FILTOMAT M100C Series User manual

FILTOMAT®

Automatic Water Filters

Installation, Operation and

Maintenance Manual

M100-750 & 1500 Series

Models: M102C, M103C & M104C

Model No:

Serial No.:

Screen Size:

TRIANGLE FILTRATION & IRRIGATION

17 Hinkler Road, Mordialloc, Vic. 3195 .Australia

Ph: 03 9580 2122 Fax: 03 9580 3131

www.trianglefiltration.com.au

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

2

TABLE OF CONTENTS

Introduction...............................................................................................................3

Specifications.............................................................................................................4

Safety instructions......................................................................................................5

Dimensional installation diagram ..................................................................................6

Operating principles....................................................................................................7

Installation ................................................................................................................8

Commissioning...........................................................................................................9

Troubleshooting .......................................................................................................10

Adjusting the rinse controller .....................................................................................10

Maintenance ............................................................................................................11

Parts schedule .........................................................................................................12

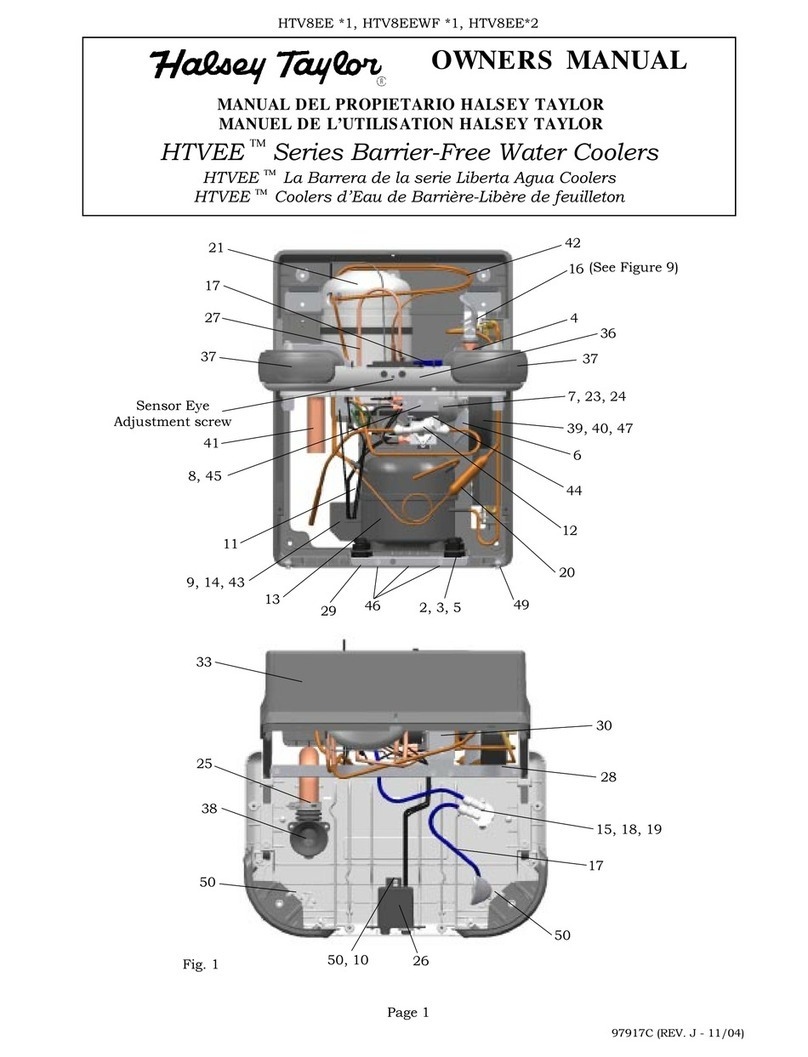

Parts drawing #1 - Exploded view M102C & M103C .....................................................13

Parts drawing #2 - Cover lid assembly. All Models .......................................................14

Parts drawing #3 - Collector assembly M102C & M103C. ..............................................15

Parts drawing #4 - Exploded view M104C...................................................................16

Parts drawing #5 - Collector assembly M104C.............................................................17

Control system - Hydraulic ........................................................................................18

Screen removal procedure ........................................................................................19

Warranty.................................................................................................................20

Note : Please quote the Filter Model Number, located on the filter housing with your inquiry.

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

3

INTRODUCTION

The FILTOMAT® M100C series filter is a well designed, simple to install and easy-to-operate automatic

water filter. The FILTOMAT will work with a range of fine screen mesh sizes from 50 to 800 micron, to

suit various applications and is available with 2"& 3" BSP female inlet/outlet ports and 4” flanged.

The FILTOMAT filters are selected to meet your specific needs according to flow rates and water quality.

The M102C, M103C & M104C model filters are generally installed as stand-alone units for low flow rates.

For higher flow rates and/or where a larger screen area is required, a range of larger models is also

available. The filters are delivered fully assembled, requiring simple connections to the inlet, outlet and

drain lines. Proper care and maintenance will give many years of trouble free operation.

General Description

Water enters the filter through the inlet pipe and passes through a coarse screen, which protects the

cleaning mechanism from larger particles. It is not designed to accumulate quantities of large suspended

solids as it is not cleaned automatically. The water then flows through a fine screen that filters out the

smaller particles, and the filtered water continues on through the outlet. The smaller particles accumulate

on the fine screen surface and forms a "filter cake", the cake build-up increases the differential pressure

(DP) across the fine screen, and at a pre-set DP point, the automatic self-cleaning cycle is actuated, which

basically consists of nozzles sucking the debris off the screen and expelling it out the drain line.

This innovative self-cleaning process, effectively removes the dirt particles from the fine screen, while still

maintaining flow downstream during the cleaning cycle.

The M100C series Filtomat filters are hydraulically operated, utilizing the system flow and water pressure,

no external power source is required. This method of control enables operation at remote installation sites.

Where electrical power is available, the option of electric control can also be provided with the filter, or

alternatively, where the customer has an existing PLC available with spare capacity, the filter can be fitted

out and supplied, ready for integration with the customer’s PLC.

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

4

SPECIFICATIONS

General

Maximum flow rate M102C = 25 m3/hr

M103C = 50 m3/h

M104C = 80 m3/h

Consult with your local agent regarding

optimum flow, for your application.

Min. working pressure 200 kPa Or lower, if pressure is increased for flushing

Max. working pressure 800 kPa

Flat screen 620cm2900cm2 for M104CFilter area

Moulded screen 700cm2950cm2 for M104C

Inlet/Outlet diameter 50, 80 & 100mm

(2", 3" & 4”)

2” or 3” BSP Female Thread

4” Table D Flanges

Max. working temperature 550C

Empty / Full weight - M102C

-M103C

-M104C

22kg / 38kg

25kg / 40kg

35kg / 62kg

Flush data

Drain line 40 mm (1 1/2") Drain line to be 50 N.B. Minimum

Flushing cycle time 10 seconds Depending on the working pressure

Backwash water per cycle 30 litres at 200 kPa

Minimum flow/press. required 14 m3/hr (4 l/sec) Min. of 200 kPa at inlet during flush cycle

Flush criteria Differential pressure (DP) set point at 50 kPa (adjustable)

Construction materials

Filter housing Epoxy-coated mild steel (St.St.316 available on request)

Filter lid High density polypropylene

Coarse screen Reinforced nylon

Fine screen Stainless Steel 316 mesh, PVC or moulded plastic support structure

Cleaning mechanism PVC and Stainless Steel

Motor assembly Reinforced nylon, brass, stainless steel

Control tubing Polyethylene

Seals BUNA-N

Control Brass, Stainless Steel , PVC, Acetal

Filtration screen sizes available

Type Moulded screen Flat screen

micron 500 300 200 130 100 80 800 400 200 150 130 100 80 50

mm 0.5 0.3 0.2 0.13 0.1 0.08 0.8 0.4 0.2 0.15 0.13 0.1 0.08 0.05

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

5

SAFETY INSTRUCTIONS

General

¾Carefully read the installation and operating instructions prior to installing the filter.

¾While working on the filter, basic safety instructions should be adhered to, to avoid injury to

individuals, or property damage in the vicinity.

¾Note: Once the filter is pressurised, it may commence a self-cleaning cycle automatically, without

prior warning.

¾Modifications to the equipment are not permitted, without written consent from the manufacturer or

it’s representative.

Operation, Control and Maintenance

¾Before unscrewing bolts or fittings, make sure the pressure in the filter has been relieved.

¾Minimize water leakage, where possible, to reduce the danger of slipping, electrocution or damage to

the equipment.

¾Always open and close valves gradually.

¾Manual cleaning of the filter element using high pressure water, should be performed in accordance

with the cleaning system instructions, without endangering personnel or the working area.

¾Manual cleaning of the filter element using acid or other chemical agents should be performed in

accordance with the relevant material safety instructions and without endangering the operator or the

working area. Eye protection and suitable gloves must be worn.

Use of Lifting Equipment

¾When using lifting equipment, ensure the item to be lifted is tied securely and in a safe manner.

¾Avoid working below lifted equipment.

¾Wear a safety helmet when using lifting equipment.

¾Beware of overhead electrical power lines.

¾DIMENSIONAL INSTALLATION DRAWING

NOTE: This is a conceptual installation drawing. (piping /valves etc. are not included.)

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

6

*

753 (29.6")

400 (15.7")

554 (21.8") (710) (28")

960 (15.7")

328 (12.9")

210 (8.3")

DRAIN

185 (7.3")

3

2

4

5

16

Key:

1. 2" Inlet manifold

2. 2" Inlet butterfly valve

3. 2" Filtomat M102-C filter

4. 2" Outlet butterfly valve

5. 2" Bypass butterfly valve

6. 2" Outlet manifold

* Minimum length required for servicing.

Filters may be installed either in a vertical or horizontal position to suit your application.

Note: A bypass should not be installed on irrigation applications, or where the supply of

filtered water is critical.

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

7

Operating Principles

The automatic self-cleaning cycle is simple and effective, and takes 5-10 seconds, with only minor

interruption, if any, to the downstream water supply. (this is relative to the water supply/pump

performance available).

Water flows from the inlet through the coarse and fine screens to the outlet. The filter cake builds up on

the fine screen and when it reaches the pre-set differential pressure (DP) of 50kPa, the rinse controller is

actuated and starts the cleaning cycle.

The exhaust valve opens to atmosphere, creating a pressure drop in the rotor chamber, which creates

suction at the nozzle tips, removing the dirt built up on the screen surface.

The backflush water flows through the nozzles to the collector pipe and via the rotor to the exhaust valve

and out through the drain. The escaping water flowing through the rotor forces the dirt collector assembly

to spin, and move up vertically at the same time, subsequently the nozzles are sucking the dirt off the

total screen area. When the first stroke is completed, the exhaust valve closes for a few seconds, and the

rinse controller activates the second backflush stroke (downward). The dirt collector assembly rotates and

moves downward returning to its original position and the exhaust valve shuts.

The two stroke helical movement of the dirt collector assembly as described, ensures that the nozzles

sweep the entire fine screen surface twice per cleaning cycle.

This self-cleaning process takes approximately 10 seconds, depending on the operating pressure.

Exhaust valve

Rotor chamber

Rinse controller

Drain

Rotor

Fine screen

Outlet

Nozzles

Inlet

Dirt collector

Collector pipe

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

8

INSTALLATION Read these instructions carefully before installing and operating the filter.

Design Recommendations

The filter can be mounted vertically or horizontally.

¾For a prolonged high flow and low pressure condition, due to the filling of pipelines on start up, it is

recommended a pressure sustaining valve (PSV) is installed downstream of the filter. The PSV will

ensure backpressure on the filter, and controlled filling of the pipeline.

¾The filter inlet pressure should not drop below 200 kPa during the rinse cycle. If this cannot be

ensured, consult your local dealer or manufacturer’s agent.

¾If water supply is essential at all times, it is recommended that a manual or automatic by-pass be

installed.

¾The drain line should be 50 mm (2”) minimum, and open to atmosphere, to minimise backpressure on

the filter. Avoid running the drain line more than 12 metres or placing it on a rising slope.

¾Secure the drain line to prevent movement/damage during the rinse cycle.

¾Minimise bends and elbows on the drain line. Note: The complete cover lid assembly can be removed

and rotated at 90ºintervals to allow a more direct route to your drain point. The filter drain line outlet,

should not be located near the pump suction inlet.

¾The Rinse Controller has a 1”BSP Fem. (25 mm) drain port on the bottom which bleeds about ½ litre

per backflush cycle. This can also be connected to the main drain line, preferably at an angle to

eliminate any backflow or backpressure.

¾We recommend a mechanical non-return valve be installed downstream of the filter.

¾The pressure gauge supplied, is to be mounted on the three-way valve on the filter.

¾Check that there is sufficient space to remove the cover assembly and the screen from the filter for

servicing and troubleshooting.

Preparations for Installation

¾Provide suitable lighting around the filter area, for good visibility and safe maintenance.

¾Arrange suitable platforms and safety barriers where required, for safe access to the filter.

¾It is recommended a mechanical non-return valve be installed downstream of the filter to prevent

backflow damage to the screen.

¾Allow enough space for dismantling and maintenance of the filter.

Installation Procedure

Ensure the direction of flow is according to the arrows marked on the filter housing.

1. Connect a minimum of 2" (50mm) pipe to the drain. The drain line should be installed so that it creates

minimal resistance to a flow of 20m3/h. Water should flow freely from the drain line to atmosphere.

2. Connect a minimum of 1" (25mm) flexible tube to the rinse controller drain port. Ensure this drain line

is open to atmosphere.

IMPORTANT!!

¾Prevent static backpressure or reverse flow through the filter.

¾Install a manual isolating valve after (downstream) the filter.

¾Install a manual isolating valve before (upstream) the filter if there is any static head on the

inlet side.

¾If the inlet operating pressure falls below 250 kPa install a pressure sustaining valve (PSV)

after the filter.

NOTE: Once pressurized the filter may flush automatically, without prior warning.

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

9

COMMISIONING

Before using the filter, go through the following check-list carefully. No special training is required to carry

out these activities.

¾Check that the filter is mounted in the correct flow direction.

¾Check that all the control tubes are connected properly and that all connections are tight.

¾Check that the three-way mini-valve is turned to the automatic position. The arrow on the knob should

point to AUTO, and the red sticker }on the filter.

¾The nominal diameter of the drainpipe should be 2" (50mm), do not restrict the drain line, it should be

open to atmosphere.

¾Shut the upstream and downstream isolation valves.

¾Check that there is sufficient space to remove the cover lid assembly and the screen from the filter for

servicing/troubleshooting.

¾Check that the drain line has a union fitted, to allow removal of the cover lid assembly for servicing.

¾Check that the pressure gauge has been fitted on the brass 3-way valve.

GETTING STARTED

First operation of filter

After completing the preparation check-list above, perform the following steps:

1. Slowly open the inlet valve at the filter, and pressurize the vessel.

2. Check for leaks and repair if necessary.

3. Check that the minimum inlet pressure remains 200 kPa or higher.

4. Start a manual flush by turning the three-way valve to the OPEN position for a few seconds, and then

turn it back to AUTO. You may have to cycle the unit several times to clear the lines of air.

5. Slowly open the outlet valve at the filter. If you are filling the pipeline/s after the filter, throttle this

valve and maintain pressure (above 200 kPa) at the filter, until the lines are full and pressurised.

(unless a pressure sustaining valve is fitted to perform this function.)

6. If there is a by-pass valve, close it slowly.

7. Ensure the flow through the filter does not exceed the filter’s maximum flow rate.

8. Start a manual flush by turning the three-way valve to the OPEN position for a few seconds, and then

turn it back to AUTO. The cycle duration is approx. 5-10 seconds.

9. During the self-cleaning cycle, check the pressure at the filter inlet does not drop below 200 kPa, and

check the pressure in the rotor chamber.

NOTE: The minimum pressure in the rotor chamber should be 150 kPa lower than the inlet pressure.

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

10

Problem Possible Cause Solution

Pressure differential is not

correct

Pump not running

3-way manual flush valve in

open/closed position

Perform a manual flush as follows:

1. Close the filter outlet valve

2. Check that the filter outlet and inlet

pressures are equal

3. Perform a manual flush as in item 8,

page 9.

4. Check the pressures at the inlet valve

and in the rotor chamber

Rinse controller dripper

leaking water constantly.

Filter may be blocked, proceed as per above

to clear filter.

Filter not cleaning

Rinse controller has been

adjusted incorrectly

Check and re-adjust screw on rinse controller

(see below)

Excessive pressure in

the rotor chamber

Drain pipes are not clear, or

too small in diameter.

Check if drain lines are clear. If necessary

replace with a larger (diameter) flush drain

line, or shorten the existing lines.

Insufficient inlet

pressure (less than 200

kPa)

Inlet valves not fully open

Pump not running.

Open inlet valves to maximum.

Increase the inlet pressure or throttle the

outlet to increase pressure during the

cleaning cycle. Fit PSV valve

Coarse filter is blocked Check coarse filterPressure differential

exceeds 70 kPa during

normal operation

Fine screen has build-up of

material. Rinse controller

needs adjusting

Remove screen and high press. clean.

Adjust rinse controller (see below)

Check for blockage at high pressure sensing

line no.7 or no.5 low press. line

Inlet lines blocked Check inlet linesWater does not flow

through the filter

Isolating valves are closed

Pump not running/lost prime

Filter blocked

Open isolating valves

Check pump/foot valve

Repeat steps 1-4 as above at para.1

ADJUSTING THE RINSE CONTROLLER

NOTE: Improper adjusting of the rinse controller may cause the filter

to malfunction.

1. Disconnect the 1”(25mm) rinse controller drain line.

2. Flush the filter manually, using the 3-way valve as per item 8, Page

9 to ensure you start with a clean filter.

3. Loosen the locking nut on the long nose (1) and loosen the

adjusting screw (2), anticlockwise, slowly until a self-cleaning cycle

begins.

4. Turn the adjusting screw (2) clockwise 1.5 turns, and then tighten

the locking nut (1). This adjusts the rinse controller for a

differential pressure of approx. 50 kPa.

5. Observe at least one automatic self-cleaning cycle, if possible,

checking the differential set point with the gauge on the 3–way

valve.

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

11

MAINTENANCE

Before shutting down the filter, flush the filter manually via the 3-way valve. By doing this you can

observe the cleaning efficiency of the unit. By checking the inlet/outlet pressure on the gauge.

NOTE: De-pressurize the filter before disassembly or maintenance (close inlet, and then outlet valve),

then manually flush the unit to release the pressure from the vessel, check the pressure gauge to make

sure all pressure has been relieved.

Checking the Filter

1. Remove the filter cover lid assembly by unscrewing the 8 nuts. (Note: a thinner nut is fitted under

the drain line).

2. Extract the fine screen using the screen puller provided,(refer to page 19) and clean if necessary,

the screen is only retained by the o-rings on the outside diameter. Cleaning is best achieved using a

high pressure water cleaner (Gernie), only spray the screen from the inside out !. If there is an

iron oxide or calcium carbonate build up on the mesh, you will need to clean it with a diluted acid

solution (1:10 hydrochloric acid:water). Make sure suitable protective equipment is worn, a 5 minute

soaking and then pressure clean as above. (repeat if necessary). Avoid long periods in the acid

solution, as this will ruin the screen.

3. Check the coarse screen and clean if necessary.

4. Check the O-rings of the fine screen, replace if necessary and apply suitable lubricant.

5. Install the fine screen, pushing it home on the o-rings.

6. Fit the cover lid assembly, carefully aligning the dirt collector shaft into the bearing and fit and

fasten the 8 nuts, fit the thin nut first. Just nipping them up is enough!

7. Perform First Operation of Filter as on page 9.

Decommissioning

If the filter is to be shut down for any period of time, e.g. The end of an irrigation season the following

procedure should be followed:

1. With the pump on, close the outlet isolating valve completely and perform two manual rinses.

2. Turn the pump off.

3. Close the inlet valve if fitted.

4. To restart the system open the inlet valve and do the same as above, then open the downstream

valve slowly with the valve open enough to re-charge the down stream pipework, (not required if a

PSV valve is fitted) maintain at least 200 kPa backpressure on the filter while doing this. Once the

pipeline has been pressurised open the valve fully.

Note: If in doubt, please call us for assistance.

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

12

PARTS SCHEDULE for Models M102/3 & 4C

No. Description Cat. No.

1 Filter housing 05-1XX4-12XX

1.1 Stud bolt 1/2" X 108 (X4) 85-2431-08-108

1.2 Stud bolt 1/2" X 100 (X3) 85-2431-08-100

1.3 Stud bolt 1/2" X 97 85-2431-08-097

1.4 Plastic plug 1/4" 8211-0121-0400

1.5 Plastic plug 1/4" 8211-0121-0400

2-A Fine screen – flat (M102/3) 15-1203-0XXX

2-B Fine screen – moulded (M102/3) 15-1203-1XXX

2-C Fine screen – flat (M104) 15-1303-0XXX

2-D Fine screen – moulded (M104) 15-1303-1XXX

2.1 O-Ring (647) Soft (X2) 81-41-4001-0674

3-A Dirt collector Assy. (M102/3) 15-1024-0019

3-B Dirt collector Assy. (M104) 15-1004-0023

3.1 Rotor assembly 55-1006-0010

3.1.1 Lower bearing 65-3004-0602

3.1.2 Rotor bearing housing 65-1024-0026

3.1.3 Rotor 51-5510-0023

3.1.4 Self tapping screw 5/8" (X4) 85-4125-08-015

3.2-A Dirt collector sub Assy. (M102/3) 15-1034-0105

3.2-B Dirt collector sub Assy. (M104) 15-1004-0022

3.2.1 Dirt collector top plug 65-1024-0064

3.2.2 Bolt 3/8" X 8 (X4) 85-4125-08-009

3.2.3 Dirt collector pipe (M102/3) 65-1024-0063

3.2.3 Dirt collector pipe (M104) 65-1024-0066

3.2.4 Nozzle assembly 55-1024-0357

3.2.6 Dirt collector bottom plug 65-1004-0060

3.2.7 Dirt collector shaft (M102/3) 65-1024-0020

3.2.7 Dirt collector shaft (M104) 65-1044-0052

4 Filter lid assembly 15-1070-0024

4.1 Filter lid 55-1070-0090

4.2 O-Ring 6x3mm 81-41-4100-0603

4.3 Plug 1/4" BSP 82-11-0121-0400

No. Description Cat. No.

4.4 Nut ¼” 85-2231-04-000

4.5 Washer 65-1008-0212

4.6 O-ring (P2-107) 81-41-4000-0107

4.7 Elbow fitting 6 x ¼” 82-11-6469-4604

4.8 Diaphragm 81-41-4561-0003

4.9 Spring support 61-5510-0042

4.10 Spring 65-1008-0202

4.11 Spring plug guide 61-5510-0041

4.12 Rod tie 65-1008-0203

4.13 Washer 1/4" (X8) 85-2312-06-000

4.14 Nut 1/4" (X8) 85-2211-04-000

4.15 Diaphragm cover 51-5510-0021

4.16 Elbow fitting 6 X 1/4" 82-11-7469-4604

4.17 Rod tie (X7) 65-1024-0102

4.18 Rod-tie diaphragm support 65-1024-0031

4.19 O-Ring (P2-107) 81-41-4000-0107

4.20 Nut 65-1008-0007

4.21 Exhaust valve assembly 55-1006-0100

4.21.

1

Exhaust valve seal (X2) 81-41-4561-0047

4.22 Exhaust valve seat 55-1006-0206

4.23 O-Ring (P2-351) 81-41-4000-0351

5 Flushing chamber (Partition) 51-5510-0025

6 Self tapping screw 5/8" X 8 85-4125-08-015

7 Lid seal 81-41-4561-3015

8 Lock nut 1/2" UNC 85-2221-08-000

9 Nut 1/2" UNC (X7) 85-1211-08-000

10 Washer 1/2" (X8) 85-1311-08-001

11 Nipple 1 1/2” BSP 83-2920-0150-0105

12 Rinse controller 15-1007-0101

12.1 Bolt ¼” 85-4111-04-012

13 3-Way valve 84-31-70-0011

13.1 Nipple ¼” x 1/8” 83-4324-1012-1925

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

13

PARTS DRAWING #1 – Filter Exploded View M102/3

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

14

PARTS DRAWING #2 – Cover Lid Assembly M102/3&4

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

15

PARTS DRAWING #3 - Collector/Rotor Assembly M102/3

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

16

PARTS DRAWING #4 – Exploded View – M104C

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

17

DRAWING #5 – Collector/Turbine Assembly – M104C

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

18

Hydraulic Control System

1 = Green 8 mm fittings

7 = Red 6 mm fittings

3 & 5 = Black 6 mm fittings

drain

3

7

1

5

1

5

73

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

19

FILTOMAT M100-750 Installation & maintenance – 06.2005 - -

20

Warranty

The manufacturer warrants the product only against defects in material and workmanship for (1) year

from date of installation. This limited warranty is valid only when the product is used in accordance with

the manufacturer’s standards and instructions and on condition that the customer fulfills his/her

obligations set forth in this manual. The manufacturer’s liability is limited to the replacement of defective

parts with new or rebuilt parts, free of charge.

This warranty is extended only to the original purchaser. A purchase receipt or other proof of date of

original purchase is required before warranty performance is rendered.

This warranty only covers failures due to defects in materials or workmanship, which occur during normal

use. It does not cover damage caused by accidents, misuse, abuse, neglect, mishandling, misapplication,

alteration, modification or service by anyone other than the manufacturer or any person/agent authorized

by the manufacturer.

The manufacturer is not liable for incidental or consequential damages resulting from the use of this

product or arising out of any breach of this warranty. All express and implied warranties, including the

warranties of merchantability and fitness for a particular purpose, are limited to the applicable warranty

period set forth above.

Faulty replaced parts are to be returned to Triangle Filtration for inspection and assessment, so they in

turn can claim warranty replacements from the manufacturer.

If you have any questions, contact your local dealer or our service department.

This manual suits for next models

5

Table of contents