6

PROCEDURE C— Replacing the Media in the Bottom

Chamber of the DirectFlo DuoSoft

Follow steps 1-6 of PROCEDURE Bto replace the media in the top chamber of the

DirectFlo DuoSoft Softener.

Follow the procedure below to replace the media in the

bottom chamber. Ion exchange resin is generally used in the bottom section.

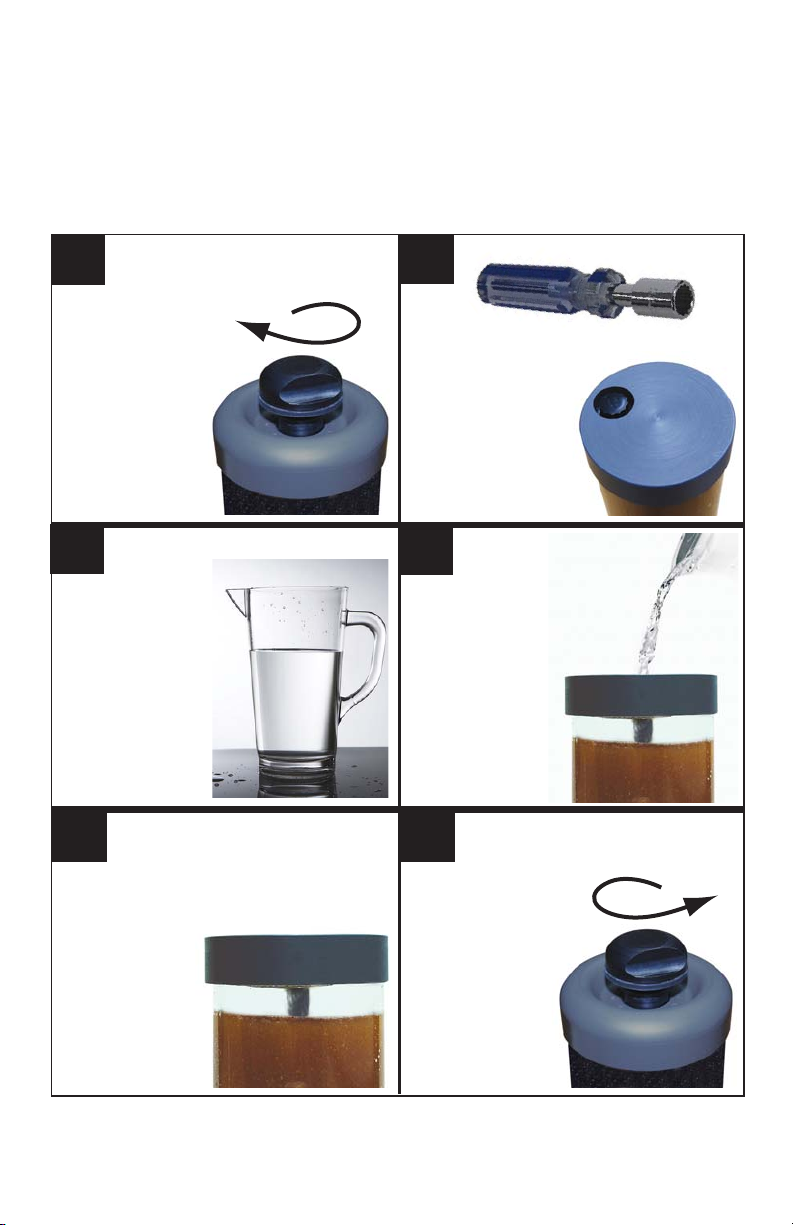

Turn the softener upright.

Turn the large black plug

on the top of the

softener

counterclockwise

until it becomes

loosened. Lift

the plug up

about 1”.

Use a 12-point 9/16”

nut driver to remove

the small black

plug on the

bottom of the

sampler.

Fill the softener to 1” from

the top with selected media.

NOTE: To facilitate the filling

process, a funnel can be used or

water can be

added to the

media.

If dry media was

added, fill the

chamber with water

and replace the small

black plug.

NOTE: Do not

overtighten plug.

Lift the plug up about 1”.

Continue turning the plug

counterclockwise

until it can be

removed.

Fill the softener to 1” from

the top with selected media.

NOTE: To facilitate the filling

process, a funnel can be used or

water can be

added to the

media.

1. 2.

3. 4.

5. 6.