROPERTIES – HFC-227ea (FM-200) .....................................................................................1

1.4 USE and LIMITATIONS................................................................................................................................2

1.4.1 Exposure........................................................................................................................................................2

1.4.2 Exposure Limits.............................................................................................................................................2

1.4.3 Toxicity...........................................................................................................................................................3

1.4.4 Noise..............................................................................................................................................................3

1.4.5 Turbulence.....................................................................................................................................................3

1.4.6 Chilling...........................................................................................................................................................3

1.4.7 Visibility..........................................................................................................................................................3

1.4.8 Pressure ........................................................................................................................................................3

1.5 AGENT STORAGE CONTAINERS..............................................................................................................4

1.5.1 Rupture Disc..................................................................................................................................................4

1.5.2 Containers w/ 1” (25mm) Valve.....................................................................................................................5

1.5.3 Containers w/ 2 ½” (65mm) Valve.................................................................................................................7

1.5.3.1 Floor Mounting Kits.................................................................................................................................8

1.5.4 Containers w/ 3” (80mm) Valve.....................................................................................................................9

1.5.4.1 Mounting Straps....................................................................................................................................10

1.6 ITEMS FURNISHED W/ CONTAINERS.....................................................................................................11

1.6.1 Nameplate ...................................................................................................................................................11

1.6.2 Siphon Tube ................................................................................................................................................11

1.6.3 Victaulic Coupling & Nipple .........................................................................................................................11

1.6.4 Pressure Gauge ..........................................................................................................................................11

1.6.5 Pressure Gauge Adapter.............................................................................................................................12

1.6.6 Agent Fill Valve............................................................................................................................................12

1.6.7 Agent Release Module (ARM).....................................................................................................................13

1.6.8 Mounting Hardware For GCA & ARM .........................................................................................................13

1.7 GAS CARTRIDGE ACTUATOR (GCA) .....................................................................................................14

1.8 CONTAINER ACCESSORIES....................................................................................................................15

1.8.1 Liquid Level Indicator (LLi) ..........................................................................................................................15

1.8.2 Low Pressure Switch...................................................................................................................................16

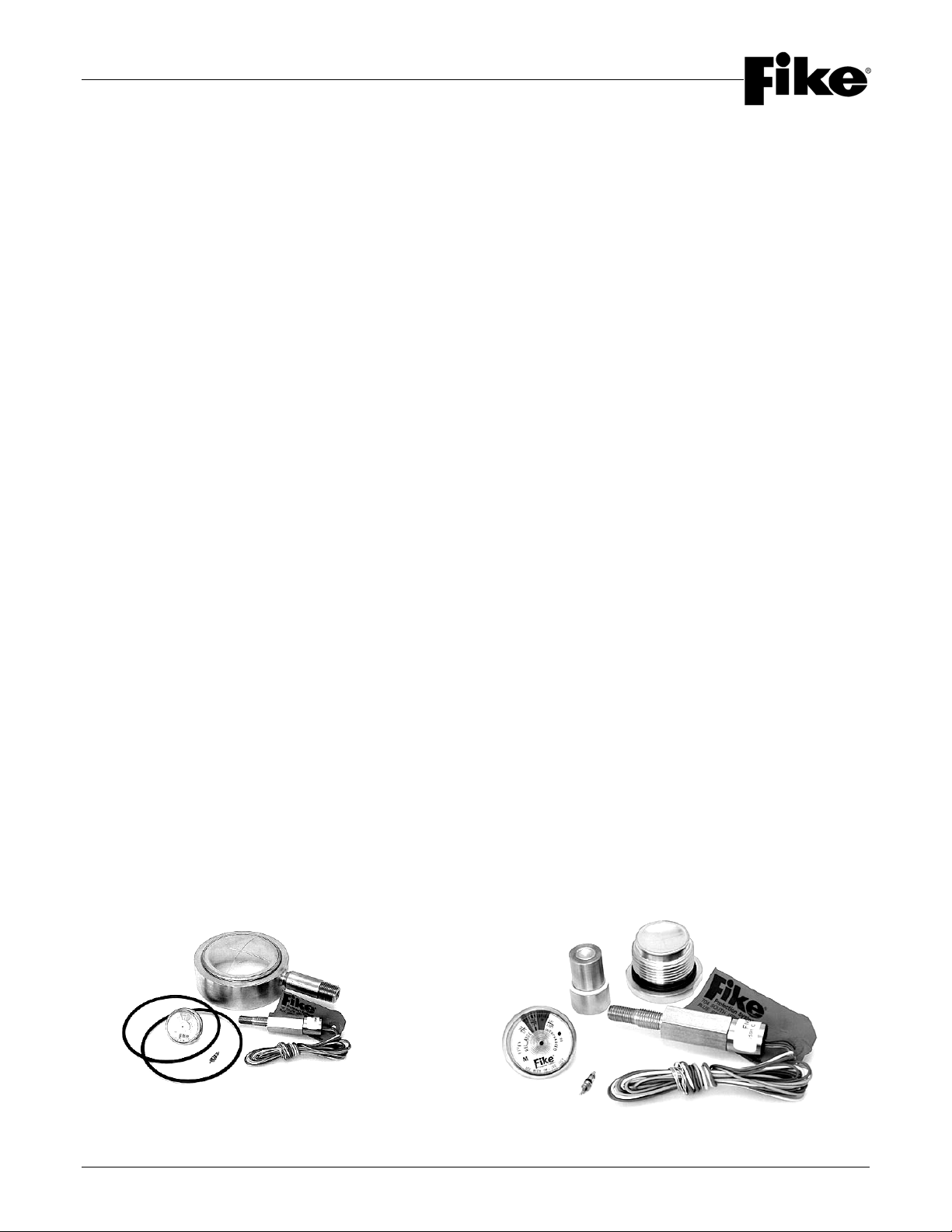

1.8.3 Reload Kits ..................................................................................................................................................16

1.8.3.1 Reload Kit – 1” Valve ............................................................................................................................17

1.8.3.2 Reload Kit – 2½ “ Valve ........................................................................................................................18

1.8.3.3 Reload Kit – 3” Valve ............................................................................................................................19

1.9 CONTAINER ORDERING FORMAT..........................................................................................................20

TABLE OF CONTENTS

Manual P/N: 06-215 (Rev G)

1.10 DISCHARGE NOZZLES.............................................................................................................................21

1.10.1 Pre-Engineered Discharge Nozzles............................................................................................................21

1.10.2 Engineered Discharge Nozzles...................................................................................................................22

1.10.3 Nozzle Ordering Format for Engineered Discharge Nozzles......................................................................22

1.11 CHECK VALVES ........................................................................................................................................23

1.12 CAUTION / ADVISORY SIGNS..................................................................................................................24

1.12.1 Do Not Enter Sign........................................................................................................................................24

1.12.2 Exit Sign.......................................................................................................................................................24

1.12.3 Do Not Enter Sign........................................................................................................................................24

1.12.4 System Abort Sign.......................................................................................................................................24

1.12.5 System ReleaseSign...................................................................................................................................24

1.12.6 Main/Reserve Sign......................................................................................................................................24

1.13 CONTROL SYSTEM & ACCESSORIES....................................................................................................25

1.13.1 Control Panels.............................................................................................................................................25

1.13.2 Manual Acturator.........................................................................................................................................25

SECTION 2 – SYSTEM DESIGN...............................................................................................................39 PAGES

2.1 DETERMINE HAZARD TYPE.......................................................................................................................1

2.2 DETERMINE CONCENTRATION PERCENTAGE ......................................................................................1

2.2.1 Class "A" or "C" Hazards – Automatically Activated .....................................................................................1

2.2.2 Class "A" or "C" Hazards – Manually Activated ............................................................................................1

2.2.3 Class B Flammable Liquids-Automatically or Manually Activated System ...................................................2

2.3 SAFETY RECOMMENDATIONS..................................................................................................................2

2.3.1 Normally Occupied Spaces...........................................................................................................................2

2.3.2 Normally Non-Occupied Spaces...................................................................................................................2

2.3.3 All Spaces......................................................................................................................................................2

2.4 DETERMINE AGENT QUANTITY ................................................................................................................3

2.4.1 Determine The Hazard Volume.....................................................................................................................3

2.4.2 Calculate Agent Required..............................................................................................................................3

2.4.3 Additional Considerations..............................................................................................................................6

2.4.3.1 Tee Design Factor ..................................................................................................................................6

2.4.3.2 Altitude Correction Factors .....................................................................................................................8

2.4.3.3 Determine Actual Concentration at Maximum Temperature ..................................................................8

2.4.3.4 Leakage ..................................................................................................................................................9

2.5 SYSTEM DESIGN CONCEPT ....................................................................................................................10

2.5.1 Pre-Engineered Systems Concept..............................................................................................................10

2.5.2 Engineered Systems Concept.....................................................................................................................10

2.5.3 Modular Systems.........................................................................................................................................10

2.5.4 Central Storage Systems.............................................................................................................................10

TABLE OF CONTENTS

Manual P/N: 06-215 (Rev G)

2.6 CONTAINER SELECTION..........................................................................................................................11

2.6.1 Container Size and Fill Range.....................................................................................................................11

2.6.2 Container Location(s)..................................................................................................................................12

2.6.3 Storage Temperature Limitations................................................................................................................12

2.7 NOZZLE SELECTION.................................................................................................................................13

2.7.1 System Type................................................................................................................................................13

2.7.2 Nozzle Flow Rates.......................................................................................................................................13

2.7.2.1 Engineered Nozzles..............................................................................................................................14

2.7.3 Nozzle Area Coverage ................................................................................................................................14

2.7.4 Nozzle Placement........................................................................................................................................15

2.7.4.1 Ceiling Heights Greater Than 16'-0" (4.9 m).........................................................................................16

2.7.5 Nozzle Discharge Obstructions...................................................................................................................17

2.8 PIPING NETWORK LIMITATIONS (ENGINEERED SYSTEMS)...............................................................18

2.8.1 Tee Split Ratios ...........................................................................................................................................18

2.8.1.1 Bullhead Tee.........................................................................................................................................18

2.8.1.2 Side-Thru Tee.......................................................................................................................................18

2.8.2 Maximum Elevation Differences in Pipe Runs ...........................................................................................19

2.8.3 Tee Orientation............................................................................................................................................20

2.8.4 Estimating Pipe Size (Engineered Systems)...............................................................................................21

2.8.4.1 Discharge Duration ...............................................................................................................................21

2.8.4.2 Minimum Flow Rates ............................................................................................................................21

2.8.5 Minimum Piping Distance (Engineering Systems)......................................................................................22

2.8.5.1 Distance from a Tee to an Elbow or Tee..............................................................................................22

2.8.5.2 Distance from an Elbow to a Tee..........................................................................................................22

2.8.6 Equivalent Length Values............................................................................................................................23

2.9 ENGINEERED SYSTEM DESIGN LIMITS.................................................................................................24

2.9.1 Percent of Agent In Pipe..............................................................................................................................24

2.9.2 Location of First Tee....................................................................................................................................24

2.9.3 Liquid Arrival Time.......................................................................................................................................25

2.9.4 Liquid Runout Time .....................................................................................................................................25

2.10 MANIFOLD OPTIONS (ENGINEERED SYSTEMS)...................................................................................26

2.11 PER-ENGINEERED SYSTEMS DESIGN...................................................................................................29

2.11.1 Piping Layout...............................................................................................................................................29

2.11.2 Determining Pipe Sizes...............................................................................................................................29

2.11.2.1 Single Nozzle Piping Table – 35 lb. thru 215 lb. Containers ................................................................30

2.11.2.2 Two Nozzle Piping Table – 60 lb. thru 375 lb. Containers....................................................................31

2.11.2.3 Four Nozzle Piping Table – 60 lb. thru 375 lb. Containers...................................................................32

TABLE OF CONTENTS

Manual P/N: 06-215 (Rev G)

2.11.3 Determining the Total Pressure Drop (TPD)...............................................................................................33

2.11.3.1 Piping Layout Diagram......................................................................................................................... 33

2.11.3.2 Total Pressure Drop (TDP) Calculation................................................................................................34

2.11.3.2-A Single Nozzle Factors Table ..........................................................................................................34

2.11.3.2-B Two Nozzle Factors Table..............................................................................................................36

2.11.3.2-C Four Nozzle Factors Table.............................................................................................................38

SECTION 3 – SAMPLE PROBLEM...........................................................................................................17 PAGES

3.1 DETERMINE HAZARD VOLUME.................................................................................................................1

3.2 CALCULATE AGENT REQUIRED.............................................................................................................. 2

3.2.1 Determine Concentration At Maximum Temperature................................................................................... 2

3.3 ESTABLISH SYSTEM CONCEPT ...............................................................................................................3

3.3.1 Container Selection.......................................................................................................................................3

3.3.2 Nozzles Required..........................................................................................................................................3

3.4 LAYOUT PIPING NETWORK.......................................................................................................................5

3.5 SAMPLE FLOW CALCULATION.................................................................................................................7

SECTION 4 – SYSTEM INSTALLATION ..................................................................................................21 PAGES

4.1 AGENT STORAGE CONTAINERS..............................................................................................................1

4.1.1 Mounting Details for Vertical / Horizontal Containers....................................................................................1

4.1.1.1 Mounting Details 20 lb. & 35 lb. (8L & 15L) Container ...........................................................................2

4.1.1.2 Mounting Details 60 lb. (27 L) Container................................................................................................3

4.1.2 Mounting Details for Inverted (Spherical) Containers ...................................................................................4

4.1.2.1 Mounting Details 125 lb. (51 L) Container..............................................................................................4

4.1.2.2 Mounting Details 215 lb. (90 L) Container..............................................................................................5

4.1.3 Mounting Details for Vertical (Upright) Containers........................................................................................6

4.2 DISCHARGE PIPING CONNECTIONS........................................................................................................7

4.2.1 1" (25mm) Valve Connections.......................................................................................................................7

4.2.2 2-1/2" (65mm) Valve Connections.................................................................................................................7

4.2.3 3" (80mm) Valve Connections.......................................................................................................................8

4.3 MANIFOLDS………………………………………………………………….......................................................8

4.3.1 1" NPT Check Valve Installation..................................................................................................................10

4.3.2 2" NPT Check Valve Installation..................................................................................................................10

4.3.3 3" NPT Check Valve Installation..................................................................................................................10

4.4 PIPING AND FITTING MATERIALS ..........................................................................................................11

4.4.1 Pipe Size Changes......................................................................................................................................12

4.4.1.1 Pipe Size Change at a Tee...................................................................................................................12

4.4.1.2 Pipe Size Change at an Elbow .............................................................................................................12

4.4.1.3 Pipe Size Change at a Coupling...........................................................................................................12

4.4.2 Installing Main Discharge Piping.................................................................................................................12

TABLE OF CONTENTS

Manual P/N: 06-215 (Rev G)

4.5 NOZZLE INSTALLATION...........................................................................................................................13

4.5.1 360°Nozzles ...............................................................................................................................................14

4.5.2 180°Nozzles ...............................................................................................................................................14

4.5.3 Nozzle Set Screw Installation......................................................................................................................14

4.6 GAS CARTRIDGE ACTUATOR (GCA) / AGENT RELEASE MODULE (ARM) .......................................15

4.6.1 2-1/2" (65 mm) Valve (Inverted Container) GCA Installation......................................................................15

4.6.2 1" & 3" (25 mm & 80 mm) Valve GCA Installation.......................................................................................16

4.7 CONTAINER ELECTRICAL CONNECTIONS ...........................................................................................17

4.7.1 Gas Cartridge Actuator (GCA) Safety Recommendations..........................................................................18

4.7.2 Gas Cartridge Actuator (GCA) Installation Procedure ................................................................................19

4.8 LOW PRESSURE SWITCH........................................................................................................................20

4.8.1 Low Pressure Switch Wiring........................................................................................................................21

SECTION 5 – FINAL SYSTEM CHECKOUT...............................................................................................2 PAGES

5.1 HAZARD AREA CHECK ……………...........................................................................................................1

5.1.1 Area Configuration.........................................................................................................................................1

5.1.2 Area Leakage ……........................................................................................................................................1

5.1.3 Enclosure Integrity - Door Fan Testing..........................................................................................................1

5.2 CONTAINERS ………………........................................................................................................................2

5.3 DISCHARGE PIPING ………........................................................................................................................2

5.4 NOZZLES......................................................................................................................................................2

5.5 AUXILIARY FUNCTIONS …….....................................................................................................................2

SECTION 6 – SYSTEM MAINTENANCE....................................................................................................3 PAGES

6.1 DISCHARGE PIPING....................................................................................................................................1

6.2 DISCHARGE NOZZLES...............................................................................................................................1

6.3 AGENT STORAGE CONTAINERS..............................................................................................................1

6.4 GAS CARTRIDGE ACTUATORS.................................................................................................................2

6.5 CONTAINER TEST AND INSPECTION.......................................................................................................2

6.6 PRESSURE GAUGE & LOW PRESSURE SWITCH MAINTENANCE .......................................................3

6.6.1 Replacing a Pressure Gauge or Low Pressure Switch.................................................................................3

6.6.2 Adding a Low Pressure Switch......................................................................................................................3

APPENDIX – MATERIAL SAFETY DATA SHEETS.................................................................................13 PAGES

Material Safety Data Sheet – HFC-227ea Agent .............................................................................. 8 Pages

Material Safety Data Sheet – Gas Cartridge Actuator (GCA)........................................................... 3 Pages

4BA Container Information................................................................................................................ 2 Pages

This page intentionally left blank

INTRODUCTION

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 1 of 1

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January, 2010

Fike is pleased to provide a “Design, Installation and Maintenance Manual” for our Clean Agent Fire Suppression

systems w/ FM-200™ agent. This document has been revised to incorporate the latest design requirements

found in NFPA Standard 2001, as well as the most up-to-date information available for our products.

This manual has been provided for those individuals that are responsible for the design, installation, and/or

maintenance of Fike Clean Agent Fire Suppression systems. Others such as architects, engineers, sales and

marketing personnel, etc. will find the information herein useful as well.

Fike offers two concepts of system design that are described within the following chapters.

1. Pre-Engineered Systems – These are simple “boilerplate” systems that operate within a pre-

determined set of criteria as tested and approved by Underwriters Laboratories Inc. These systems

do not require the designer to perform a complicated set of hydraulic flow calculations and they are

intended to provide a fast, easy means of designing systems.

2. Engineered Systems – These are the more complicated, elaborate systems that operate within a less

restrictive set of criteria as tested and approved by Underwriters Laboratories Inc. These systems

are designed within the basic parameters outlined in this manual, and their performance is evaluated

with the assistance of the Fike Flow Calculation Program.

Tests have shown that the Fike Flow Calculation Program can accurately determine the expected

performance of the Clean Agent Fire Suppression system when it is discharged. This provides the

system designer with the maximum degree of flexibility possible as it pertains to flow imbalance, tee

splits, piping configurations, etc.

Fike Clean Agent Fire Suppression systems must be installed and maintained in accordance with the limitations

established NFPA Standard no. 2001, Clean Agent Extinguishing Systems, as well as the limitations set forth by

Underwriters Laboratories Inc. The information contained within this manual defines these limitations in detail.

Enough information is incorporated into this manual to allow those responsible for designing Fike Clean Agent

Fire Suppression systems to properly do so, and for the parties responsible for verifying the system design to

determine if the design parameters have in deed been met.

The data contained within this manual is provided for informational purposes only. Fike believes this data to be

accurate; however, all dimensions are approximate and this document is presented without any guarantee or

warranty whatsoever.

Any questions concerning the information presented in this manual should be addressed to:

Fike Corporation

P.O. Box 610

Blue Springs, MO 64013

Phone: (816) 229-3405

Fax: (816) 229-5082

Webpage: www.fike.com

This page intentionally left blank

SECTION 1 – EQUIPMENT

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 1 of 25

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January, 2010

This section covers the hardware utilized by Fike Clean Agent Fire Suppression Systems, including the optional

items that are available. All of the information contained herein is believed to be accurate and up-to-date.

However, it should be noted that all dimensions shown are approximate and Fike reserves the right to make

adjustments as necessary.

1.1 AGENT

The extinguishing agent used in Fike Suppression Systems is Heptafluoropropane – more commonly known by its

ASHRAE designation: HFC-227ea. HFC-227ea is a colorless, odorless, liquefied compressed gas. (See the

Physical Properties Table below.) It is stored as a liquid, but dispensed into the hazard as a colorless,

electrically-nonconductive, gaseous vapor due to its relatively low boiling point. HFC-227ea has been tested and

verified to be safe for use in occupied spaces when used as specified in the U.S. EPA Significant New Alternative

Policy (SNAP) rules. Tests have proven that exposure to HFC-227ea is safe and effective in extinguishing fires at

low concentrations; most of which are well below the EPA’s maximum exposure levels. HFC- 227ea is approved

for use in occupied areas up to a 10.5% concentration by volume with mandated egress time of five (5) minutes.

1.2 PERFORMANCE

HFC-227ea’s mechanism of extinguishing fires is considered active. Its primary action is through physically

cooling the fire at the molecular level. HFC-227ea belongs to the same class of agents used in refrigeration and

as such, is an efficient heat transfer agent. HFC-227ea removes the thermal energy from the fire to the extent

where the combustion reaction cannot sustain itself. Additionally, there is a chemical action that provides a

secondary means of extinguishing the fire. Trace amounts of free radicals are released into the fire – thereby

inhibiting the chain reaction of combustion. HFC-227ea does not significantly reduce oxygen levels and is safe

for use in occupied spaces in accordance with the U.S. EPA guidelines. HFC-227ea can be removed from the

protected space by simple means of ventilation after discharge.

1.3 PHYSICAL PROPERTIES OF HFC-227ea (FM-200™)

Chemical Name 1,1,1,2,3,3,3-Heptafluoropropane

Chemical Formula CF CHFCF

CAS No. 431-89-0

Molecular Wt. 107.03

Boiling Point, 1 atm, oC (oF) -15.9

oF (3.9)

Freezing Point, oC (oF) -133 (-204)

Flammable Limits nonflammable

Critical Temperature, oC (oF) 101.6 (214.9)

Critical Pressure, kPa (psia) 2930.6 (424.7)

Critical Density, kg/m3(lb/ft3) 621 (38.77)

Liquid Density @ 25oC (77oF), kg/m3(lb/ft3) 1386 (86.53)

Vapor Density @ 25 oC (77oF) and 1atm, kg/m3(lb/ft3) 7.148 (0.4462)

Specific Heat, Liquid (Cp) @ 25oC (77oF), kJ/kg-oC (Btu/lboF) 1.247 (0.2979)

Specific Heat, Vapor (Cp) @ 25oC (77oF), kJ/kg-oC (Btu/lboF) and 1 ATM 0.8136 (0.1945)

Vapor Pressure, Saturated @ 25oC (77oF), kPa (psia) 453.3 (65.7)

Heat of Vaporization @ B.P., kJ/kg (Btu/lb) 132.6 (56.7)

Thermal Conductivity, Liquid @ 25oC (77oF),W/m-oC (Btu/hr-ftoF) 0.0533 (0.0308)

Thermal Conductivity, Vapor @ 25oC (77oF),W/m-oC (Btu/hr-ftoF) 0.0127 (0.0073)

Viscosity, Liquid (lb/ft-hr) @ @ 25oC (77oF), cP (lb/ft-hr) 0.2442 (0.5907)

Relative dielectric strength @ 1atm, 25oC (N2 =1) 2.00

Solubility of Water in HFC-227ea @ 20oC (68oC ), ppm 600

Ozone Depletion Potential 0.0 (CFC-11 = 1)

Global Warming Potential, GWP (100 yr. ITH. For CO2, GWP = 1) 2900

Atmospheric Lifetime, years 36.5

TSCA Inventory Status Reported, Included

European List of New Chemical Substances EINECS, Listed (207-079-2)

SNAP Status Listed

Inhalation Exposure Limit TLV Not Established DuPont AEL = 1000

ppm 8 hr & 12 hr TWA

SECTION 1 – EQUIPMENT

Page 2 of 25 Fike Clean Agent System w/ FM-200™ UL / ULC Ex4623

Revision Date: January, 2010 Manual P/N: 06-215 (Rev G) FM 3010715

1.4 USE AND LIMITATIONS

Fike HFC-227ea Systems must be designed and installed in accordance with the requirements outlined in this

manual, and in accordance with the requirements of the Standard for Clean Agent Extinguishing Systems, NFPA

2001, latest edition. HFC-227ea systems are primarily used to protect hazards that are enclosed; this provides a

means to establish and maintain an effective extinguishing concentration. Typical hazards that can be protected

include the following.

Electrical and electronic hazards

Telecommunications facilities

Storage Rooms – Flammable liquids and gases

High value assets, where the associated down-time would be costly

HFC-227ea systems shall NOT be used on fires involving the following materials.

Chemicals or mixtures of chemicals which are capable of rapid oxidation in the absence of air. Examples

include Cellulose Nitrate and Gunpowder.

Reactive metals such as Lithium, Sodium, Potassium, Magnesium, Titanium, Zirconium, Uranium, and

Plutonium

Metal hydrides such as Sodium Hydride and Lithium Aluminum Hydride

Chemicals capable of undergoing auto thermal decomposition. Examples include Organic Peroxides and

Hydrazine.

1.4.1 EXPOSURE

Although HFC-227ea is considered to be non-toxic, the EPA has established the guidelines controlling the

amount (concentration) of agent provided for the protected area. Based on PBPK modeling, the EPA allows

HFC-227ea for use where people are normally present (normally occupied spaces) up to concentration of 10.5%

by volume with exposure limited to 5 minutes or less.

WARNING: The discharge of clean agent systems to extinguish a fire can result in potential hazard to

personnel from the natural form of the clean agent or from the products of combustion that result

from exposure of the agent to the fire or hot surfaces. Unnecessary exposure of personnel either

to the natural agent or to the products of decomposition shall be avoided.. The requirement for

pre-discharge alarms and time delays are intended to prevent unnecessary exposure to humans

where their presence is not critical to the operation of the area being protected. Suitable

safeguards shall be provided to ensure prompt evacuation of (and prevent entry into) protected

areas after discharge.

1.4.2 EXPOSURE LIMITS

HFC-227ea systems provided for Normally Occupied Spaces can be designed for concentrations above to the

NOAEL level of 9% by volume, given that means be provided to limit exposure to design concentrations shown in

Table 1.4 that correspond to a maximum permitted human exposure time of five (5) minutes.

HFC-227ea

Concentration ppm Human Exposure

Time (minutes)

9.0% 90,000 5.00

9.5% 95,000 5.00

10.0% 100,000 5.00

10.5% 105,000 5.00

11.0% 110,000 1.13

11.5% 115,000 0.60

12.0% 120,000 0.49

TABLE 1.4

SECTION 1 – EQUIPMENT

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 3 of 25

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January, 2010

HFC-227ea systems provided for Normally Non-Occupied Spaces can be designed for concentrations in

excess of the LOAEL concentration of 10.5%. Where a possibility exists for personnel to be exposed, means

shall be provided to limit exposure times in accordance with the above table. In the absence of the information

needed to fulfill the conditions listed above, the following provisions shall apply.

Where egress takes longer than 30 seconds but less than 1 minute, the HFC-227ea system shall not

be designed for a concentration exceeding the LOAEL of 10.5% by volume.

Where egress takes less than 30 seconds, the HFC-227ea system can be designed for a

concentration that exceeds the LOAEL of 10.5% by volume.

1.4.3 TOXICITY

With a database in excess of 70 toxicity tests, HFC-227ea has been extensively tested and approved by

institutions and agencies around the world. The LC50 toxicity rating for HFC-227ea is greater than 800,000 ppm.

When you consider that most HFC-227ea systems are designed for concentrations providing 105,000 ppm or

less, it is evident that HFC- 227ea is safe to use.

HFC-227ea will decompose to form halogen acids when exposed to extremely high temperatures. The formation

of these acids is minimized by using fast-acting Fike detection and control systems, and proper system design

and installation of the piping system to deliver the agent quickly. The generation of by-products from the HFC-

227ea discharge will be minimal when properly applied.

1.4.4 NOISE

The high-pressure discharge from the nozzle(s) of a system can cause noise that is loud enough to be startling,

but ordinarily insufficient to cause traumatic injury.

1.4.5 TURBULENCE

The high velocity discharge from the nozzle(s) can be sufficient enough to dislodge substantial objects located

directly in the discharge path. Enough general turbulence may be created within the enclosure to move

unsecured paper and light objects.

1.4.6 1.4.6 CHILLING

Direct contact with the vaporizing agent being discharged from the nozzle(s) will have a chilling effect on objects

and can cause cryogenic burns to the skin. The liquid phase vaporizes rapidly when mixed with air, thus limiting

the hazard to the immediate vicinity of the discharge nozzle.

1.4.7 VISIBILITY

Although HFC-227ea is odorless, discharging the agent into a humid atmosphere may cause a reduction in

visibility for a brief period of time due to condensation of water vapor normally present in the room atmosphere.

1.4.8 PRESSURE

The normal operating pressure of a Fike HFC-227ea clean agent extinguishing system unit is 360 psig @ 70oF

(24.8 bar @21oC). This is accomplished by adding a charge of nitrogen to the HFC-227ea agent. Since these

are pressurized vessels, care must be observed when handling, filling and transporting storage containers. The

anti-recoil devices (baffle plugs or baffle plates) MUST be in place whenever the charged container is removed

from the piping network.

SECTION 1 – EQUIPMENT

Page 4 of 25 Fike Clean Agent System w/ FM-200™ UL / ULC Ex4623

Revision Date: January, 2010 Manual P/N: 06-215 (Rev G) FM 3010715

1.5 AGENT STORAGE CONTAINERS

The Agent Storage Container is a steel pressure vessel designed to hold the HFC-227ea under pressure until it is

discharged. All Fike HFC-227ea Containers are suitable for use at storage temperatures of +32oF to +130oF (0oC

to 54.4oC). Each container is manufactured in strict accordance with Department of Transportation / Transport

Canada (DOT / TC) regulations and undergoes extensive pressure and leak testing before shipment to the field.

All Fike HFC-227ea Containers are shipped from the factory fitted with an anti-recoil device installed in the

discharge valve outlet – in accordance with DOT / TC requirements. The anti-recoil device ensures the contents

of the pressurized container will be released in a slow, controlled, rate of discharge if the valve is opened during

the shipping and handling process. HFC-227ea Containers are filled with agent within the allowable range of 40

lbs/ft3to 70 lbs./ft3(640 kg/m3to 1121 kg/m3) of container volume in accordance with DOT / TC requirements. All

containers are filled in 1 lb. (0.5 kg) increments to the user-specified level defined for each container. Each HFC-

227ea container is super-pressurized with dry nitrogen to a working pressure of 360 psig at 70oF (24.8 bar at

21oC) after filling. Fike HFC-227ea Containers are available in twelve different sizes (capacities). Each container

includes a discharge outlet valve, fill valve, pressure gauge, mounting bracket or mounting strap(s), agent release

module, and provisions for the accessories available for that particular container size and/or style.

The Discharge Outlet Valve is a rupture disc (metal diaphram), pressure operated device that allows the agent to

be released from the container and into the protected space via the associated piping network and nozzle(s). The

Discharge Outlet Valve can be either welded or threaded to the Agent Storage Container (except for the 125i &

215i containers available with welded valves only).

Activation of the Discharge Outlet Valve is accomplished by one of two methods.

Standard operation of the valve is accomplished by a Gas Cartridge Actuator (GCA) that produces

the pressure wave (energy) necessary to open the valve. The GCA is an electrically operated device

that is activated by a signal from the control panel or the optional manual actuator device.

If the contents of the container are subjected to temperatures exceeding 160oF (71oC), the pressure

associated with the thermal expansion of the agent will be sufficient to open the valve automatically.

NOTE: The Discharge Valve also fulfills the pressure relief valve requirements in accordance with DOT

regulations.

NOTE: Containers manufactured by Fike for use with HFC-227ea to DOT 4BA requirements can be found in

Appendix B.

1.5.1 RUPTURE DISC

The Rupture Disc is the heart of the Fike HFC-227ea Discharge Outlet Valve. Each is manufactured to exacting

tolerances and standards by Fike to ensure their reliability and performance. The Rupture Disc is a pre-scored

metal membrane formed into a domed shape and scored with four pressure-relief lines across the domed surface

at right angles to each other. When the pressure in the container rises to the pre-determined level, the rupture

disc will open along the score lines – thus allowing the contents to be released into the piping network. The four

segments of the rupture disc “fold back” during discharge to produce the minimum amount of flow restriction

possible.

SECTION 1 – EQUIPMENT

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 5 of 25

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January, 2010

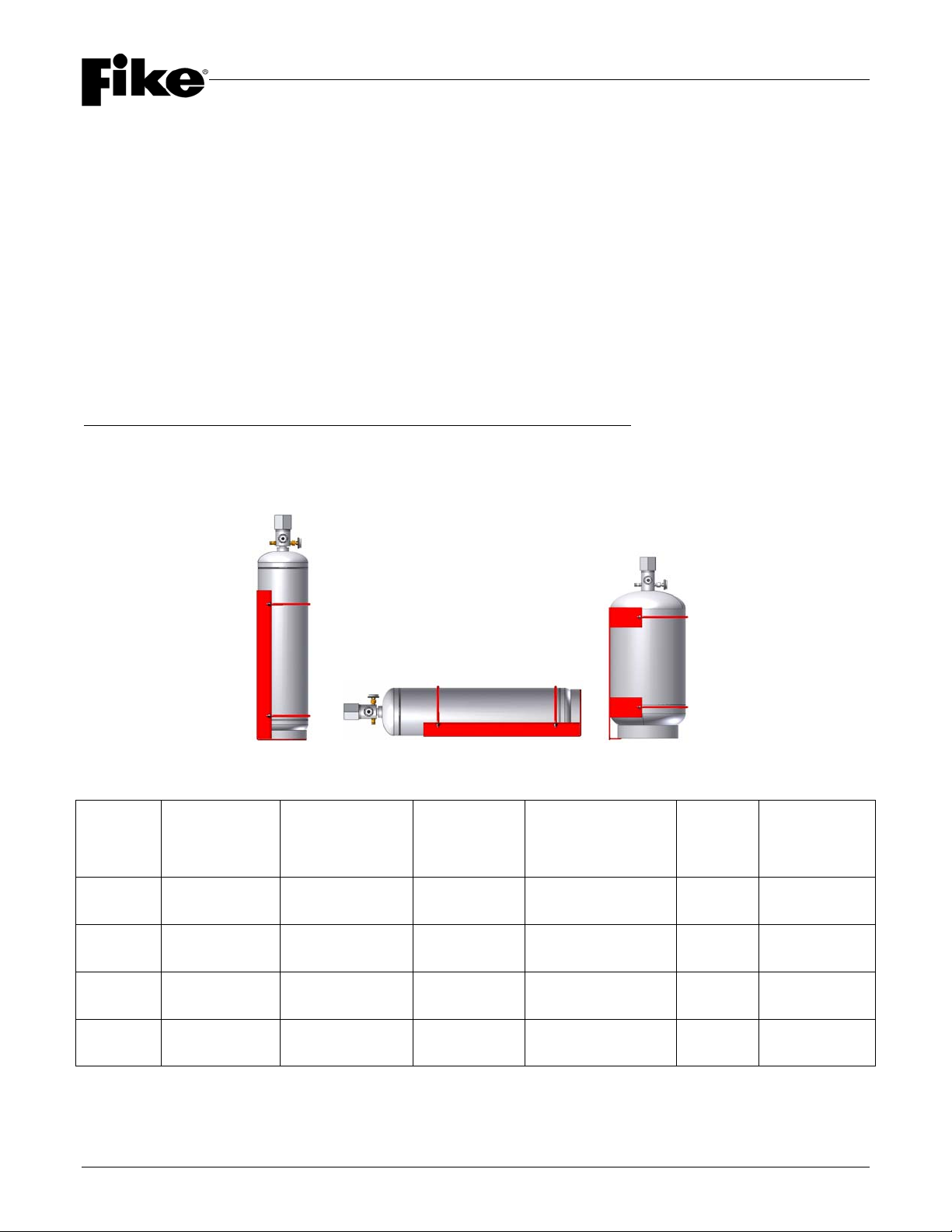

1.5.2 CONTAINERS – 1” (25 mm) VALVE

Containers are available in the following sizes (capacities): 20, 35, 60, and 100 lb. (8.5, 15, 27, and 44 L). Each

of these containers utilize a 1” NPT (25 mm) discharge outlet valve, consisting of a 1” (25 mm) rupture disc

assembly operated by a Gas Cartridge Actuator (GCA).

All containers are designed and fabricated in accordance with DOT 4BW500 requirements. Containers are also

available with dual markings that meet the requirement of both DOT and TC; the associated ratings for these

containers are 4BW500/4BWM500.

For ordering information, refer to Section 1.9 of this section.

Each container is supplied with a 1” NPT (25 mm) anti-recoil device (pipe plug) installed in the adapter nut (outlet)

of the discharge valve. The pipe plug supplied has a 1/8” (4 mm) hole drilled through the plug to allow the

container pressure to vent safely to atmosphere in the event that the discharge valve is activated prior to

installation.

The 20, 35 and 60 lb. (8.5, 15 and 27 L) containers can be mounted in either the horizontal or upright (valve up)

positions.

The 100 lb. (44 L) container MUST be installed in the upright (valve up) position. Horizontal mounting of the 100

lb. (44 L) container is not allowed. Mounting Brackets are supplied with each container, and each must be

anchored to an appropriate load-bearing structure.

NOTE: The 20 lb. (8.5 L) container (P/N 70-098) is approved for ENGINEERED Systems only.

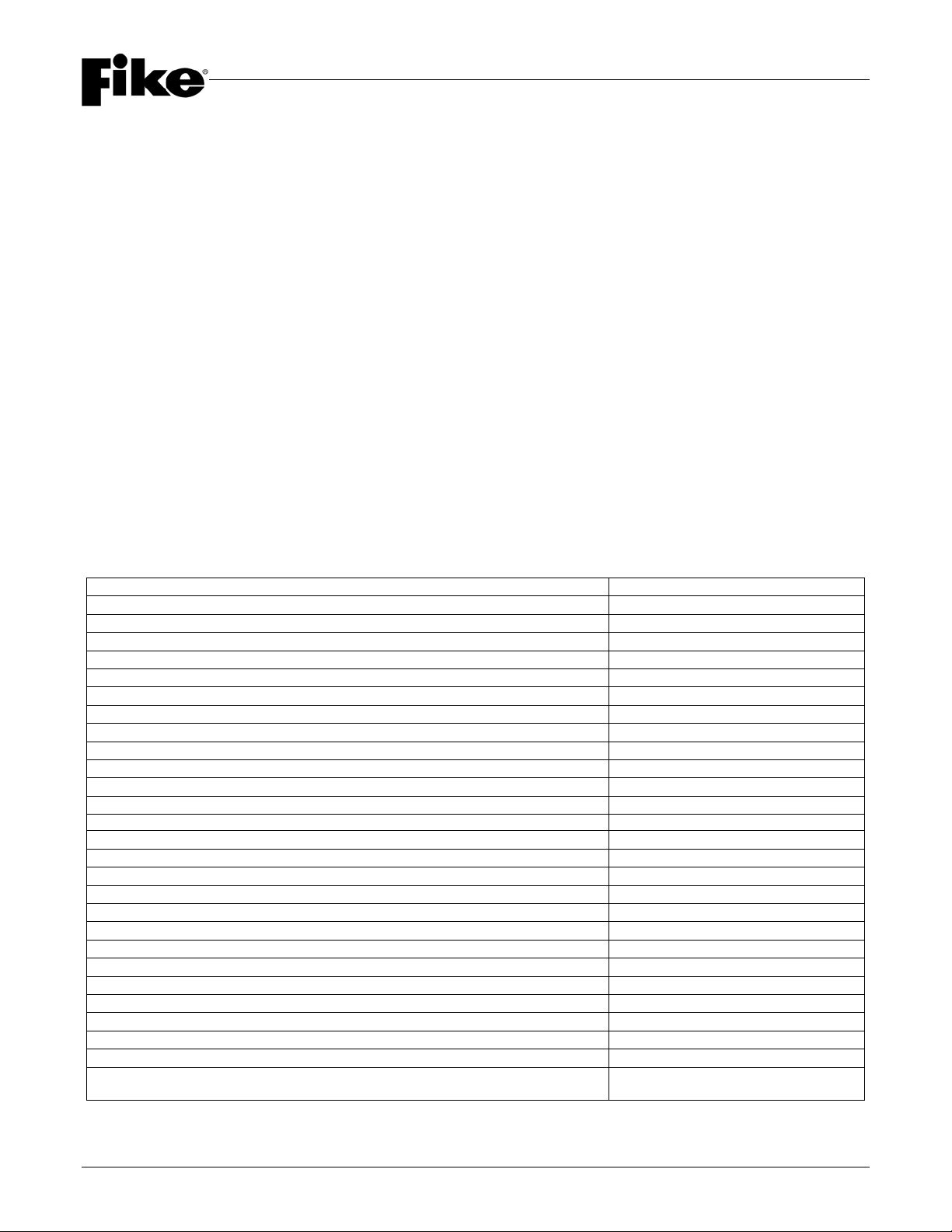

CONTAINER DATA TABLES

Container

Size

Container

Part Number

(w/ Welded Valve)

Container

Part Number

(w/ Threaded Valve)

Fill Range

lbs. (kg) Mounting

Position Valve

Size Approx.

Tare Weight

20 lb.

(8.5 L)

70-098 70-098T

12.0 – 21.0

(5.5 – 9.5) Upright - Horizontal 1” NPT

(25 mm) 21.0 lbs.

(9.5 kg)

35 lb.

(15 L)

70-089 70-089T

22.0 – 38.0

(10.0 – 17.0) Upright - Horizontal 1” NPT

(25 mm) 31.0 lbs.

(14.1 kg)

60 lb.

(27 L)

70-152 70-152T

39.0 – 68.0

(18.0 – 30.5) Upright - Horizontal 1” NPT

(25 mm) 43.0 lbs.

(19.5 kg)

100 lb.

(44 L)

70-153 70-153T

63.0 – 108.0

(28.5 – 48.5) Upright (Valve Up) 1” NPT

(25 mm) 61.0 lbs.

(27.7 kg)

SECTION 1 – EQUIPMENT

Page 6 of 25 Fike Clean Agent System w/ FM-200™ UL / ULC Ex4623

Revision Date: January, 2010 Manual P/N: 06-215 (Rev G) FM 3010715

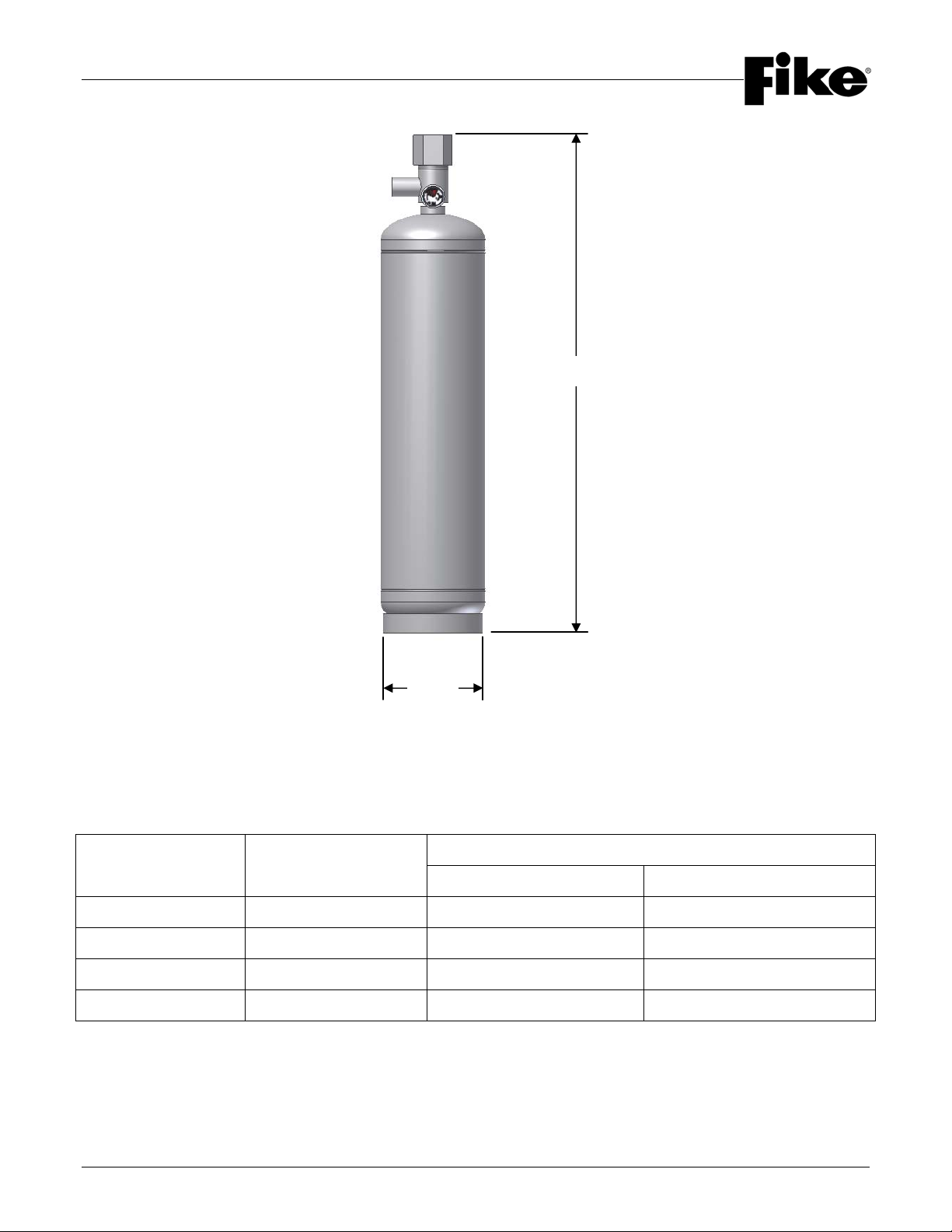

NOTE: All dimensions shown are approximate

Dimension “B”

Container Size Dimension “A” Container w/ Welded Valve Container w/ Threaded Valve

20 lb. (8.5 L) 7” (178 mm) 21-1/2” (546 mm) 23-1/2” (597 mm)

35 lb. (15 L) 7” (178 mm) 32-1/2” (826 mm) 35” (889 mm)

60 lb. (27 L) 10-3/4” (273 mm) 28” (711 mm) 29-1/4” (743 mm)

100 lb. (44 L) 10-3/4” (273 mm) 38-3/4” (984 mm) 40-3/4” (1035 mm)

“B”

“A”

SECTION 1 – EQUIPMENT

UL / ULC Ex4623 Fike Clean Agent System w/ FM-200™ Page 7 of 25

FM 3010715 Manual P/N: 06-215 (Rev G) Revision Date: January, 2010

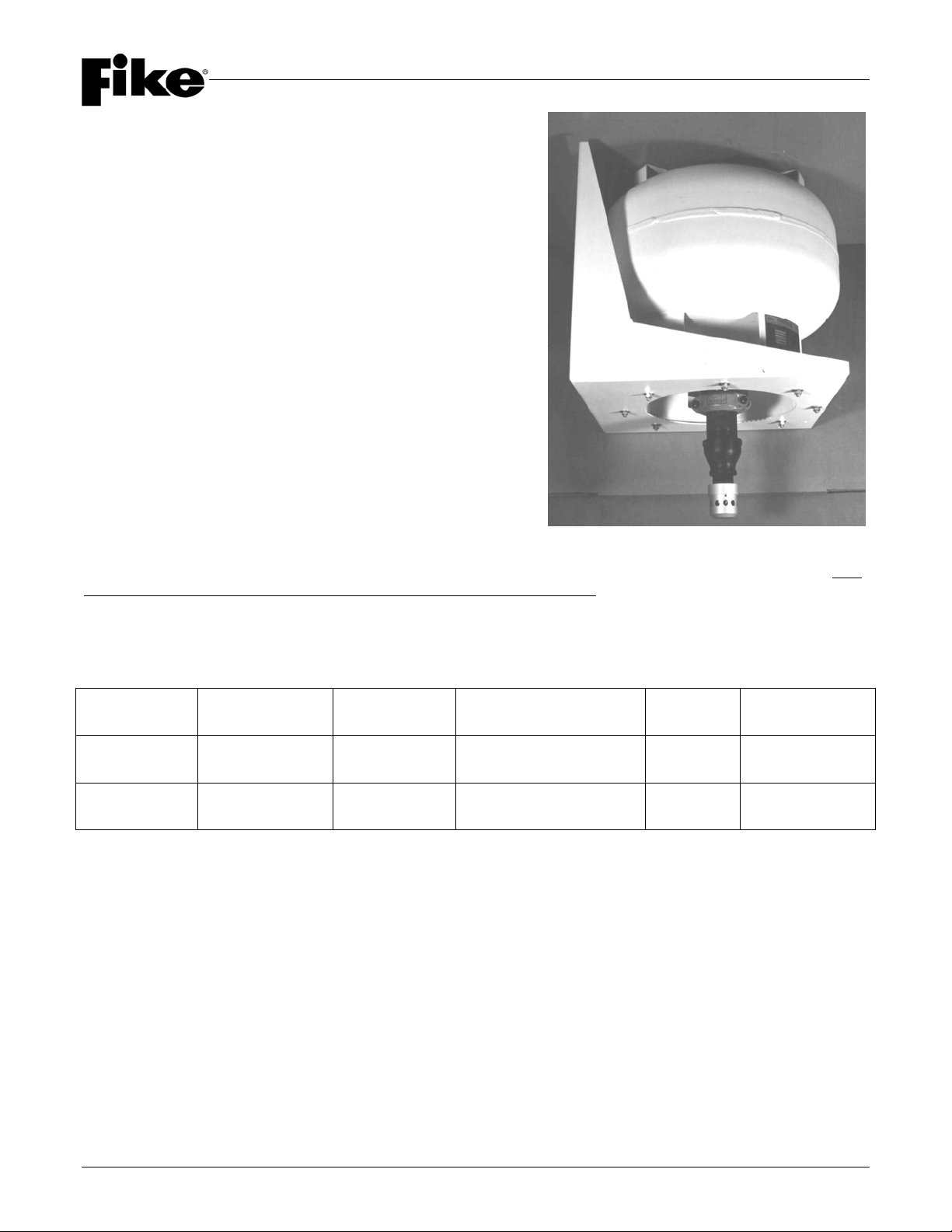

1.5.3 CONTAINERS w/ 2 ½” (65 mm) VALVE

Inverted (Spherical) HFC-227ea Containers are available in the

following sizes (capacities): 125 and 215 lb. (51 and 90 L). Both

of these containers utilize 2-1/2” NPT (65 mm) discharge outlet

valves, consisting of 2-1/2” (65 mm) rupture discs operated by

Gas Cartridge Actuators.

All containers are designed and fabricated in accordance with

DOT requirements. The associated rating is 4BA500.

Containers are also available with dual markings that meet the

requirement of both DOT and TC; the associated ratings for

these containers are 4BA500/4BAM500.

For ordering information, refer to Section 1.9 of this section.

Each container is supplied with 2-1/2” (65 mm) anti-recoil devices

consisting of a steel baffle plate with a 3/8” dia. (10 mm) hole

drilled through the plate. This allows the container pressure to

safely vent to atmosphere if the discharge valve is activated prior

to installation. The baffle plate is installed in the Grooved

Coupling attached to the discharge outlet valve.

The 125 and 215 lb. (51 and 90 L) Inverted Containers MUST be

installed in the valve down (inverted) position. Mounting Brackets

are supplied with each container, and each must be anchored to

an appropriate load-bearing structure.

Both containers are equipped with a Liquid Level Indicator Boss to install the optional Liquid Level Indicator. This

device must be installed prior to filling the container with HFC-227ea agent.

CONTAINER DATA TABLES

Container

Size

Container

Part Number Fill Range

(lbs.) Mounting

Position Valve

Size Approx.

Tare Weight

125 lb.

(51 L)

70-041 73 – 126

(33.5 – 57)

Inverted

(Valve Down)

2-1/2” NPT

(65 mm) 141.0 lbs.

(64.0 kg)

215 lb.

(90 L)

70-077 128 – 223

(58.5–101.0)

Inverted

(Valve Down)

2-1/2” NPT

(65 mm) 200.0 lbs.

(90.7 kg)

SECTION 1 – EQUIPMENT

Page 8 of 25 Fike Clean Agent System w/ FM-200™ UL / ULC Ex4623

Revision Date: January, 2010 Manual P/N: 06-215 (Rev G) FM 3010715

*All dimensions shown are approximate

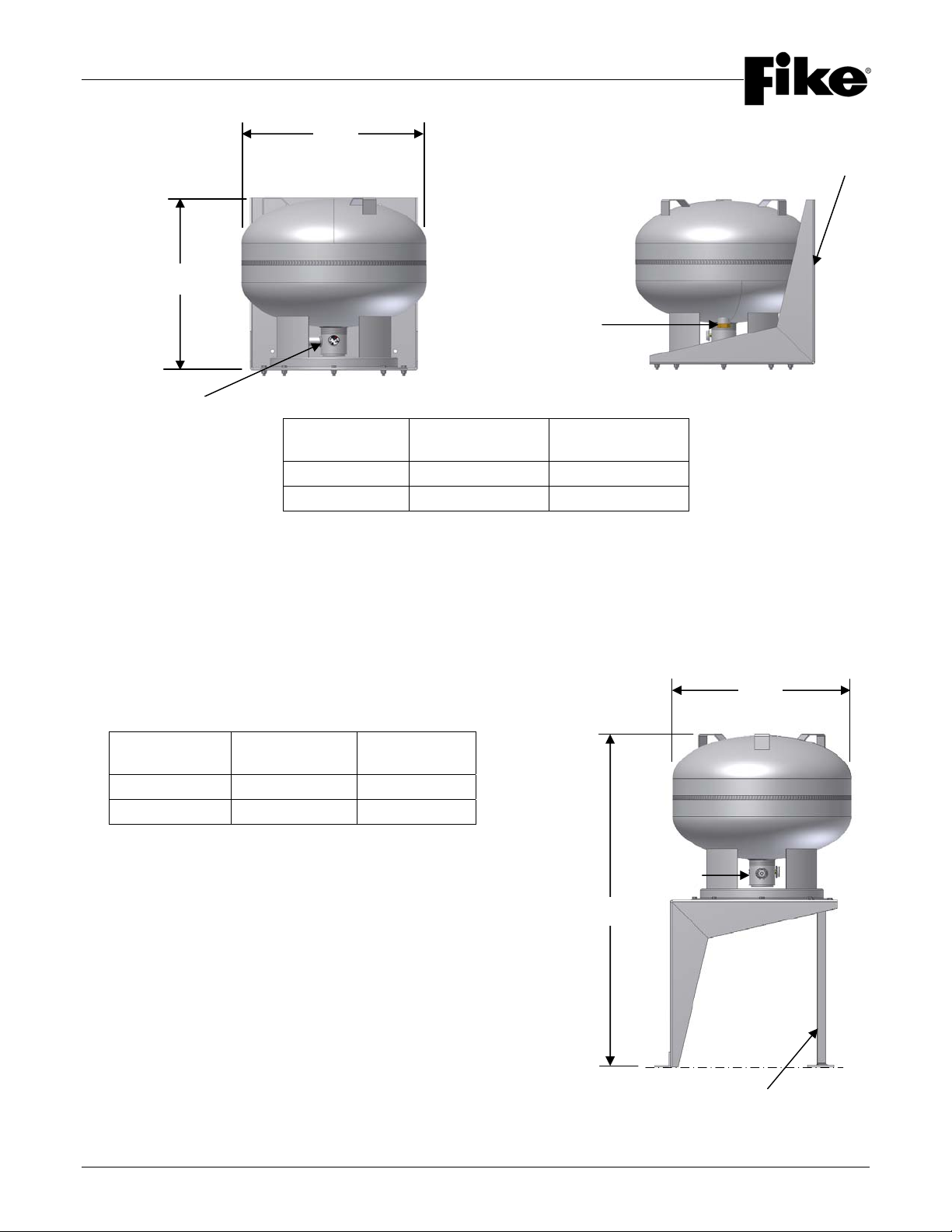

1.5.3.1 FLOOR MOUNTING KIT

An optional Floor Mounting Kit is available for the Inverted Containers that allows the container to be mounted

near the floor. Two kits are available as follows:

P/N 70-1197 Mounting Bracket – 125 lb. (51 L) Container

P/N 70-1198 Mounting Bracket – 215 lb. (90 L) Container

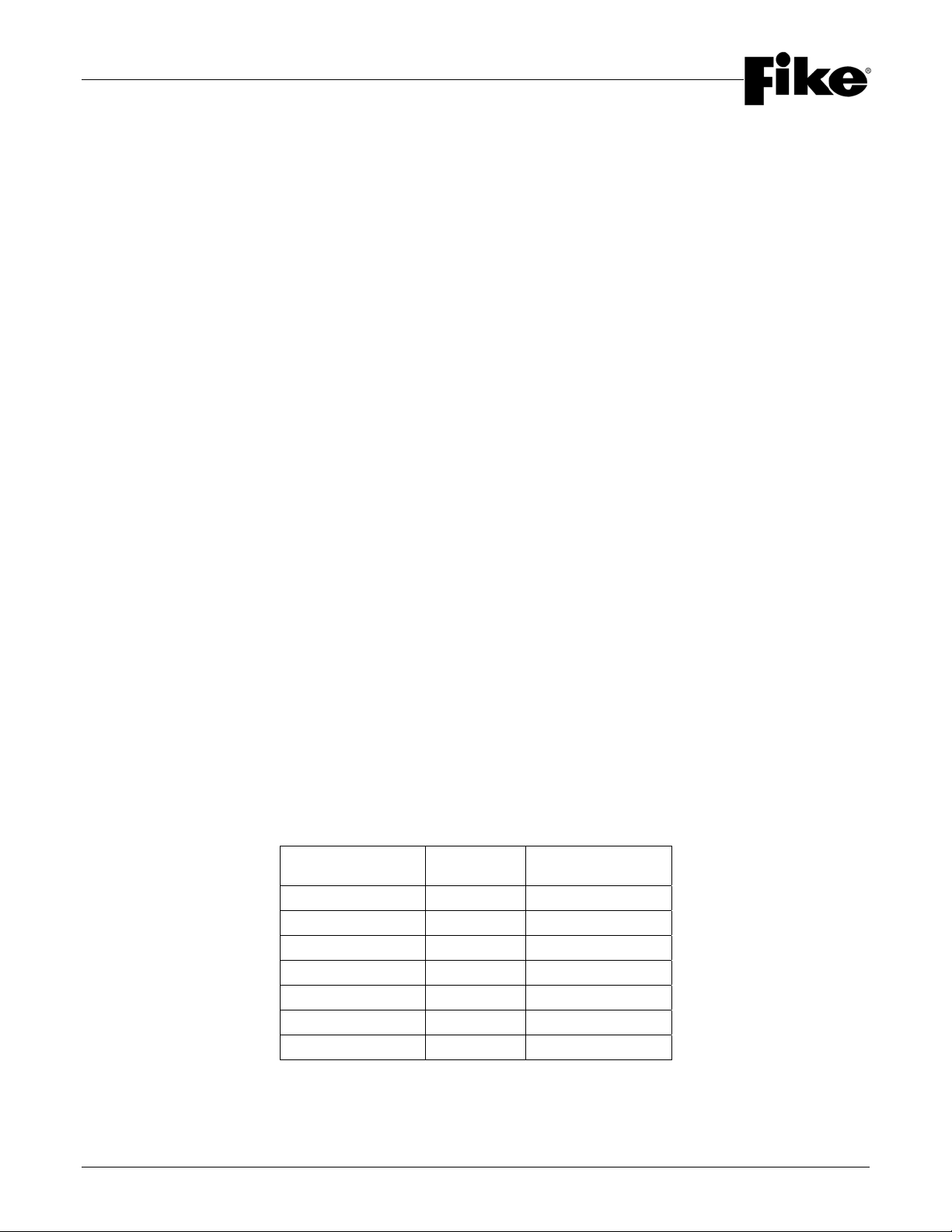

All dimensions shown are approximate

Container

Size Dim. “A”

inch (mm) Dim. “B”

inch (mm)

125 lb. (51 L) 20” (508 mm) 20-1/4” (515 mm)

215 lb. (90 L) 24” (610 mm) 23-3/4” (605 mm)

Container

Size Dim. “A”

inch (mm) Dim. “B”

inch (mm)

125 lb. (51 L) 22-1/2” (572) 39-3/4” (1010)

215 lb. (90 L) 26-1/4” (667) 45-3/4” (1162)

Li

q

uid Level Boss

Mounting Bracket

“A”

“B”

Outlet Valve

“B”

“A”

Mounting Surface 1 ½” (40mm) Pipe

Cut to 18 3/8” (46.67mm) Long

Outlet Valve

Table of contents

Popular Laboratory Equipment manuals by other brands

Ametek

Ametek Reichert XCEL 255 user guide

Teledyne Cetac Technologies

Teledyne Cetac Technologies ASX-500 Alignment procedure

Bio-Optica

Bio-Optica PF200 User and service manual

Mind Peak

Mind Peak WaveRider operating manual

Liquid Instruments

Liquid Instruments Moku:Go quick start guide

Phcbi

Phcbi MLS-3020U operating instructions