Filters itm HYDRAULIC-200-H User manual

Table of contents

Other Filters itm Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Avantco

Avantco 23 WG Installation, use and maintenance handbook

Ecoplus

Ecoplus Pi3900 EP-1000-TAC Owner's manual & installation guide

Water Boss

Water Boss 97WB-IF Installation and service

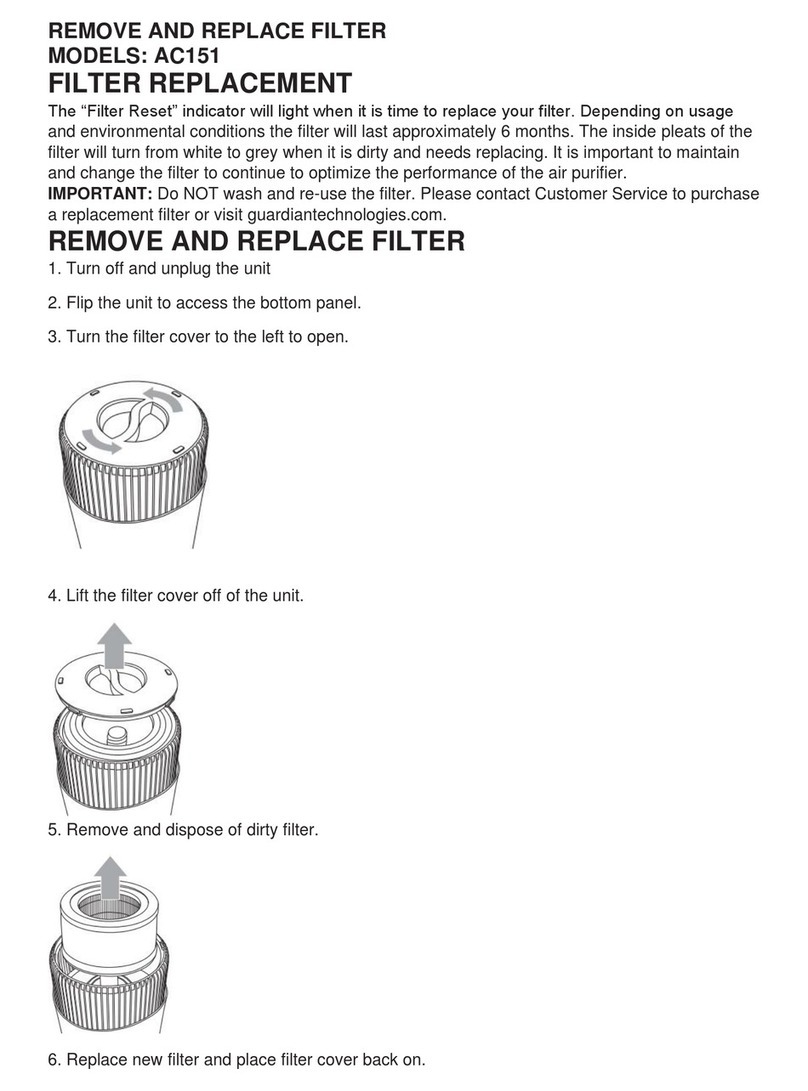

Germguardian

Germguardian AC151 Remove & Replace Instructions

Waterco

Waterco MultiCyclone12 Plus Installation and operation manual

AQUA FORTE

AQUA FORTE RD430 manual

Plasma Made

Plasma Made CA-R series Installation and user manual

Pure-Pro

Pure-Pro ERS-106RP user manual

aqua technix

aqua technix Aqua AQ 280 original operation manual

Ro-Man

Ro-Man 400-600 GPD RO Entire guide

Pureit

Pureit Pureit Copper+ Mineral RO+UV+MF instruction manual

Alfalaval

Alfalaval MBUX 510T-34C instruction manual

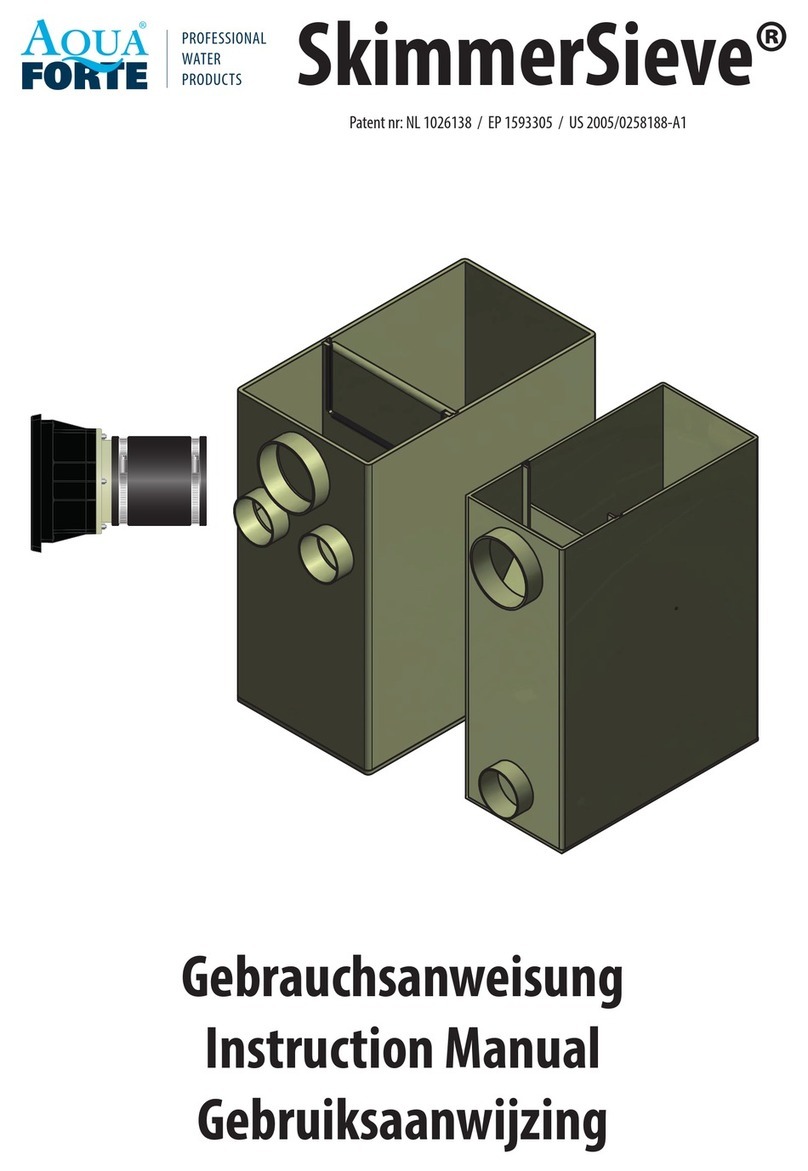

AQUA FORTE

AQUA FORTE SkimmerSieve Low instruction manual

Pure-Pro

Pure-Pro RS-103TDS user manual

MASTER PNEUMATIC-DETROIT, INC.

MASTER PNEUMATIC-DETROIT, INC. L29D Installation and Maintenance

Alto-Shaam

Alto-Shaam CombiGuard Installation, operation & maintenance manual

Pro-Aqua

Pro-Aqua PRO-UC-ROSTD manual

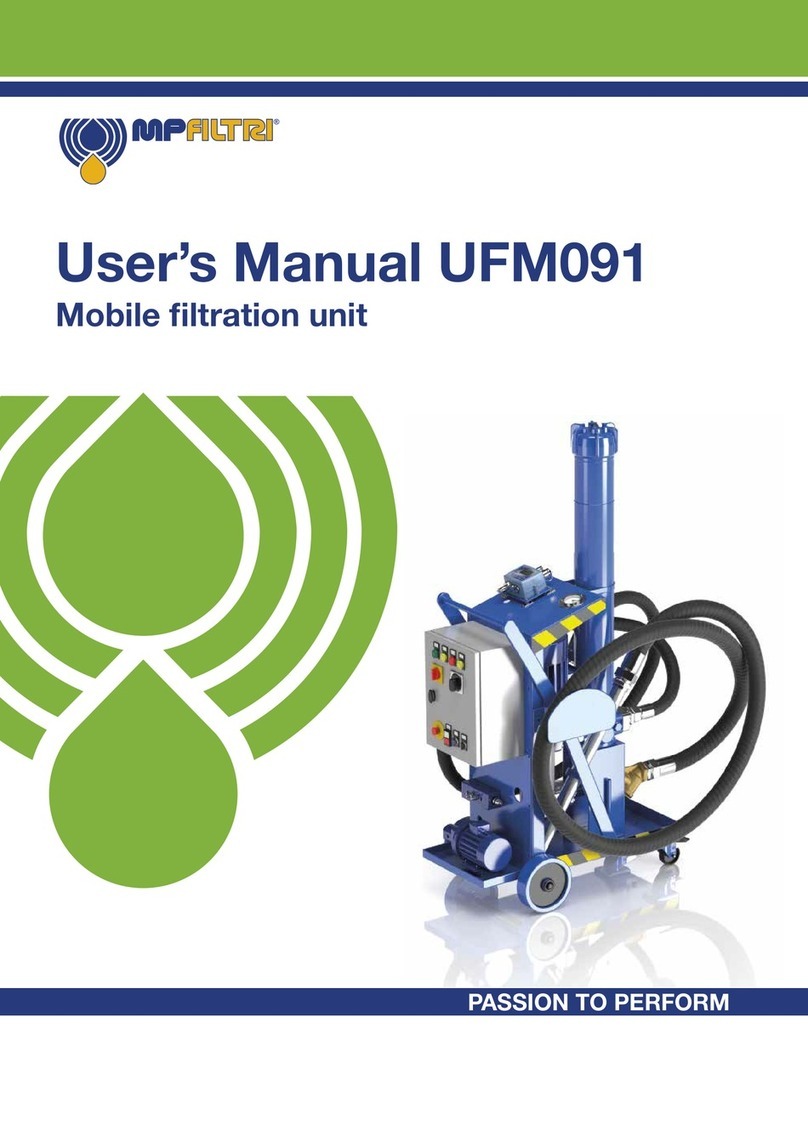

MPFiltri

MPFiltri UFM091 user manual