Filters itm FBR User manual

www.itmfilters.com

Sand Filters

User manual FBR / FCR

Serial number:

_________________

Purchase date:

_________________

ARM SAND FILTER (FBR)

CREPINE SAND FILTER (FCR)

www.itmfilters.com

Index

User manual FBR / FCR

1. Introduction ...................................................................................................................... 1

1.1 Filter identification.................................................................................................... 1

1.2 Basic concepts ........................................................................................................... 1

2. Data Sheet......................................................................................................................... 2

2.1 Arm Sand Filter (FBR) ................................................................................................ 2

2.2 Crepine Sand Filter (FCR)........................................................................................... 4

3. Installation......................................................................................................................... 6

4. Operation .......................................................................................................................... 6

5. Maintenance and spare parts ........................................................................................... 6

5.1 Maintenance ............................................................................................................. 6

5.2 Exploded view ........................................................................................................... 7

6. Product warranty .............................................................................................................. 8

USER MANUAL FBR /FCR

www.itmfilters.com

1. Introduction

First of all, we want to thank you for purchasing this filter, the result of the work of a group of

people committed to offering the correct solution to each filtration process. All products

designed and manufactured by ITM Filters meet self-imposed requirements for quality,

efficiency and durability. This philosophy is accredited through certification by external bodies.

The highest efficiency of the system is obtained with correct operation and maintenance, please

properly follow the indications in this manual throughout the life of the product. We invite you

to visit our website: www.itmfilters.com for more information about our products and our

company policies.

1.1 Filter identification

The filter is identified with the following decal:

1.2 Basic concepts

Filtration surface: Area that allows water to pass while retaining suspended particles.

Recommended flow: Optimal filtration must take into account the quality of the source water

and its use. The quality of the source water is divided into 4 sections, which have maximum

theoretical flows. The sectorization corresponds to the particles per million diluted in the water.

Stretch 1: 0-50 ppm.

Stretch 2: 50-100 ppm.

Stretch 3: 100/200 ppm.

Stretch 4: >200 ppm.

Loss of pressure: It is the difference in load produced between two points of the same flow. The

friction of the water with the filter medium produces a loss of energy. The diluted substances

are trapped in the mesh generating a decrease in the porosity of the filter medium, which causes

an increase in the pressure drop. The pressure drop measurement is carried out by means of a

pressure tap on the inlet manifold and another one on the outlet manifold.

USER MANUAL FBR /FCR

1

IMAGE 1

www.itmfilters.com

2. Data Sheet

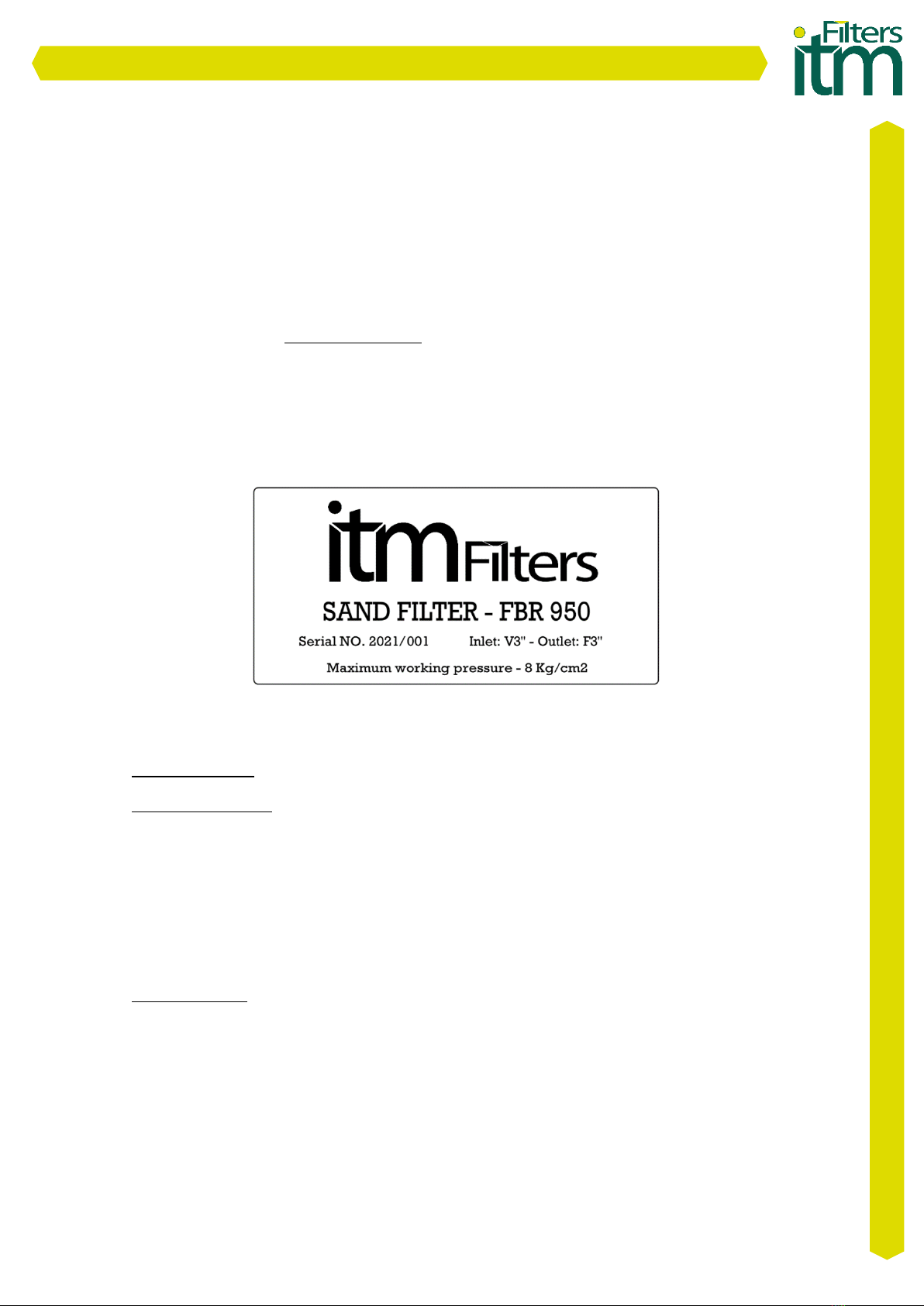

2.1 Arm Sand Filter (FBR)

MODEL

ØI

ØO

Flows (m³/h)

Filtration

Surface

(cm²)

Net

Weigh

t (kg)

Sand

(kg)

Qmax

< 50ppm

50/100ppm

100/200ppm

FBR-500

(1-½" - H/H)

Rosca Hembra

1-½"

Rosca

Hembra

1-½"

16

8

5

3,5

1963

43

100

FBR-700

(2" - V/H)

Victaulic 2"

Rosca

Hembra 2"

26

13

8

5,5

3848

61

225

FBR-950

(3" - V/B)

Victaulic 3"

Brida 3"

46

26

16

11

7088

126

500

FBR-1200

(4" - V/B)

Victaulic 4"

Brida 4"

76

36

20

15

11310

176

800

TABLE 1

Manufacturing technical characteristics:

-Materials:

oCarbon steel metal components.

oZinc plated screws 6.8.

oEDPM gaskets: 60 SHORE.

-Superficial treatment:

oSurface shot blasting up to SA ½ grade.

oTwo-layer EPOXY-POLYESTER powder paint finish, oven-polymerized RAL 6004.

-Working characteristics:

oMaximum operating temperature 50ºC.

Working pressure = 8 kg/cm²

USER MANUAL FBR /FCR

2

IMAGE 2

www.itmfilters.com

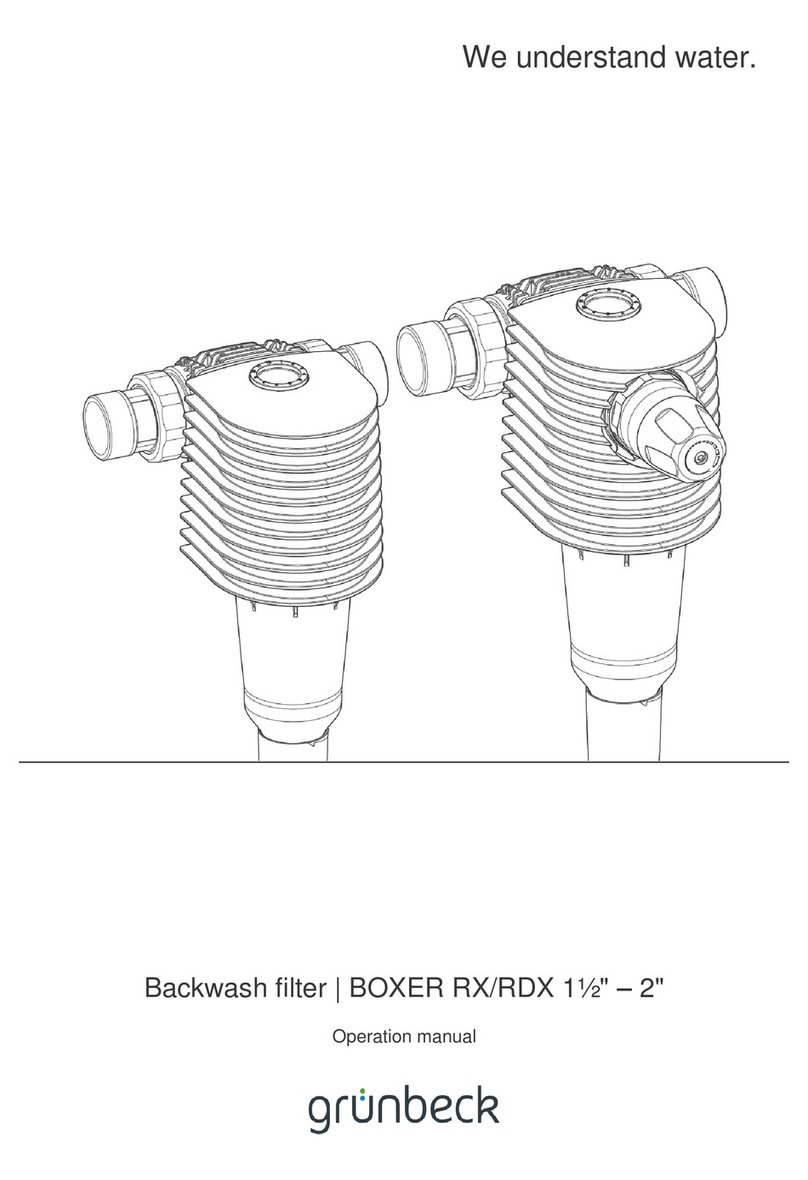

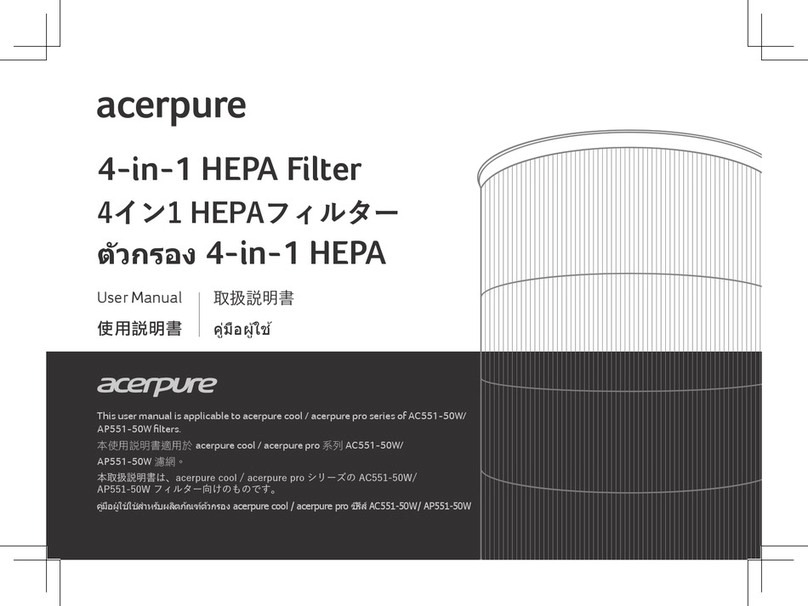

Dimensions FBR

MODEL

Dimensions (mm)

ØD

H

M

W

FBR-500 (1-½" - H/H)

500

900

350

286

FBR-700 (2" - V/H)

700

940

350

396

FBR-950 (3" - V/B)

950

1215

450

530

FBR-1200 (4" - V/B)

1200

1215

450

665

TABLE 2

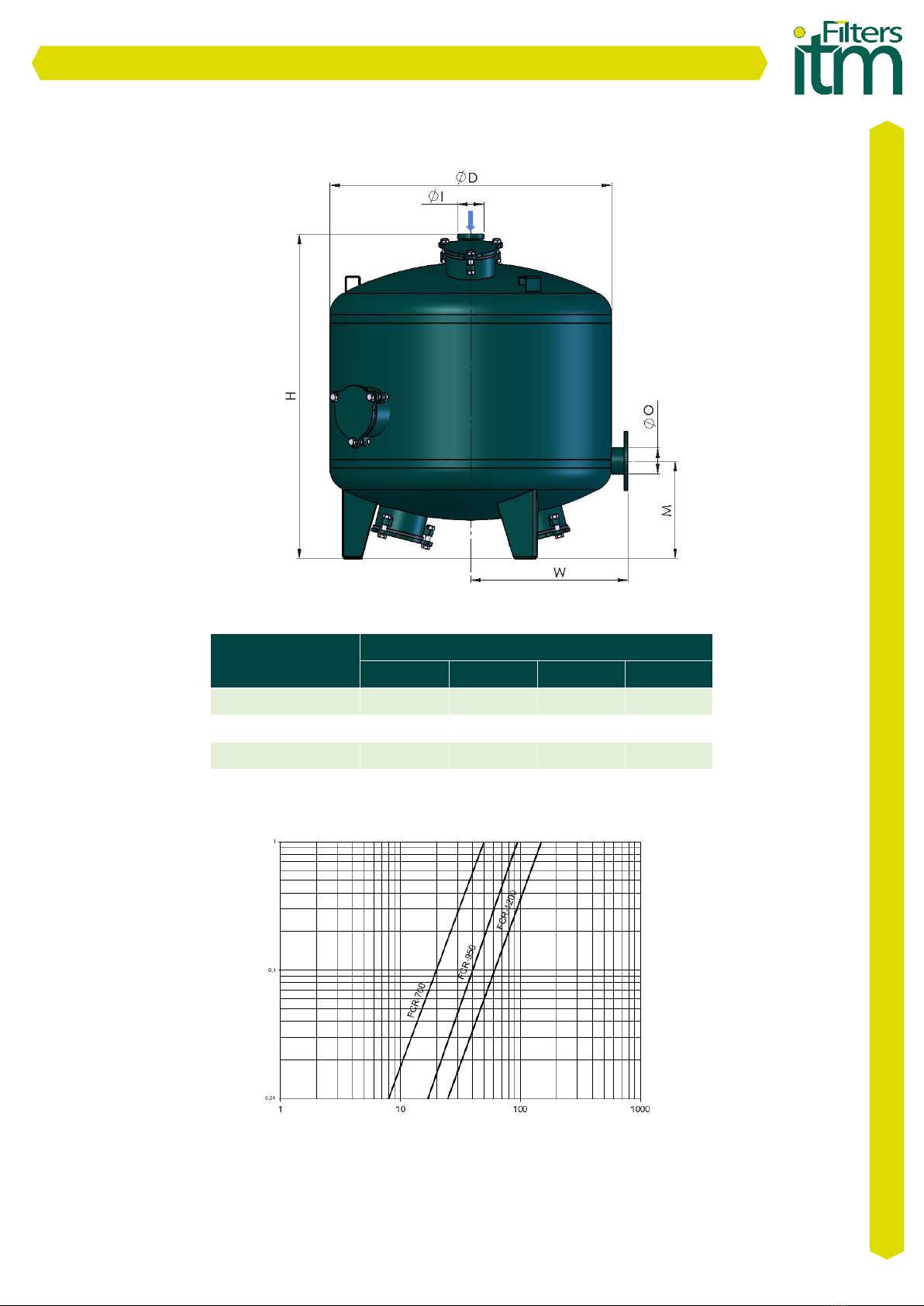

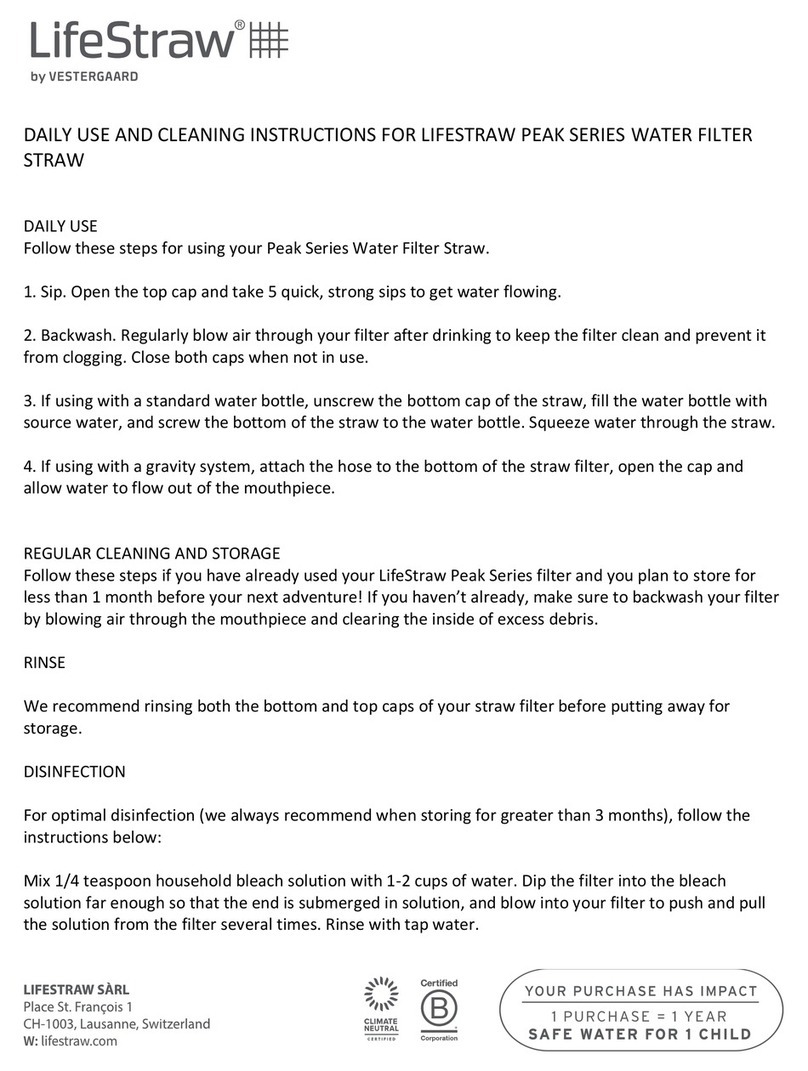

CHART 1

Water

inlet

USER MANUAL FBR /FCR

3

IMAGE 3

Flow (m3/h)

FBR load loss

Pressure loss - Kg/cm2

www.itmfilters.com

2.2 Crepine Sand Filter (FCR)

MODEL

ØI

ØO

Flows (m³/h)

Filtration

Surface

(cm²)

Net

Weight

(kg)

Sand

(kg)

Qmax

< 50ppm

50/100ppm

100/200ppm

FCR-700

(2" - V/H)

Victaulic 2"

Rosca

Hembra 2"

26

13

8

5,5

3848

88

150

FCR-950

(3" - V/B)

Victaulic 3"

Brida 3"

46

26

16

11

7088

194

375

FCR-1200

(4" - V/B)

Victaulic 4"

Brida 4"

76

36

20

15

11310

246

550

TABLE 3

Manufacturing technical characteristics:

-Materials:

oCarbon steel metal components.

oZinc plated screws 6.8.

oEDPM gaskets: 60 SHORE.

-Superficial treatment:

oSurface shot blasting up to SA ½ grade.

oTwo-layer EPOXY-POLYESTER powder paint finish, oven-polymerized RAL 6004.

-Working characteristics:

oMaximum operating temperature 50ºC.

Working pressure = 8 kg/cm²

USER MANUAL FBR /FCR

4

IMAGE 4

www.itmfilters.com

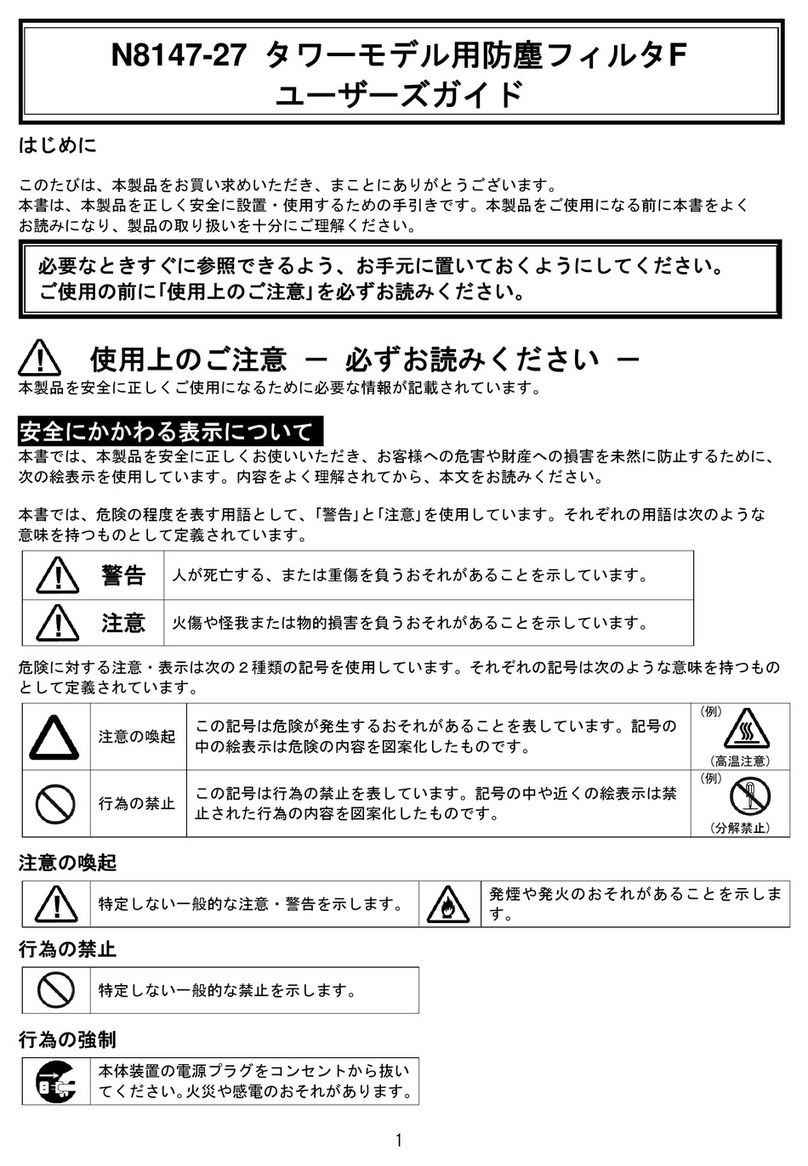

Dimensions FCR

MODEL

Dimensions (mm)

ØD

H

M

W

FCR-700 (2" - V/H)

700

940

350

396

FCR-950 (3" - V/B)

950

1095

330

530

FCR-1200 (4" - V/B)

1200

1128

375

665

TABLE 4

CHART 2

USER MANUAL FBR /FCR

5

Water

inlet

IMAGE 5

Flow (m3/h)

FCR load loss

Pressure loss - Kg/cm2

www.itmfilters.com

3. Installation

1. Place the filter on a flat surface. If more than one filter is purchased and they are

stacked, they must be separated by unscrewing the union on the upper supports.

2. Position the inlet and outlet manifolds, fixing the flanges with their corresponding

gaskets.

3. Connect the drainpipes and direct to the desired area.

4. Filter filling. First fill the water filter halfway. Open the top cover and pour the filter

material slowly to avoid damage to the internal structure. The amount of sand required

is indicated in the technical sheet (Page 2).

5. Place the pressure gauges, one on the water inlet manifold and the other on the filtered

water outlet manifold.

6. Check that the unions are tight, turn on the water supply and verify that there is no leak.

7. Carry out a first cleaning to remove possible impurities from the sand.

8. Filtering. Open the water flow at the recommended flow rate (depending on the quality

of the water) and at a working pressure of 8 kg/cm².

9. When the pressure gauges indicate a pressure difference equal to or greater than 0.5

kg/cm², clean the filter by reversing the direction of the water.

4. Operation

Sand filtration is a highly efficient and in-depth filtration method. It consists in the physical

separation between water and the substances that are suspended in it. The water descends

through the filter bed of sand where impurities are trapped, and the system of arms allows the

filtered water to escape.

When the sand filter becomes clogged, it produces a pressure difference between the water

inlet and outlet. The cleaning cycle begins when a pressure difference of 0.5 kg/cm is reached.

The cleaning cycle consists in reversing the direction of circulation: the water rises and carries

all the particles trapped in the sand filter bed and it is expelled.

5. Maintenance and spare parts

5.1 Maintenance

1. Avoid leaving the filter without water for proper maintenance of the filter material. If

the sand becomes dry and caked, open the lower mouth of the filter, empty its contents

and replace it. In case the sand does not evacuate properly, connect the water flow to

facilitate its exit.

2. Proper filter maintenance includes checking the condition of the paint. Damage caused

by corrosion must be corrected.

USER MANUAL FBR /FCR

6

www.itmfilters.com

5.2 Exploded view

Nº

DENOMINATION

FBR MODELS

FBR-500

FBR-700

FBR-950

FBR-1200

U.

Code

U.

Code

U.

Code

U.

Code

1

Body

1

FBR-500-02

1

FBR-700-02

1

FBR-950-02

1

FBR-1200-02

2

Arm holder pipe

1

FBR-500-03-00

1

FBR-700-03-00

1

FBR-950-03-00

1

FBR-1200-03-00

3

Collector arm 1’’ L=110

4

Ref. 06437

-

-

-

-

-

-

Collector arm 1’’ L=160

6

Ref. 06436

4

Ref. 06436

-

-

4

Ref. 06436

Collector arm 1’’ L=225

-

-

8

Ref. 06435

20

Ref. 06435

22

Ref. 06435

4

Cuff link 1’’

-

-

-

-

16

Ref. 06439

40

Ref. 06439

5

Arm extension 1’’ L=100

-

-

-

-

16

Ref. 06438

40

Ref. 06438

6

Hex nut M16

6

DIN933

6

DIN933

6

DIN933

9

DIN933

7

Flat washer D16

6

DIN125

6

DIN125

6

DIN125

9

DIN125

8

Loading manhole cover

2

FBR-500-05

2

FBR-500-05

2

FBR-500-05

3

FBR-500-05

9

Gasket

2

FBR-500-09

2

FBR-500-09

2

FBR-500-09

3

FBR-500-09

10

Hex nut M16

6

DIN934

6

DIN934

6

DIN934

9

DIN934

TABLE 5

1

2

6

3

4

USER MANUAL FBR /FCR

7

7

8

9

5

10

www.itmfilters.com

6. Product warranty

1. All ITM FILTERS products are guaranteed for 1 year from the date of invoice.

2. The replacement of defective parts is covered by the warranty, being necessary to

indicate the serial number and allow the verification by our staff.

3. Take into account the user manual for the installation of the product and check the

operating parameters in the technical tables.

4. To obtain a correct filtration, the size of the filter element must be smaller than that of

the substances suspended in the water to be filtered.

5. This warranty will not apply in the event of damage or defects produced in the product

as a result of or related to:

i. Tearing, elimination or manipulation of the identifying label of the product.

ii. Improper or unauthorized use of the product by the buyer.

iii. An improper assembly or installation that does not correspond to that established

by ITM FILTERS.

iv. The pertinent periodic cleanings.

v. Arm damage caused by the poor maintenance of the sand.

vi. The use of water that does not meet the established quality or is outside the

specifications indicated in the technical tables.

vii. A use of flow discordant with the water quality according to the parameters defined

in the technical tables.

viii. Pressures that differ from the established working pressure.

ix. The wear of materials caused by fatigue, abrasion or high temperatures.

x. Any external alteration, modification or repair of the products, except by ITM

FILTERS and its technical representatives.

xi. Damages produced during the transport of the product.

xii. Third party damage, theft or vandalism.

6. At ITM FILTERS we are committed to quality, which is why we have the ISO 9001, ISO

14001, ISO 45001 and EN 1090 certifications. In addition, during the manufacture of our

filters we have established our own quality control in which we ensure that the product

meets all quality requirements optimally. If you notice any defects, please contact your

dealer.

7. For any claim, it is essential to present this document, the serial code of the

corresponding product and the purchase invoice.

USER MANUAL FBR /FCR

8

This manual suits for next models

8

Table of contents

Other Filters itm Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Toro

Toro Aqua-Clear AC-40 Installation & user guide

AquaTools

AquaTools AT8236 owner's manual

Master Water Conditioning

Master Water Conditioning MBA Series Installation and operation manual

acerpure

acerpure ZC.X01TG.06J user manual

spotzero

spotzero ZTCII2000 User manual & installation guide

Monacor

Monacor FGA-40 operating instructions

Dupla

Dupla Perfect Clean PC 1 Instructions for use

Sears

Sears 625.345600 owner's manual

Vestergaard

Vestergaard LifeStraw PEAK Series instructions

NEC

NEC N8147-27 user guide

PureDrop

PureDrop AquaCube Installation and maintenance manual

Aqua Ultraviolet

Aqua Ultraviolet Ultima II Pro 3" Series instruction manual