Fike FAAST XT 68-302 User manual

FK-600-000 1 I56-4223-001

SPECIFICATIONS

Electrical Characteristics

External Supply Voltage 18 – 30 VDC

Average SLC Operating Current 300 µA

Power Reset 1 sec

Relay Contact Ratings 3.0A @ 30VDC, 0.5A @125VAC

Environmental Ratings

Operating Temperature 32F (0C) to 100F (38C)

Sampled Air Temperature -4F (-20C) to 140F (60C)

Humidity 10 to 95% non-condensing

IP Rating IP30

68-302 FAAST

Fire Alarm Aspiration Sensing Technology®

INSTALLATION AND MAINTENANCE INSTRUCTIONS

I56-4223-001

The purpose of this document is to provide practical information for mount-

ing and connecting to FAAST XT. For full product information, which includes

installation guidelines, instructions for safe use, and warranty and safety

information, refer to the FAAST XT Comprehensive User Guide available at

systemsensor.com/68-302userguide or by scanning the QR code.

ITEMS INCLUDED WITH UNIT

• FAAST XT (68-302) unit

• Mounting bracket and hardware

• Installation and Maintenance Instructions

• USB interface cable

• PipeIQ software, comprehensive manual, and other helpful documents

may be downloaded at systemsensor.com/faast

CONNECTING TO FAAST XT

FAAST XT requires a configuration download from PipeIQ in order to initialize.

This connection can be achieved using either the USB port located on the front of

the device, or the Ethernet port located inside the wiring cabinet.

CONNECTING TO FAAST XT VIA USB

NOTE: In order to connect your computer to the FAAST XT using a USB con-

nection, a USB driver must first be installed. The driver installation occurs

during the installation of PipeIQ version 2.0 or later. Once the driver is in-

stalled, connect to the device using the following steps.

1. Launch PipeIQ.

2. Create a new project and select FAAST XT device, or open an existing project

3. Expand the tree view in the left side navigation pane to reveal the device

4. Right click on the device and select ‘Connect Device’

5. Select USB, The USB combo box should already be populated with FAAST

XT (Com Port Number).

6. Select Read only/Administrator(requires password – default is ‘password’)

mode Click Connect.

CONNECTING TO FAAST XT VIA ETHERNET

Default Device IP Configuration

IP Address: 192.168.1.10

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.1.1

Primary DNS: 0.0.0.0

Secondary DNS: 0.0.0.0

CONFIGURE YOUR PC

Your PC will need to be sitting on the same local area network as the FAAST XT device

in order to establish communication. Change your PC’s IP address to 192.168.1.15 by:

1. Accessing your network setting in your PC’s control panel

2. Open ‘Local Area Connection’ settings and select ‘Properties’

3. Select ‘Internet Protocol Version 4 (TCP/IPv4) and then select ‘Properties’

4. Select ‘Use the following UP address and enter 192.168.1.15. If the

subnet mask does not automatically populate, enter 255.255.255.0

into the subnet mask field.

5. Hit OK and close out of the network menus.

(Important Note: Before changing your PC’s IP address, be sure to take note of

whether your IP is currently dynamically set, or is a static IP address. If your PC

is assigned a static IP address, make note of the IP address and subnet mask so

that you can change back to the proper settings after the FAAST XT is configured.)

CONNECT USING PIPEIQ

1. Launch PipeIQ. (PipeIQ may be downloaded from systemsensor.com/faast)

2. Create and save a new project, or open an existing project

3. Expand the tree view in the left side navigation pane to reveal the device

4. Right click on the device and select ‘Connect Device’

5. Change the User field to ‘Administrator’ and enter the password – the

default password is ‘password’ – then hit ‘Connect’

6. Upon connection, a green check will appear next to the device in the

navigation tree

INSTALLATION

This equipment must be installed in accordance with all local and national

codes and regulations.

PIPE INSTALLATION

The pipe layout is designed using the PipeIQ software package. Refer to the

Comprehensive Instruction Manual to design the pipe network. All pipe must

be installed in accordance with local and national codes and regulations. The

pipe network should be complete before proceeding with the physical and

electrical system installation.

PHYSICAL UNIT INSTALLATION

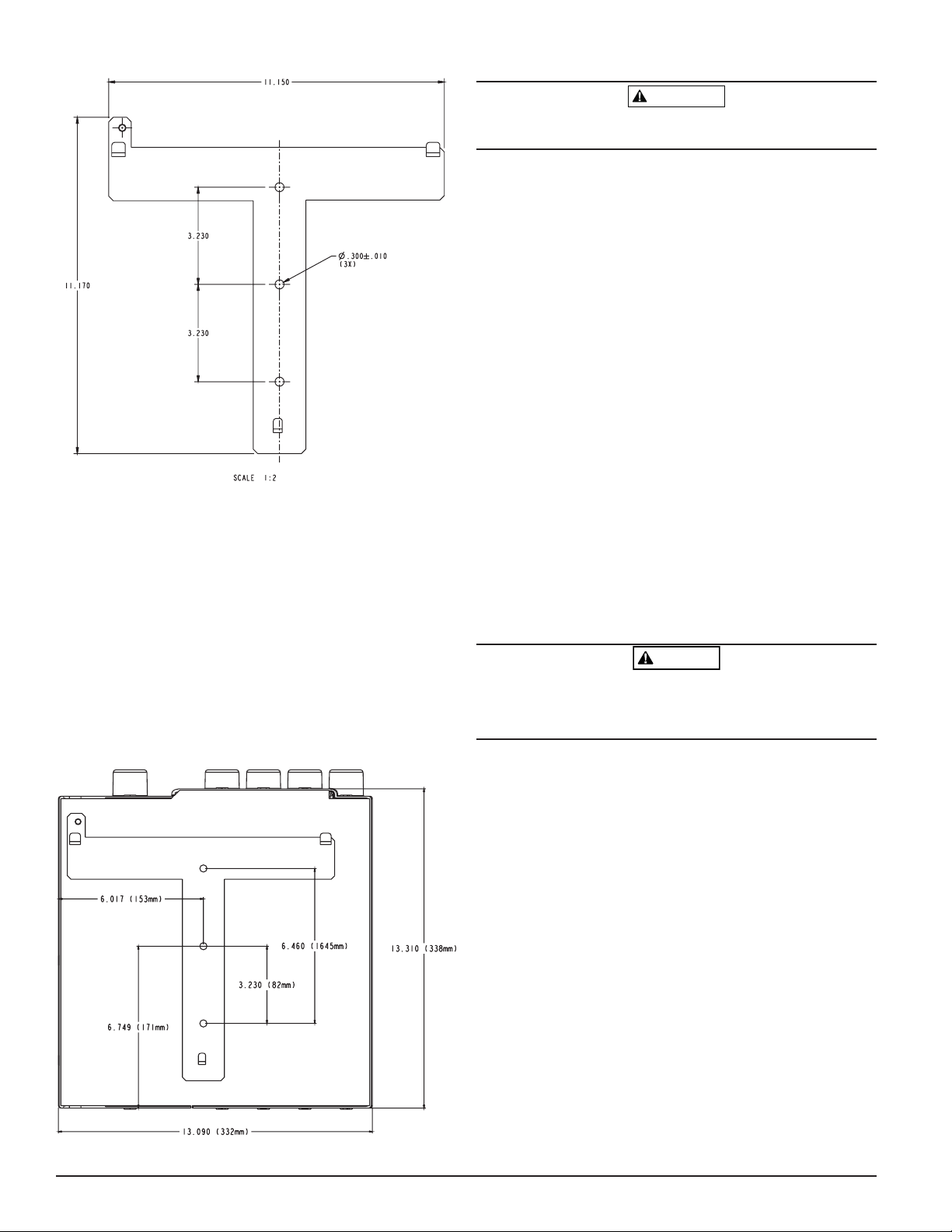

WARNING

Make sure that there are no pipes or electrical wires within the wall before

drilling any mounting holes

SECURING THE MOUNTING BRACKET

The typical mounting location for the FAAST XT unit is on the wall. The unit

is mounted to the wall using the enclosed mounting plate. Figure 1 shows the

wall mounting plate. For easier access to the FAAST XT unit, it is preferred to

position the mounting plate in an easily accessible location.

1. Place the mounting bracket on the wall in the desired location and use

it as a template to locate the necessary mounting holes.

2. Mark the hole locations and remove the bracket. It is recommended to

secure the bracket using the 4 outer mounting holes.

3. Using a drill and the proper size bit for your mounting hardware, drill

the necessary holes.

4. Use appropriate fasteners to accommodate the mounting surface and

FAAST XT device weight.

5. Secure the bracket to the wall.

704 S. 10th Street

Blue Springs, MO 64015

Phone: 816.229.3405; Fax: 816.228.9277

www.fike.com

R

FIGURE 1: WALL MOUNTING PLATE

FIGURE 2: MOUNTING SLOTS FOR MOUNTING STUDS

CONNECTING THE AIR SAMPLING PIPE

ATTENTION

Detailed pipe network information and best practices can be found in the

Pipe Installation Guide, available for download at systemsensor.com/faast

The input and output ports are designed to accept nominal one inch pipe

(25mm). The input and output ports are tapered to provide fast, easy, pushfit

connection of the sampling pipe to the unit. Perform the following procedure

to connect the air sampling pipe to the unit.

1. Square off and de-burr the end of the sampling pipe. Ensure that the

pipe is free from any particles that might interfere with the pipe con-

nection.

2. Remove the input plug from the input port being used (either the top

or bottom of the unit).

3. Inset the air sampling pipe into the port, ensuring a snug fit. DO NOT

glue these pipes.

EXHAUST PIPE

The device should always be exhausted in to the space that it is monitoring.

There are some circumstances where it may be necessary to connect a pipe to

the exhaust port to divert the exhaust away from the location of the unit. Add-

ing as little as 2ft of exhaust pipe also acts as a muffler for the fan – ensuring

quieter operation. The output ports are tapered the same as the input ports, to

provide fast, easy, push-fit connection of an exhaust pipe to the unit. Perform

the following procedure to connect the exhaust pipe to the unit.

1. Square off and de-burr the end of the sampling pipe. Ensure that the

pipe is free from any particles that might interfere with the pipe con-

nection.

2. Remove the input plug from the input port being used (either the top

or bottom of the unit).

3. Inset the air sampling pipe into the port, ensuring a snug fit. DO NOT

glue these pipes.

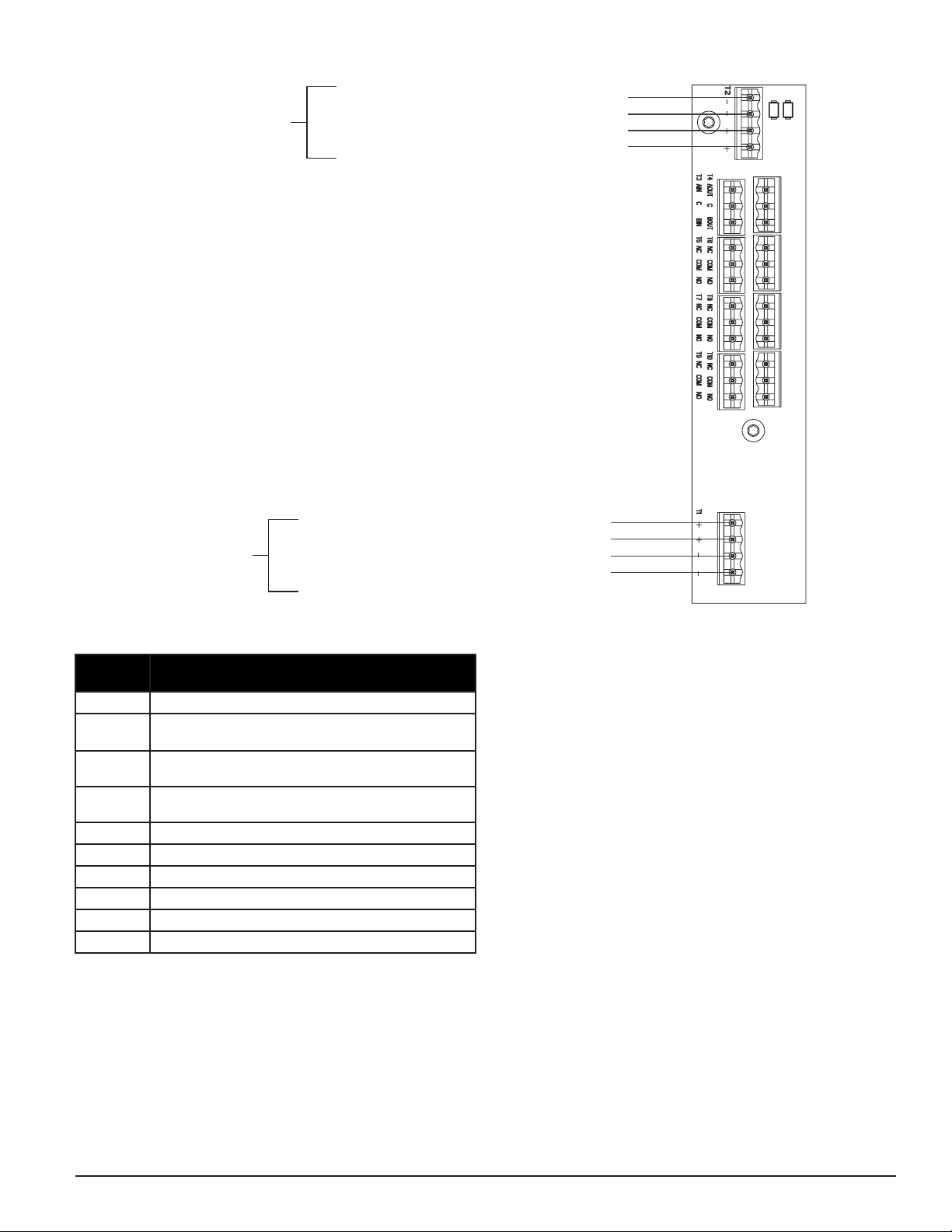

WIRING

WARNING

Before working on the FAAST XT system, notify all required authorities that

the system will be temporarily out of service. Make sure all power is removed

from the system before opening the unit. All wiring must be in accordance

with local codes.

POWER CABLES

Use the power ratings of the unit to determine the required wire sizes for each

connection. Use the power ratings of the connected products to determine the

wire size.

CONDUIT USAGE

If electrical conduit is used for system wiring, terminate the conduits at the

cable entry ports on the top or bottom of the unit, using the appropriate con-

duit connectors.

1. Run all wiring, both power and alarm, through the conduit and into

the left side of the unit enclosure, as seen in Figure 3.

2. Attach the appropriate wires to the supplied Euro connector. Follow

appropriate local codes and electrical standards for all cabling.

3. Plug the appropriate connector into the mating connector on the unit.

ASP115-00

ASP116-00

FK-600-000 2 I56-4223-001

MOUNTING THE DETECTOR TO THE BRACKET

Once the mounting plate is attached, the unit is ready to be mounted on to the

plate. Perform the following procedure to mount the unit.

1. Before installing the unit onto the bracket, remove the appropriate

conduit caps from the top or bottom left side of the unit to match the

orientation of the wiring. See Figure 4 for location of the wiring access

plugs.

2. Line up the unit with the four mounting clips and the mounting studs

on the left side.

3. Push the unit down onto the mounting clips and secure it with the

supplied washer and nut on the mounting stud protruding through the

mounting slot shown in Figure 2.

TERMINAL

BLOCK

T1 External Power – Powers Aspirating Smoke Detector

T2 SLC power – Powers SLC Interface Circuit. Isolated from

External Power

T3 RS 485 Rx

Rx and Tx can be wired in a half duplex configuration

T4 RS 485 Tx

Rx and Tx can be wired in a half duplex configuration

T5 Alert Relay – Maintains state on loss of power

T6 Action1 Relay – Maintains state on loss of power

T7 Action2 Relay – Maintains state on loss of power

T8 Fire1 Relay – Maintains state on loss of power

T9 Fire2 Relay – Maintains state on loss of power

T10 Fault Relay – Maintains state on loss of power

CABLING REQUIREMENTS

The FAAST XT system provides a series of Euro style pluggable terminals,

located behind the left side door of the unit. Refer to Table 1 for the proper

electrical connections to the unit. Refer to Table 2 for a typical connection for

monitoring the FAAST XT system at a Fire Alarm Control Panel (FACP).

TABLE 1. TERMINAL DESIGNATIONS SYSTEM POWERING

The following procedure describes how to initially power up the FAAST XT system.

1. Unplug the unit’s power connector to the unit before turning on the

power.

2. Turn on the power.

3. Check the voltage at the connector. Make sure it is within the required

voltage range.

4. If the voltage is within the proper range, reconnect the power connec-

tor to the unit. Do not connect the SLC at this point in order to enable

configuration.

5. Connect a computer, with PipeIQ installed, to the unit using either the

USB connection on the front of the device, or the Ethernet port located

in the left side wiring door. (See the ‘Connecting to FAAST XT’ for

detailed connection instructions.)

6. Use the PipeIQ software to set up the unit configuration required for

the particular application.

7. The PC may now be disconnected unless a permanent networked con-

nection is desired.

8. Connect to SLC

9. Verify the system fan starts up and air begins to flow out of the ex-

haust port. The user interface will provide the device status.

10. The device will establish an airflow baseline during the first five min-

utes of operation. After five minutes, the airflow level display will

provide the true measured airflow status. The device will give visual

indication of the baselining period on the LCD screen.

FK-600-000 3 I56-4223-001

FIGURE 3. POWER AND ALARM CONNECTION BLOCK

To Next SLC Device –

From FACP or Previous Device –

From FACP or Previous Device +

To Next SLC Device +

SLC

Connection

To Next Device +

24V External

Power

From Power Supply or Previous Device +

From Power Supply or Previous Device –

To Next Device –

ASP114-02

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used

in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installa-

tion. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

This Class B digital apparatus complies with Canadian ICES-003.

FCC STATEMENT

Fike Industries warrants its enclosed smoke detector to be free from defects in materials

and workmanship under normal use and service for a period of three years from date

of manufacture. Fike Industries makes no other express warranty for this smoke detec-

tor. No agent, representative, dealer, or employee of the Company has the authority to

increase or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the repair or replacement of any part of the smoke

detector which is found to be defective in materials or workmanship under normal use

and service during the three year period commencing with the date of manufacture. After

contacting your local Fike Industries representative for issuing a Return Authorization

number (RA #__________) and arrange for return return of the defective units. Please

WARRANTY

include a note describing the malfunction and suspected cause of failure. The Company

shall not be obligated to repair or replace units which are found to be defective because

of damage, unreasonable use, modifications, or alterations occurring after the date of

manufacture. In no case shall the Company be liable for any consequential or incidental

damages for breach of this or any other Warranty, expressed or implied whatsoever, even

if the loss or damage is caused by the Company’s negligence or fault. Some states do not

allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This Warranty gives you specific legal

rights, and you may also have other rights which vary from state to state.

This aspiration detector does not produce any hazardous laser radiation and is certified

as a Class 1 laser product under the U.S. Department of Health and Human Services

(DHHS) Radiation Performance Standard according to the Radiation Control for Health

and Safety Act of 1968. Any radiation emitted inside the smoke detector is completely

within the protective housings and external covers.

The laser beam cannot escape from the detector during any phase of operation.

The Center of Devices and Radiological Health (CDRH) of the U. S. Food and Drug

Administration implemented regulations for laser products on August 2, 1976. These

regulations apply to laser products manufactured after August 1, 1976. Compliance is

mandatory for products marketed in the United States.

LASER SAFETY INFORMATION

FK-600-000 4 I56-4223-001

©Fike 2015

Other Fike Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

LORD

LORD MicroStrain 3DM-CV5-10 Protocol manual

LaserLiner

LaserLiner AirMonitor PURE manual

Elcometer

Elcometer 204 operating instructions

aquilar

aquilar AquiTron AT-WFM Installation & operation instructions

Schmidt

Schmidt MZ-422 Series instruction manual

CID Bio-Science

CID Bio-Science CI-600 instruction manual