9

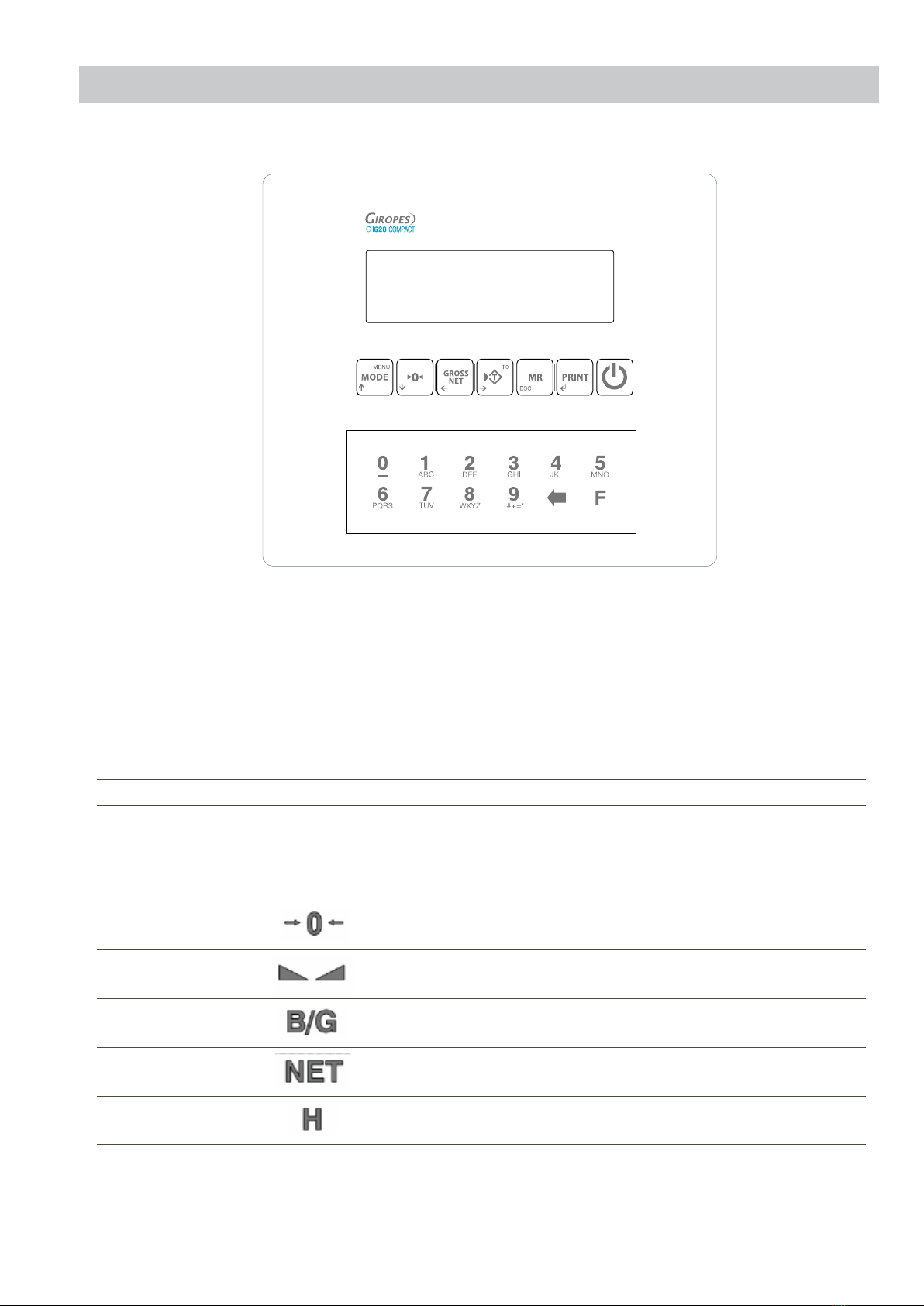

ENENUSER MANUAL GI620 COMPACT

In the edit menus: In the numeric menus, directly enter the digit represented

on the key.

In alphanumeric menus, the letters or symbols described.

Pressing change from letter to number and vice versa.

The left arrow serves to delete one by one the last digit in editing.

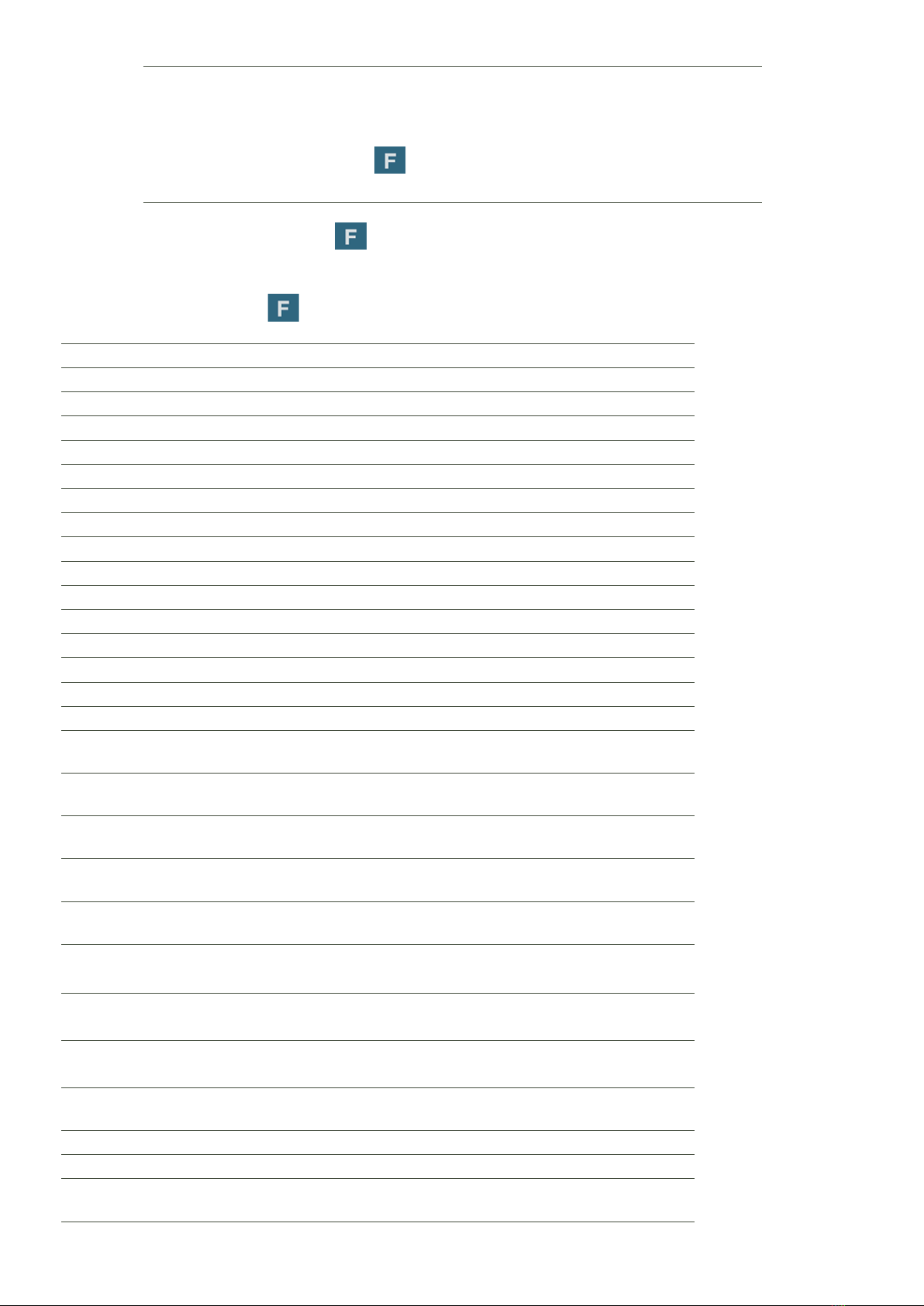

The key, pressed from the weighing mode can be combined with two digits to have direct access to different functions or menus of the

device.

In the weight-window, first press the

key followed by the two corresponding numbers in the table, entered one by one.

F10 Access the edit menu of the Plate register

F11 Access the activation menu of the Plate register

F12 Deactivate the currently active Plate register

F20 Access the edit menu of the Register 1

F21 Access the activation menu of the Register 1

F22 Deactivate the currently active Register 1

F30 Access the edit menu of the Register 2

F31 Access the activation menu of the Register 2

F32 Deactivate the currently active Register 2

F40 Access the edit menu of the Register 3

F41 Access the activation menu of the Register 3

F42 Deactivate the currently active Register 3

F50 Access the edit menu of memorized tares (only in Tare_version)

F51 Access the activation menu of memorized tares (only in Tare_version)

F52 Deactivate the currently active memorized tare (only in Tare_version)

F70 Deletes the table of weighings performed

F71 Delete the Totals of the Plate register (TOTREG option) or delete the info of Plate register

completely (ALLREG option)

F72 Delete the Totals of the Register 1 (TOTREG option) or delete the info of Register 1 comple-

tely (ALLREG option)

F73 Delete the Totals of the Register 2 (TOTREG option) or delete the info of Register 2 comple-

tely (ALLREG option)

F74 Delete the Totals of the Register 3 (TOTREG option) or delete the info of Register 3 comple-

tely (ALLREG option)

F75 General delete. Eliminates the weighing table, as well as the Plate register and Register 1, 2

and 3

F76 General delete of programmed tares. Eliminate the table of memorized tares

(only in Tare_version)

F80 Sequential activation of records previously saved in memory. Plate register, Register 1,

Register 2 and Register 3

F81 Sequential introduction of information (free, without previously storage in memory).

Plate register, Register 1, Register 2 and Register 3

F90 In static automatic or dynamic mode, it allows you to configure the number of axles. (In these

two working modes it is mandatory to enter the number of axles in order to operate)

F96 Activates the static manual axle-weighing mode. Channels P1 and/or P2

F97 Activates the static automatic axle-weighing mode. Channels P1 and/or P2

F98 Activates the dynamic axle-weighing mode. Channel P3 (P4 in this case does not act as a

channel but as a connector in the case of working with two platforms in this mode)