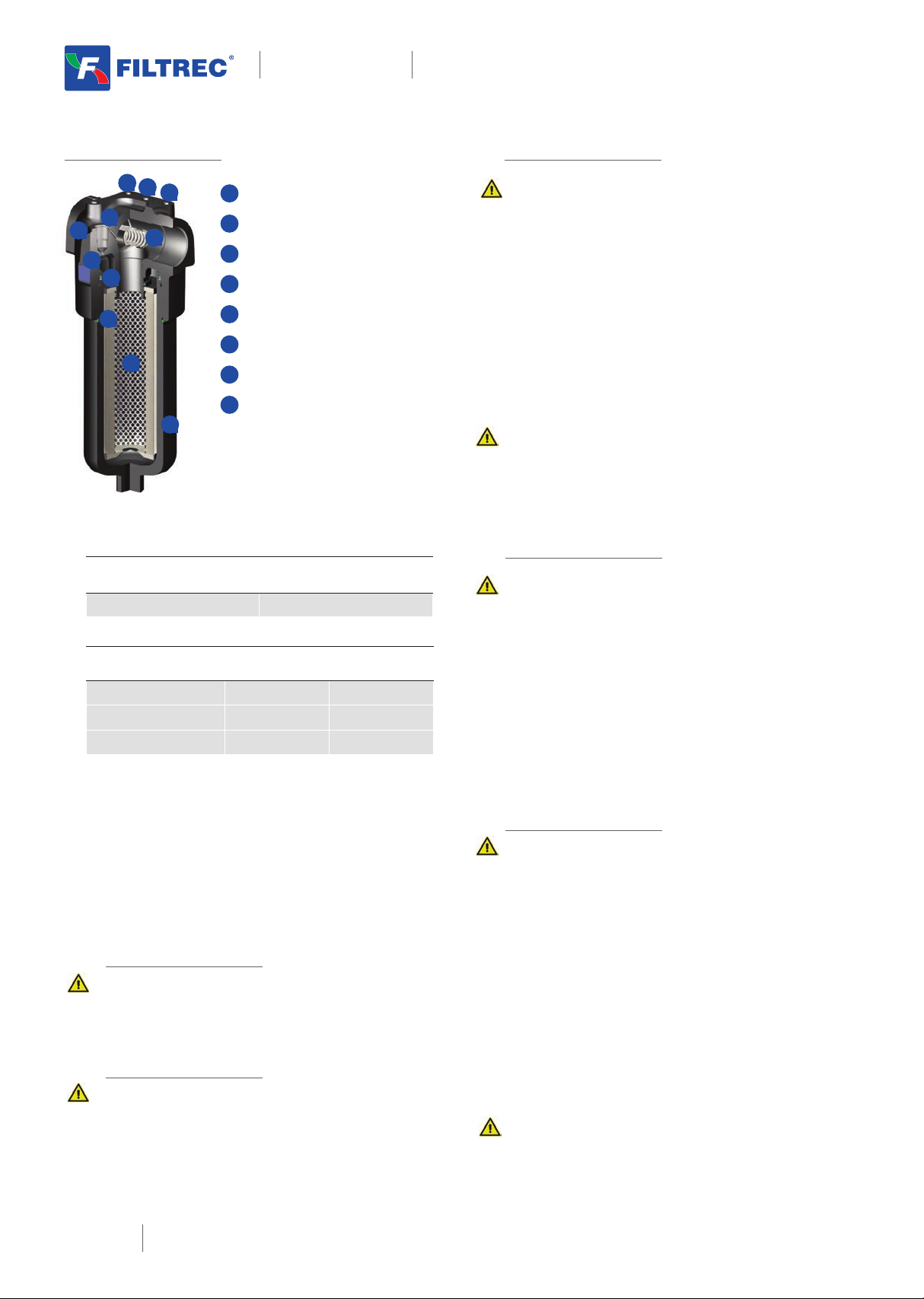

USER TIPS INSTALLATION

1

2

3331

6

7

7

8

5

4

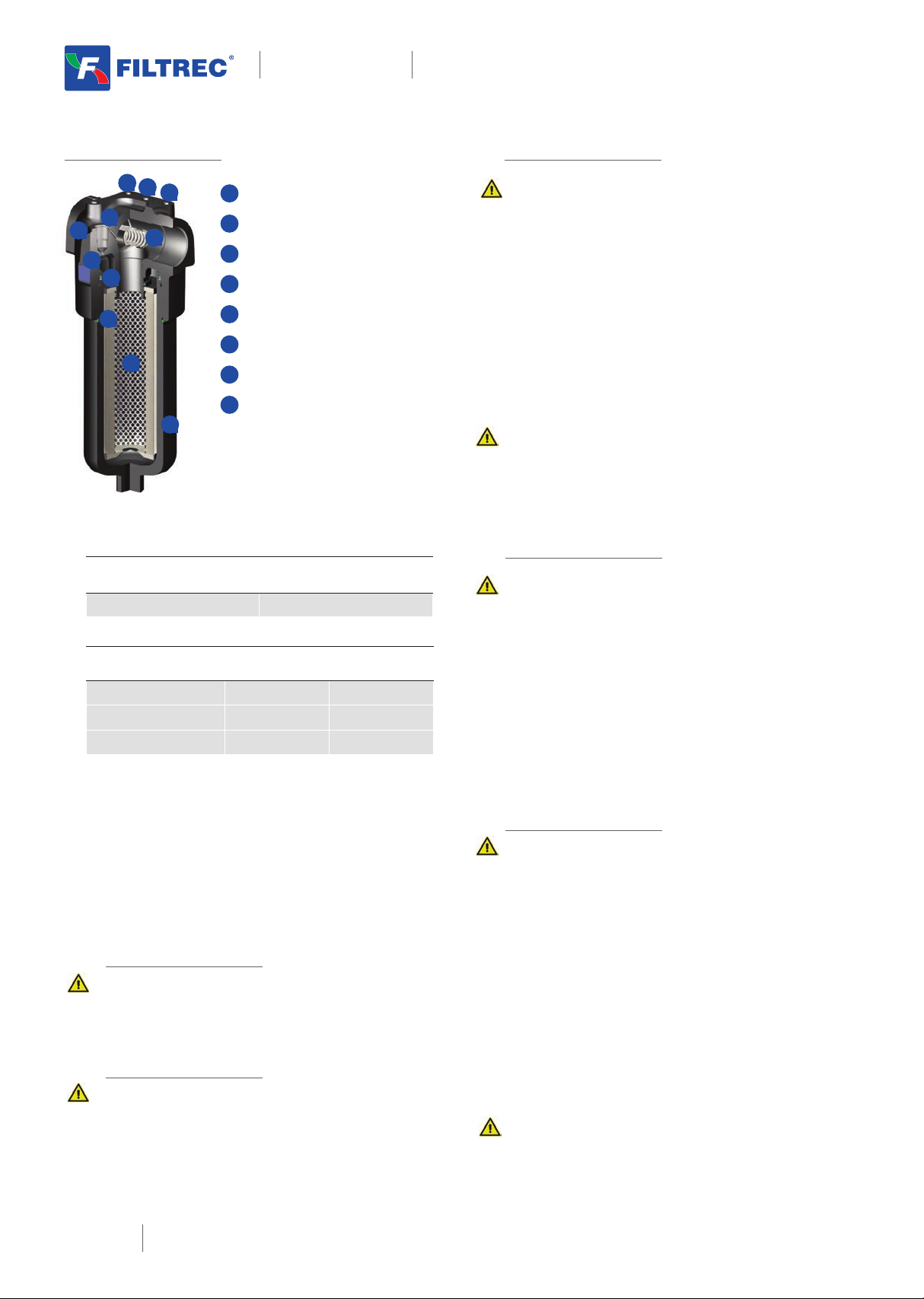

FILTER HEAD

2INDICATOR PORT

3FIXING HOLES

4BY- PASS VALVE

5FILTER ELEMENT

6FILTER BOWL

7SEAL KIT

8IDENTIFICATION LABEL

1. the IN and OUT ports must be connected to the

hoses in the correct flow direction (an arrow

shows on the filter head (1)

2. the filter housing should be preferably mounted

with the bowl (6) downward

3. secure to the frame the filter head (1) using the

threaded fixing holes (3)

4. verify that no tension is present on the filter after

mounting

5. enough space must be available for filter

element replacement

6. the visual clogging indicator must be in a easily

viewable position

7. when a electrical indicator is used, make sure

that it is properly wired

8. never run the system with no filter element fitted

9. keep in stock a spare FILTREC filter element for

timely replacement when required

OPERATION

1. the filter must work within the operating

conditions of pressure, temperature and

compatibility given in the first page of this data

sheet

2. the filter element must be replaced as soon as

the clogging indicator signals at working

temperature (in cold start conditions, oil

temperature lower than 30°C, a false alarm can

be given due to oil viscosity)

3. If no clogging indicator is mounted, replace the

element according to the system manufacturer’s

recommendations

WARNING

Make sure that Personal Protective Equipment (PPE) is

worn during installation and maintenance operation.

DISPOSAL OF FILTER ELEMENT

The used filter elements and the filter parts dirty of oil

are classified as “Dangerous waste material”: they

must be disposed according to the local laws by

authorized Companies.

MAINTENANCE

1. make sure that the system is switched off and

there is no residual pressure in the filter

2. unscrew the bowl (6) by turning it anti-clockwise

and remove it

3. remove the dirty element (5)

4. fit a new FILTREC element (5), verifying the part

number, particularly concerning the micron

rating; open its plastic protection on the open

end side and insert it onto the spigot in the filter

head, then remove completely the plastic

protection

5. clean carefully the bowl; check the O-rings (7)

conditions and replace if necessary

6. lubricate the bowl's thread (6) and screw it by

hand in the filter head (1) by turning it

clockwise

7. screw in the bowl to stop

8. the used filter elements cannot be cleaned

and re-used

INDICATOR TIGHTENING TORQUE

V05/E05/V08/E08 50 Nm

SPARE SEAL KIT PART NUMBER

NBR FKM

F280-D120/24/21 06.021.00090 06.021.00135

F280-D140/41/43 06.021.00095 06.021.00137

F280 SERIES 6/8

HYDRAULIC DIVISION F280 SERIES