Flexicon PF7 User manual

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User

Manual

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 1

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

Contents

Section 1 - Safety notes and installation 8

1 Disclaimers 9

2 Declaration of conformity 10

3 Declaration of incorporation 11

4 Safety information 12

4.1 Definitions of symbols on the pump or pumphead 12

4.2 Intended purpose 12

4.3 Tube bridge open indicator 13

4.4 Shipping and handling 13

5 Peristaltic pumps - an overview 14

6 When you unpack your pump 15

6.1 Before storage 15

6.2 After storage 16

7 Lifting and carrying 17

8 Key features of QC14 pumphead 18

9 Pumphead mounting and removal 19

10 Installation position 20

11 Setting up the fluid path 21

11.1 Tube selection 21

11.2 Y-connector selection 22

11.3 Fluid path layout 23

12 Changing the tube 25

12.1 Maximising tube life 28

13 Connecting to a power supply 29

13.1 Checking and replacing the fuse 31

14 Control wiring 32

Section 2 - Pump operation 35

15 Pump controls and interface 39

15.1 Keypad operation 39

15.2 USB keyboard operation 40

15.3 USB devices 41

15.3.1 Compatible devices 41

15.3.2 USB device troubleshooting 42

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 2

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

3 PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual

15.4 Glossary of icons 42

16 Switching the pump on for the first time 45

16.1 Powering up 45

16.2 Language selection 46

16.3 Enable United States Food and Drug Administration (FDA) 21CFR

Part 11 Compliance 47

16.3.1 FDA 21CFR Part 11 compliant functions 47

16.4 Setting the time zone 48

16.5 Setting the filling method 49

16.6 Setting the pump administrator 50

16.7 Setting a password 50

17 Switching the pump on after initial setup 52

18 Log in 53

18.1 Select a user 53

18.2 Enter the username if FDA 21CFR Part 11 compliance is enabled 54

18.3 Entering your password 54

19 Menu navigation 56

20 Recipe mode 57

20.1 Load recipe 57

20.2 Create new recipe 58

20.3 Volume 58

20.4 Density 58

20.5 Tube size 58

20.6 Speed 59

20.7 Acceleration 59

20.8 Deceleration 59

20.9 Anti-drip 59

20.10 Start delay 60

20.11 End delay 60

20.12 First fill delay 60

20.13 Between fill delay 60

20.14 Vial weight 61

20.15 Vial weight tolerance 61

20.16 Weigh check frequency 62

20.17 Fill tolerance 63

20.17.1 Setting fill tolerance limits 64

20.18 Auto-recalibration tolerance 65

20.19 Recalibration reminder 65

20.20 Recalibration pause 65

20.21 Protected recipe 66

20.22 Save recipe 66

20.23 Print recipe 66

20.24 Delete recipe 66

21 Priming and continuous pumping mode 67

21.1 Prime slow and Prime fast 68

21.2 Continuous pumping 68

21.3 Fluid recovery 69

21.4 Priming the pump 69

21.4.1 Eliminating trapped air from the tube 69

22 Calibrate mode 70

22.1 Single-fill calibration with a balance connected 71

22.1.1 Calibration value entry 71

22.1.2 Calibration summary 72

22.2 Single-fill calibration without a balance connected 73

22.2.1 Calibration summary 74

22.3 Multi-fill calibration with a balance connected 75

22.3.1 Calibration summary 77

22.4 Multi-fill calibration without a balance connected 78

22.4.1 Calibration summary 80

23 Dispense mode 81

23.1 Batch size 81

23.2 Batch name 81

23.3 Start manual batch 82

23.3.1 Calibration whilst dispensing 83

23.3.2 Auto-recalibration 85

23.3.3 Pausing a batch 87

23.3.4 Calibration whilst paused 88

23.3.5 Add note to report 89

23.3.6 Fluid sample 90

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 4

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

5 PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual

23.3.7 End batch 90

23.4 Start Zero waste batch 91

23.4.1 Start Zero waste batch 94

23.4.2 Zero waste filling - weigh checked fill 95

23.4.3 Zero waste filling - non weigh checked fill 97

23.4.4 Pausing a Zero waste batch 98

23.4.5 Resuming a Zero waste batch 98

23.5 Test fill 99

23.6 Index filling machine 99

24 Reports mode 100

24.1 View batch report 101

24.2 Print batch report 103

24.3 Delete batch report 103

24.4 Export reports to USB flash drive 103

25 Settings mode 104

25.1 Log out 104

25.2 Filling method 104

25.3 Units 105

25.4 Language 105

25.5 Change password 105

25.6 Operator access restrictions 105

25.7 Supervisor access restrictions 108

25.8 Printer and balance 108

25.9 Default recipe 108

25.10 Session timeout period 109

25.10.1 Session timeout while pumping fluid 109

25.11 Password expiry duration 109

25.12 Users 110

25.12.1 Block user 111

25.13 Prime speeds 112

25.14 Calibration settings 112

25.14.1 First calibration fill amount 112

25.14.2 Recalibration averaging 113

25.14.3 Weigh check option 113

25.14.4 Remove from batch option 113

25.15 Reporting 113

25.15.1 Batch reports 113

25.15.2 Auto delete 114

25.16 Time and date 114

25.17 Pump info 115

25.18 Sound level 115

25.19 Network 116

25.19.1 DHCP 116

25.20 Backup and reset 116

25.20.1 Delete all reports 116

25.20.2 Delete all recipes 116

25.20.3 Import all data 116

25.20.4 Export all data 119

25.20.5 Start USB firmware update 121

25.20.6 Factory reset 123

26 WMFTG NetTools — Network and user account setup 124

26.1 Connecting pump to a PC directly—Connection option 1 124

26.1.1 Configure pump for direct connection 124

26.1.2 Configure PC for direct connection 125

26.2 Connecting pump to a PC via Ethernet network— Connection

option 2 126

26.3 Initial pump set-up 127

26.3.1 User account setup for PC to Pump network connectivity 130

26.4 Generate a security certificate (Optional) 131

26.4.1 Generate a CA certificate 132

26.4.2 Install CA certificate in Windows 133

26.4.3 Use the CA certificate to generate a Device Certificate which is

installed on the PF7+ 139

27 WMFTG NetTools — Installation and operation 143

27.1 Installation of NetTools 143

27.2 Launch NetTools 143

27.2.1 User Interface 144

27.3 Logging in to the pump 145

27.4 Changing the pump name 147

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 6

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

7 PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual

27.5 Saving a recipe 149

27.6 Saving a report 151

27.7 Saving an audit trail log 152

27.8 Saving a batch report without a network using USB flash drive 153

27.9 Export as PDF 155

Section 3 - Technical specifications and ordering 158

28 Pump specifications 159

29 Materials of construction 161

29.1 Dimensions 162

30 Spares and accessories 163

31 Pump maintenance (including cleaning) 166

31.1 Service 166

31.2 Cleaning 166

32 Troubleshooting 168

33 Warranty 169

33.1 Conditions 169

33.2 Exceptions 169

34 Returning pumps 171

35 Name and address of manufacturer 172

36 Trademarks 173

37 Version history 174

Section 4 - List of figures and tables 175

38 List of figures 176

39 List of tables 178

Section 1 - Safety notes and

installation

1 Disclaimers 9

2 Declaration of conformity 10

3 Declaration of incorporation 11

4 Safety information 12

4.1 Definitions of symbols on the pump or pumphead 12

4.2 Intended purpose 12

4.3 Tube bridge open indicator 13

4.4 Shipping and handling 13

5 Peristaltic pumps - an overview 14

6 When you unpack your pump 15

6.1 Before storage 15

6.2 After storage 16

7 Lifting and carrying 17

8 Key features of QC14 pumphead 18

9 Pumphead mounting and removal 19

10 Installation position 20

11 Setting up the fluid path 21

11.1 Tube selection 21

11.2 Y-connector selection 22

11.3 Fluid path layout 23

12 Changing the tube 25

12.1 Maximising tube life 28

13 Connecting to a power supply 29

13.1 Checking and replacing the fuse 31

14 Control wiring 32

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 8

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

9 PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual

1 Disclaimers

The information in this document is believed to be correct, but Watson- Marlow

Flexicon A/S accepts no liability for any errors it contains, and reserves the right to

alter specifications without notice.

WARNING: This product must not be used for patient-connected

applications.

This logo means the feature is exclusive to PF7+.

2 Declaration of conformity

Watson-Marlow Limited

Falmouth

Cornwall

TR11 4RU

England

1. PF7/PF7+ Peristaltic Filler.

2. Manufacturer:

Watson Marlow Ltd

Bickland Water Road

Falmouth

TR11 4RU

UK

3. This declaration of conformity isissued under the sole responsibility of the manufacturer.

4. All models and versions of the PF7/PF7+ series of peristaltic filler with all approved pumpheads, tubing and

accessories.

5. The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

ROHS Directive EU 2016/863

6. Harmonised standards used:

BS EN61010-1:2010+A1-2019 Safety requirements for electrical equipment for measurement, control, and

laboratory use Part 1: General Requirements

BS EN61326-1:2013 Electrical equipment for measurement, control and laboratory use – EMC requirements Part 1:

General Requirements

BS EN60529:1992+A2:2013 Degrees of protection provided by enclosures (IP code)

7. Intertek Testing and Certification Ltd, No: 3272281, performed compliance testing to UL 61010-1:2012 and CSA

C22.2#61010-1-12:2012 and issued certification of compliance to these standards.

Signed for and behalf of:

Watson Marlow Ltd

Falmouth, 01 April 2021

Simon Nicholson, Managing Director, Watson-Marlow Limited

Watson-Marlow Fluid Technology Group Telephone +44 (0) 1326 370370

A Spirax-Sarco Engineering plc company

EU declaration of conformity

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 10

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

11 PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual

3 Declaration of incorporation

Watson-Marlow Limited

Falmouth

Cornwall

TR11 4RU

England

1. Manufacturer:

Watson Marlow Ltd

Bickland Water Road

Falmouth

TR11 4RU

UK

2. Person authorised to compile the technical documentation:

Nancy Ashburn

Design and Engineering Director

Watson Marlow Ltd

Bickland Water Road

Falmouth

TR11 4RU

3. All models and versions of the PF7/PF7+ series of peristaltic fillerwith all approved pumpheads, tubing and

accessories.

4. The essential Health andSafety requirements (Annex 1) of the Directive have been applied and fulfilled and the

relevant technical documentation has compiled in accordance with part B of AnnexVII of the directive. This unit is also

in compliance with the following directives:

Machinery Directive 2006/42/EC

EMC Directive 2014/30/EU

ROHS Directive EU 2016/863

5. We undertake to transmit, in response to a reasoned request, by appropriate national authorities, relevant information

on the partly completedmachinery identified above, and shall be without prejudice to our intellectual property rights.

The method of transmission shall be bymail or email.

6. In accordance with the Machinery Directive 2006/42/EC this unit must not be putinto service until the final machinery

into which it is to be incorporated has been declared inconformity with the provisions of thedirective where

appropriate.

Signed for and behalf of:

Watson Marlow Ltd

Falmouth, 01 August 2020

Simon Nicholson, Managing Director, Watson-Marlow Limited

Watson-Marlow Fluid Technology Group Telephone +44 (0) 1326 370370

A Spirax-Sarco Engineering plc company

EU declaration of incorporation

4 Safety information

This safety information should be used in conjunction with the rest of this operating

manual.

This pump and pumphead should only be used by competent, suitably trained

personnel after they have read and understood the manual and considered any

hazard involved. If the pump is used in a manner not specified by WMFTG , the

protection provided by the pump may be impaired. Any person who is involved in

the installation or maintenance of this equipment should be fully competent to carry

out the work. This person should also be familiar with the appropriate local health

and safety regulations.

4.1 Definitions of symbols on the pump or pumphead

An appropriate safety instruction should be followed or caution to

a potential hazard exists.

Rotating Parts

Complies with the applicable EC directives

Dangerous voltage

The pump or packaging cannot be handled as domestic waste.

Dispose of the pump and packaging at an appropriate recycling

centre for the recovery of electrical and electronic equipment.

4.2 Intended purpose

The PF7/PF7+ is a peristaltic fluid dispensing pump suitable for viscous, shear-

sensitive hygienic and aseptic applications. This pump must be used only for its

intended purpose.

WARNING: This product must not be used for patient-connected

applications.

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 12

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

13 PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual

4.3 Tube bridge open indicator

There are rotating parts inside the pumphead. Isolate the pump

from input power before opening the pumphead tube bridge or

access tray.

The pumphead features magnetic safety switches in both the tube

bridge and access tray. If the tube bridge or access tray are

opened the pump will not operate and a warning screen is

displayed.

The tube bridge must be closed for the warning screen to clear and the pump to

start.

Additionally for the QC14 pumphead the access tray must be closed for the warning

screen to clear and the pump to start.

4.4 Shipping and handling

The pump does not require special precautions to ship.

The PF7 contains a non-replaceable Manganese Dioxide Lithium Battery (Li/MnO2),

IEC CR2032, with a typical capacity of 225 mAh, containing 0.07 g of Lithium.

The PF7+ contains a non- replaceable Manganese Dioxide Lithium Battery

(Li/MnO2), IEC CR2016, with a typical capacity of 140 mAh, containing 0.0036 g of

Lithium.

5 Peristaltic pumps - an overview

Rollers or shoes in a peristaltic pump compress the tube or hose as they rotate,

creating a vacuum which draws fluid through the tube.

Nothing but the pump tube or hose touches the fluid, eliminating the risk of the

pump contaminating the fluid, or the fluid contaminating the pump.

www.wmftg.com/how-do-peristaltic-pumps-work

The figure shows fluid being drawn into a pump tube, trapped by the pumphead

roller, and expelled when the next roller passes over the tube. As the rollers rotate,

a vacuum is formed in the tube, pulling in more fluid, for the next roller pass.

The complete closure of the tube when it is occluded (squeezed) between the roller

and the track, gives the pump its positive displacement action, preventing backflow

and eliminating the need for check-valves when the pump is not running.

Peristaltic pumps are self-priming and self-sealing against backflow. No valves are

required in infeed or discharge line, except those specified in "Table 3 - Tube sizes"

on page 21.

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 14

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

15 PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual

6 When you unpack your pump

Lift the pump according to standard Health and Safety guidelines

using both lifting points. (Refer to "Lifting point locations" on

page 17)

DO NOT lift the pump by holding the pumphead as the access tray

can disengage.

1. Unpack all parts carefully, retaining the packaging.

2. Make sure you have all components in "Supplied components" below:

Table 1 - Supplied components

PF7/PF7+ pump drive unit, fitted with a QC14 pumphead.

QC14 pumphead tube lock set

Power supply cable for country of use

Safety information booklet

3. Inspect components for damage. If anything is missing or damaged, contact

your Watson-Marlow sales office or distributor.

4. Dispose of the packaging at an appropriate recycling centre. The outer carton

is made of corrugated cardboard.

6.1 Before storage

Pump:

1. Make sure you have all components in "Supplied components" above.

2. Refer to "Pump specifications" on page 159 for storage specifications.

Tubing:

1. Make sure use-by-dates are clearly marked.

6.2 After storage

Pump:

1. Make sure you have all components in "Supplied components" on the previous

page.

2. Inspect components for damage.

3. Make sure that all parts of the pump work correctly.

Tubing:

1. Inspect for damage.

2. Make sure tubing use-by-dates are not exceeded.

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 16

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

17 PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual

7 Lifting and carrying

Disconnect the power cable and other wired connections and

remove the tube from the pumphead before moving the pump.

Failure to do so could result in a trip hazard or damage to the

pump, cables, connectors or tube.

Lift the pump according to standard Health and Safety guidelines

using both lifting points. (Refer to "Lifting point locations" below)

DO NOT lift the pump by holding the pumphead as the access tray

can disengage.

11

1 Lifting points

Figure 1 - Lifting point locations

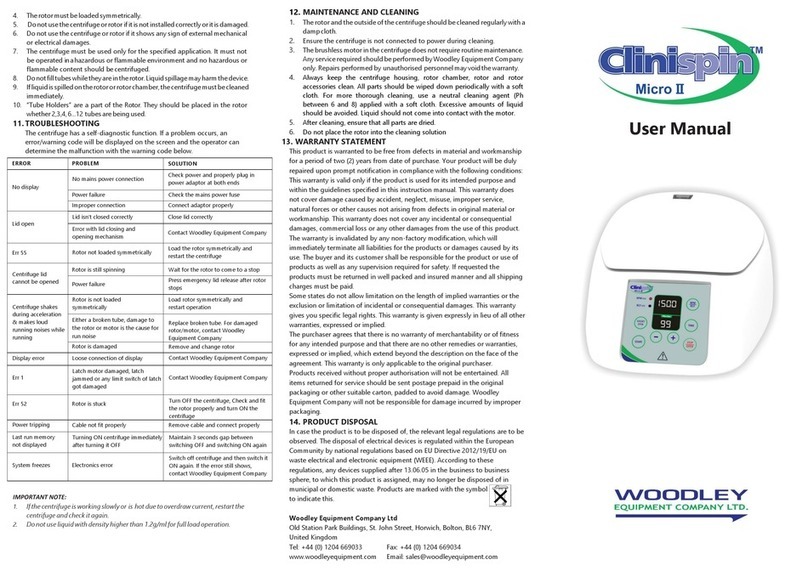

8 Key features of QC14 pumphead

Figure 2 - Key features of QC14 pumphead

Table 2 - Key features of QC14 pumphead

Name Description

1. Tube Bridge The removable upper portion of the pumphead.

2. Locking

lever* Locks the tube bridge in place.

3. Track

Maintenance free spring loaded track fingers.

Accommodate different Accusil tube sizes

without adjustment.

4. Rotor Rotates to produce smooth accurate flow.

5. Access tray* Removable tray for pumphead cleaning. (Note:

Access tray is consumable wearing part)

*Pumphead safety—Pump will only operate when the integral safety switches are

in the correct position.

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 18

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

19 PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual

9 Pumphead mounting and removal

Isolate from power supply to secure the motor against accidental

start-up. Only qualified personnel can lift, transport, install,

operate, maintain and repair the pump.

The pumphead is held in position with two hex bolts located as shown below. To

remove the pumphead, use a 5 mm hex key to remove the bolts.

The hex bolts are tightened to the pump using 3.6-4 Nm of torque.

Figure 3 - Pumphead mounting and removal

10 Installation position

This product does not comply with the ATEX directive and must

not be used in explosive atmospheres.

•Position the pump on a work surface or bench.

•Clear the top, front and back of the pump of obstructions so the controls and

wiring connections are easily accessible when the pump is in use. The pump's

power input plug is the disconnecting device (for isolating the motor drive

from the power supply in an emergency).

PF7/PF7+ Peristaltic Filler with QC14 Pumphead User Manual 20

EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN EN

Other manuals for PF7

1

This manual suits for next models

2

Table of contents

Other Flexicon Laboratory Equipment manuals