SAFETY..................................................................................................................................... 3

FORWARD................................................................................................................................ 5

SHEET PILE DRIVER APPLICATIONS..................................................................................... 5

MAINTENANCE......................................................................................................................... 6

STANDARD PRACTICES................................................................................................6

CARRIER COMPATIBILITY....................................................................................................... 7

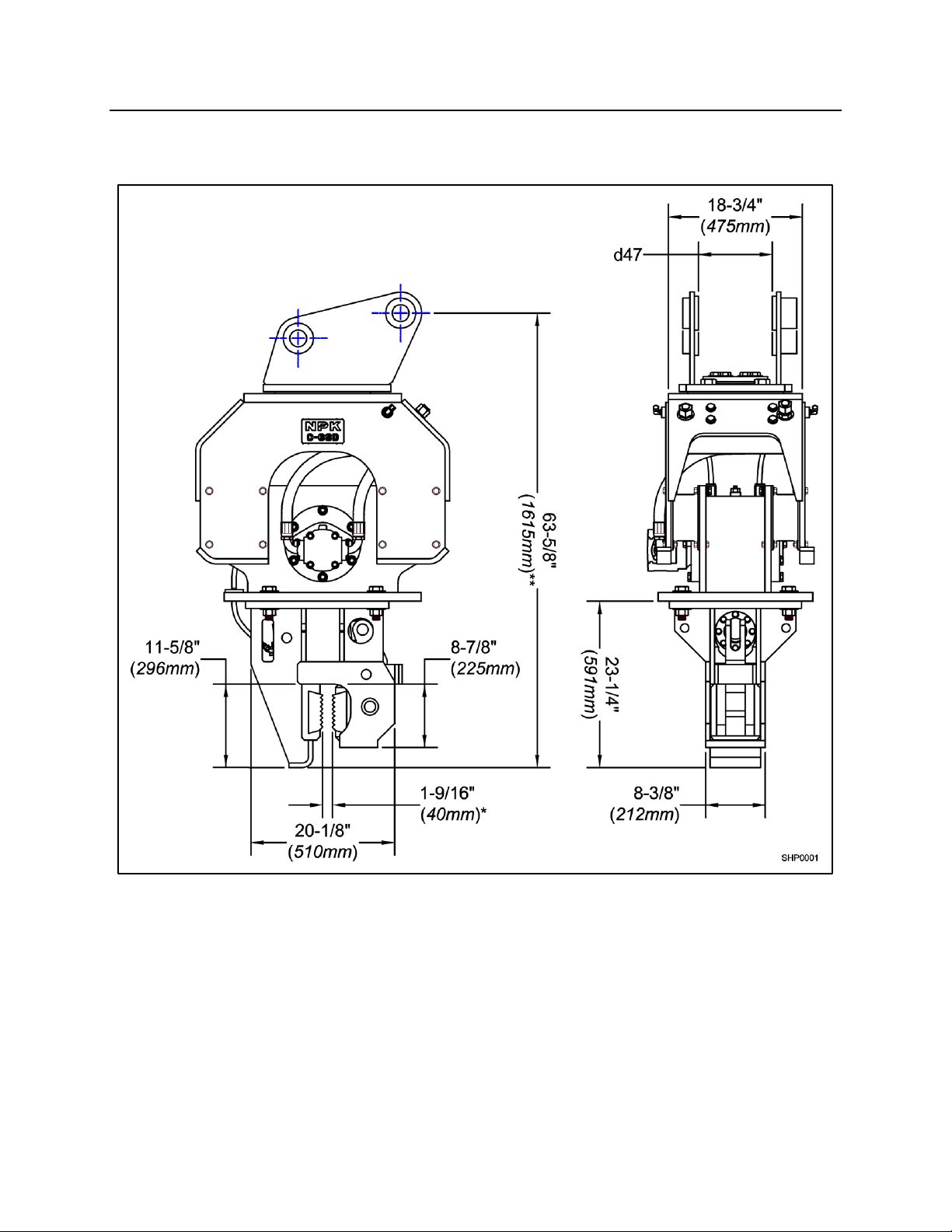

SPECIFICATIONS..................................................................................................................... 8

C6CSD............................................................................................................................9

C8CSD..........................................................................................................................10

C10CSD........................................................................................................................11

SHEET PILE DRIVER STRUCTURE........................................................................................12

C6CSD THROUGH C10CSD SHEET PILE DRIVERS...................................................12

SHEET PILE DRIVER SERIAL NUMBER LOCATION..............................................................15

HYDRAULIC INSTALLATION...................................................................................................16

NPK HYDRAULIC INSTALLATION KITS.......................................................................16

HYDRAULIC LINES.......................................................................................................16

SHUT-OFF VALVES......................................................................................................16

RETURN OIL.................................................................................................................17

PREVENTION OF CONTAMINATION...........................................................................18

CHANGING THE FILTER ELEMENT AND HYDRAULIC OIL.........................................18

CONTROL VALVES......................................................................................................19

CONTROL SYSTEM FOR CLAMP CYLINDER..............................................................20

HYDRAULIC QUICK DISCONNECTS...........................................................................21

NPK APPROVED CONNECTION QUICK DISCONNECTS ...........................................22

PRECAUTIONS ............................................................................................................22

MECHANICAL INSTALLATION................................................................................................24

MAINTENANCE AND INSPECTION.........................................................................................25

DAILY MAINTENANCE.................................................................................................25

SEMI-ANNUAL MAINTENANCE ...................................................................................26

REPLACE BEARING LUBRICATION OIL..........................................................26

TWENTY HOUR INSPECTION .....................................................................................27

JAW TOOTH PLATE (CHUCK) INSPECTION ...............................................................28

RUBBER MOUNT INSPECTION...................................................................................28

HOSE CONNECTIONS.................................................................................................29

LUBRICANT TERMS AND DEFINITIONS ................................................................................30

OIL CAPACITY SPECIFICATIONS...........................................................................................32

LOWER FRAME............................................................................................................32

BEFORE OPERATION.............................................................................................................33

DECIDE IF SWIVEL LOCK FEATURE WILL BE USED..................................................33

OPERATION.............................................................................................................................34

PRE-CHECKS...............................................................................................................34

CHECK FASTENERS FOR PROPER TIGHTNESS ..........................................34

JAW TOOTH PLATE (CHUCK) INSPECTION...................................................34

RUBBER MOUNT INSPECTION.......................................................................34

HOSE CONNECTIONS .....................................................................................35

CHECK SHUT-OFF VALVE POSITION.............................................................35

SHEET/PILE DRIVING AND EXTRACTING..................................................................36

SWIVEL FEATURE............................................................................................36

CHUCKING THE SHEET PILE......................................................................................38

LIFT THE SHEET PILE..................................................................................................38

POSITIONING THE SHEET PILE..................................................................................39

PILE DRIVING OPERATION.........................................................................................40

PULLING OPERATION.................................................................................................41