Below Ground

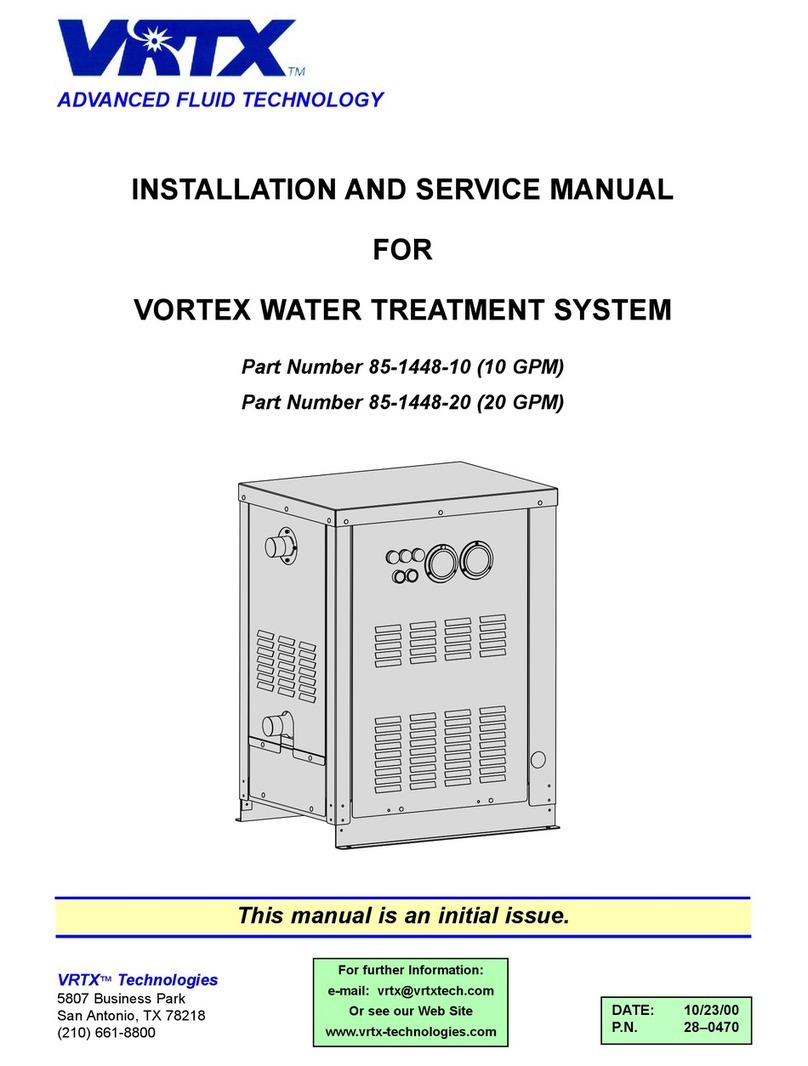

Remove the steel or aluminum cover and the internal packing material. Prior to installing the filter, a

12" pipe will need to be buried with a 90° elbow to receive the discharge pipe at the bottom of the

filter. This pipe will need to be installed to carry first flush water and debris to grade or to storm as

applicable.

Place the stainless steel base over the elbow on a firm base of gravel or pre-poured concrete slab.

The base plate should rest level on the concrete platform or compacted area with the end of the

elbow visible through the round opening in the base plate. Make certain the base plate rests flat on

the ground or concrete slab. If there are void areas, they must be filled in.

Insert the housing of the RH9521-12 into the open elbow through the opening in the stainless steel

base plate. It is critical that the vertical pressure of the RH9521-12 housing is absorbed completely by

the base plate. If any of the weight is not distributed properly, ad ustments to the base plate will be

necessary.

Rotate the rainwater inlet to the required direction to meet the incoming trunk line from the

downspouts. Rotate the clean water outlet to the required direction to connect to the tank.

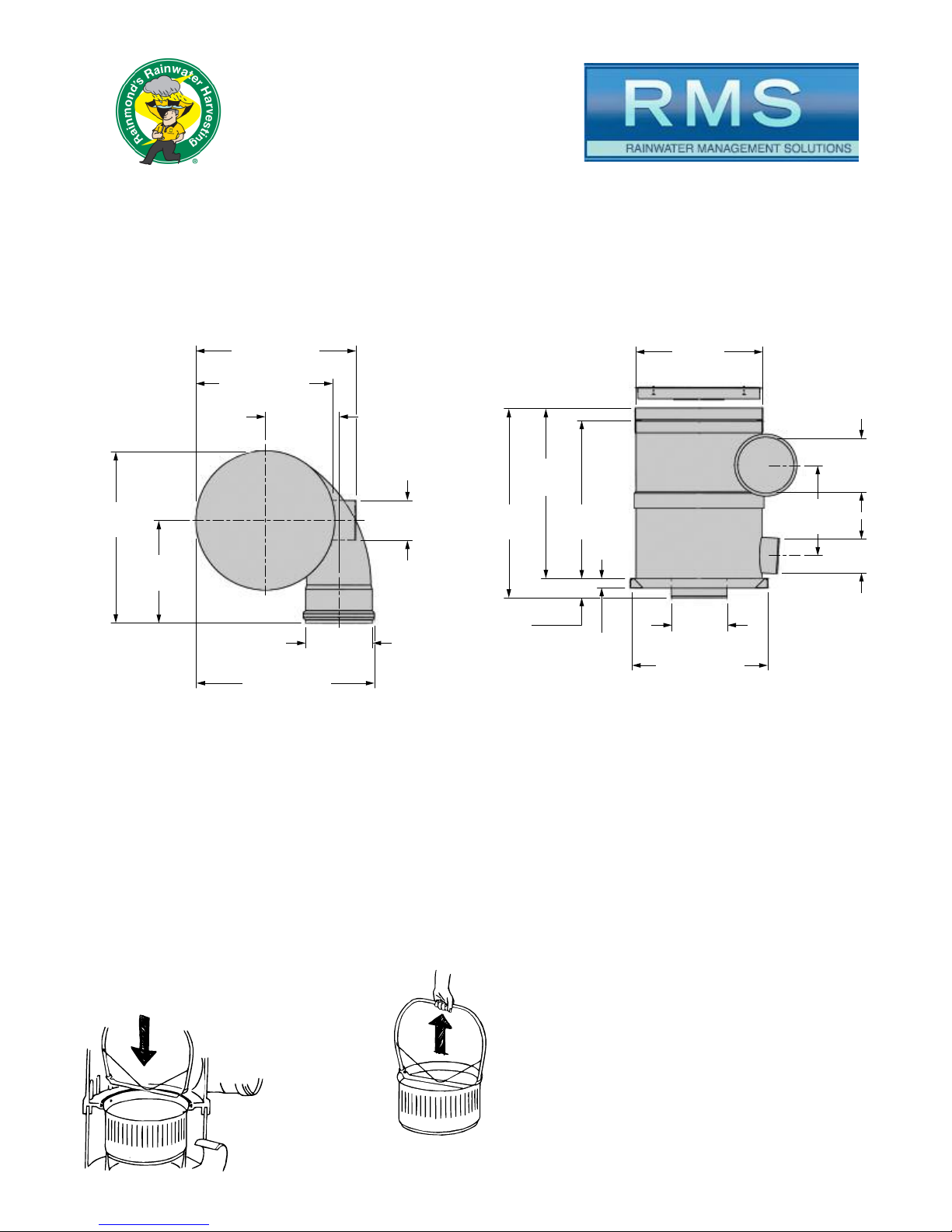

Remove the pipe inlet protector from the rainwater inlet on the filter by removing the rubber seal ring

from the inlet bushing. Push the inlet protector out from the inside and replace the rubber seal ring in

the inlet bushing. Make the connection from the trunk line to the filter using a minimum of 40" of

horizontal 12" pipe to reduce the velocity of flow and calm the water to maximize efficiency. The 8"

inlet pipe to the tank should be attached to the clean water outlet on the filter and the inlet of the tank

using a minimum 1/8" fall per linear foot to ensure gravitational flow to the tank.

Once all connections are made and the filter has been checked to ensure it is level and plumb,

backfill the filter using gravel or wet sand.

If the top of the filter housing is below grade, an extension can be added to the filter. The child

protection plate must be removed from the ring and moved to the top ring once installed. The

extension is then placed in the ring on the top of the filter and secured using stainless steel screws

with washers and nuts. An additional top ring will be necessary to support the top of the extension

and receive the child protection plate and lid. Once the exact length of the extension is determined,

remove the excess.

Secure the intermediate ring to the top of the extension ring using stainless steel screw with washers

and nuts and attach the child protection plate. The lid can then be placed on the filter and the

remaining backfilling can take place.

Note: Please see the additional installation notes included at the end of this section.

2