aquilar AquiTron AT-WFM Installation instructions

AT-WFM

Water Flow Monitor

AquiTron

INSTALLATION

& OPERATION

INSTRUCTIONS

AT-WFM

Water Flow Monitor

LEAK DETECTION SOLUTIONS

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

Table of contents

A. General Information

B. Product Information

C. Fitting The Module

D. Wiring

E. Plumbing Installation

F. Helpful Hints

G. Maintenance

H. Connection

1. Power & Battery Connection

2. Volt Free Relay Connections

3. External Trigger Input

4. Water Meter Connection

5. Solenoid Valve Connection

6. Pulse Output Connection

I. Home Screen

J. Setting The AT-WFM

K. Menu Screen

1. Controller Info

2. Installer Info

3. Manual Override

4. Event History

L. Setup (For Authorised Users Only)

1. Date and Time

2. Protection Level Mode

a. Volume Per

b. Timed

c. Crosscheck

3. Protection Level Time

4. Meters

5. Pulse Rate

6. Valves

7. Change Installer Info

8. Factory Reset

M. Event Log Messages

THE AT-WFM IS SUITABLE FOR INTERNAL USE

ONLY

POWER SUPPLY

100/240Vac, 50/60Hz, 0.15A

POWER CONSUMPTION

5 Watts Maximum

RELAYS

Number: 1 volt-free relay contact

Type: SPDT

Rating: 3 A at 250Vac/24 Vdc

TEMPERATURE

Operating: 5°C to 85°C

ENCLOSURE

White ABS. 177 mm x 114 mm x 65 mm (L x H x D)

TOUCHSCREEN

Resistive 4.3 inch TFT. Resolution: 480 x 272 pixels. Screen

size: 95 x 54 mm.

INSTALLATION ITEMS

(NOT SUPPLIED)

• Wall fasteners for surface mounting (four

screws)

TOOLS REQUIRED

• Drill or hole punch for electrical /

conduit entries

• Phillips (cross-head) screwdriver

• Flat-head screwdriver

TYPES OF WATER METER

To ensure compatibility with the AT-WFM it is strongly

recommended to use the Aquilar range of water meters. Third

party meters must be capable of supplying a dedicated volt free

pulse for volumes of 1/10/100 litre(s).

PULSE OUTPUT

Two channel

TYPES OF VALVE

Compatible with AquiTron AT-V-XX, AT-BV-XX, AT-VP-XX, AT-V-B-XX

valve ranges.

MAXIMUM OPERATING PRESSURE*

16 Bar

MINIMUM FLOW RATES*

AT-WFM will detect any ow rate greater than 0.15m3/h.

*AT-V-XX Flanged Buttery Valve and AT-BV-XX Ball Valve require

additional equipment: AT-RU1 Relay Unit

Please read the instructions carefully before attempting to install and connect the AT-WFM unit.

AT-WFM

Water Flow Monitor

A. GENERAL INFORMATION

The AquiTron AT-WFM water monitoring system that has been specically designed to help achieve the requirements of BREEAM 2018

(BRE Environmental Assessment Method). The AT- WFM system will allow designers, M&E contractors and developers to achieve the one

of the two WAT 03 Credits available to reduce the impact of water leaks that may otherwise go undetected. (To obtain the second available

WAT 03 credit Please see our product AT-OFC). The AT-WFM system is designed to monitor water owing through a pulse water meter. If

the volume of water exceeds the pre-set limit (customer adjustable) the system will alert the customer and, if an optional valve is tted,

can isolate the mains water, therefore limiting the amount of water lost to a leak and subsequent damage.

B. PRODUCT INFORMATION

LEAK DETECTION SOLUTIONS

1

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

*When using Aquilar supplied water meters or valves only.

Actual rates dependent on model used. Please see relevant data

sheets.

STORAGE

Keep the module in a dry place prior to

installation to avoid possible damage to

internal components.

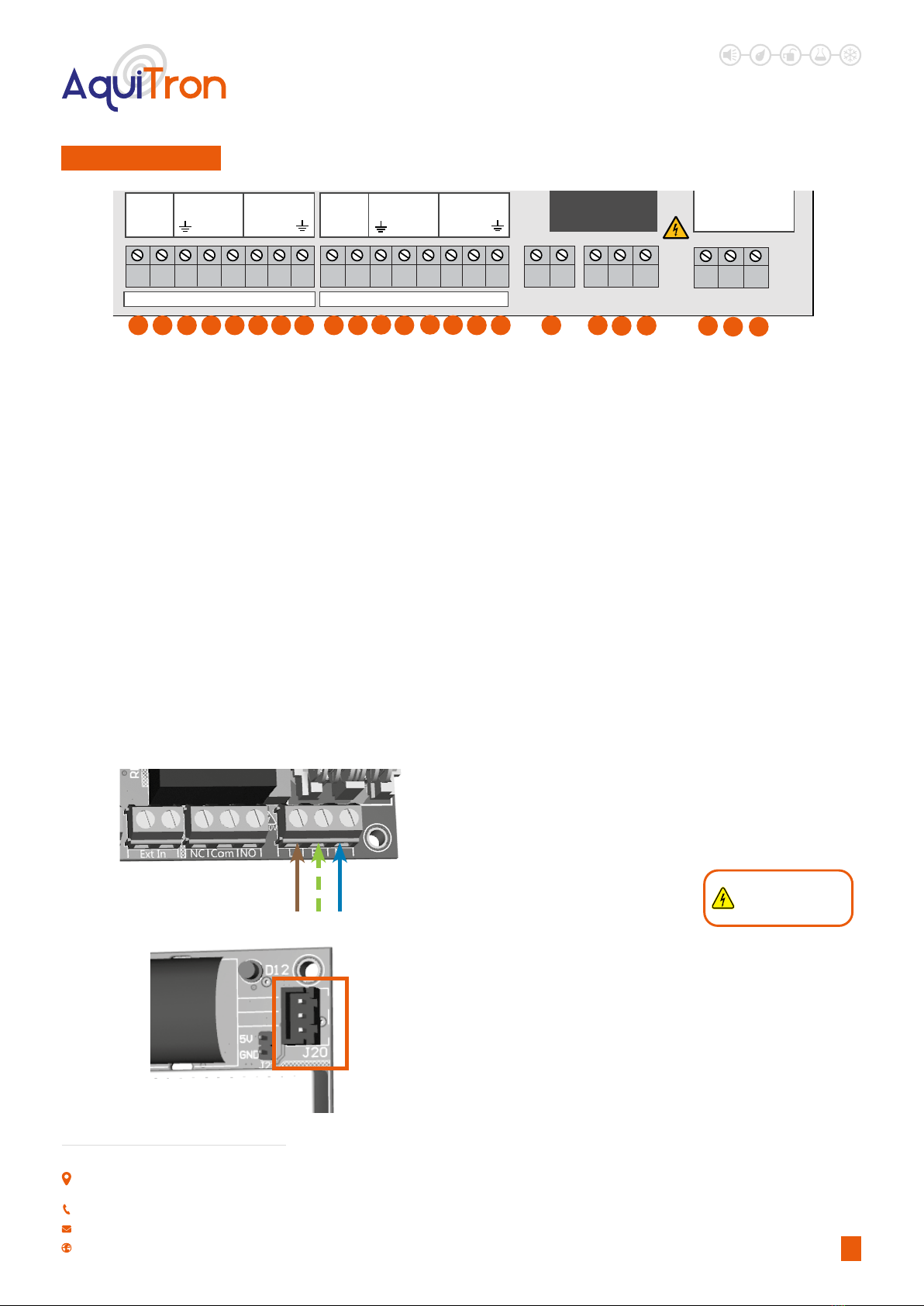

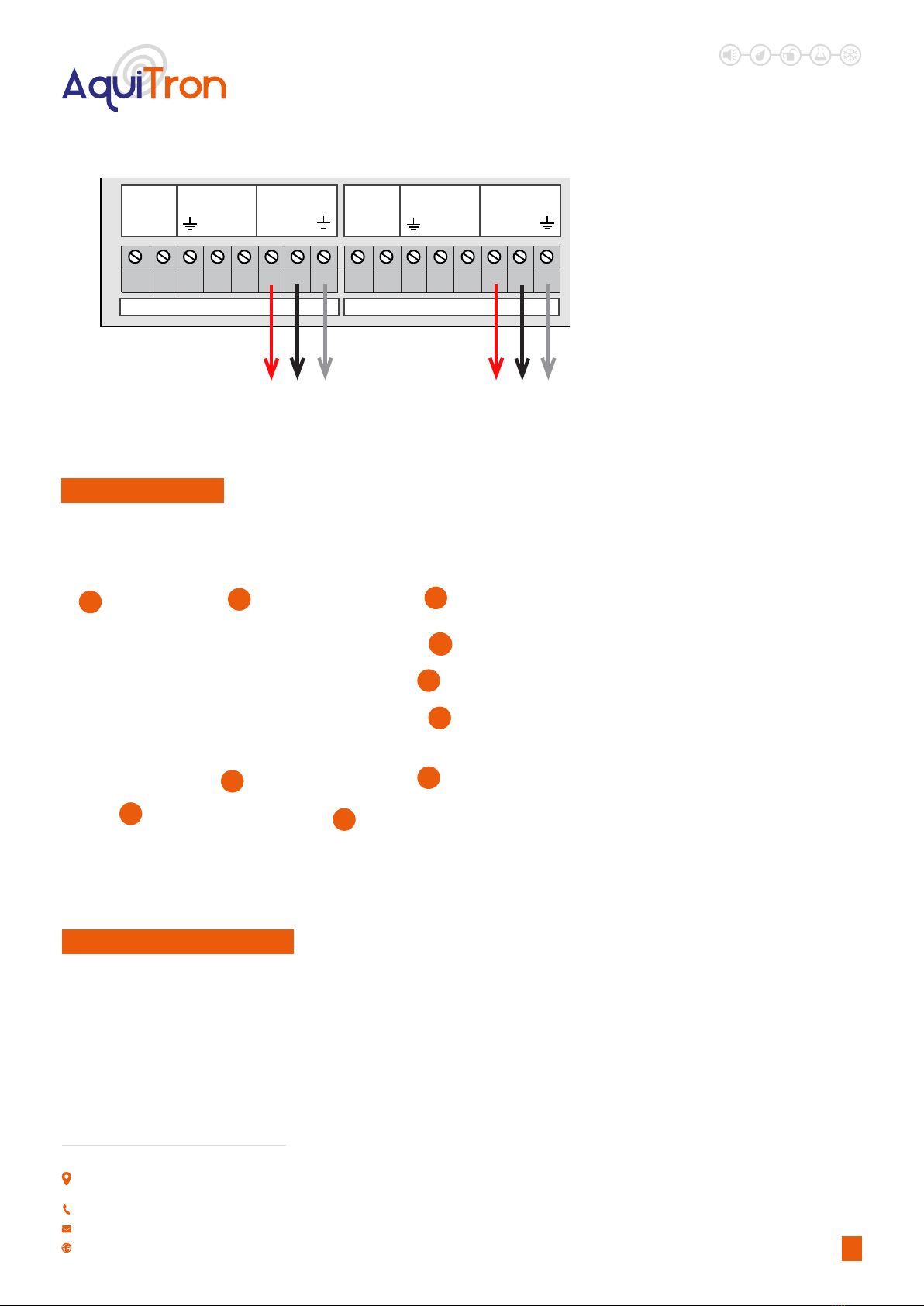

CHANNEL 1 CHANNEL 2

SOL 1 SOL 2METER 1 IN METER 2 INPULSE 1 OUT PULSE 2 OUT

+ - + -+ -+ -+ -

+ -

12

3 4 5

6

7

8

9

10

LEAK DETECTION SOLUTIONS

1. Channel 1 terminals

2. Channel 2 terminals

3. External Trigger Input

terminals

4. Volt Free Relay terminals

5. Mains power in terminals

6. Battery Connector

7. Power LED

8. Back-up battery

9. Serial Connector

10. Buzzer

2

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

MAXIMUM PULSE CIRCUIT LENGTH

500 metres maximum. For circuit lengths (over 50m) cable

should be grounded to prevent interference. Connect ground at

controller end only.

NUMBER OF CHANNELS

2 Maximum, can be used single channel

CONNECTION TO MODULE

Via the SPDT volt free relay output

APPROVALS

• EMC Directive 2014/30/EU:

• BS EN61000-6 3:2007+A1:2011

• BS EN IEC 61000-6 1:2019

• UKCA CE

COMPONENT LAYOUT

Figure 1 - Component View

C. FITTING THE MODULE

The unit should be installed in a dry area with easy access. This controller is not suitable for external use.

Before installation the front section should be removed and stored somewhere safe. NOTE : To open the enclosure

Remove the two screws at the bottom of the enclosure see Fig B. on page 3.

To remove carefully unplug the interface board as shown in g A. Before doing so make sure that the AT-WFM is switched

o and the battery is disconnected.

Using the pre-drilled holes use suitable xings to secure the base unit to a at surface. If the base is distorted the front

cover may not t correctly.

It is recommended mains power is provided from an adjacent un-switched fused spur. This must be fused correctly. Fuse

rating should be 3 amps.

It is recommended not to apply power until all connections are complete.

Once all connections are in place the front panel should be plugged in and the front panel attached.

Note: Do not allow the front panel to hang from the ribbon cable. Take care not to trap or damage the ribbon cable when

installing the front panel.

LEAK DETECTION SOLUTIONS

3

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

AT-WM should be installed by a competent installer, in-line with current IEE regulations, using sound engineering practice

and in recommendations laid down by the HVCA.

D. WIRING

The diagrams will serve as a visual aid, but it is recommended that a competent plumber carries out the assembly and

installation of any included water meters and solenoid valves in line with the manufacturer’s instructions. Direction of ow

is essential for correct operation. Connect the pipe to the water meter / valve according to markings on the valve body.

Apply pipe compound sparingly to male threads only. Ensure compound does not enter valve or meter. Avoid undue strain

on pipework by proper support and alignment. Type PN16 mating anges will be required on some models over 50mm.

Never hold the water meter or solenoid body when tightening.

E. PLUMBING INSTALLATION

Figure A - Interface board

Connector : Plugged In Connector : Disconnected

We recommend that meters and valves attached to the AT-WFM are installed with a maintenance by-pass and strainers to

prevent debris entering them. They can be tted vertically or horizontally. Note the direction of the ow arrows marked on

the water meter and valve to ensure they are tted correctly. Do not overtighten plastic ttings. Observe rules on distance

from pipe elbows to meters to ensure correct ow through the water meter.

F. HELPFUL HINTS

Clean periodically depending on conditions. Keep the medium owing through the water meter / valve free from dirt. While

in service, the Solenoid Valve should be operated at least once a month to ensure proper cleaning and closing. We strongly

recommend a strainer is tted prior to any meters or valves to prevent debris fouling the mechanism.

G. MAINTENANCE

Figure B - To open enclosure

remove both screws.

LEAK DETECTION SOLUTIONS

4

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

If the unit is to be used as single channel unit (only one water meter) use indicated channel 1 connections. Using wiring

instructions above, connect each accessory to the controller. See relevant section for further connection details.

The Input connection can be made to an intruder alarm for automatic switching between high and low volume periods

when the alarm is activated. This should be a volt free contact.

H. CONNECTION

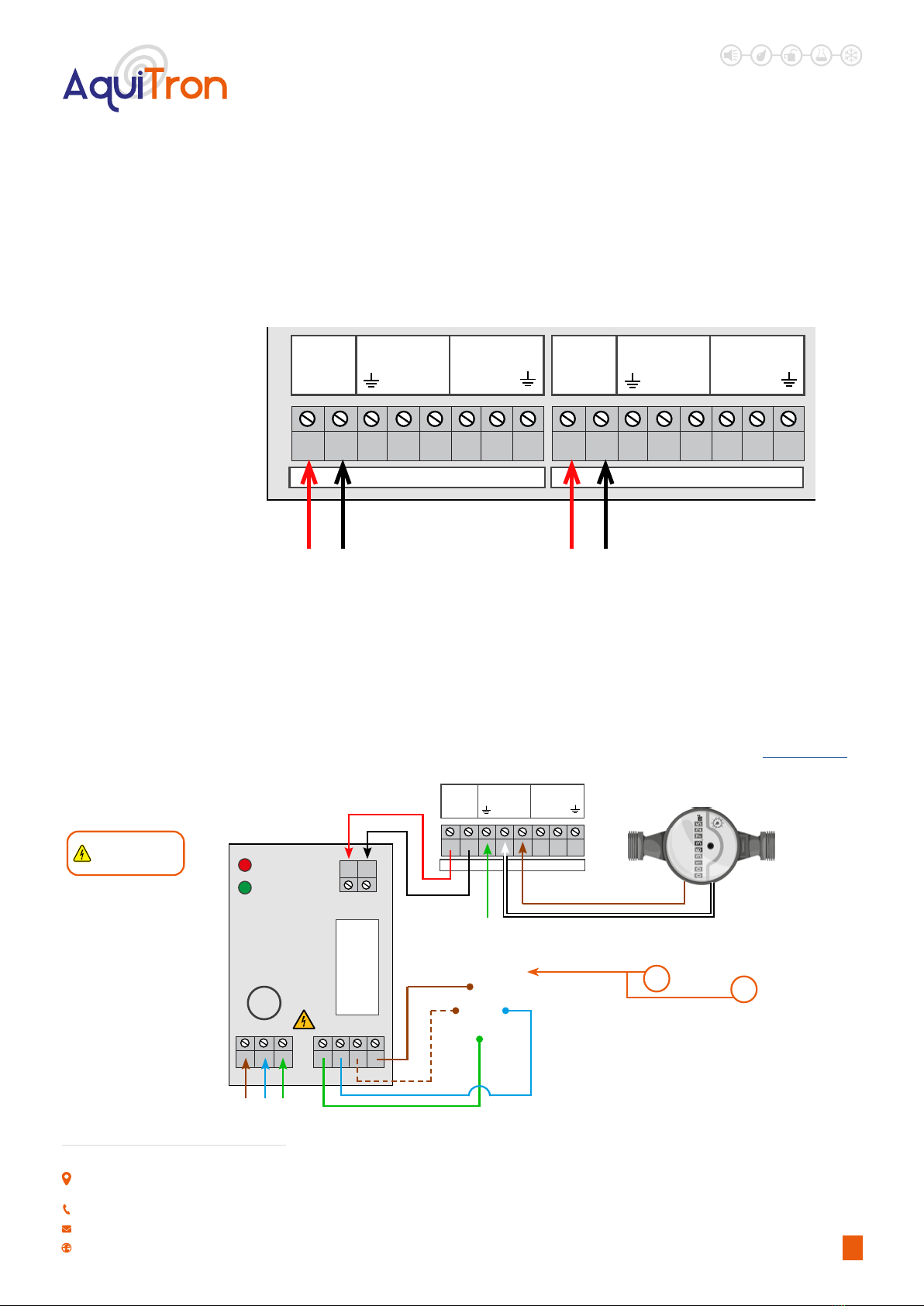

Figure 2 - Connection Layout

CHANNEL 1 CHANNEL 2

SOL 1 SOL 2METER 1 IN METER 2 INPULSE 1 OUT PULSE 2 OUT

+ - + -+ -+ -+ -

+ -

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

1. 6Vdc Solenoid Valve Ch1 + ve Connection

2. 6Vdc Solenoid Valve Ch1 - ve Connection

3. Pulse Ground Connection

4. Meter 1 (Ext) Pulse +ve Connection

5. Meter 1 (Ext) Pulse -ve Connection

6. Pulse Output to BMS Ch1 (Ext) +ve

7. Pulse Output to BMS Ch1 (Ext) -ve

8. Pulse Out Ground Connection

9. 6Vdc Solenoid Valve Ch2 +ve Connection

10. 6Vdc Solenoid Valve Ch2 -ve Connection

11. Pulse Ground Connection

12. Meter 2 (Ext) Pulse + ve Connection

13. Meter 2 (Ext) Pulse -ve Connection

14. Pulse Output to BMS Ch2 (Ext) +ve

15. Pulse Output to BMS Ch2 (Ext) -ve

16. Pulse Out Ground Connection

17. External Volt Free Trigger Input

18. Normally Closed - Volt Free Relay Output

19. Common - Volt Free Relay Output

20. Normally Open - Volt Free Relay Output

21. Live - Mains Input Connection

22. Earth - Mains Input Connection

23. Neutral - Mains Input Connection

20 21 22 23

H1. POWER & BATTERY CONNECTION

Figure 3 - Power Connections IMPORTANT : All wiring

should only be done by a

qualied electrician

It is recommended to use an un-switched fused spur to provide local

isolation of the AT-WFM.

Power supply should be 100-240Vac 50/60Hz.

Note: This unit must be earthed.

Live

Earth

Neutral

The battery back-up should be enabled by plugging the battery pack

into the unit (connector J20)

Important Note: Do not plug in battery until unit has fully

started up. Plugging a battery in during the boot up process

can cause damage to the controller.

Figure 4 - Battery Connector

LEAK DETECTION SOLUTIONS

5

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

H2. VOLT FREE RELAY CONNECTIONS

Figure 5 - Volt Free Relay

Connections

Note: This output is volt free, no power is provided from these

terminals.

The AT-WFM is equipped with a single SPDT volt free relay for

control of accessories. This relay output operates when the unit

goes into alarm. It can switch a maximum resistive load of 3amps @

230Vac/24Vdc.

The relay allows for control of equipment requiring a normally open

or closed volt free contact, such as BMS. Or can be used to control

remote accessories such as AT-SD3 speech diallers or AT-BCN-A

beacons, third party valves etc.

H3. EXTERNAL TRIGGER INPUT

Figure 6 - External Volt Free

Connection

This input allows the controller to be put in and out of high and low

volume settings by external equipment such as a key switch or alarm

system. i.e intruder alarm for entry / exit setting.

A volt free normally open input is required. If enabled in software

closing this contact will place the AT-WFM unit into low volume

mode. See section L3. for set up information.

Volt Free Relay Output

Normally

Closed

Normally

Open

Common

External Volt Free

Trigger Input

H4. WATER METER CONNECTION

Connect the pulse output of the water meter to the AT-WFM as shown above. The connections are not polarity sensitive. If the cable on the

meter requires extending the connection should be made using a shielded 2 core cable.

Minimum cable size should be 1.0mm² for runs of up to 100m, for runs above this we recommend a minimum cable size of 1.5mm². For

cable runs above 50m or runs adjacent to mains cabling the shield of the pulse cable should be grounded at the controller end only using

one of the indicated ground terminals to prevent interference.

Figure 7 - Pulse

Input connections

CHANNEL 1 CHANNEL 2

SOL 1 SOL 2METER 1 IN METER 2 INPULSE 1 OUT PULSE 2 OUT

+ - + -+ -+ -+ -

+ -

Pulse Shield

Ground

Connection

Meter 1 (External)

Pulse Connection

White +ve

Brown -ve

Meter 2 (Internal)

Pulse Connection

White +ve

Brown -ve

Pulse Shield

Ground

Connection

Note: Meters connected to

the AT-WFM should provide

dedicated volt free pulse for

volumes of 1/10/100 litre(s).

LEAK DETECTION SOLUTIONS

6

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

H5. SOLENOID VALVE CONNECTION

Figure 8 - Solenoid Vavle Connections

CHANNEL 1 CHANNEL 2

SOL 1 SOL 2METER 1 IN METER 2 INPULSE 1 OUT PULSE 2 OUT

+ - + -+ -+ -+ -

+ -

6Vdc Solenoid Valve

Connection Ch1 (External)

6Vdc Solenoid Valve

Connection Ch2 (Internal)

The AT-WFM can directly control two AT-V-P-xx or AT-V-B-xx solenoid valves only. The valves should be connected as shown above.

The valve should be connected to the same channel as the water meter. If two channels are being used with only one valve (standard

BREEAM setup) the valve should be connected to channel 2 (internal).

If using AT-V-xx or AT-BV-xx buttery or ball valves an AT-RU1 valve controller must be used. Please see the connection diagram below.

Power Connections to Relay (Mains), 230Vac supply L = Live, N = Neutral, E = Earth

Power Connections to Relay (Relay Valve), 230Vac supply L1= Live Close, L2= Live Open, N = Neutral, E = Earth

Control Connections from AT-WFM Controller 1= Solenoid +, 2= Solenoid -

NOTE: Wiring should only be done by a qualied electrician

Third party valves are not recommended for use with this controller. They can be controlled via the volt free relay output. See section H2.

AT-RU1 RELAY UNIT CONNECTIONS

Figure 8 - AT-RU1 Connections

3A

Close

Open

LE

N E N L1 L2

1 2

Water

Meter

CHANNEL 1

SOL 1 METER 1 IN PULSE 1 OUT

+ - + -+ -

Live

Neutral

Earth

Brown

White

IMPORTANT : All wiring

should only be done by a

qualied electrician

Pulse Ground

Connection

1 - Neutral

2 - Live (Opens Valve)

3 - Live (Close Valve)

E - Earth

1

2

3

E

L1 - Close Valve

L2 - Open Valve

AT-V-XX

Buttery Valve

AT-BV-XX

Ball Valve

AT-RU1

Relay Unit

Valve DIN plug

Connections

LEAK DETECTION SOLUTIONS

7

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

H6. PULSE OUTPUT CONNECTION

Figure 9 - Pulse Output

Connections

The AT-WFM is equipped with an onbard two channel pulse splitter. This enable the unit to give real time ow volume information to

external equipment such as a BMS. A two core shielded cable should be used with the shield grounded at the AT-WFM in the relevant

ground terminal as shown above.

CHANNEL 1 CHANNEL 2

SOL 1 SOL 2METER 1 IN METER 2 INPULSE 1 OUT PULSE 2 OUT

+ - + -+ -+ -+ -

+ -

Pulse Output to BMS Ch1

(External)

Pulse Output to BMS Ch1

(Internal)

Pulse Shield /

Ground Connection

Pulse Shield /

Ground Connection

Note: Pulse outputs provided mirror the

pulses received from the water meters

connected to the Meter In connection(s).

I. HOME SCREEN

When rst turning on the AT-WFM it will boot up to the home screen. From his screen you have an overview of the system status and

settings. The information available is listed below.

D

D

E

F

ABC

G

H

I

J

A. Displays current screen

B. Displays date and time

C. Status LED:

• Green – System on and no

alarm present

• Red – System is in alarm

• Blue – System is in manual

override

• (Pulsing LED in any of the

above colours indicates

unit is running on battery

power)

D. Displays system status:

• Ok – System is monitoring

and no alarms present

• Leak – System has

detected a leak and is in

alarm

E. Displays valve status: Open

or closed

F. Displays volt free relay

status: On or O

G. Displays protection value:

Options for what is

displayed here will depend

on protection mode

selected.

H. Reset Alarm button

I. Displays protection mode

J. Menu button

Figure 10 - Home Screen

J. SETTING THE AT-WFM

The AT-WFM requires settings to be adjusted to suit the conditions of the application it is to be tted to. For correct operation it is essential

the information entered into the unit is as accurate as possible.

Once all connections have been made power should be applied to the AT-WFM. To ensure power is being received check the red mains

LED is lit on the main PCB.

The status LED on the front of the AT-WFM should be green to indicate it is monitoring and no alarms are present.

LEAK DETECTION SOLUTIONS

8

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

K. MENU SCREEN

Home>>Menu

The menu screen has six buttons for navigating

around the AT-WFM.

Note: On all screens pressing the ‘Back’ button will

take you to the previous screen.

Figure 11 - Main Menu

K1. CONTROLLER INFO

Home>>Menu>>Controller Info

Figure 12 - AT-WFM Controller Information Screen

The Controller Info screen gives live detailed

information on the systems current setup and status

Status of System: Displays if the system is ‘Ok’, in

‘Leak’ alarm or has an ‘Error’.

Protection Level Times: This displays the current high

volume ‘Building occupied’ period see section L2B.

Current Operation Mode: Displays selected mode for

high volume period see section L3.

Valve Status (1&2): Displays whether valves are

enabled and if so whether currently open or closed

see section

Meter Value (1&2): Displays if meter is enabled, and if

so current live meter reading see section L4.

Software Version: Displays version number for

currently installed software

K2. INSTALLER INFO

Home>>Menu>>Installer Info

Figure 13 -Installer Information Screen

This screen displays the installer contact information.

By default it has Aquilar contact details loaded. These

details can be changed to show the details of the

installation / commissioning / current maintenance

company. See section L7.

LEAK DETECTION SOLUTIONS

9

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

K3. MANUAL OVERRIDE

Home Screen>>Menu>>Manual Override

Figure 14 -Manual Override Screen

Note: Caution should be taken before enabling

the manual override as this means the system

will not go into alarm for the selected time period and

your building will not be protected.

Pressing the on button enables the override. There are

four pre-set override time periods available. 15, 30, 45

and 60 minutes. These are selected by using the up or

down arrow.

Once a time period is selected the status LED will

change to blue and a countdown begins and runs for

the selected time period. Once this has reached zero

the status LED will return to green and the system will

automatically go back to normal operation.

Manual Override can be cancelled at any time by pressing the cancel button. The system will then revert back to normal operation as per

the programmed parameters.

K4. EVENT HISTORY

Home Screen>>Menu>>Event History

Figure 15 - Event History Screen

The events history contains information on any alarms

and programming/setup changes. The system will

retain the last 1000 events. Once this is full the oldest

events will drop o the list as new ones are recorded.

All events recorded have a date and time stamp and

are ordered according to this. With the most recent

events listed rst at the top of the list.

Use the arrows beside the events screen to scroll

through to older events.

Important Note: For accurate recording of events, the

date and time must be set up accurately on the system

during commissioning (see section L1.)

LEAK DETECTION SOLUTIONS

10

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

L. SETUP (FOR AUTHORISED USERS ONLY)

Home Screen>>Menu>>Setup>>Password>>Enter

To prevent unauthorised tampering with settings,

pressing the setup button in the menu screen will ask

you to input a password before entering into the setup

menu.

Using the on screen keyboard input AT-WFM then

press enter. DEFAULT PASSWORD : ATWFM Use

Capitals

This will open the setup menu.

Figure 16 - Setup - Password Screen

From this page you can access the screens necessary

to setup the AT-WFM controller.

Figure 17 - Main Setup

LEAK DETECTION SOLUTIONS

11

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

L1. DATE AND TIME

Menu>>Setup>>Password>>Date and Time

Figure 18 - Date / Time Setup Screen

Important Note: For correct operation of the

system it is essential the date and time are

correctly entered here.

To adjust the date and time press the edit button

under the value you wish to adjust.

Use the side arrows to select the value you wish to adjust, then the up and down arrows to select the required value. Only true values can

be selected. Press enter to return to the time and date screen then enter to save the values and return to the setup menu.

Note: The AT-WFM system has a real time clock that will retain the correct time and date in the event of power loss.

LEAK DETECTION SOLUTIONS

12

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

L2. PROTECTION LEVEL MODE

Menu>>Setup>>Password>>Protection Level Mode

Protection Level mode is the measurement used to monitor the ow through the pulse meters. There are three modes available:

• Volume per

• Timed

• Crosscheck

The other settings available on this screen will change according to the mode selected.

L2.A VOLUME PER

Figure 19 - Protection Level - VOLUME MODE

Default setting is ‘Volume Per’. In this mode the

system will allow a set amount (volume) of water

through the pulse meter during a dened period. e.g.

1500ltr water volume allowed in any half hour period.

In this setting there are three further options for

dening that period:

• ½ Hour

• Hour

• Day

By combining these values you increase or decrease

the ‘sensitivity’ of the systems measurement of ow

volume.

To edit the ow volume, press the edit button under the high or low volume value you wish to adjust to enter the value edit screen. Then

use the arrows to select and adjust values, then press enter to save and return to the screen above. (See section L3. on adjusting high low

volume times).

In the example shown in Fig.19 above the system will allow 1500ltr per half hour during high volume periods, and 60ltr per half hour

during low volume periods. Any water use above this level will put the system into alarm.

L2.B TIMED

Timed does not measure volume. Instead it will

allow water ow for dened periods of time. Periods

available are:

• 10 minutes

• 15 minutes

• 30 minutes

• 60 minutes

Any uninterrupted ow above this user dened time

will put the AT-WFM into alarm. In the example in g.20

the unit is set for 10 minutes. If the water ows for 11

minutes the system will go into alarm. If the water runs

for 9 minutes, stops, then ows for another 9 minutes,

stops, etc the system will not go into alarm.

Figure 20 - Protection Level - TIMED MODE

There are two reset options available:

Manual Reset – The Reset button must be pressed to stop the alarm and reset the controller

Automatic Reset – The controller will automatically reset as soon as the water ow stops

Note: A ow switch can be used in place of pulse water meters on this setting if required.

LEAK DETECTION SOLUTIONS

13

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

L2.C CROSSCHECK

Figure 21 - Protection Level - CROSSCHECK MODE

Crosscheck gives the AT-WFM exibility to be used

in applications where a comparison of two meters is

required, e.g. a block of ats with heat interface units,

especially useful if ats are left unoccupied for long

periods. The ow and return into each at can be

monitored. If more water goes in than comes out then

the water loss will be noted by the AT-WFM and an

alarm generated.

There are two adjustment in this section that aect the

sensitivity of alarm conditions, tolerance and volume

per.

Tolerance is measured in percentage and allows a dierential of up to 20% between channel pulse inputs. Options are:

• 0%

• 10%

• 20%

Volume per species the period of measurement. Options are:

• ½ hour

• Hour

• Day

e.g.1. Select tolerance 10% and volume per ½ hour. This means each half hour if the pulse input of each channel varies by more than

10% the system will go into alarm. On this setting an expected 100ltr measurement could vary by up to 20ltrs per half hour before an

alarm would be given. Total of 480ltrs per 24 hour period.

e.g.2. Select tolerance 20% and volume per Day. This allows up to 20% dierence in channel pulse inputs in any 24 hour period. On this

setting an expected 100ltr measurement would only allow 40ltrs dierence over a 24hr period.

Important Note: Selecting 0% tolerance requires the pulse inputs to be matched at all times.

Important Note: For eective operation identical pulse Meters with high accuracy must be used. Contact Aquilar for details on our

range of suitable water meters.

LEAK DETECTION SOLUTIONS

14

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

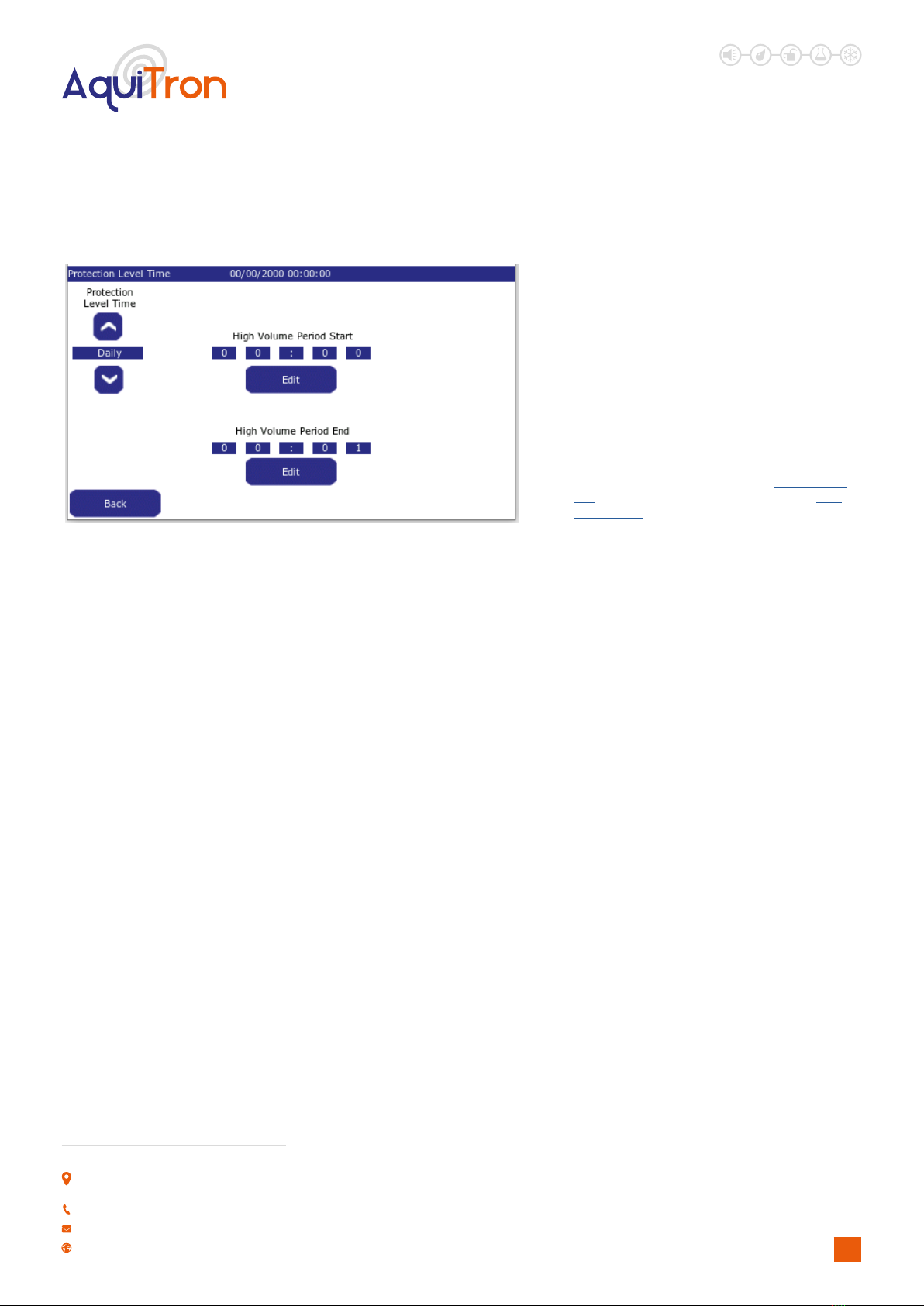

L3. PROTECTION LEVEL TIME

Menu>>Setup>>Password>>Protection Level Time

Figure 22 - Protection Level Time

Time select options are:

• Daily – Times are the same for all days

• Weekly – Dierent times can be set for each

day (each day must be set individually)

• Week/End – Times are set for week days and

weekends separately

• Ext Input – High and low volume times are

triggered via an external input such as a key

switch or alarm system i.e intruder alarm for

entry / exit setting. Trigger inputs must be a

normally open volt free contact (See section

H.2, closing to trigger into low volume. (See

section H.3 for connection information)

In this screen you set the start and end times required for high volume level. Any time outside of the parameters input here are

considered low volume level by the controller, and will be measured as such according to the volume levels in put in section H2. Volume

per.

The general rule for the high volume times is to set this higher value for when the building is occupied. Eg. For an oce you may want

to set the high volume (building is occupied) period to start at 8.00 and end at 18.00. In this example in the time between 6pm and

8am the controller will be using the low volume (building is unoccupied) setting.

In all options press the edit button under the value you wish to adjust to enter the edit screen, then use the arrows to select and enter

the value, press enter to save.

L4. METERS

Menu>>Setup>>Password>>Meters

Figure 23 - Meters Pulse Screen

The meter (pulse inputs) are enabled on this screen.

The example in g.23 shows meter 1 enabled (on)

and meter 2 o. If two pulse meters are being used

both should be enabled here.

To enable, or disable, a meter simply press the on/o

button on the screen.

The meter values shown on the meter dials should

be entered using the edit buttons. This will ensure

the meter readings match the controller readings to

make meter reading possible from one position, at

the AT-WFM.

LEAK DETECTION SOLUTIONS

15

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

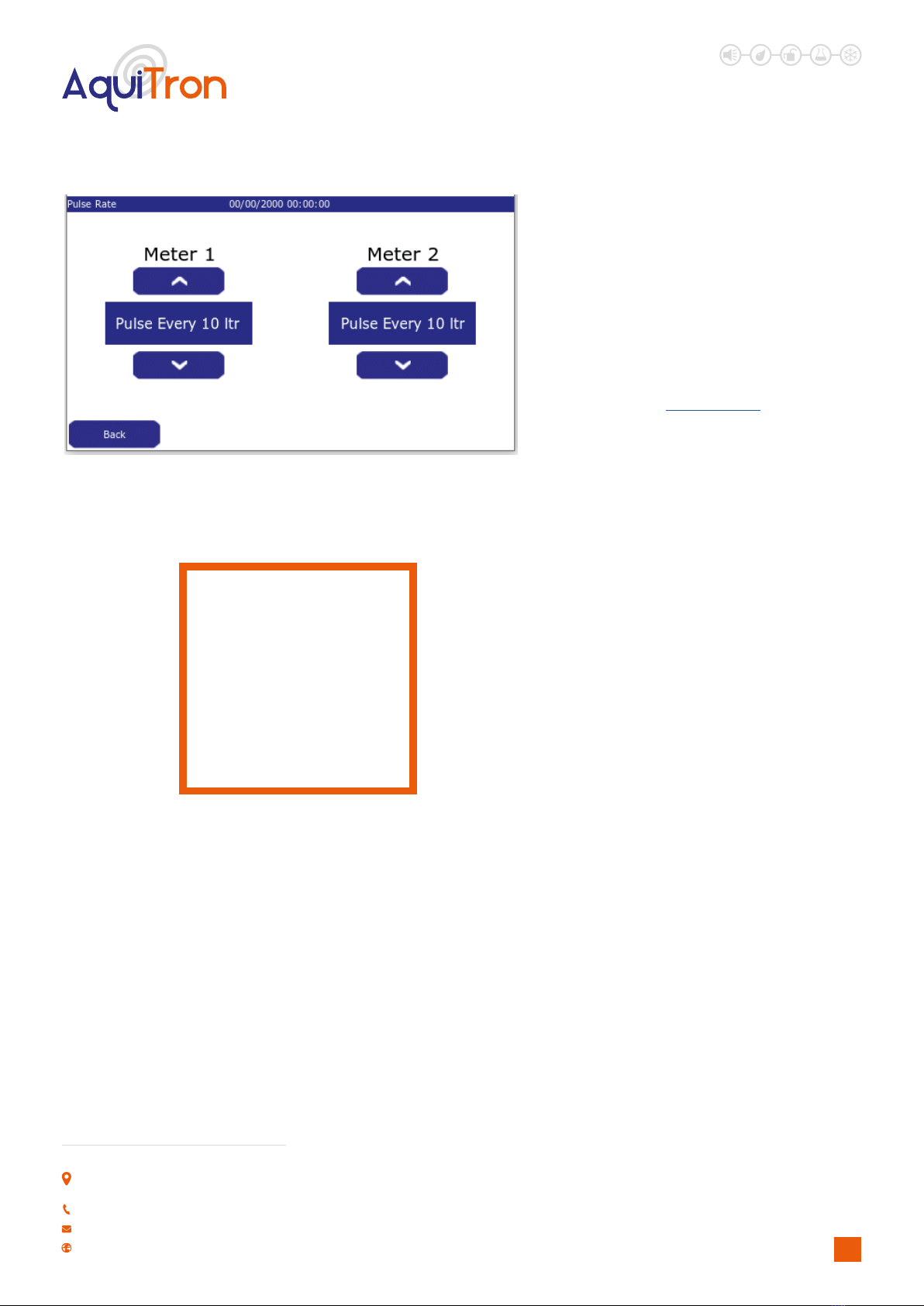

L5. PULSE RATE

Menu>>Setup>>Password>>Pulse Rate

Figure 23 - Meters Pulse Rate Setup

Pulse rates for the water meters connected to the

system are selected here. Options available are

pulse every: 1, 10, 100 litres. It is important that the

pulse selected should match the output from the

meter tted. If not the system will not be able to

accurately measure water volume.

Please contact Aquilar if you require a suitable pulse

meter.

Note: If this screen is blank it is because no meters

have been enabled. (See section H4)

Fig 23.a shows a typical pulse

transmitter, this is where a pulse is

taken to be connected to the AT-WFM

control panel.

Figure 23.a - Typical Cyble

LEAK DETECTION SOLUTIONS

16

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

L7. CHANGE INSTALLER INFO

Menu>>Setup>>Password>>Change Installer Info

Figure 25 - Installer Information Change Screen

On this screen the installer information can be

changed. By default Aquilar details are shown.

To make changes to the information shown simply

press the ‘Change’ button next to the information

you wish to adjust. This will bring up the on-screen

keyboard. Type in the new information and press

enter to save.

Note: Entering no information, not pressing enter, or

pressing back will keep the existing information.

L6. VALVES

Menu>>Setup>>Password>>Valves

Figure 24 - Valve(s) Setup Screen

If valves are tted they must be enabled here for the

system to control them. To enable or disable use the

on screen On/O button for each valve. See section

H5. For connection details.

IMPORTANT NOTE: Only use AquiTron valves on this

system.

See Section B “Types Of Valves”.

LEAK DETECTION SOLUTIONS

17

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

PO POWER ON

Device powered on

POWER OFF

Mains power lost, operating from battery

System detected that mains power to the unit has been removed and that the system is operating from the battery. This message will not

be logged if power is removed and there is no battery backup.

MAINS POWER RETURNED

Mains power returned

System has detected that the mains power to the unit has been restored and the display has returned to normal operation. This message

will not be logged if power is removed and there is no battery backup.

LA LEAK ALARM

Leak Alarm

Message to record the time when a new leak is discovered. This message will be logged every time the system goes into alarm

AR ALARM RESET

Alarm Reset

Message to record that the system has been reset.

Log messages can only be viewed directly on the screen under Menu > Event History. It is possible to scroll through them by using the

up and down arrows.

M. EVENT LOG MESSAGES

L8. FACTORY REST

Menu>>Setup>>Password>>Factory Reset>>Conrm

Figure 26 - Factory Reset Screen

The AT-WFM can be reset back to factory default

settings. If this screen is selected you will be asked

to conrm or cancel this action. To exit without

resetting press cancel. To proceed press conrm.

All settings will need to be re-entered, including time

and date.

Important Note: This action will revert the unit back

to default settings and delete all history. It is non-

reversible.

LEAK DETECTION SOLUTIONS

18

Unit 30, Lawson Hunt Industrial Park,

Broadbridge Heath, Horsham, West Sussex,

RH12 3JR

+44 (0) 1403 216100

www.aquilar.co.uk

Important: All information, including illustrations, is believed to be reliable. Users, however, should independently evaluate the suitability

of each product for their application. Aquilar Limited makes no warranty as to the accuracy or completeness of the information, and

disclaims any liability regarding its use. The only obligations of Aquilar Limited are those in the Aquilar Standard Terms and Conditions of

Sale for this product, and in no case will Aquilar Limited be liable for any incidental, indirect, or consequential damages arising from the

sale, resale, use or misuse of the product. Specications are subject to change without notice. In addition, Aquilar Limited reserves the

right to make changes – without notication to Buyer

– to processing or materials that do not aect compliance with any applicable specication.

AquiTron is a trademark of AquiTron Limited

Aquilar is a trademark of Aquilar Limited

V1.2 06.2022

SYSTEM FAULT

System Fault

Message will be displayed when a system fault has been detected, if problem persists please contact Aquilar.

MC PROTECTION LEVEL MODE CHANGED

Protection level mode changed to XXXX (X can be volume per, timed, crosscheck)

Logs a mode change upon exit of the Protection Level Mode screen.

TC PROTECTION LEVEL CHANGED

Protection level time changed to XXXX (X can be daily, weekly, week/weekend, Ext input)

Logs a time change upon exit of the Operating Mode screen.

VC PROTECTION VOLUME CHANGED

Protection volume XXXX changed to YYYY (X can be high or low, Y is the new volume amount)

Logs that manual override mode has started upon exit of the manual override screen.

OS MANUAL OVERRIDE STARTED

Manual override started for XXXX (X will be the time the manual override has been set for)

Logs a change to either high volume amount or low volume amount upon exit of Protection Level Mode screen whilst volume per mode is

selected.

OS MANUAL OVERRIDE ENDED

Manual override ended: XXXX (X can either be timeout or manual)

Logs that manual override mode has nished by either timeout or it has been cancelled manually.

Table of contents

Other aquilar Measuring Instrument manuals