Filtercorp LS-1 Series User manual

USER MANUAL

Anodized Aluminum

MODELS: LS-1-60

LS-1-100

Retain this manual for future reference.

Getting the most out of your frying program

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816 WWW.FILTERCORP.COM

2

To Our Valued Customers

Introduction

Page 3

Page 4

Description & Construction Page 5

Safety & Installation Page 6

Operating Instructions Page 7-8

Frying Oil Maintenance Page 9

Equipment Specifications Page 10

Dimensions & Detail Drawings Page 11-12

Troubleshooting Page 13

Original Equipment Warranty Page 14

Warranty Registration

Note to Service Technicians

Wiring Diagram

Pump Installation View

Parts Listings

Page 15

Page 16

Page 17

Page 18

Page 19-22

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816 WWW.FILTERCORP.COM

3

Thank you for purchasing a Filtercorp portable cooking oil filter. Filtercorp is a

leading manufacturer of premium quality cooking oil filter equipment. We are proud

of our reputation for quality and our commitment to customer satisfaction.

To get the maximum benefit this equipment can deliver, please read this User Manual

and Instruction Sheet and watch the FRYING OIL MANAGEMENT DVD that was

included with this appliance. Ensure anyone using this equipment is familiar with

the information in this Manual, the Instruction sheet, and in the DVD.

Need support? We are here to help. Our technical support center is staffed by

experienced technicians eager to help you. Our Customer Service number is

(800)473-4526, and we are available 8:00 am (pst) to 4:00 pm (pst).

Sincerely,

Pius Eigenmann

President

Filtrox North America

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816 WWW.FILTERCORP.COM

4

Please read all sections of this manual and retain for future reference. Always

wear protective apparel such as heat resistant gloves, apron, and face shield

when filtering hot oil. Please refer to your Standard Operating Procedures re-

garding policy and procedure.

The LS-1 Portable Filter is designed to remove food and other solids from the

cooking oil used in your deep fat fryer.

For best results use SuperSorb®CarbonPads.

The LS-1 Filter rolls easily for use wherever it is needed and can easily be stored

out of the way. The low profile allows the unit to roll directly under the drain

valve outlet extension pipe on the fryer. This design makes it easier to drain

the fryer.

This product has been certified as commercial cooking equipment and is

intended for professional use only and is to be operated by qualified

personnel only.

A Filtercorp Authorized Service Center (FASC) should perform maintenance

and repairs. Installation or repairs by unqualified personnel may void the

manufacturer’s warranty.

! WARNING

Improper installation, adjustment, alteration, and/or maintenance can cause

property damage, injury or death. Read the installation, operating and mainte-

nance instructions thoroughly before installing, servicing or troubleshooting

this equipment.

Do not use LS-1 Filter to transport hot cooking oil to discard storage.

! NOTICE

If, during the warranty period, the customer uses a part for this Filtercorp

equipment other than an unmodified new or recycled part purchased directly

from Filtercorp, or any of its Authorized Service Centers, and/or the part being

used is modified from its original configuration, this warranty will be void.

Further, Filtercorp and its affiliates will not be liable for any claims, damages

or expenses incurred by the customer which arise directly or indirectly, in

whole or in part, due to the installation of any modified part and/or part re-

ceived from an unauthorized service center.

If, during this warranty period, the customer uses this equipment for purpos-

es other than to filter cooking oil, this warranty will be void.

!ATTENTION

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816 WWW.FILTERCORP.COM

5

The LS-1 is a portable filter machine for filtering hot cooking oil in the restaurant

industry. The LS-1 comes in two sizes – the LS-1-60 with a 60 lb. oil capacity and

the LS-1-100 with a 100 lb. oil capacity. It has been designed to utilize Filtercorp’s

SuperSorb® CarbonPad.

The SuperSorb® CarbonPad is widely acknowledged to be the finest filtration

system for cooking oils, giving the operator significant savings in oil usage and the

best food quality results.

The LS-1 includes features to make the filtration of hot cooking oil as easy and ef-

fective as possible. Included are a removable pan for ease of clean up and a sturdy

frame for long life and durability.

Frame Anodized Aluminum Construction

Pan Welded Anodized Aluminum construction with integrated

handles for easy removal and cleaning.

Motor Rugged 1/3 Horsepower UL and NSF approved motor and

gear pump designed for long life.

Electrical Controls All electrical controls are UL approved and designed to give

reliable performance.

Hoses Half inch diameter, Teflon lined, covered hoses having UL and

NSF approvals.

Nozzle Filtercorp’s uniquely designed stainless nozzle is designed to

reduce splashing while providing a spray that helps in washing

the walls of the fryer during filtering.

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816 WWW.FILTERCORP.COM

6

Product Safety

Safety is of utmost importance when working with heated cooking oils. Throughout

this manual you will see the word WARNING which means there is potential danger

of equipment damage or personal injury.

Read all instructions thoroughly before installing or operating this equipment.

Inspection and Setup

1. Your LS-1 will arrive crated for shipping.

2. Before removing the LS-1 from the crate, inspect the crate for damage.

If damage is seen, please contact the delivering carrier.

3. After inspecting, remove the LS-1 from the crate. You will find that the filter is

already completely assembled. Simply hook up the hoses and plug in the

electrical cord.

4. Check to make sure the following items are included in the crate:

•Return hose assembly

•Unifit (pad-holder) assembly

•Carton of 10-day supply SuperSorb®CarbonPads

•12-foot, 110 v, 3-prong electrical power cord

•3” pad scraper

•QR Code Operations Manual and Documentation

5. You are now ready to filter. WARNING – Always follow the operating

instructions in this manual when operating the filter.

Note: The LS-1 is equipped with a 12-foot oil-proof electrical power cord with

ground. WARNING – This ground is to protect the operator from electrical

shock in the event of an equipment malfunction. DO NOT remove or tamper

with the ground feature!

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816 WWW.FILTERCORP.COM

7

The LS-1 has been designed to operate very simply. It is designed as a one-way filter

having a simple on/off switch to engage the motor. The quick-disconnect fitting allows

for only one-way hook up of hoses.

1. Put a SuperSorb®CarbonPad into the Unifit® PadHolder with rough side facing

out, smooth side towards the screen support. Place the Unifit® PadHolder into

the bottom of the filter pan. WARNING – Always wear splash goggles or face

shield, protective gloves, and appropriate protective safety wear.

2. Check fryer vat capacity and oil volume to ensure cooking oil does not overfill the

pan. WARNING – The LS-1-60 can hold 60 lbs of cooking oil and the

LS-1-100 can hold 100 lbs of cooking oil. Do Not try to filter a fryer with a

larger capacity than the LS-1 Filter.

3. Attach the drain extension of the fryer to the fryer drain. WARNING – The end

of the drain as well as other parts of the fryer and filter may be hot! Use

protective gloves.

4. Roll the LS-1 to the fryer; making sure the fryer drain extension drains into the

pan. WARNING – Always position the filter so that the filter pan is in the

proper position beneath the drain. This will prevent heated cooking oil

from splashing on the floor. Plug in the LS-1 electrical cord.

5. Open the fryer drain valve slowly, draining the cooking oil from the fryer into the

filter pan.

6. Make sure the return hose is hooked up and the nozzle is placed into the fryer.

Push the on/off switch to “on” position.

7. As the cooking oil is filtered through the SuperSorb® CarbonPad and returned

to the fryer, use the nozzle with returning oil to wash down the sides of the fryer.

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816 WWW.FILTERCORP.COM

8

8. Once the sides of the fryer are washed down and the bottom of the fryer is clean

of all food debris, close the fryer drain valve. Pump all remaining oil from the

LS-1 filter back into the fryer. Push the on/off switch to the off position.

WARNING – Never attempt to remove or disconnect hoses when the filter

motor is operating.

9. Filter cycle is now complete. Move to the next fryer vat and repeat the process

– Steps 2 – 8.

10. When finished with filtering the final fryer vat, continue to pump a small amount

of air through the pump/motor assembly to ensure cooking oil is not left in the

hoses or pump.

11. Cleaning (CAUTION—Wait for Filter to cool before cleaning!):

•Unplug the main power cord

•Disconnect inlet suction tube at lower quick-disconnect ring

•Remove unifit pad holder assembly

•Discard used CarbonPad into trash bin

•Disconnect the return hose from upper quick-disconnect ring

•Prior to storing hose drain excess cooking oil from hose by holding nozzle

of filter hose over fryer and lifting opposite end of return hose

•Clean the inside of the pan and wipe dry. CAUTION—During cleaning

DO NOT pump water with the filter pump.

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816 WWW.FILTERCORP.COM

9

Cooking

1. Cooking temperature not to exceed 360F/185C. Preferably less than 350F/175C.

2. Never turn fryer temperature up before or during a busy period.

3. Turn fryers down or off when not in use. Cover fryers not in use.

4. Never load baskets over a fryer. Never salt food over a fryer.

5. Cook similar foods in the same fryer and separate food types if possible.

6. Skim the fryers often.

7. Add make-up oil often. Do not allow the fryer to be under-filled. Do not over-fill

fryers.

8. Never cascade, or downstream oil. Never add old cooking oil to new cooking oil.

Filtering

1. Filter each and every day. (Each day of filtering missed, cuts 1 to 2 days of oil-life.)

2. Use a new SuperSorb® CarbonPad each day.

3. It is preferable to filter at the close of business, or after peak periods.

4. Ensure that no water is in the filter pan before inserting a SuperSorb® CarbonPad.

5. Turn fryer off, however, filter while cooking oil is still hot (not less than 280° F).

6. If there are multiple fryers being used, filter the newest cooking oil first, oldest

cooking oil last.

7. After draining cooking oil into the filter, wait 2-3 minutes before turning on the

pump. Use this time to clean the fryer. Use the LS-1 return hose to rinse debris

from the fryer.

8. After rinsing the fryer check to make sure fry pot is clean of all debris. Then close

the drain valve and re-fill fryer.

9. After filtering, allow filter to cool, then clean the filter pan, but never use soap.

Avoid kinking the hoses. Dry completely before setting up with a new SuperSorb®

CarbonPad.

Discarding

1. Discard only on the basis of a quality standard. Food quality is the best quality

index, but test kits that have been evaluated against food quality may be used.

2. If there are multiple fryers being used, discard only the fry pot that misses the

quality mark.

3. Discard cooking oil on a quality standard, not operational ease or by the day of the

week.

4. Have a manager or a trained person make the discard decision

5. If possible, have the same person make all discard decisions.

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816 WWW.FILTERCORP.COM

10

64 Lbs.

16.75” wide x 23.75” deep x 27.25” high

11.75”

1.63 cubic feet or 12.1 gallons

60 Lbs. of oil or 7.7 gallons

Viking Hot Oil Hub Mount Pump, Capacity: 4.6 GPM at 1725

RPM, 1/3 HP, Capacitor Start, Dual Gear, Positive Displacement

Pump, 115 volt, 6.2 Amperes, 50/60-Cycle Motor, Manual Ther-

mal Overload

Standard 3 wire, 110 Volt Plug-In Cord (12 feet in length)

0.090 Anodized Aluminum

Dimensions for LS-1-60

Weight

Overall Dimensions

Pan Height

Total Pan Capacity

Oil Capacity

Pump/Motor

Electrical Plug

Material

83.5 Lbs.

16.75” wide x 33.5” deep x 27.25” high

11.75”

2.52 cubic feet or 18.7 gallons

115 Lbs. of oil or 14.7 gallons

Viking Hot Oil Hub Mount Pump, Capacity: 4.6 GPM at 1725

RPM, 1/3 HP, Capacitor Start, Dual Gear, Positive Displace-

ment Pump, 115 volt, 6.2 Amperes, 50/60-Cycle Motor, Man-

ual Thermal Overload

Standard 3 wire, 110 Volt Plug-In Cord (12 feet in length)

0.090 Anodized Aluminum

Weight

Overall Dimensions

Pan Height

Total Pan Capacity

Pump Motor

Electrical Plug

Material

Dimensions for LS-1-100

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

11

23.75” 16.75”

27.25”

12.5”

LS-1-60

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

12

33.5” 16.75”

27.50”

12.5”

LS-1-100

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

13

PROBLEM POSSIBLE CAUSE SOLUTION

Unit will not turn on A) Power cord is not plugged in

B) Power Breaker is tripped

C) Motor is overloaded

A) Check both filter connection

and power outlet

B) Check to ensure the power

outlet breaker in your building

is on and hasn’t been tripped

C) Let motor cool down. Slide

open the reset button cover on

the side of the LS-1 pump/

motor box. Press reset

button. Retry the power

switch.

Warning: make sure the

power switch is in the “off”

position before pressing the

reset button.

Motor runs but will not

pump

A) Hose or pump is blocked A) Disconnect & clean hoses with

warm water to loosen

solidified shortening.

Drain & dry completely.

Hoses leak at the

connections

A) Loose connections A) Check to ensure all hose

connections are properly

attached and locked.

For additional information, please contact your nearest Authorized Service Agency.

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

14

Warranty Registration for Filtercorp LS-1 Series Portable Filter

Model Number:

Serial Number:

Store Name:

Store Number:

Address:

City:

State:

Zip:

Telephone:

Date of Purchase:

Dealer or Rep Purchased From:

Dealer Invoice Number:

IMPORTANT!

Please complete the Warranty Registration and return to Filtrox

North America dba Filtercorp.

Filtrox North America

5506 6th Ave S. Suite 107

Seattle, WA

98108

Email: sales@filtercorp.com

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

15

machine used to filter edible cooking oils and fats

using Filtercorp filtering media.

8. Certain parts of the Equipment have different

warranty periods, which are set forth below:

a. High temperature pick-up and return

hoses – ninety (90) days from date of

installation.

b. Rubber seals, power cord, and gaskets –

ninety (90) days from date of installation.

c. Frame – Five (5) years from date of

shipment from the factory.

d. Casters – One (1) full year; two (2) year

partial from date of installation.

9. OCU’s exclusive remedy on a claim of any kind

relating to the Equipment whether in contract or in

tort or under any other legal theory, and whether

arising out of warranties, representations,

instructions, installations or defects from any cause

shall be limited to repair or replacement of the

defective Equipment.

10. In no event shall Filtercorp be liable, whether in

contract or in tort, or under any other legal theory,

for loss of use, revenue or profit, or for incidental,

indirect, or special or consequential damages or for

any other loss or claim arising from or relating to

the Equipment.

11. This warranty is exclusive and in lieu of all of other

warranties, express or implied or statutory,

including but not limited to, implied warranties of

merchantability or fitness for a particular purpose or

usage of trade, and constitutes the only warranty of

Filtercorp with respect to the Equipment.

12. Any claims or disputes arising from or related to the

Equipment or under this document shall be

governed by the laws of the State of Washington,

and the venue of any such claims or disputes shall

be in courts located in King County Washington,

and the OCU expressly consents to the personal

and subject matter jurisdiction of such courts.

It is the policy of Filtercorp that its products are subject to continual improvement. The Company reserves

the right to alter the design of any of its products without prior notification. In such circumstances the

Equipment described above may differ in certain respects from the one supplied. Filtercorp assumes no

responsibility to up-date any delivered or in-service Equipment and, furthermore, Filtercorp shall not have

any obligation to modify the product or Equipment instructions or this warranty regarding

Filtercorp warrants its new product(s) to be free from defects in material and workmanship for a period of

the lesser of: (i) two (2) years from date of original installation, or (ii) thirty (30) months from the date of

shipment from the factory, provided that proof of installation date is supplied to Filtercorp prior to work be-

ing performed.

This Warranty shall be subject to the following conditions and limitations:

1. This warranty is limited to an original commercial

user (“OCU”) purchasing new Professional

Restaurant Equipment (“Equipment”) for use with

Filtercorp filter media.

2. Filtercorp’s obligation under this warranty is limited

to repair or replacement of the defective Equipment

(or any part of such Equipment) and the labor for

such repair or replacement. Filtercorp shall not be

liable for any defect unless it has received written

notice of such defect within 30 days of the date that

the OCU learns of such defective equipment.

3. Filtercorp’s warranty obligation as to labor costs is

limited to the normal labor charges incurred for

such repair or replacement for work done at an

authorized Filtercorp service agency. Additionally,

for warranty work performed within ninety days

after the Equipment is installed, Filtercorp shall be

responsible for the normal labor charges for such

work provided that it is performed within fifty (50)

miles from an office of an authorized Filtercorp

agency and performed by an authorized Filtercorp

agency. OCU is solely responsible for any labor

charges for such work on Equipment that is

installed outside the continental United States.

4. Filtercorp shall have no obligation as to any

Equipment which have been misapplied, abused,

used in a manner other than its intended and

normal service, subjected to harsh or improper

chemical action or poor water quality, or which has

had unauthorized modifications or serviced by

unauthorized service personnel, damaged by flood,

fire or acts of God or other causes, or which has

the serial number removed or altered.

5. Adjustments such as calibrations, leveling,

tightening of fasteners or utility connections

normally associated with original installation, are

the responsibility of the dealer or installer and not

that of Filtercorp.

6. Filtercorp shall have no liability for the cost of part

(s), labor or travel time to replace fuses or to reset

circuit breakers resulting in whole or part from the

Equipment or its operation. These costs are the

responsibility of the OCU.

7. Filtercorp shall have no obligation as to any

Equipment damage or failure relating to or resulting

from its use for any purpose other than as a filter

Professional Restaurant Equipment

ORIGINAL EQUIPMENT WARRANTY

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

16

This manual is not a stand alone document. You must read

and become familiar with the content of the User Manual

and Instruction sheet (LS-1 Portable Filter Procedures) to

effectively troubleshoot and repair this equipment.

1. The pump operates, but does not pump oil. This is often diagnosed as a bad

pump but usually is caused by a block or crimp in the pick-up hose. To test the

pump, remove the pick-up hose quick disconnect and put your finger on the

pump intake. If it pulls a good vacuum, the pump is good. The pick-up hose

may be kinked such that it permits a small amount of flow (when you test the

hose, water flows through it) but not enough to operate effectively.

2. Water should never be run through the pump. Water will cause corrosion with-

in 24 hours. The corrosion will lock up the pump. If water is accidentally

pumped, immediately flush the pump with hot cooking oil.

3. Pumps that do not rotate can often be adjusted to correct the problem instead

of replacing the pump. See page 23 step 13.

4. A quick disconnect that won’t connect is usually caused by particles inside the

quick disconnect. Using the filter system without a filter pad causes the parti-

cles to circulate and become lodged in the quick disconnects and the pump.

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

17

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

18

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

19

Parts Listing

Item Part Number Description

1848-04

861

2.5”Caster (Swivel with Brake), Aluminum Units

2” Rear Caster (Swivel with Brake)

2845-01AL

No Longer Available

846-07

Filter Base/Frame (LS-1-60)

Filter Base/Frame (LS-1-85)

Filter Base/Frame(LS-1-100)

3860 2” Front Caster (Rigid)

41005

1063

1075

8” Standard Safety Handle

7” Safety Handle (Short)

5.75” Safety Handle (Extra Short)

51064 Pick Up Hose—3/8” x 21” L w/3/8” male fittings

61012

1012A

Quick Disconnect Fitting, 3/8” Female, NPT

Safety Donut for Part #1012

71001-8

1001-16H

1001-40H

1001-45H

100-95H

Unifit Padholder Base (F-8)

Unifit Padholder Base (F-16)

Unifit Padholder Base (F-40)

Unifit Padholder Base (F-45)

Unifit Padholder Base (F-95)

2

1

5

36

4

7

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

20

Parts Listing

Item Part Number Description

1Identification Plate

2847-08 Cord Wrap

3870 Electrical Power Cord—12 ft., 110 volt, 3 prong

4847-62Kit Receptacle—Female

5847-01 On-Off Switch

6847-07 Rear Panel

7847-09 Reset Button Cover

8847-06 Front Cover

2

1

5

3

6

4

7

8

FILTROX NORTH AMERICA · 5506 6TH AVE S. SUITE 107 SEATTLE WA 98108 · 425-820-4850 FAX 425-820-2816

This manual suits for next models

2

Table of contents

Popular Water Filtration System manuals by other brands

Kessel

Kessel EasyClean free NS 25 Installation and operating instructions

Katadyn

Katadyn MyBottle owner's manual

Apec Water

Apec Water ROES-PH75 Installation instructions & owner's manual

BWT

BWT RTM CS S-500 Installation and operating instructions

Biosan

Biosan Labaqua operating manual

Water Tec

Water Tec CP operating manual

Pentair

Pentair BIOSHIELD CLP41A6-XN Installation and user guide

Eden

Eden 501 user manual

WaterLogic

WaterLogic WL7 FW Installation procedures

Puroserve

Puroserve HT series Operation manual

Blue Mountain

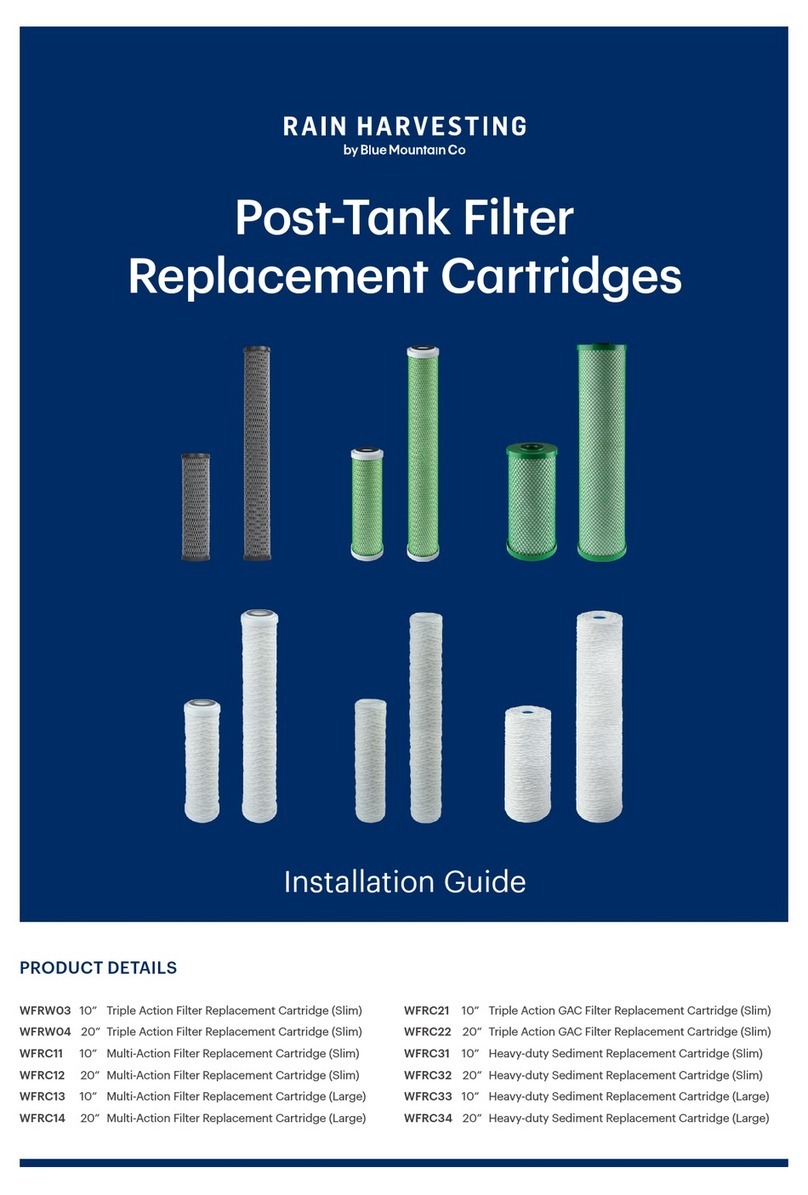

Blue Mountain Rain Harvesting WFRW03 installation guide

SMC Networks

SMC Networks ZFA100- 02 Series Operation manual