Filsa ILV-660 User manual

Page

Index

ILV-660

Talleres Filsa, S.A.U. www.filsa.es• • • • •E-08100 Mollet del Vallès (Barcelona) Tel. +34 93 570 46 01 Fax +34 93 570 24 71 [email protected] 01

10/15 MI-ILV660-EN-01© by FILSA

Vibrating level indicator

for solids

Operating

Instructions

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

Operating instructions

1. Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

1.1 Intended use

1.2 Function

1.3 Technical data

1.4 Materials

1.5 Dimensions

2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

2.1 Preparing for use

2.2 Mechanical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

2.3 Electrical connection

3. Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

3.1 Commissioning

3.2 Normal operation

3.3 Inexpert handling

4. Maintenance, servicing and spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

4.1 Maintenance

4.2 Servicing

4.3 Spare parts

5. Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

6. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

Read these Safety instructions before using the device for the first time and follow the Operating instructions.

Safety instructions

1. The installation, initial operation and maintenance should only be carried out by a qualified expert with electrical know-how.

2. Comply with the local and statutory rules and/or the VDE0100.

3. Before electrical connection, check the specifications on the data plate and the technical data of this manual.

4. A fuse must be connected in series to the supply voltage, according to the Standard and Normative documents.

5. Protect the signal contacts of the limit switch against voltage peaks when inductive or capacitive loads are connected.

6. The device may be put into operation only if the electrical connection is correct. To secure the type of protection, the sealing cap and the gasket

must be placed correctly and the screw nut of the cable gland has to be fixed and fastened to the cable entry.

7. The earth connection of the device has to be installed in such a way that mechanical damage will be excluded.

8. The probe must not be hit by the filling stream. To avoid this, deflect the filling stream or install a deflection screen or a protection roof. It is also

recommended to install a protection roof when the controllers are used as empty-indicator or medium-indicator in silos where vaults could be formed

or where high loads above it could exist.

9. For a proper function, the device should be installed with a 20 º to 30 º slope from the horizontal onto the silo wall to to facilitate the flow of the

material and to prevent the material from remaining over the probe.

10. The most sensitive part of the controller is the probe, do not hit or deform the probe it, the device can become useless.

11. Switch off the power supply, before disconnecting the device.

ILV-660

02 Talleres Filsa, S.A.U. www.filsa.es• • • • •E-08100 Mollet del Vallès (Barcelona) Tel. +34 93 570 46 01 Fax +34 93 570 24 71 [email protected]

10/15 MI-ILV660-EN-02© by FILSA

ILV660-001

Instrucciones de uso

1. Descripción

1.1 Indicaciones para su aplicación

The vibrating level indicator ILV-660 is to be used to control the

maximum or minimum level of bulk solids in silos or vessels.

It is recommended for dusty and powdery, granulated and grainy

bulk goods like dust, flour, grain, sand, plastic, etc.

1.2 Funcionamiento

The probe must to be exposed to the material. The probe of these

controllers is activated to its resonant frequency by a piezoelectric

system. When the product covers the probe, the vibration is

dampened and the control unit reverses the signal.

When the product disappears from the fork, it returns to the normal

vibrating state and the signal turns to the initial position.

The device has a insensitive rod between the probe and the

proccess connection to avoid the possibility of settle of the product

over the probe up to 75 mm.

1.3 Technical data

Manufacturer Talleres Filsa, S.A.U.

Address Bernat Metge, 33

08100 Mollet del Vallès

(Barcelona)

Name Vibrating level indicator

Type ILV-660 ref: 2190-0-600

Supply voltage 24 V DC ± 10 %

1 W

3

Density of the product From 0.05 t/m

Maximum pressure +10 bar

Cable entry DIN43650 connector

Detecting level 1 s

Starting vibrating 2 ... 5 s

Weight 0.73 kg

Max. load upon the probe 80 N

1.4 Materials

Housing and probe Stainless Steel 1.4301

with a minimum

3

bulk density from 0.05 t/m and a maximum grain size of 10 mm.

It is not recommended for sticky solids or products that have the

tendency to settle over the fork.

Power consumption

Response time

Product temperature -20 °C ... +70 °C

Ambient temperature -20 °C ... +60 °C

Transistor output PNP or NPN depending on the

connection

Function status Relay enabled: red LED

Resonance frecuency 460 Hz

Protection IP65 according DIN EN60529

350 mA / 24 V DC

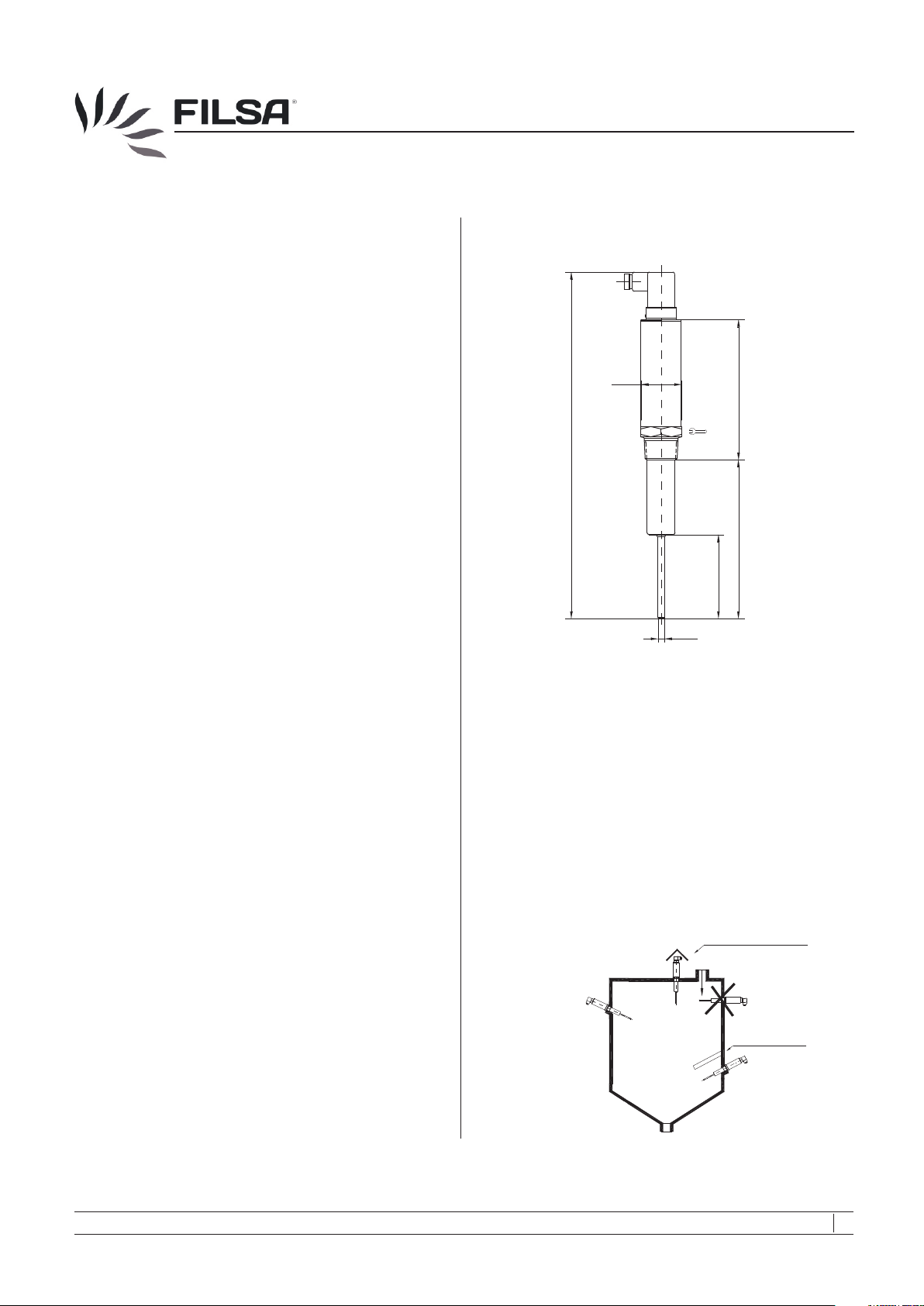

1.5 Dimensions

Approximate measures are given in mm.

-

-

-

2. Installation

2.1 Preparing for use

The probe must not be hit by the filling stream. To avoid this,

deflect the filling stream or install a deflection screen or a

protection roof. It is also recommended to install a protection roof

when the controllers are used as empty-indicator or medium-

indicator in silos where vaults could be formed or where high

loads above it could exist.

For a proper function, the device should be installed with a 20 º to

30 º slope from the horizontal onto the silo wall to to facilitate the

flow of the material and to prevent the material from remaining

over the probe.

Read the Safety instructions and the Operating instructions before

using the controller.

ILV-660

Talleres Filsa, S.A.U. www.filsa.es• • • • •E-08100 Mollet del Vallès (Barcelona) Tel. +34 93 570 46 01 Fax +34 93 570 24 71 [email protected] 03

10/15 MI-ILV660-EN-03© by FILSA

Probe

LED

137

Ø 40

340

157

82

Ø 6.5

36

1 " tappered

DIN 2999

Weather protection

Protection roof

ILV660-002

3. Use

3.1 Commissioning

- Put the controller into operation only if the installation and the

electrical connection have been done correctly.

3.2 Normal operation

- Use the controller in its intended application only.

- Comply with the specifications

- If the controller is damaged, disconnect it immediately.

- It is forbidden to make changes to the device. This violates the

Normative.

3.3 Inexpert handling

- Ignoring the Safety instructions and the Operating instructions.

- Not intended use.

- Making changes or handling the controller.

- Violation against applicable Law and Standards.

- Using of non original parts.

4. Maintenance, servicing and spare parts

4.1 Maintenance

- If used correctly, no specific maintenance is required.

4.2 Servicing

- Check and review the state of the housing, the probe and the

correct commutation of the electrical contact, as well.

4.3 Spare parts

- There are no spare parts for this controller.

5. Storage

- Store the controller in a dry and dust-free environment.

6. Disposal

-

- The controller can be recycled.

- The disposal applies to the valid environmental Guidelines

according to the location of the carrier and the local

manufacturing conditions.

on the data plate and the technical

data of this manual.

Switch off the power supply, before disconnecting the device.

2.2 Mechanical connection

The device can be mounted horizontally or vertically depending on

the model.

The normal installation is by screwing the device onto the deposit

wall, with a mounting flange or

2.3 Electrical connection

Connection diagram

with an appropiate support to fix it.

Level selector: To connect the device or the level selection

adjustment, take out the cap of the DIN connector and, if it is

necessary the sealing gasket. Turn the selector to detect high or

low level:

High level detection: Selector in position FSH. For high level

detection, the relay is disengaged when the probe is covered

of product or there is no supply. Red LED switched off.

Low level detection: Selector in position FSL. For low level

detection, the relay is disengaged when the probe is

uncovered of product or there is no supply. Red LED switched

off.

- Fasten the DIN connector after making the electrical connection.

- Fix and fasten the screw of the DIN connector to ensure the

water-tightness.

DIN connector

ILV-660

04 Talleres Filsa, S.A.U. www.filsa.es• • • • •E-08100 Mollet del Vallès (Barcelona) Tel. +34 93 570 46 01 Fax +34 93 570 24 71 [email protected]

10/15 MI-ILV660-EN-04© by FILSA

LED Level selector

[

Terminal

1

2

3

4

PNP

+24 V DC = 3

+ of load

+24 V DC

[

NPN

- of load

= 4

+24 V DC

[

ILV660-003

1

32

4

FSL

FSH

1 2

1 2

1 2

1 2

ILV660-004

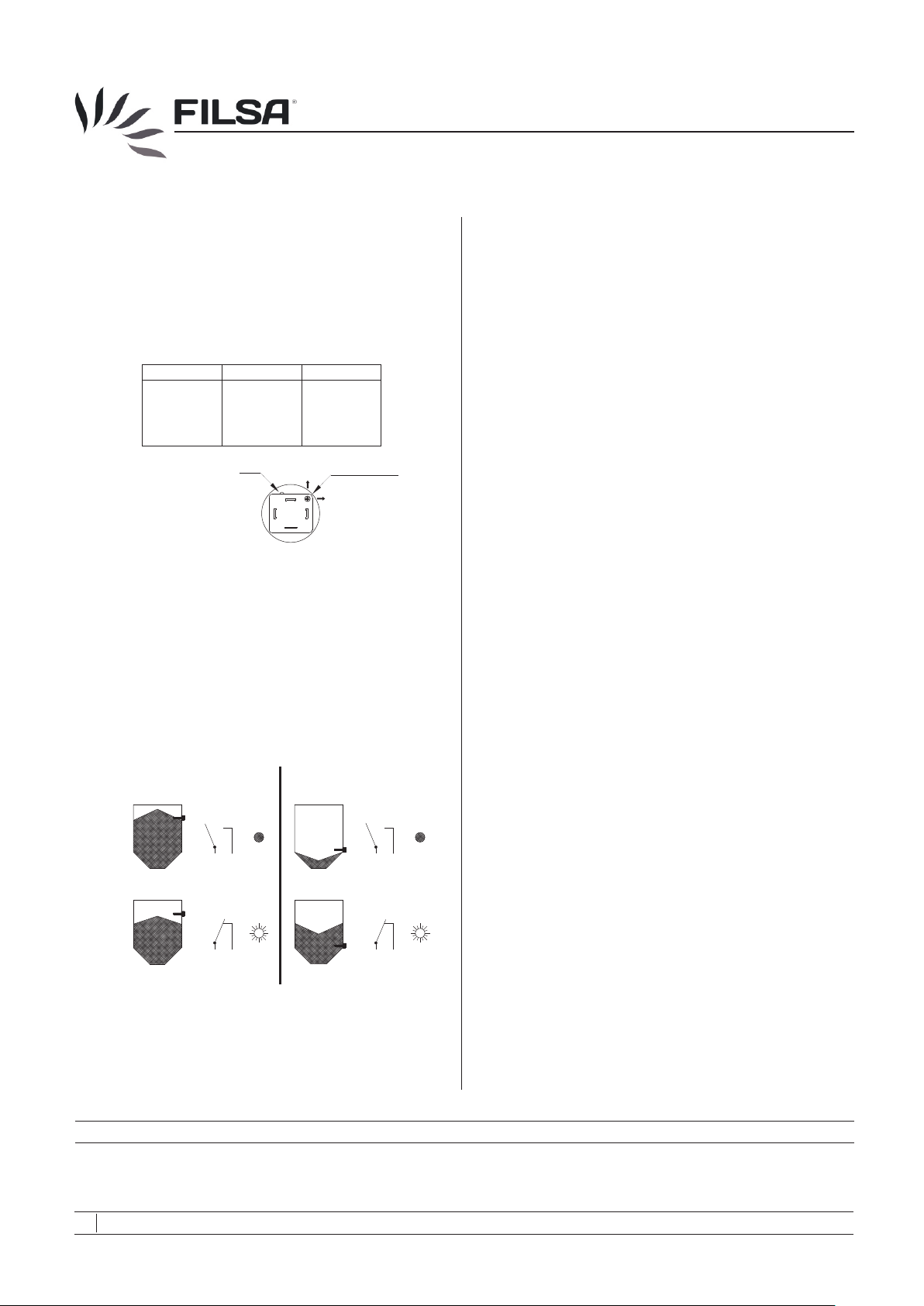

High level detection (FSH) Low level detection (FSL)

LED

Relay LED

Relay

Emptying

Filling

Empty

Full

Deposit Deposit

FILSA constantly strives to improve its products and reserves the right to modify designs, materials and data without prior notice.

Keep this manual for further questions!

Other Filsa Measuring Instrument manuals