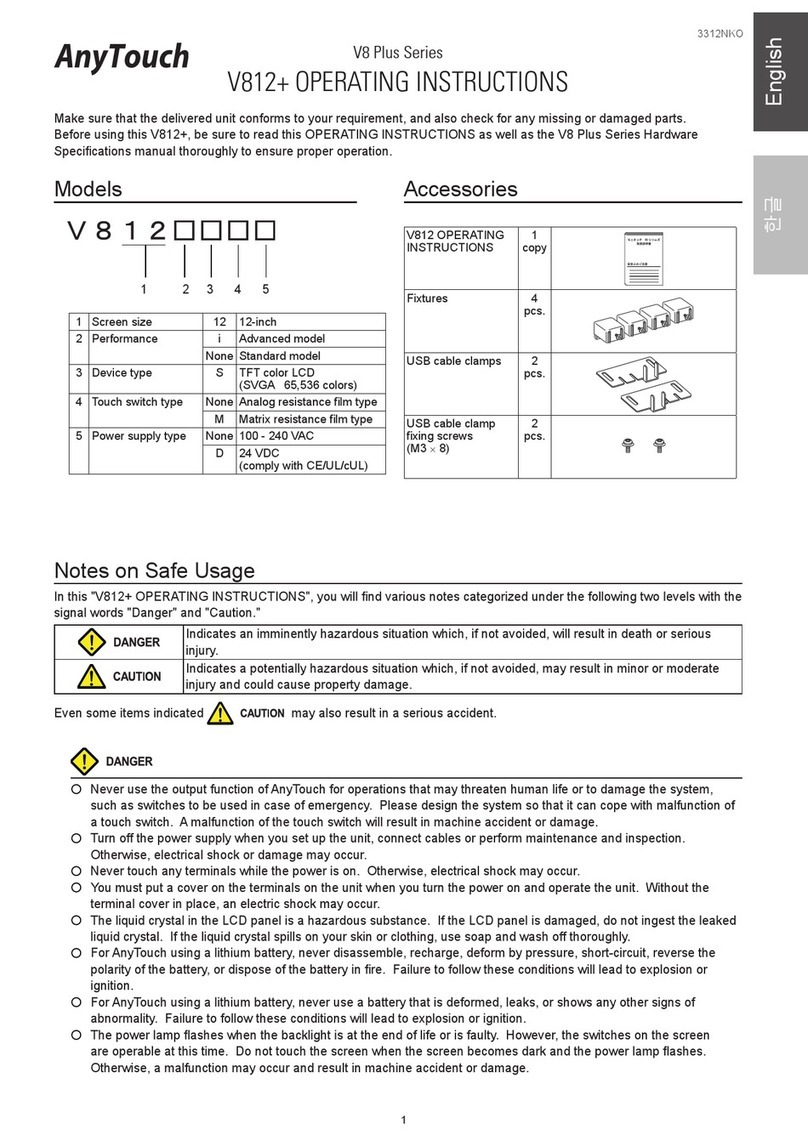

Fike TWINFLEX SRP User manual

26-1362-01

TWINFLEX®SRP

Fire Suppression System

Remote Status Indicator (RSI)

(Suitable for TWINFLEX®SRP Control Panel from V01.000)

Engineering and Commissioning Manual

(TO BE RETAINED BY THE COMMISSIONING ENGINEER)

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

2

Fike’s policy is one of continual improvement and the right to change a specification at any time without notice is reserved. Whilst every

care has been taken to ensure that the contents of this document are correct at time of publication, Fike shall be under no liability

whatsoever in respect of such contents.

Due to the complexity and inherent importance of a life risk type system, training on this equipment is essential and commissioning should

only be carried out by competent persons.

Fike cannot guarantee the operation of any equipment unless all documented instructions are complied with, without variation.

E&OE.

TWINFLEX, Mulitpoint, Fike and Fike Corporation are registered trademarks of Fike Corporation and its subsidiaries. All other trademarks,

trade names or company names referenced herein are the property of their respective owners.

Fike equipment is protected by one or more of the following patent numbers: GB2426367, GB2370670, EP1158472, PT1035528T,

GB2346758, EP0917121, GB2329056, EP0980056, GB2325018, GB2305284, EP1174835, EP0856828, GB2327752, GB2313690

© 2016 Fike Safety Technology Ltd. All rights reserved. Document issued January 2016.

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

3

Contents

Introduction........................................................................................................................................................... 5

System Design...................................................................................................................................................... 5

Equipment Guarantee .................................................................................................................................. 5

Anti-Static Handling Guidelines.................................................................................................................... 5

Warning........................................................................................................................................................ 5

EMC.............................................................................................................................................................. 6

The TWINFLEX® SRP System............................................................................................................................. 6

Remote Status Indicator (RSI)............................................................................................................................. 6

Mounting the RSI .................................................................................................................................................. 7

Physical Dimensions .................................................................................................................................. 10

General Assembly .............................................................................................................................................. 10

Ribbon Cable Connection .......................................................................................................................... 11

Fixing Front Panel To Back Box.................................................................................................................11

Installation and Commissioning ....................................................................................................................... 12

Topology & Cabling.................................................................................................................................... 12

Maximum Cable Lengths............................................................................................................................12

Power Supply & Connections..................................................................................................................... 13

Power Connection Table..................................................................................................................13

Current Drawn by Single Remote Status Indicator @ 24.0V DC.....................................................13

Separate Power Supply Requirements............................................................................................13

Remote Status Indicator Back Board Power Supply Connections ..................................................13

Peripheral Bus Connections.......................................................................................................................14

SRP Control Panel Connector Board Peripheral Bus Connections................................................. 14

Remote Status Indicator Back Board Peripheral Bus Connections................................................. 14

Ext Switches SW1 and SW2 Connection Examples.................................................................................. 15

RSI With External Switch Connections............................................................................................ 15

RSI Without External Switch Connections. EOL must be present..................................................15

SRP Control Panel Peripheral Bus Settings .............................................................................................. 16

RSI Panel Settings .....................................................................................................................................16

Setting RSI Address/Number........................................................................................................... 16

RSI Buzzer.......................................................................................................................................16

LCD Contrast..............................................................................................................................................17

Powering Up...............................................................................................................................................17

Commissioning...........................................................................................................................................18

Fault finding................................................................................................................................................ 18

General Operation of Remote Status Indicator ............................................................................................... 19

RSI Front Panel..........................................................................................................................................19

LED Indication............................................................................................................................................ 19

Fire Alarm Controls..................................................................................................................................... 20

System Controls.........................................................................................................................................20

Extinguishant Release Controls ................................................................................................................. 20

Access Levels............................................................................................................................................. 21

Access Level 1 (Normal).................................................................................................................. 22

Access Level 2 (User):..................................................................................................................... 23

End User Training............................................................................................................................................... 25

Maintenance........................................................................................................................................................ 25

Technical Data .................................................................................................................................................... 25

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

4

Remote Status Indicator Specification ....................................................................................................... 25

Fire Alarm System Notice.................................................................................................................................. 26

To Enable the Control Panel Keys............................................................................................................. 26

To Manually Operate the Fire Alarm Sounders..........................................................................................26

Following a Fire Alarm Operation............................................................................................................... 26

Following a Fault Condition........................................................................................................................26

Important Notes .................................................................................................................................................. 27

Fire Alarm User Notice....................................................................................................................................... 27

Engineers Notes ................................................................................................................................................. 29

Technical Support .............................................................................................................................................. 30

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

5

Introduction

This Manual is intended as a guide to the engineering and commissioning principles of the TWINFLEX®

SRP Remote Status Indicator and covers the system hardware information only.

Due to the complexity and inherent importance of a system covering a ‘Life Protection Risk’, training on

this equipment is essential and commissioning should only be carried out by competent and approved

persons. For further details of the availability of commissioning services, please contact your supplier.

System Design

This document does not cover Fire Alarm system design and a basic understanding is

assumed.

A knowledge of BS5839: Pt 1: 2002: Fire Detection and Alarm Systems for Buildings

is essential.

It is strongly recommended that a suitably qualified and competent person is consulted in

connection with the Fire Alarm System design and that the entire system is commissioned

in accordance with the current national standards and specifications.

Equipment Guarantee

The equipment carries no warranty unless the system is installed, commissioned and

serviced in accordance with this manual and the relevant standards by a suitably qualified

and competent person or organisation

Anti-Static Handling Guidelines

Immediately prior to handling any PCBs or other static sensitive devices, it is essential to

ensure that a personal connection to earth is made with an anti-static wrist-strap or

similar apparatus.

Always handle PCBs by their sides and avoid touching any components. PCBs should also

be stored in a clean dry place, which is free from vibration, dust and excessive heat and is

protected from mechanical damage.

Warning

Do not attempt to install this equipment until you have fully read and understood

this manual.

Failure to do so may result in damage to the equipment and could invalidate the warranty.

For technical support please contact your distributor. Do not call the Fike Safety

Technology support department unless your distributor has first given their advice and

attempted to rectify the issue.

Technical support will not be available if the instruction manual has not been read and

understood. Please have this instruction manual available whenever you call for technical

support.

!

!

!

!

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

6

EMC

This equipment when installed is subject to the EMC directive 2004/108/EC. It is also

subject to UK Statutory Instrument 2006 No. 3418.

To maintain EMC compliance, this system must be installed as defined within this manual.

Any deviation from this renders the installer liable for any EMC problems that may occur

either to the equipment or to any other equipment affected by the installation.

The TWINFLEX® SRP System

The TWINFLEX®SRP system is an intelligent ‘2-wire’ system utilising a conventional-type cabling

format.

The system is classed as ‘Analogue non-addressable’ due to the architecture used within the design. All

field devices including sounders can be connected to the zone via a common 2-core screened cable.

The devices communicate with the Control Panel using the TWINFLEX®data protocol.

Remote Status Indicator (RSI)

The TWINFLEX®Remote Status Indicator connects to a Control Panel and reports events that occur on

the system. It does not connect to any detection devices.

The TWINFLEX®RSI can also perform fire alarm system controls over the network (i.e. Silence Alarms,

Reset, Sound Alarms & Silence Buzzer). In addition, the RSI can put the system into the Manual

Release ONLY operation mode and it can activate a Manual Extinguishant Release.

A maximum of 8 RSI(s) can be connected to a single SRP Control Panel.

The maximum cable length from the SRP Control Panel to an RSI is 500 metres. If 8 RSIs are used,

they must all be within the maximum 500 metres cable length.

All external connections are made on the back board.

The Ext. Switches SW1 and SW2 are to be used for the external HOLD and RELEASE functions

respectively. SW1 must be a momentary Normally Open switch. SW2 must be a Normally Open

switch. If the Ext. Switches are not going to be implemented, then a 3.3KΩEOL must be used for

termination.

!

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

7

Mounting the RSI

First identify the proposed location for the RSI. Ensure that it will be easily accessible and that account

is taken of any subsequent work that may affect access.

The RSI should be located at an access point to a building which is not covered by the SRP Control

Panel. RSIs can also be located in other buildings which are connected to the SRP Control Panel. It

should be mounted on a flat, vertical wall at a height where the indicators may be seen without difficulty.

Do not locate the RSI at high level where stepladders or other access equipment may be

required, in spaces with restricted access, or in a position that may require access panels to be

removed.

Do not locate the RSI where extremes of temperature or humidity may occur i.e. close to a heat

source, or where there is any possibility of condensation or water ingress.

Like all electronic equipment, the RSI may be affected by extreme environmental conditions. The

position selected for its installation should therefore be clean and dry, not subjected to high levels of

vibration or shock and at least 2 metres away from any pager or radio transmitting equipment. Ambient

temperatures should be within the range given within the “Technical Data”section, e.g. not directly over

a radiator or heater.

In common with all microprocessor-controlled panels, the RSI may operate erratically or may be

damaged if subjected to lightning-induced transients. Proper earth/ground connections will greatly

reduce susceptibility to this problem.

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

8

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

9

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

10

Physical Dimensions

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

11

General Assembly

Ribbon Cable Connection

Fixing Front Panel To Back Box

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

12

Installation and Commissioning

Topology & Cabling

All system wiring should be installed to comply with BS 5839: Pt 1: 2002 and BS 7671 (wiring

regulations) and any other standards relevant to the area or type of installation. A cable complying with

BS 5839: Pt 1: 2002 Category 1 (cable required to operate for prolonged periods during fire conditions)

is required. This must be a 2-core 1.5mm2screened fire resistant cable (i.e. MICC, FP200, Firetuff,

Firecell, Lifeline or equivalent).

In order to protect against possible data corruption it is important to ensure the following points are

adhered to:

1. The cable screen must be connected to the SCRN terminal for each circuit at the RSI.

2. The cable screen must not be connected to earth/ground at any point other than the

Control Panel (at the SCRN terminal provided). Do not connect the screen to a metal back

box.

3. The cable screen continuity must be maintained at every point of the circuit, using the

terminals provided or a suitable connection block.

4. Do not use a 4-core cable for 24V supply and communications, due to the possibility of data

corruption. It is essential that two 2-core screened cables are used, one for the 24V DC

supply and the other for communications.

Maximum Cable Lengths

The maximum total cable length from the Control Panel to an RSI is 500 metres for power and

communication.

Up to 8 RSIs can be used but they must all be within the maximum 500 metres cable length.

The maximum cable length from the RSI to the HOLD and RELEASE switches is 100 metres.

Refer to the “Power Supply & Connections”and “Peripheral Bus Connections”sections below for further

details.

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

13

Power Supply & Connections

24V DC Power is provided to the RSI from the Control Panel via the AUX PWR 1 or AUX PWR 2

connectors on the SRP Control Panel connector board. The preferred cable to carry the 24V from the

Control Panel to the RSI is 2-core 1.5mm2screened fire resistant cable (i.e. MICC, FP200, Firetuff,

Firecell, Lifeline or equivalent).

The maximum total cable length from the SRP Control Panel to an RSI is 500 metres.

Up to 8 RSIs can be connected but they must all be within the maximum 500 metres cable length and

must be wired +24V to +24V, 0V to 0V, Screen to Screen and so on.

Power Connection Table

SRP Control Panel

First RSI

Second RSI

AUX PWR +

+24V

+24V

AUX PWR -

0V

0V

SCRN

Screen

Screen

When powering an RSI from the panel, the extra current will reduce the battery backup run time and

has to be allowed for in the battery calculations.

NOTE: A jumper wire MUST be installed between the Screen of the Power and the Screen of the

Peripheral Bus if power is provided by the SRP Control Panel.

Current Drawn by Single Remote Status Indicator @ 24.0V DC

Quiescent (default screen, back light off)

15.0mA

Controls enabled (back light on)

35.0mA

Separate Power Supply Requirements

The RSI can be powered by a separate 24V power supply if required. The RSI working voltage range is

between 21V DC to 32V DC with a maximum current of 50.0mA.

NOTE: If an RSI is powered from something other than the SRP Control Panel, the screen of the cable

MUST be connected to the Screen of the back board but no jumper from Power Screen MUST be

connected to the Screen of the Peripheral Bus.

Remote Status Indicator Back Board Power Supply Connections

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

14

Peripheral Bus Connections

Communication between the SRP Control Panel and RSI is established via a multi-drop RS-485

Peripheral Bus using 2-core 1.5mm2screened fire resistant cable (i.e. MICC, FP200, Firetuff, Firecell,

Lifeline or equivalent).

The maximum total cable length from the Control Panel to an RSI is 500 metres.Up to 8 RSIs can be

used but they must all be within the maximum 500 metres cable length. The RSIs must be wired

A to A, B to B, Screen to Screen and so on. The peripheral bus must be run from the SRP Control

Panel to the first RSI, then to the second RSI and so on. The peripheral bus must not be spurred from

one central point.

SRP Control Panel Connector Board Peripheral Bus Connections

There are two sets of peripheral bus connections on the SRP Control Panel Connector Board. These

are connections A1/B1 and A2/B2. These are linked on the SRP Control Panel so either set can be

used for the Field Connections. A 120Ω termination resistor must also be fitted across either A1/B1 or

A2/B2 on the last RSI as indicated in the diagram below.

Remote Status Indicator Back Board Peripheral Bus Connections

The last RSI on the network must have a 120Ω End of Line (EOL) resistor fitted across A and B

of the RSI PERIPHERAL BUS terminal

NOTE: A jumper wire MUST be installed between the Screen of the Power and the Screen of the

Peripheral Bus if power is provided by the SRP Control Panel.

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

15

Ext Switches SW1 and SW2 Connection Examples

EXT SWITCHES SW1 must only be used for the HOLD operation.

EXT SWITCHES SW2 must only be used for the RELEASE operation.

The maximum cable length from the EXT SWITCHES connector on the RSI Back Board to the

SW1-HOLD and SW2-RELEASE switches is 100 metres. The Activation Resistor may be either

680Ωor 470Ω.

NOTE: A jumper wire MUST be installed between the Screen of the Switch Connection and the Screen

of the Peripheral Bus.

RSI With External Switch Connections

RSI Without External Switch Connections. EOL must be present.

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

16

SRP Control Panel Peripheral Bus Settings

To set up the SRP Control Panel to supervise the RSI(s) installed in the system, set the Write Enable

switch to ON position, login with Engineer level access, and select “13 RSI SUPERVISION”from the

MAIN MENU. Then using the UP/DOWN and LEFT/RIGHT arrow keys, navigate to each relevant RSI

address and set the MODE to On.

When this is done press ESC to return to the SRP Control Panel’s MAIN MENU. The SRP Control

Panel will now be set up to supervise the selected RSI(s) and will report them as missing if there is a

cable break or loss of communications. Set the Write Enable switch back to OFF position.

NOTES:

If an RSI address MODE is turned ON and the RSI is not connected to the Peripheral Bus, the

panel reports an “RSI Missing”fault.

The RSI must be supervised to be fully functional. The Home Screen on the RSI indicates that

it is supervised by displaying a check mark next in the upper right corner of the display.

RSI Panel Settings

Setting RSI Address/Number

Each RSI has to be set with a unique address in the range 1 –8, the default address is 1. This is done

using DIL switches A0 to A2.

NOTES:

The RSI must be reset or power cycled for changes to take effect.

The RSI address is indicated on the Home Screen in the upper right corner of the RSI display.

Address Settings

A0 (1)

A1 (2)

A2 (3)

RSI Address

Off

Off

Off

1

On

Off

Off

2

Off

On

Off

3

On

On

Off

4

Off

Off

On

5

On

Off

On

6

Off

On

On

7

On

On

On

8

RSI Buzzer

The local RSI internal buzzer can be switched off using DIL switch SP1 (4).

Buzzer Setting

SP1 (4)

Buzzer State

On

Buzzer on

Off

Buzzer off

This setting only affects the local buzzer state and has no effect on the panel buzzer or other RSIs on

the system.

NOTE: The RSI must be reset or power cycled for changes to take effect.

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

17

LCD Contrast

LCD Contrast

The LCD contrast can be adjusted by rotating the screw on the variable resistor, located in the upper

right of the main RSI PCB.

Powering Up

Turn on the SRP Control Panel to initialize the RSI. The RSI briefly displays the start-up message:

When communication between the RSI and SRP Control Panel is established, the HOME screen shows

the same date and time as displayed on the SRP Control Panel:

NOTES:

The Time/Date format on the RSI is same as the SRP Control Panel.

The RSI displays the same Home Screen message as the SRP Control Panel (lines 2 and 3).

If the Home Screen is modified on the SRP Control Panel, the Home Screen on the RSI gets

updated automatically.

The RSI Access Level and Address is displayed in the upper right corner of the RSI display.

“NM”is NORMAL access and “US”is USER access, depending on the Enable Key Switch

position. The “x” represents the RSI address with a value between 1 and 8.

A check mark appears next to the Access Level to indicate that the RSI is being supervised.

RSI INITIALIZED

WAITING FOR PANEL...

01/23/2016 04:56 √NMx

TWINFLEX RELEASING

FIKE(UK)

Turn Key/Press Enter

Rotate anticlockwise to

reduce the contrast

(lighten text)

Rotate clockwise to

increase the contrast

(darken text)

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

18

Commissioning

Ensure that the RSI has been correctly and securely mounted to the wall.

For each RSI, verify that the Date and Time match the date and time on the SRP Control Panel.

For each RSI, verify that a check mark appears in the upper right corner of the RSI Home Screen.

For each RSI, carry out all 5 tests from the “2. TEST MODES” option in the MAIN MENU.

Verify that the Current Events on the RSI are displayed correctly and match the Current Events on

the SRP Control Panel.

If SW1 HOLD operation and SW2 RELEASE operation are being used, verify that they function

correctly.

Ensure the system users and responsible persons have been trained properly. See the “End User

Training” section below.

Fault finding

If the Date and Time do not update on the RSI and are not in sync with the SRP Control Panel, check

the wiring between the SRP Control Panel and the RSI.

If the supervision check mark is not present in the upper right corner of the RSI’s display, check

the RSI supervision setting on the SRP Control Panel. Also, verify the address setting on the RSI.

The SRP Control Panel reports an “RSI Missing”fault and the RSI reports an

“SRP Communication Timeout . . .” message if the communication is lost between them. Check the

wiring and the RSI supervision setting.

The RSI reports a “NON-Supervised RSI Function Disabled” message when trying to view Current

Events and the RSI is not being supervised by the SRP Control Panel. Fix the supervision setting on

the SRP Control Panel.

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

19

General Operation of Remote Status Indicator

RSI Front Panel

LED Indication

The LED operation of the RSI is described below. The LED indication can also be confirmed by

checking the message displayed in the RSI information window or by accessing the relevant Current

Event from the RSI menu. The SRP Control Panel logs may also be checked.

Description

Colour

State

Reason

FIRE –1 LED (left)

Red

Flashing

The Control Panel is in the Fire 1 state. Other indicators will show the origin.

Continuous

The Control Panel is in the fire state and sounders have been silenced.

FIRE –2 LED (right)

Red

Flashing

The Control Panel is in the Fire 2 state. Other indicators will show the origin.

Continuous

The Control Panel is in the Fire 2 state and sounders have been silenced.

RELEASE IMMINENT

Yellow

Flashing

The Control Panel has reached a pre-release state and the counter is

counting down to release.

Continuous

The Control Panel has reached a pre-release state and the counter is

counting down to release and sounders have been silenced.

RELEASED

Yellow

Flashing

The Control Panel has reached the release state and release outputs have

been activated.

Continuous

The Control Panel has reached the release state and release outputs have

been activated and sounders have been silenced.

HOLD ACTIVE

Yellow

Flashing

A hold activation has been received and the panel is currently in a hold

mode. System operation will continue once the hold condition is cleared.

Continuous

This LED goes continuous on a silence.

SYSTEM

POWER

Green

Continuous

This indicates that power is being supplied to the RSI panel.

FAULT

Yellow

Flashing

The Control Panel is in the fault state. Display will show details.

Continuous

A Fault condition exists and the Silence Buzzer button has been activated

DISABLED

Yellow

Flashing

An input, output or zone has been disabled on the Control Panel.

Continuous

This LED goes continuous on a silence.

CONTROLS

ENABLE

(fire alarm controls)

Yellow

Continuous

Fire Alarm Controls and Access Level 2 are enabled through the Enable Key

Switch.

MANUAL

(auto/manual)

Yellow

Continuous

Manual mode operation has been enabled from this RSI panel.

Flashing

Manual mode operation has been enabled from the Control Panel or other

remote RSI panel.

General Indication LEDs System Indication LEDs

System

Controls

Auto/Manual

Key Switch

Extinguishant

Release

RSI Information

Window

Fire Alarm

Controls

Enable Key Switch

TWINFLEX®SRP Remote Status Indicator Engineering and Commissioning Manual

20

Fire Alarm Controls

The Silence Alarms button will silence any fire alarm sounders that are currently sounding.

The Reset System button will reset the SRP Control Panel and place the system into a non-alarm state.

The Sound Alarms button will activate all fire alarm sounders.

The Silence Buzzer button will silence the buzzer on the SRP Control Panel and all RSI panels.

System Controls

SELECTION ARROW

Press the ESC key to exit to the previous menu.

Extinguishant Release Controls

Auto/Manual operation

When in ‘manual’mode, the following will occur during a detection and release process:

i. If a zone is enabled and it detects a fire, the panel will log the detection and operate like

normal. All appropriate outputs will activate, sounders will sound, the piezo will activate, etc.

ii. If a SECOND zone activates, the panel will log the detection but will remain in Fire 1 and will

not advance to Pre-Release or Release.

iii. If the system is placed back into ‘automatic’ mode, it will then advance to Pre-Release or

Release and proceed like normal.

VIEW CURRENT EVENTS

5. ALL EVENTS

1. FIRE EVENTS

2. FAULT EVENTS

The main Fire Alarm Controls may be enabled by

turning the key switch to the controls enabled position

to go from access level 1 to access level 2.

The menus may be navigated by using the UP / DOWN keys to move the

required selection to the line with the SELECTION ARROW. Pressing

enter will then select the chosen option.

The top line shows the current menu name.

In the example below, pressing enter will select the VIEW CURRENT

FIRE EVENTS option.

The extinguishant release switch allows the user to manually

release the extinguishing agent from the RSI. To operate the

switch, the user must pull down the protective cover and then

push the release button.

The auto/manual key switch allows the user to place the fire

alarm system in ‘automatic’ or ‘manual’ operation modes. When

set to the default ‘automatic’ mode, the SRP Control Panel will

operate in a normal fashion and will advance to release through

automatic detection methods. The ‘manual’ LED will blink if the

‘manual’ mode has been set from the SRP Control Panel or by

another RSI, and will be continuous if the adjacent key switch has

been turned.

When set to ‘manual’, the SRP Control Panel’s zone circuits will

not advance the system into release. In this mode, the only way

to release the extinguishant is to manually activate it.

Table of contents

Popular Touch Panel manuals by other brands

Phoenix Contact

Phoenix Contact UM EN TP 3 Series user manual

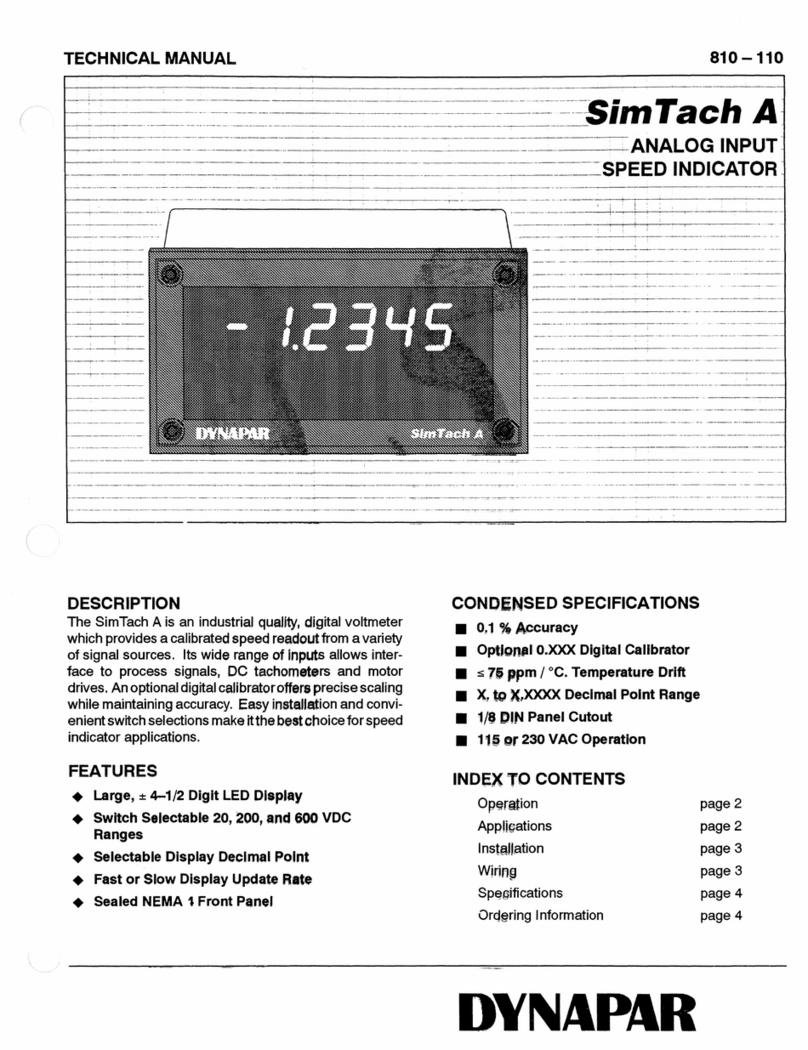

DYNAPAR

DYNAPAR SimTach A STA00 Technical manual

Winmate

Winmate W07IB3S-PCO1-POE user manual

Toshiba

Toshiba TR PMIU user manual

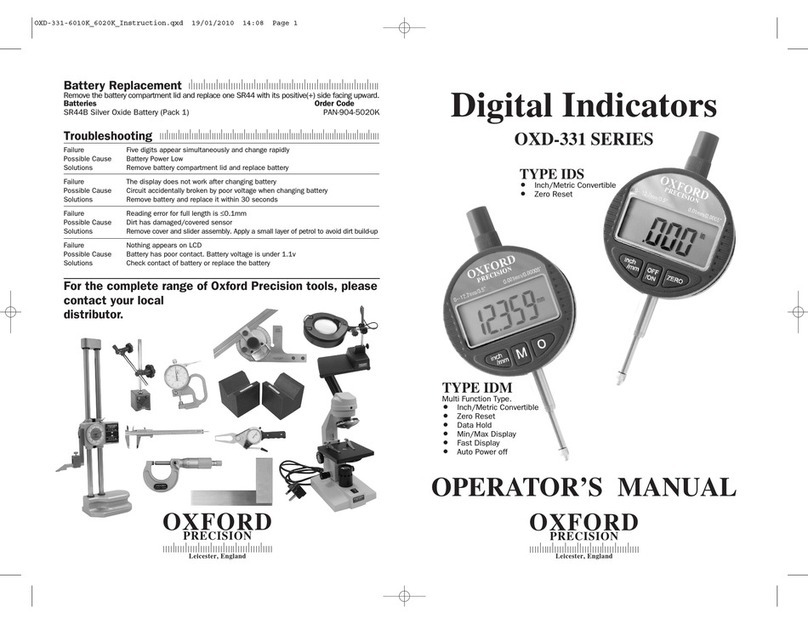

Oxford PRECISION

Oxford PRECISION OXD-331 IDM Operator's manual

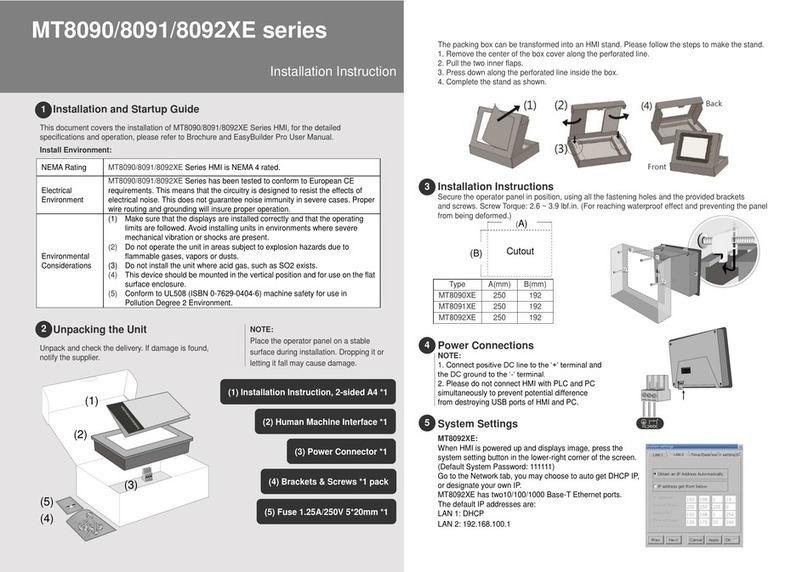

weintek

weintek MT8091XE Series Installation instruction