Fike OSI-RI-FIK User manual

SPECIFICATIONS

Wire Gauge for Terminals: 14 AWG (1.6 mm), 14 AWG (2.08 mm2)

Operating Voltage Range: Without isolator: 15 to 32 VDC (12 or 24VDC nominal, non-polarized),

15-28.5V when using isolators

Maximum Standby Current: 13 mA @ 32 VDC, 14 mA @ 24 VDC, 20 mA @ 15 VDC

Maximum Alarm Current (LED on): 22 mA @ 32 VDC, 15 mA @ 24 VDC, 22 mA @ 15 VDC

Operating Humidity Range: 0% to 95% Relative Humidity, Non-condensing

Operating Temperature Range: –4°F to 131°F (-20°C to +55°C).

UL-Listed for use from 32°F to 100°F (0°C to 37.8°C)

Adjustment Angle: 20 degrees vertical, 50 degrees horizontal

Sensitivity Levels: Level 1 25%, Level 2 30%, Level 3 40%, Level 4 50%

Fault Condition (Trouble): Long-term drift reference out of 20% range, beam blockage or detector out of alignment, imager saturated

Alignment Aid: LED directional arrows

Alarm Indicator: Local red LED and remote output

I56-6957-000

QUICK START GUIDE

704 S. 10th Street

Blue Springs, MO 64015

Phone: 800.979.3453; Fax: 816.228.9277

www.fike.com

OSI-RI-FIK

Smoke Detection System

This guide provides information on how to install the OSI-RI-FIK Smoke De-

tection System.

Extensive product and critical product security information can be found

in the OSI-RI-FIK Installation Guide (Document No. E56-6957) available at

http://www.fike.com/06-912.

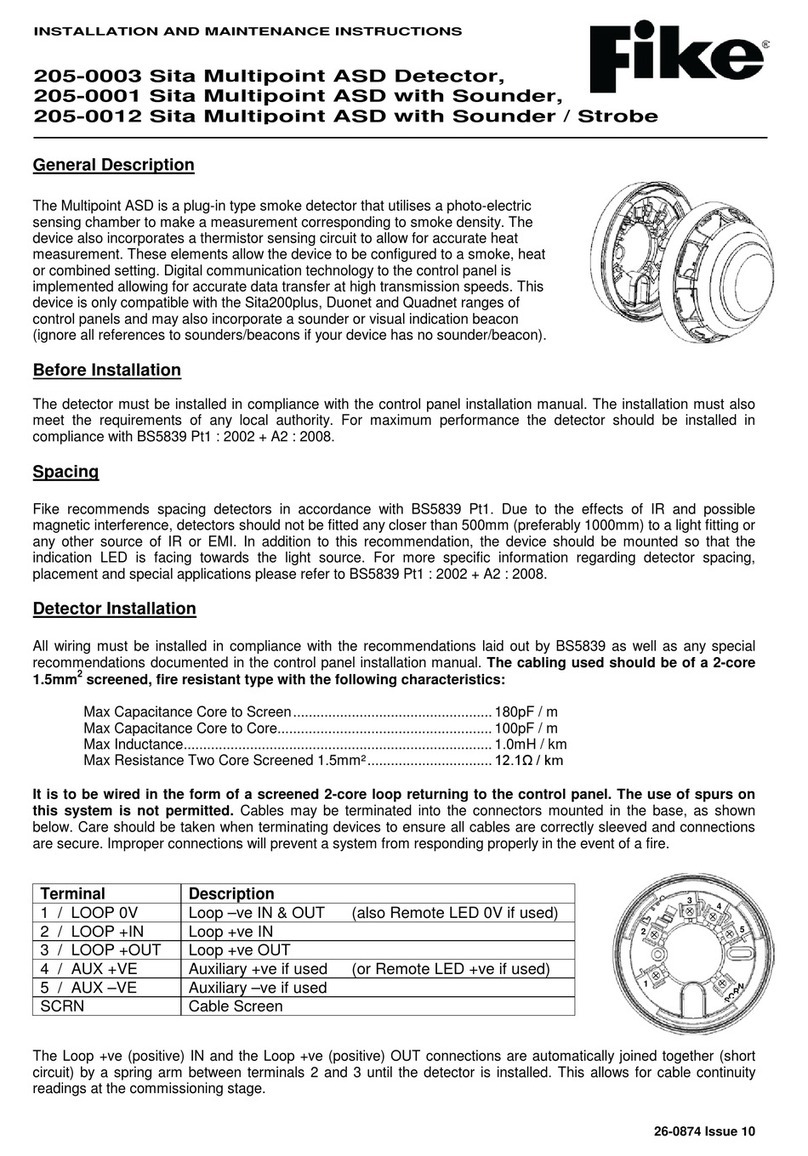

The OSI-RI-FIK system consists of an Imager and a reflector. (See Figure 1.)

FIGURE 1. IMAGER AND REFLECTOR

C2051-00, C2052-00

DETERMINE THE POSITIONS OF THE IMAGER AND REFLECTOR

COMPONENTS

Make sure that the intended mounting locations meet the following criteria

(See Figure 2.):

• Detector spacing must comply with local codes and standards

• Reflector must be located within the Field of View (FOV) of the Imager

• Clear path between the reflector and Imager

• Mounted well above the head-height of people and obstructions

• Avoid direct sunlight onto the units

The Imager and reflector should be placed within a recommended distance

below the ceiling. (See Figure 3.) This value will vary according to regional

specifications, geometry, and specific requirements for the installation. The

distance for flat ceilings and basic spacing requirements (S) is shown in the

following table.

Standard Distance from Ceiling Maximum Spacing (S)

NFPA 72 12 in. (300 mm) minimum 60 ft (18.3 m)

AS1670.1 1 to 23.6 in. (25 to 600 mm) 45.9 ft (14 m)

BS5839.1 1 to 23.6 in. (25 to 600 mm) 49.2 ft (15 m)

GB50166 11.8 to 39.4 in. (300 to 1000 mm) 45.9 ft (14 m)

For full information on spacing requirements, please refer to your local codes

and standards.

FIGURE 2. MOUNTING LOCATIONS

12” minimum

(0.3m)

10’ (3.0m)

minimum

Typical

30’

(9.1m) maximum

To First

Detectors

1/2 S S

Wall

C2053-00

FIGURE 3. MOUNTING LOCATIONS

Ex. Distances according to NFPA 72.

1/2 S maximum

ReflectorTx/Rx

S

Tx/Rx Reflector

16 ft. (5m) minimum

328 ft. (100m) maximum

1/4 S

maximum

C2054-00

R

http://www.fike.com/06-912

Fo

r system/product documentation including

installation, operation, and maintenance,

scan QR code or enter URL provided.

1 I56-6957-000

10/21/2020

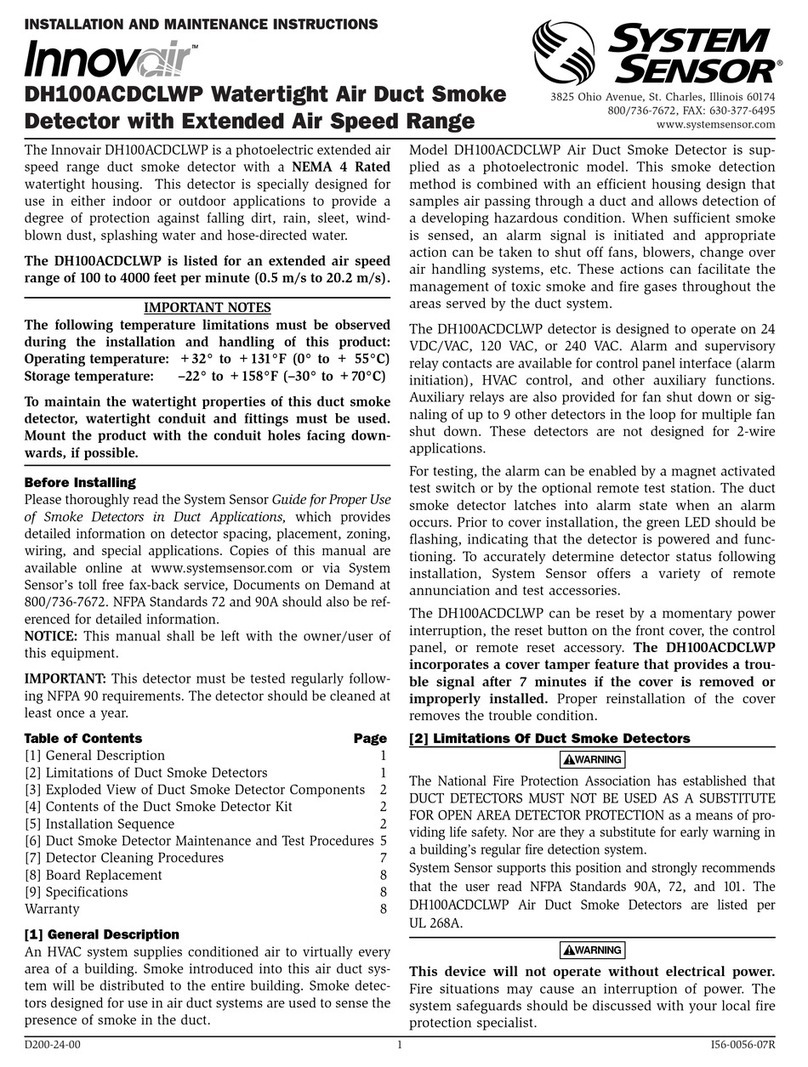

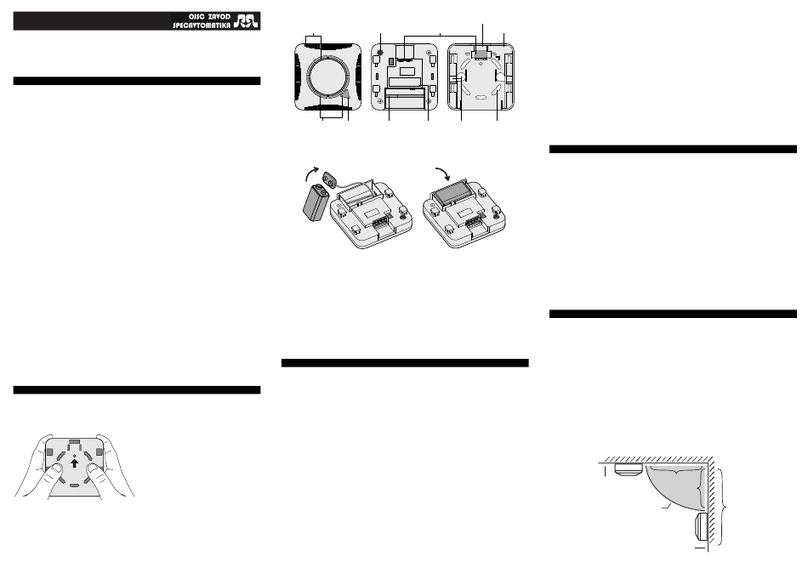

MOUNT THE REFLECTOR USING THE DRILL TEMPLATE

Refer to Appendix II. in Installation guide for drill template instructions. (See

Figure 4.)

MOUNTING THE DETECTOR

Remove detachable front rim cover. To detach the Imager part from the back-

box, loosen the 3 holding screws.

To provide cable access to the Termination Card of the Imager remove the

cut-outs from the back, bottom or top of the main assembly by using a sharp

blade to cut around the circular discs.

Secure the back box directly onto the mounting surface using any suitable

number of the 5 pilot holes in the backbox.

Use appropriate fasteners to secure the back box component to the mounting

surface.

FIGURE 4.MOUNTING THE DETECTOR

Cable knock-outs

bottom

Cable knock-outs

top

Holes for the fixing

of the detector

Large knock-out

for 4” J-Box

Mounting holes

C2055-00

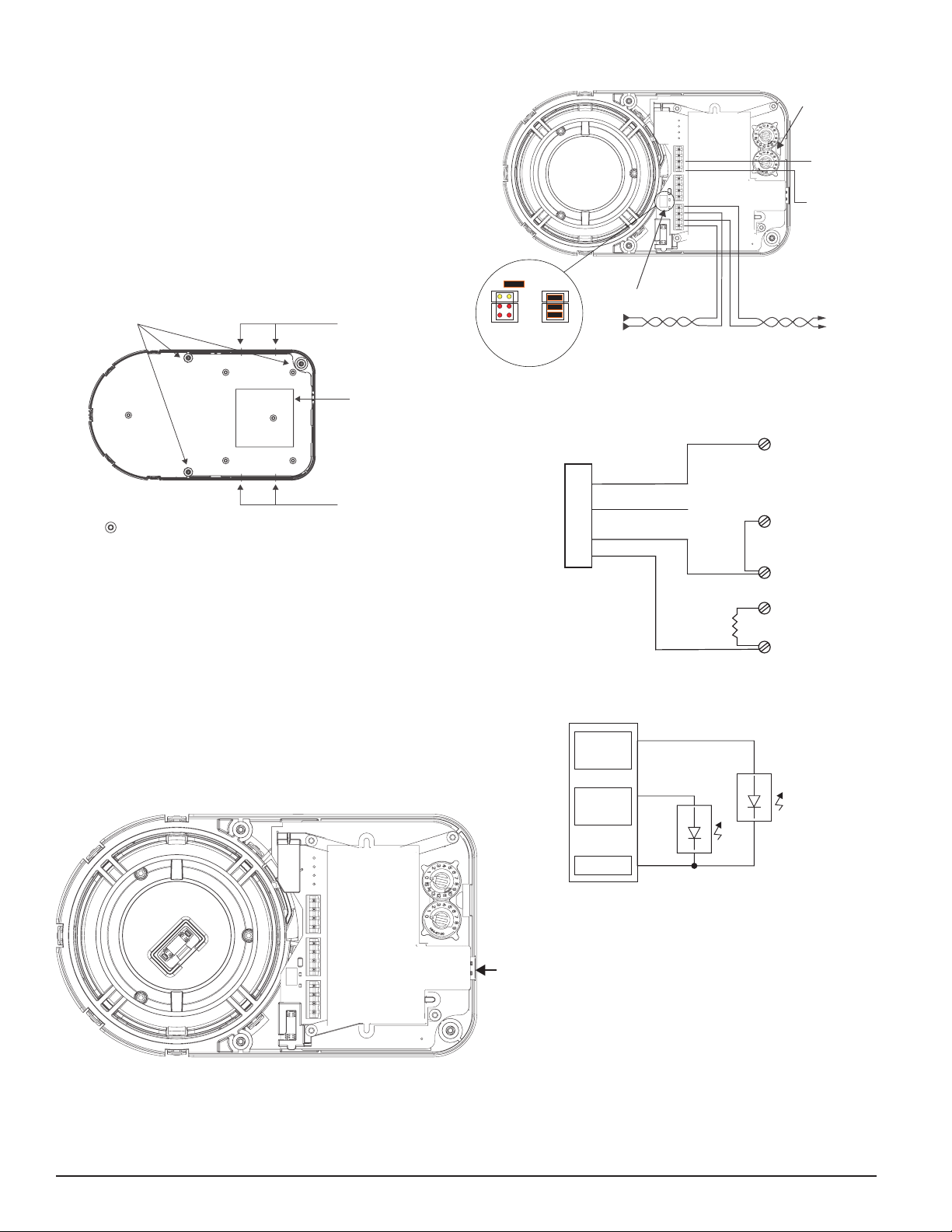

WIRE THE TERMINATION CARD ON THE IMAGER

• Wire the initiating device circuit on the Imager Termination Card using

the addressable loop. (See Figure 5.)

• Wire external power to the unit via the POWER terminals.

• Wire the Remote Indicator and/or remote test or reset units if required

(See Figure 6.).

• Securely connect the wires to the plug-in terminals and engage in the

receptacles at the back of the Imager.

• Switch on the heater if the installation requires so.

• Set the detector address using the rotary switches

• Re-attach the Imager to the back box

• Remove the protective film from the lens surface of the imager.

• Connect power to the Imager.

FIGURE 5. WIRING THE TERMINATION CARD

T3

T2

T1

Not Used

Not Used

Heater Power In -

Heater Power In +

AUX (-)

Remote Test/Reset Input

Remote Trouble Output

Remote Alarm Output

SLC - OUT

SLC - IN

SLC + OUT

SLC + IN

USB

Connector

C2056-00

FIGURE 6. WIRING THE TERMINATION CARD

Heater on/off switch

Communication Line

32 VDC max.

Twisted pair is

recommended

To next

device

From panel

or previous

device

+

-

-

+

Jumper

No heater

Isolator

Heater

No Isolator

heater

shunts

Rotary switches

for setting

the address

Heater

Power

In -

Heater

Power

In +

C2057-00

FIGURE 7. OSI-RI TERMINALS

T1

RTS151/Key

Terminals

T3

T4

T5

T2

OSI-RI-FIK Terminals

External

Jumper

10k ohm

External

Resistor

Remote Alarm Output

Remote Trouble Output

Remote Test/Reset Input

AUX -

T2-1

T2-3

T2-2

T2-4

Wiring: Single 2 pair cable , 0.8mm

2

, unshielded.

C2058-00

FIGURE 8. REMOTE LED CONNECTIONS

Alarm

Signal

Circuit

Trouble

Signal

Circuit

Yellow

Red

T2-1

T2-2

T2-4

Remote LED connections

C2059-00

2 I56-6957-000

10/21/2020

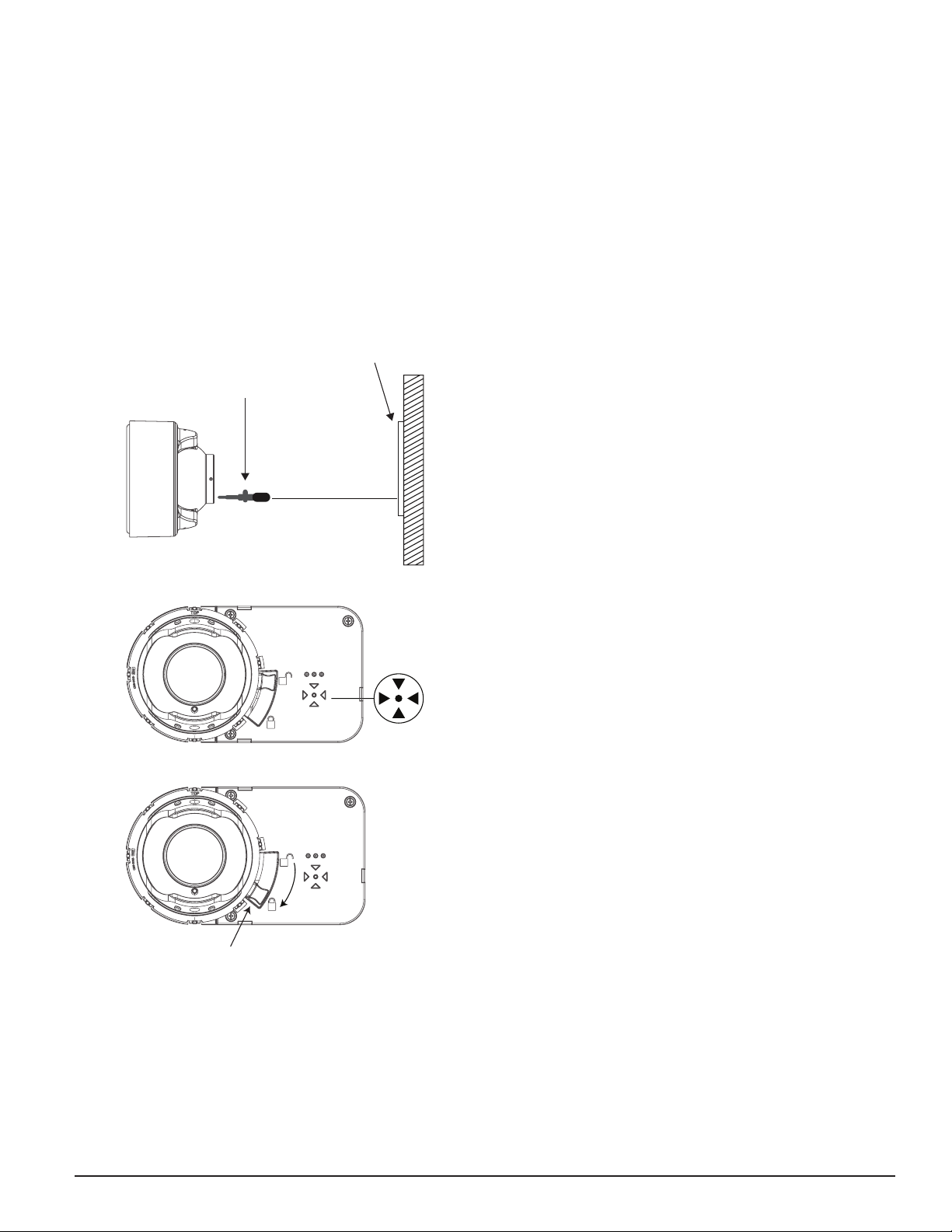

INITIALIZATION AND COMMISSIONING

Ensure that neither you nor any other objects are in the line of sight between

the detector and the reflector and start to manually align the Imager to the

reflector (See Figure 9.)

The OSP-002 Laser Alignment Tool can be used for the rough alignment if

the system is to be installed at longer distances or in heavy lit environments.

Follow these steps to adjust the optical sphere of the detector component to

align the system (See Figure 10.):

• Make sure the lever is the 3 o’clock position.

• The 4 arrows will intuitively guide the user to optimal eyeball alignment.

Likely the alignment process will start with all arrows red.

• Gently move the eyeball until all arrows and the middle green LED blink

green for the eyeball to be optimal aligned (See Figure 11.).

• When all arrows are green, gently lock the eyeball by moving the lever

down till the eyeball is solidly locked. The lever is now in the 5 o’clock

position and you feel the resistance of the locked position.

FIGURE 9. COARSE ALIGNMENT

OSP-002 Laser

Alignment Tool

Reflector

C2060-00

FIGURE 10. ARROW ARRAY

C2061-00

FIGURE 11. LOCKING AND SECURING EYE BALL

Level down

C2062-00

By locking the eyeball an internal switch is activated and the detector will

now start its initiation or commissioning process. A normal commissioning

process takes roughly 10 seconds. During the commissioning process, the

beam path must remain clear from object intrusions.In this process cycle, the

detector will measure the size of the reflector in the FOV and set the sensitiv-

ity automatically to the optimum sensitivity for the specific distance.

Before going in operational mode, the detector will show its set sensitivity.

This is shown by blinking the 4 arrows to the color yellow, reflecting the % of

selected obscuration/sensitivity. The key is; 1 blink = 25%, 2 blinks = 30%,

3 blinks = 40% and 4 blinks = 50%. After 5 seconds, the scenario will be re-

peated a second time and the arrows LEDs go out and the front OK LED blinks

green. The detector is now in operation and working correctly.

The paintable rim can now be snapped over the front to secure the locking

lever and to hide the alignment LEDS and locking mechanism.

Applying the cover also secures the locking lever in position.

TESTING THE INSTALLATION

After the commissioning, the detector must be tested for correct alarming by

using the OSP-004 test filter at the reflector or using the remote test station.

When using the RTS151KEY for testing the detector, the remote fault LED will

blink the set sensitivity of the detector. The number of blinks, similar to sec-

tion 5, will represent the set sensitivity and the sequence is repeated every 3

seconds till the detector is reset.

IMAGER RESET

The fault LED is non-latching but the alarm LED can be set to latching by the

FACP. The Imager alarm can be reset from the FACP.

OPERATION AFTER A POWER FAILURE

After a power failure of any duration, when the supply is restored, the detec-

tor will check the possible new situation versus its memorized data.

If the reflector is found in the same position and all parameters are within

acceptable limits, the detector will resume its operation and go out of fault

condition.

If any significant parameters have changed, it will remain in a fault condition

and a re-initialization will be required.

3 I56-6957-000

10/21/2020

Fike® is a registered trademark of Fike Corporation.

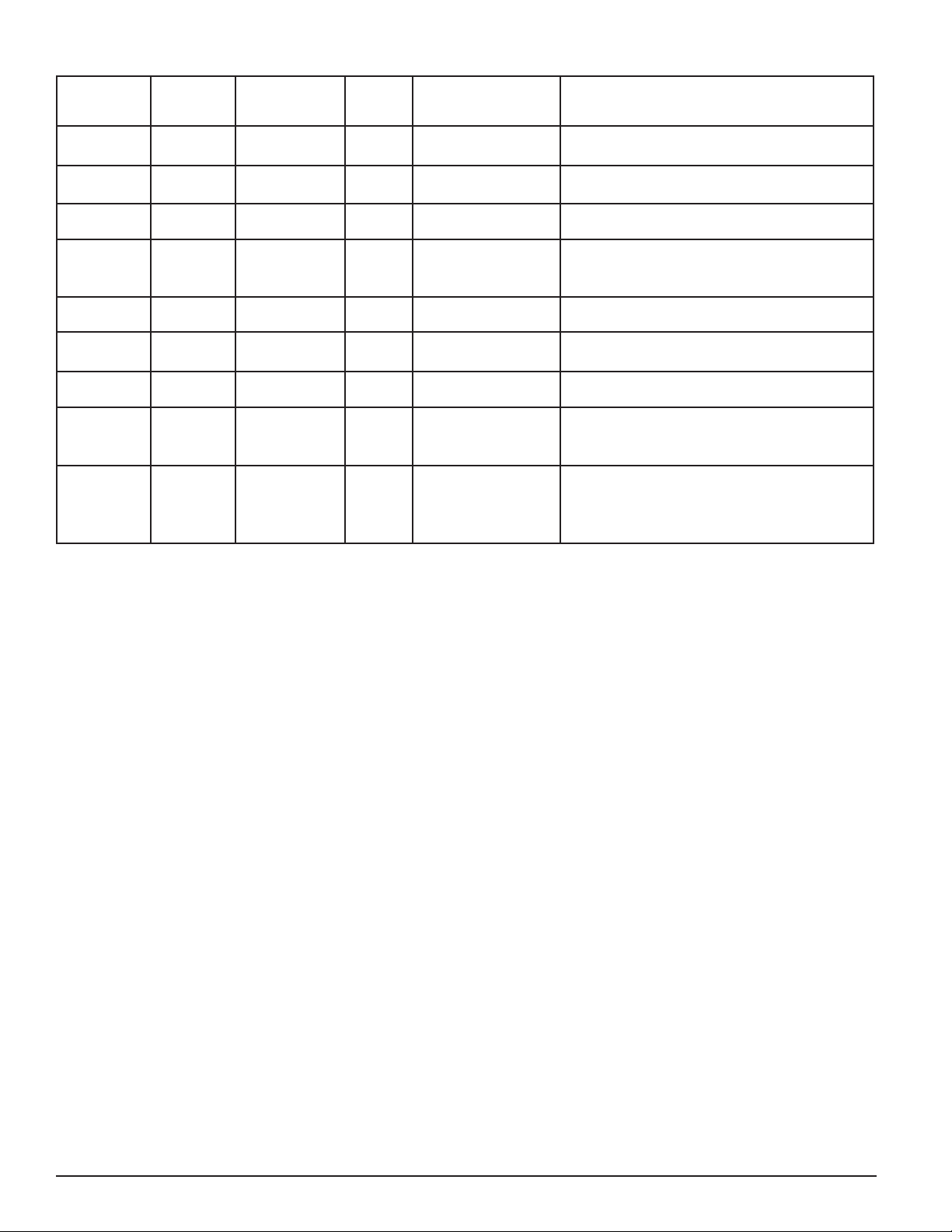

OPERATION MODES AND TROUBLESHOOTING GUIDE OSI-RI-FIK

Modes Red and Re-

mote Alarm

output

Yellow and

Remote Trouble

Output

Green Initiating meansComments & Troubleshooting Tips

Power on Off Blink Off Apply Power from dis-

charged state

• All wiring correctly done.

• Address switches set.

Alignment Off Blink Off Lever in 3:00 position and

commissioning is active

• Ready to perform alignment.

• Follow guidance from the 4 arrows to correctly align.

Initializing/

Commissioning

Off Blink Off Lock lever in 6:00 position

to start commissioning

• Commissioning and setting sensitivity.

• Do not interrupt beam.

Normal Off Off Blink Successful completion of

initialization or detector

reset

• Initializing finished.

• Detector operates normal in quiescent condition.

• Detector successfully reset.

Alarm On Off Off Smoke, Test Filter or RTS-

151KEY Test Station

• Blinks till reset from FACP.

Trouble-Drift

Compensation

Off 3 Quick Blinks Blink Long Term Drift Reference

Out of 20% Range

• Reduced IR Signal

• Clean detector and reflector.

Trouble-Beam

Blockage

Off 4 Quick Blinks Blink Beam blockage or detector

out of alignment

• Remove blockage or re-align detector

• Faulty unit.

Trouble-Imager

saturation

Off 5 Quick Blinks Blink Imager saturated • Sunlight or very strong light into detector or reflector.

• Re-position detector or reflector.

• Remove light source.

Test activated-

Pass Result

On Blinks the set sen-

sitivity by number

of blinks (1-4).

Repeats every 3

seconds till reset.

Off FACP or RTS151KEY • Remains in alarm until reset by FACP.

• Number of lit arrows indicates sensitivity level that

was selected automatically.

4 I56-6957-000

©2020 Fike. 10/21/2020

Other Fike Smoke Alarm manuals