Better Water MediPac User manual

MediPac

(Tank Feed)

Operator Manual

Better Water LLC

rev. Jun 2016

Better Water LLC. All rights reserved.

The content of this manual is the intellectual property of Better Water LLC. It is furnished for the

express use by Better Water LLC, their customers and dealers, for informational use only for operation,

service, and internal training. No part of this manual may be reproduced for distribution, sale, or any

intent other than previously described without the written permission of Better Water LLC. This manual

is subject to change without notice. Better Water LLC assumes no responsibility or liability for any error

or inaccuracies that may appear in this documentation.

Adobe and Acrobat are registered trademarks of Adobe Systems, Inc.

Better Water LLC; 698 Swan Dr; Smyrna, TN 37167; www.betterwater.com

rev. Jun 2016

MediPac, Tank Feed Operator Manual

TABLE OF CONTENTS

Our Company ……………………………………………………………………………………... 01

- Contact Us ……………………………………………………………………………………….. 01

- Technical Phone Support ………………………………………………………………………. 01

- Technical Support Info Online …………………………………………………………………. 01

- Specific Contacts ………………………………………………………………………………... 02

Introduction ………………………………………………………………………………………… 02

Warnings …………………………………………….…………………………………………….. 03

Cautions ……………………………………………….…………………………………………… 03

General Requirements and Specifications ……..……………………………………………… 04

Models ……………………………………………………………………………………………… 05

Important Information for Support ………………………………………………………………. 05

Product Description …………………………..……………………………………………………06

Detailed View of the MediPac

- Pre-Treatment Side …………………………………….……………………………………….. 07

- RO End …………………………………………………………………………………………… 07

- Post-Treatment End …………………………………………………………………………….. 08

System Components:

- MediPac Control Box …………………………………………………………………………… 09

- Pre-Treatment; Pressure Gauges …………………………………………………………….. 09

- Pre-Treatment; Thermometer …………………………………………………………………. 10

- Pre-Treatment; Blending Valve ……………………………………………………………….. 10

- Pre-Treatment; City Booster Pump ……………………………………………………………. 11

- Pre-Treatment; Automatic Control Valves ……………………………………………………. 11

- Pre-Treatment; Interlock Wiring System ……………………………………………………… 12

- Pre-Treatment; Water Softener ……………………………………………………………….. 13

- Pre-Treatment; Brine Tank …………………………………………………………………….. 14

- Pre-Treatment; Carbon Media Filtration ……………………………………………………… 15

- Pre-Treatment; Ultra-Violet Irradiation (Pre-RO) …………………………………………….. 16

- Pre-Treatment; Particulate Filtration Cartridge (10” Big Blue, 5 micron filter) …………… 17

- 1232 RO ………………………………………………………………………………………….. 18

- Post-Treatment; Repress Pump ………………………………………………………………. 19

- Post-Treatment; Ultra-Violet Irradiation (Post-RO) ………………………………………….. 20

- Post-Treatment; Pyrogen Cartridge (20”, .03 micron ultra-filter) ………………………….. 21

- Post-Treatment; Particulate Filtration (10” Big Blue, 5 micron filter) ……………………… 22

- Divert-to-Drain, Wall-Mounted …………………………………………………………………. 23

- Storage Tank and Level Control System ……………………………………………………... 24

- Remote Alarm Box ……………………………………………………………………………….25

- Disinfect Tank ……………………………………………………………………………………. 25

Operation

- General Operation ………………………………………………………………………………. 26

- Valves Legend …………………………………………………………………………………… 27

- Daily Start-Up ……………………………………………………………………………………. 30

- Monitoring Procedures ………………………………………………………………………….. 31

- Daily Shutdown ………………………………………………………………………………….. 31

rev. Jun 2016

MediPac, Tank Feed Operator Manual

Cleaning & Disinfecting

- General Cleaning and Disinfecting Overview ………………………………………………… 32

- Cleaning and Disinfecting Agents …………………………………………………………….. 33

- Disinfecting and Cleaning Procedure ……………………………………………………….... 34

- Disinfect/Clean the RO …………………………………………………………………………. 34

- Disinfect the Post-Treatment, Storage Tank, and Distribution Loop ……………………… 37

- Sanitizing the Sanitary Sample Ports …………………………………………………………. 39

Water Leak Detector ………….………………………………………………………………….. 40

Switching to Temporary DI …………………………………………………………………….. 41

System Maintenance

- General …………………………………………………………………………………………… 44

- Long Term Storage or Non-Use ……………………………………………………………….. 45

- Adjusting the Blend Valve Temperature Setting ……………………………………………...45

- Priming the City Booster Pump and Repress Pump ………………………………………… 47

- Change Particulate Filter Cartridges and Pyrogen Filter ……………………………………. 48

- Automatic Control Valves; Set Time of Day …………………………………………………. 49

- Automatic Control Valves; Set on Which Days to Regenerate/Backwash ……………….. 49

- Automatic Control Valves; Initiate a Manual Regenerate/Backwash ……………………… 49

- Automatic Control Valves; Changing Regenerate/Backwash Program Cycles ………….. 50

- Automatic Control Valves; Replacing Seals and Spacers ………………………………….. 51

Service Help

- MediPac, Post-Treatment End ………………………………………………………………….53

- MediPac; 1232 RO End ………………………………………………………………………… 54

- MediPac; Front-Side ……………………………………………………………………………..55

- MediPac Control Box (front view) ……………………………………………………………… 56

- MediPac Control Box (inside lid view) ………………………………………………………… 57

- MediPac Control Box (inside view) ……………………………………………………………. 58

Related Consumable and Replacement Items ……………………………………………..…. 59

Related Disinfectants & Cleaners ……..………………………………………………………… 61

Related Consumable Media ……………………………………………………………………... 62

Limited Warranty Terms and Conditions ……………………………………………………….. 63

Appendix A, Sample Quality Assurance Checklist ……………………………………………. 65

Appendix B, Bleach Use in the Post-Treatment Components (Tank-Feed Systems Only)…. 68

Appendix C, Calculations & Conversions

- Conversion Formulas …….……………………………………………………….…………….. 69

- Calculation for Area of Pipe Volume …………………………………………………………...69

- 3 Feet per Second Flow Velocity Rates ……………………………………………………….70

Better Water LLC; 698 Swan Dr; Smyrna, TN 37167; www.betterwater.com

Better Water LLC; rev. Jun 2016

Page 1 of 72

MediPac, Tank-Feed Operator Manual

0

Our

Company

Contact

Us

Technical

Phone

Support

Technical

Support

Info

Online

Better Water LLC is a leading integrated manufacturer of water treatment

equipment and components for the industrial, commercial and institutional

markets.

Located in Smyrna, Tennessee,

Better Water LLC continues its history

of manufacturing and distribution of

equipment specifically designed for the

renal dialysis market.

Founded in 1971, Better Water LLC has

built a reputation for solving our

customers' toughest problems with high

quality products and unmatched service.

Better Water LLC Technical Support:

698 Swan Dr Phone (615) 355-6063, press "1"

Smyrna, TN 37167 Email support@betterwater.com

Phone (615) 355-6063 Customer Service:

Fax (615) 355-6065 Phone (615) 355-6063, press "3"

Email customerservice@betterwater.com

Support is available regarding all Better Water LLC systems,

24 hours a day,7 days a week.

Normal business hours are Monday through Friday from

8:00 am until 3:30 pm, Central Standard Time (excluding holidays)

Call (615) 355-6063, press "1" for Technical Support

Emergency assistance is available after normal business hours (including

holidays) by calling (615) 708-8627.

Our website, www.betterwater.com, which is updated

frequently, contains a wealth of technical support information on the

SUPPORT tab and includes:

Operator and Service Manuals

Consumables and Accessories Lists

Technical Service Bulletins

For your convenience there are also online forms for placing Orders

and requesting Returned Goods Authorization. These are Adobe

forms that can be downloaded and either faxed or emailed to us.

Better Water LLC; rev. Jun 2016

Page 2 of 72

MediPac, Tank-Feed Operator Manual

Introduction

Specific

Contacts

Technical Support Phone (615) 355-6063, option “1”

Email support@betterwater.com

To Place an Order Fax (615) 355-6065

(purchase orders) Email orders@betterwater.com

Phone (615) 355-6063

Customer Service Phone (615) 355-6063, option “2”

(returns) Fax (615) 355-6065

Website www.betterwater.com

Helpful information and forms that can be found on our website:

- Operator & Service Manuals

- Technical Service Bulletins

- Consumables and Replacement Parts List

- Brochures

- Order Form

- Return Goods Authorization Request Form

The Better Water LLC MediPac System is manufactured to the utmost

quality. With proper operation, maintenance, and care, this device

should give you years of reliable service.

Before starting you should first read and have a thorough understanding

of this entire Operator Manual. It describes in detail the steps and

procedures for safe usage of this system.

This device was designed and built with consideration for the

information that has been provided to use on the current product water

requirements at your site of operation.

This device was designed and built as a complete water treatment

system to produce high-quality water for hemodialysis, and is not

intended for any other application.

Once the this device has been delivered, it is the responsibility of the

Medical Director to ensure that it is used, monitored, and maintained in

such a manner so as to satisfy all applicable standards. Guidelines and

other related information are available from:

- Food and Drug Administration (FDA)

- National Association of Nephrology Technicians/Technologists (NANT)

- Association for the Advancement of Medical Instrumentation (AAMI)

NOTE concerning pictures in this manual:

Pictures of devices and components may vary slightly due to product

changes, and therefore should be for general reference only.

Information concerning their use, functionality, or replacement will not

differ unless noted.

Better Water LLC; rev. Jun 2016

Page 3 of 72

MediPac, Tank-Feed Operator Manual

WARNINGS

1. It is unsafe to operate or service this device without first reading and understanding the entire

Operator's Manual. Keep this manual and other associated documentation for future reference.

2. Misuse, improper operation, and/or improper monitoring of this system could result in serious

injury, death, or other serious reactions to patients undergoing hemodialysis treatment.

3. Misuse, improper use or handling of disinfectants and chemical cleaning solutions could result

in serious injury or even death. You must comply with the information contained in the Material

Safety Data Sheet (MSDS) for the chemical being used.

4. To avoid electrical shock hazard, do not operate this device when the covers or panels are

removed.

5. ELECTROMAGNETIC INTERFERENCE: This device can create and radiate

radio frequency energy and may cause harmful interference if not installed

according to the manufacturer's instructions.

CAUTIONS

1. When used as a medical device, federal law restricts this device to sale by or on the authority

of a physician. Per CFR 801.109 (b)(1).

2. Improper operation of this device could result in a low or no-flow alarm on the dialysis

machines.

3. Misuse or improper operation of this device will void any warranty.

4. Where water is mentioned, unless otherwise noted, it must be AAMI standard quality water.

5. Plumbing connections must adhere to local statutes and any facility codes.

6. Do not remove any Caution, Warning or any other descriptive labels from the device.

7. Do not operate this device in an explosive environment or in the presence of flammable

materials.

8. Do not use this device to store, mix or transfer flammable liquids. Movement or vibrations

during shipment may cause connections to loosen.

9. Do not operate this unit in an environment where temperatures may be below 50oF or above

90oF.

10. This device should not be used for purposes outside the device’s stated applications,

specifications or limitations.

Better Water LLC; rev. Jun 2016

Page 4 of 72

MediPac, Tank-Feed Operator Manual

GENERAL REQUIREMENTS & SPECIFICATIONS

SPACE:

- The system should be level and located as close as possible to the point of use.

- Minimum space required Length 92” x Width 38” x Height 82”.

- Additional space will be required for the water softener’s brine tank, determined by the size of

the tank.

- Additional space will be required for the storage tank if a Tank-Feed system, determined by the

size of the tank.

- The floor must be capable of supporting up to 2500 lbs.

- Space considerations should include adequate operator access.

WATER SUPPLY CONNECTION:

- Requires a 1” female NPT threaded water connections, both hot and cold, with an adjacent

shut-off valve.

FEED WATER SUPPLY REQUIREMENTS:

- The importance of monitoring and controlling the municipal tap water cannot be underestimated.

The pre-treatment feed water must meet the following parameters:

- Pressure: 30 psi (minimum) to 50 psi (maximum); 40 psi (optimum)

- The minimum pressure must be maintained with water flowing at the maximum required

flow-rate. This is dynamic pressure; not static pressure.

- Flow Rate: 4 gallons per minute

- Temperature: 50° to 90° F

DRAIN REQUIREMENT:

- Requires a sanitary drain capable of discharging 15 gpm (gallons per minute) or better.

ELECTRICAL CONNECTION:

- Two electrical outlets, 115 vac, single phase, with 20 amp breakers

Better Water LLC; rev. Jun 2016

Page 5 of 72

MediPac, Tank-Feed Operator Manual

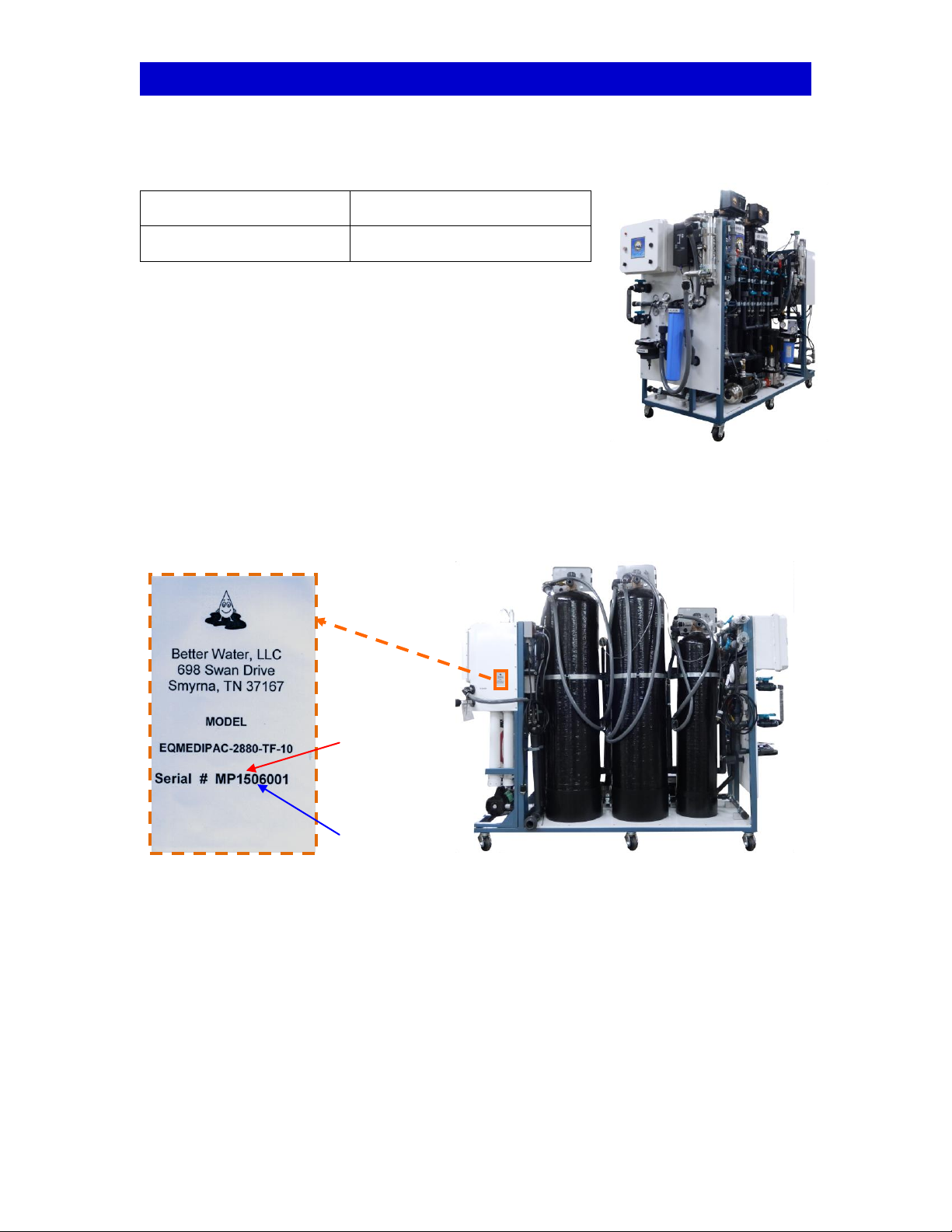

MODELS

There is only one model of the tank-feed MediPac based around the 1232 RO.

Model

Specifications

EQMEDIPAC-2880-TF-10

Tank Feed, 2880 gpd

IMPORTANT INFORMATION FOR SUPPORT

Adhered to the side of each MediPac’s RO Control Box is a label containing important information

relating to the specific unit, and details both the Model and Serial Number. Both of these

pieces of information are very important in obtaining support, determining warranty, and properly

servicing this unit. Please have this information available if you contact Technical Support.

The first four numbers in the serial number denote the year and month the device was

manufactured. In the example above the unit, was produced in 2015, in the month of June.

“15” –Year

“06” - Month

Better Water LLC; rev. Jun 2016

Page 6 of 72

MediPac, Tank-Feed Operator Manual

PRODUCT DESCRIPTION

The MediPac is designed to be a complete water system on a wheeled frame, which includes

Pre-Treatment components, a 1232 RO, and Post-Treatment components. All three of these

elements reside on a frame with the exception of the storage tank and brine tank. It designed to

support six to eight stations.

The Frame is constructed of welded steel with a durable powder-coat paint finish to reduce rust

and corrosion. The frame is mounted on sturdy casters for ease in moving should the need arise.

The MediPac Control Box is located on the left side (post-treatment end) of the rack, and both

controls and provides power to many of the MediPac components. It also contains the

components for a water leak detection system which will automatically close the main water

shutoff valve in the event a water leak is detected.

The Pre-Treatment portion of this unit is comprised of the following components:

- A Blend Valve to maintain the proper water temperature.

- A City Booster Pump to maintain adequate pressure for the system to operate.

- Carbon Filter Tanks (worker and polisher) to remove chlorine and chloramines.

- A Water Softener to reduce water hardness by removing heavy metals such as calcium and

magnesium from the water. Works in conjunction with a Brine Tank containing salt.

- An Ultra-Violet Light to reduce bacteria.

- A Sediment Filter for particulate and sediment filtration.

- There are also a Temperature Gauge, Pressure Gauges and Sample Ports for monitoring the

system’s operation.

The Reverse Osmosis unit is the 1232 RO, which resides on right side of the MediPac frame. It

consists of four membranes, and produces 2 gallons per minute RO water for the system.

The Post-Treatment portion of this unit is comprised of the following components:

- A Ultra-Violet Light to reduce bacteria.

- A 20” .03 Micron Filter for bacteria and pyrogen filtration.

- DI Connection points for use with DI Tanks.

- A 10” Big Blue 5 Micron Filter for Post-DI filtration.

- A Repressurization Pump to circulate water through the distribution loop.

- A Storage tank located near the unit is equipped with level controls to operate the RO.

- There are also a Flow-Meter, Pressure Gauges, and Sample Ports for monitoring the

system’s operation.

Better Water LLC; rev. Jun 2016

Page 7 of 72

MediPac, Tank-Feed Operator Manual

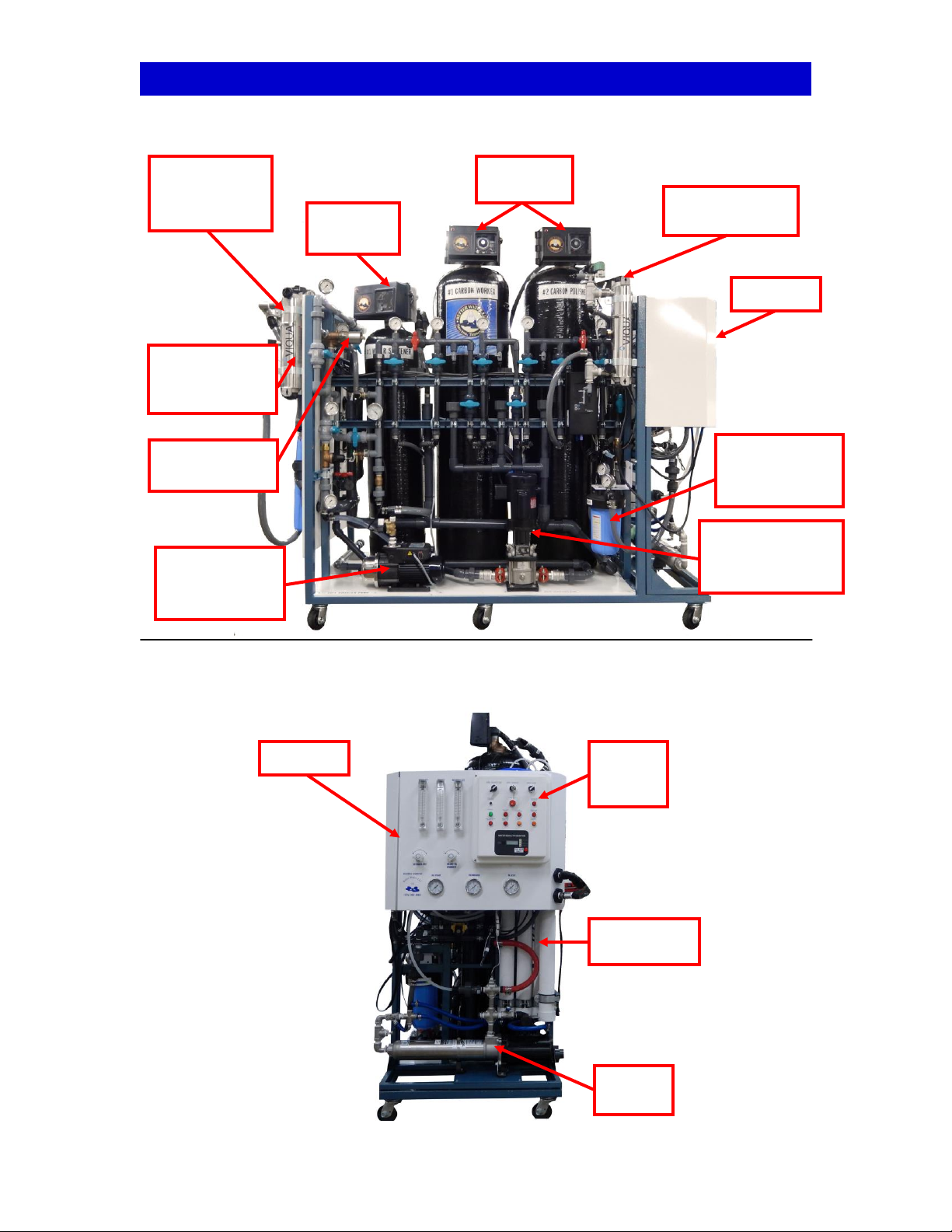

DETAILED VIEW of a MediPac, Front Side

DETAILED VIEW of a MediPac, RO End

Water

Softener

Carbon

Tanks

MediPac

Control Box

(behind UV)

1232 RO

Pre-Treatment

UV

Pre-Treatment

Blend Valve

1232 RO

RO

Control

Box

RO

Pump

Pre-Treatment

City Booster

Pump

RO

Membranes

Post-

Treatment

UV Light

Pre-Treatment

10” 5 micron

Filter

Post-Treatment

Repressurization

Pump

Better Water LLC; rev. Jun 2016

Page 8 of 72

MediPac, Tank-Feed Operator Manual

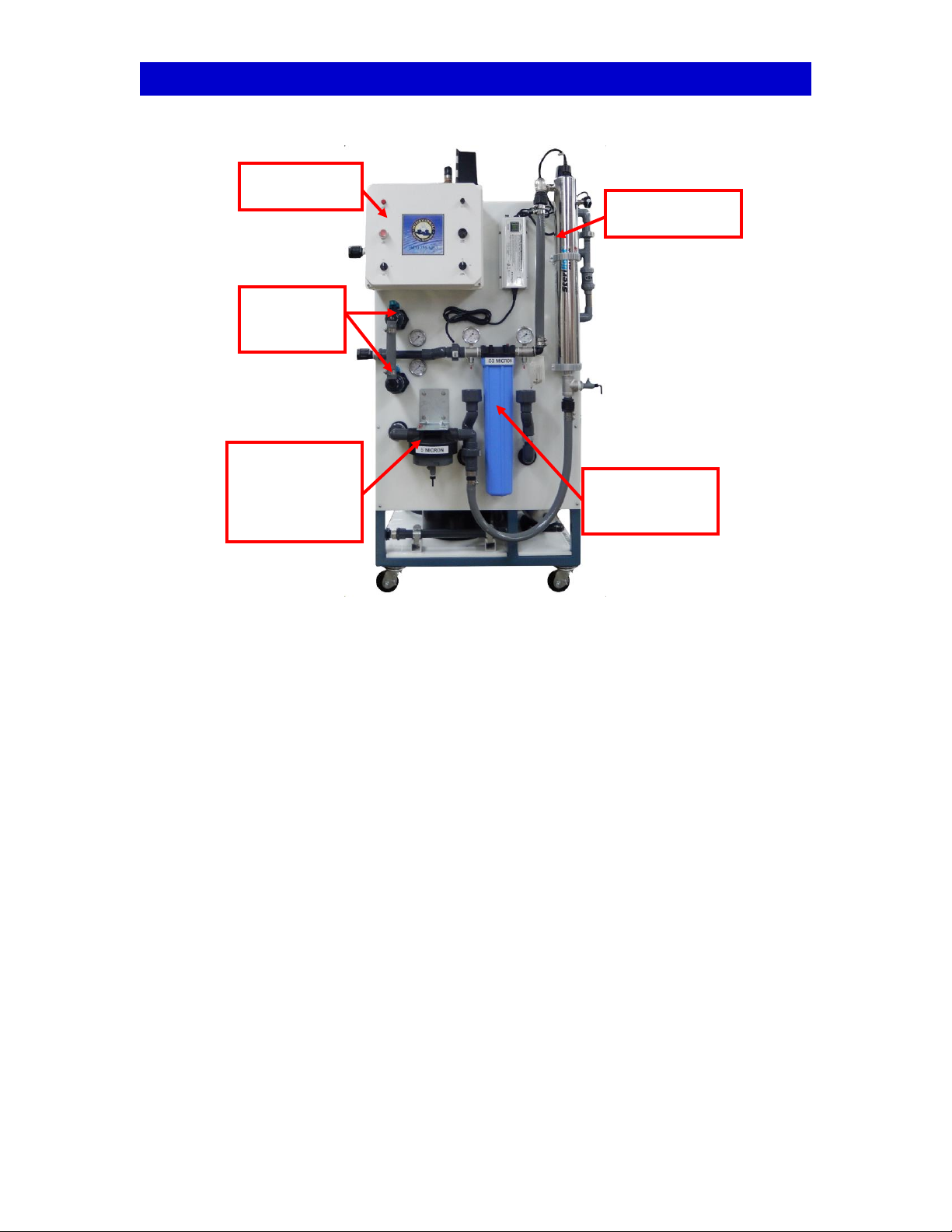

DETAILED VIEW of a MediPac, Post-Treatment End

MediPac

Control Box

Post-Treatment

UV

Post-Treatment

.03 micron

Filter

Post-Treatment

5 micron Filter

(Post-DI)

(shown with short

bowl)

DI

Connection

Header

Better Water LLC; rev. Jun 2016

Page 9 of 72

MediPac, Tank-Feed Operator Manual

SYSTEM COMPONENTS: MediPac Control Box

DESCRIPTION:

The control box is a water-tight, chemical resistant box, containing electronic components needed

to control and provide power to many of the MediPac’s components.

The MediPac Control Box does the following:

- Facilitates the Level Controls from the RO and Storage

Tank

- Controls the Water Leak Detector and Alarm

- Controls the Repress Pump

- Controls the Pre-Treatment UV and its UV Dump Valve

- Provides power to the Post-Treatment UV

- Contains components of the water leak detector and will

alarm and close the main-water shutoff valve if a water leak

is detected.

Specific operating details are discussed later in this

manual.

SYSTEM COMPONENTS: PRE-TREATMENT; Pressure Gauges

DESCRIPTION:

The monitoring of components in any water treatment system depends highly

on monitoring the pressures before and after the component. Most

components in the system will have less than 15 psi normal differential

pressure. When this differential pressure rises toward or exceeds 15 psi, the

component will require attention to determine the problem or cause.

Differential Pressure or Delta Pressure (represented by the symbol ΔP) is equal

to the Inlet Pressure minus the Outlet Pressure when the RO is running.

ΔP = Inlet Pressure – Outlet Pressure. Example: If the #1 carbon filter is showing an inlet

pressure of 60psi and an outlet pressure of 55 psi, the Δ pressure is 5 psi. Under most

circumstances, the normal ΔP of most components will be less than 15 psi.

Most components in a Better Water LLC water system are supplied with gauges that will show the

pressure before and after the specific component. Gauges used before the RO will be made of

brass and stainless steel. Gauges used in and after the RO will be made of stainless steel only.

All gauges in the system will be 0-100 psi, dry (not glycerin filled), with a 1.5% accuracy.

Better Water LLC; rev. Jun 2016

Page 10 of 72

MediPac, Tank-Feed Operator Manual

SYSTEM COMPONENTS: PRE-TREATMENT; Thermometer

DESCRIPTION:

Maximum water production of the RO depends greatly on the temperature

of the feed water. Water that is too cold will require more pressure from the

RO pump to force it through the membranes, which will put undue stress on

them, causing the membrane pressure to rise. Water that is too hot can

cause damage to the membranes. If the water gets too hot, the RO will shut

down in a high feed temp alarm.

77° F is the temperature for optimum performance of the Better Water LLC.

RO. The pre-treatment system has a stainless steel, in-line temperature gauge located just after

the blend valve. This temperature gauge will monitor the blend valve to assure adequate water

temperature of the water being supplied to the RO. The blend valve will normally be set at

approximately 72-75°F.

SYSTEM COMPONENTS: PRE-TREATMENT; Blending Valve

DESCRIPTION:

The blending valve is an automatic, mechanical device that

instantly compensates for supply line temperature and

pressure changes to maintain the pre-selected temperature

of the feed-water. The manufacturer states that this device

complies with the requirements of Federal specifications

WW-P-541/7B and all other known standards, codes, and

specifications.

MONITORING REQUIREMENTS:

Daily: Verify the selected temperature range while the RO is running.

MAINTENANCE:

* See System Maintenance section for how to adjust the blend valve, thus affecting water

temperature.

NOTE: The manufacturer states that this device, “Fails safely on hot or cold supply failure of

thermal motor failure (when so specified) to shut down flow.” When feed water flow ceases, the

RO unit will shut down, producing a low feed pressure audible and visual alarm on the RO and on

any remote alarm locations.

Better Water LLC; rev. Jun 2016

Page 11 of 72

MediPac, Tank-Feed Operator Manual

SYSTEM COMPONENTS: PRE-TREATMENT; City Booster Pump

DESCRIPTION:

The city booster pump is a stainless steel, multi-stage,

centrifugal pump designed for continuous duty service.

The pump is powered by a 1 HP, single phase, 115 vac

motor. The pump starts automatically when there is a

demand for water. This pump is designed for boosting

water pressure for circulation service.

Pump models may vary between devices.

MONITORING REQUIREMENTS:

Daily: Monitored to ensure desired pressure is maintained.

MAINTENANCE:

* See System Maintenance section for priming instructions.

SYSTEM COMPONENTS: PRE-TREATMENT; Automatic Control

Valves

DESCRIPTION: All automatic backwashing filters

and softeners are equipped with automatic control

valves, which control the backwashing/regeneration

times, cycles, and frequencies for the specific filter it

operates. These feature a 7 day calendar time

clock and has an interlock feature to prevent the RO

from running while the filter is in backwash or

regeneration. (See Interlock Wiring System Section)

MONITORING REQUIREMENTS:

Daily: Verify the controller day, and time of day is

properly set.

MAINTENANCE:

- The seals and spacers in the valve should be changed every 3 to 5 years. This may have to be

done sooner if there is a malfunction of the device.

* See System Maintenance section.

part#

EQPUGR01905

City Boost Pump

Grundfos MQ Series

part#

EQPUWA00251

City Boost Pump

Walrus TQ-800

Better Water LLC; rev. Jun 2016

Page 12 of 72

MediPac, Tank-Feed Operator Manual

SYSTEM COMPONENTS: PRE-TREATMENT; Interlock Wiring

System

DESCRIPTION:

The interlock wiring system is a safety feature, incorporated into all Better Water LLC water

systems, is a low voltage (24 vac) lockout system designed to shut down the RO machine, if

running, or prevent the RO from running, when any filter or softener goes into backwash or

regeneration.

A 24 volt signal originates at the RO and is sent to each selected piece of pre-treatment

equipment in series, and the last piece of equipment is equipped with a “jumper” to return the

signal to the RO. When a filter or softener goes into backwash or regeneration mode, the signal

is redirected to a red light on the specific control valve, which illuminates to indicate the backwash

or regeneration mode of that piece of equipment. It also starts the city booster pump, and opens

the blend valve bypass. With this signal not being returned to the RO, the RO will not run or will

stop if running when the signal is broken. The interlock wiring system utilizes quick-connect

fittings on all connections.

Better Water LLC; rev. Jun 2016

Page 13 of 72

MediPac, Tank-Feed Operator Manual

SYSTEM COMPONENTS: PRE-TREATMENT; Water Softener

DESCRIPTION: Water softening consists of a single water softener to meet

system flow demands, reduction ratios, and user criteria. The water softener

in this system is commercial/industrial grade, automatic, and custom sized

to meet the demand.

The water softener in the system has a 7 day calendar time clock to

control regeneration. The controller can be set to regenerate at pre-set times

on specific days, giving the user maximum flexibility. The controller has an

interlock feature to prevent the RO from running during the regeneration cycle.

When regenerating a red light is illuminated as an indicator of this cycle and

the RO will not run due to the interlock.

The resin is a premium grade, strong acid cation for high flow rate condensate

demineralizing made from food-grade materials that meet FDA CFR 173.25

specifications. The water softener is regenerated with salt brine that is made

from quality, premium grade salt pellets specified for water softening and/or

conditioning. Do not use rock salt, as this form of salt carries impurities and

will tend to have adverse effects on your water pre-treatment system. For information

on about brine tanks, see the previous section titled “System Components: Brine Tanks”.

MONITORING REQUIREMENTS:

Daily: This device requires daily monitoring to insure the controller clock is properly set

Daily: Check pre and post-filter pressure, and ΔP (pressure drop) across it while the RO is

running

Daily: Check the salt level in the brine tank is greater than 50%

Daily: The hardness, measured post softener, should be tested daily while the softener is under

peak demand, usually late in the afternoon.

MAINTENANCE:

- The salt level in the brine tank should be filled periodically so it doesn’t fall below 50%.

- Better Water LLC recommends that tank media be changed every three years unless…

… otherwise specified by the medical director and/or company polices,

… or the hardness breakthrough is greater than 2 grains per gallon after two verified regeneration

cycles.

Water

Softener

Better Water LLC; rev. Jun 2016

Page 14 of 72

MediPac, Tank-Feed Operator Manual

SYSTEM COMPONENTS: PRE-TREATMENT; Brine Tank

DESCRIPTION:

The water softener includes a brine tank that holds the salt which produces

the brine solution for the regeneration of the water conditioning resin. The

brine tanks supplied with all Better Water LLC water softeners are made of a

non-corrosive, plastic with a plastic grid plate in the bottom to reduce or

eliminate “bridging” of the salt (see note below). On the inside of the tank is

a brine well which houses the brine valve. This brine valve is connected with

a 3/8” or larger brine line to a single or duplex softener. Only one brine tank

is required for a duplex system. This tube serves to draw the brine solution

out of the brine tank during the “brine draw” cycle, and also to refill the brine

tank during the “brine refill” cycle of the control valve.

Better Water, LLC utilizes three safety measures with the brine valve; First, located

on the bottom of the brine valve is an air check valve. This is a device incorporated

into the brine valve to stop the flow through the brine tube in case the brine level

drops to an insufficient level. This will prevent the control valve from drawing air

into the system. Second, the brine valve is equipped with a float valve on the top,

to prevent the brine tank from overfilling, in the event of a control valve malfunction, or in the

event of a power outage during the refill cycle. Thirdly, an overflow line is installed,

in the rare case of overflow; the excess will be routed to a suitable drain.

The brine tank should only be filled with quality, premium grade salt pellets

specified for water softening and/or conditioning. Do not use rock salt, as

this form of salt carries impurities and will tend to have adverse effects on your

water pre-treatment system.

NOTE: Bridging occurs in brine tanks when the salt sticks together to form one large solid mass

of pellets, or by the salt caking in a dry-salt brine tank which causes failure of the liquid or brine

beneath the dry salt to become saturated. The result of bridging is insufficient salt in the

regeneration solution to properly regenerate the cation resin.

Brine tanks are sized according to the size of the water softener, organic scavenger, and

dealkalizer vessels. Better Water LLC, primarily uses 2 sizes of brine tanks. 16” diameter and

smaller devices will be supplied with an 18” diameter brine tank. 20” and larger devices will be

supplied with a 24” brine tank. 30” and larger devices, although seldom used, can be supplied

with even larger brine tanks. On occasion, a customer will request a smaller brine tank, due to

space restrictions. Although adequate with some procedural modifications, this is not

recommended. A smaller brine tank will require salt filling more often.

MONITORING REQUIREMENTS:

Daily: Daily monitoring of the salt level in the brine tank is required, refilling as necessary.

MAINTENANCE:

- The salt level in the brine tank should be filled periodically so it doesn’t fall below 50%. The salt

level should be maintained above the water level in the tank. It is recommended that the salt

level to rise and fall over time, and not just “top off” on a daily basis, which will allow a good “turn-

over” of the salt in the tank.

NOTE: It takes a minimum of 3 to 4 hours to fully saturate the water in the brine tank after

refilling for maximum results.

Brine tanks should be emptied and cleaned annually, or more often if necessary.

Cutaway view

of brine tank

Better Water LLC; rev. Jun 2016

Page 15 of 72

MediPac, Tank-Feed Operator Manual

SYSTEM COMPONENTS: PRE-TREATMENT; Carbon Media

Filtration

DESCRIPTION:

Carbon filtration is based upon a naturally occurring phenomenon called

adsorption, in which molecules of a liquid or gas are trapped by either the

external or internal surface of a solid. Activated carbon has a very high

internal surface area and thus is an ideal material for adsorption. Raw water

quality can be improved with the removal of trace components.

Carbon filters are backwashed periodically (every other day) to expose

new adsorption sites in the media. After backwash, a down-flow rinse

prepares the media for service.

Carbon filtration consist of at least 2 properly sized pressure vessels (tanks)

which are filled with predetermined volumes of carbon. In most systems,

two properly sized, backwashable carbon filters are connected in series with

tank #1 adsorbing the entire load and tank #2 performing a polishing task

while providing a back-up capability.

Each carbon filter in the system has a 7 day calendar time clock to control backwashing. The

controller can be set to backwash at pre-set times on specific days, giving the user maximum

flexibility. The controller has an interlock feature to prevent the RO from running during the

backwash cycle. When backwashing a red light is illuminated as an indicator of this cycle and the

RO will not run due to the interlock.

The carbon selected is of the highest quality available and meets our demanding specifications

for chlorine/chloramine removal. The carbon is granular activated, acid washed, and designed for

the purification of aqueous liquids which may be sensitive to acid soluble constituents such as

iron.

MONITORING REQUIREMENTS:

Daily: Daily monitoring should be done to insure that chlorine/chloramine free water is available

prior to each hemodialysis treatment shift. This will require testing for chlorine/ chloramines

before the first treatment of the day and prior to each treatment shift throughout the day.

Daily: This device requires daily monitoring to insure the controller clock is properly set

Daily: Check pre and post-carbon tanks (both worker and polisher), and ΔP (pressure drop)

across them while the RO is running

MAINTENANCE:

- Better Water LLC recommends that tank media be changed every three years unless…

… otherwise specified by the medical director and/or company polices,

… or the chlorine/chloramines breakthrough is greater than 0.1 parts per million after two verified

backwash cycles.

Carbon

Tank

Better Water LLC; rev. Jun 2016

Page 16 of 72

MediPac, Tank-Feed Operator Manual

SYSTEM COMPONENTS: PRE-TREATMENT; Ultra-Violet

Irradiation (Pre-RO)

DESCRIPTION:

The ultraviolet irradiation water disinfection unit consists of a UV lamp housed inside a fused

quartz sleeve which seals the lamp from direct water contact. The sleeve, in turn, is housed in a

stainless steel treatment chamber. The UV rays pass through the quartz sleeve and into the

surrounding water. These UV rays alter the DNA of many common waterborne bacteria and

sterilize (prevent reproduction) them.The low-pressure germicidal UV lamp produces a slightly

shorter UV ray in concentrated form. 90% of the energy produced by this lamp has a wavelength

of 254 nanometers, which will reduce many water-borne microorganisms.

MONITORING REQUIREMENTS:

Daily: This component must be monitored on a daily basis to insure the UV light is operating and the

bulb is on.

MAINTENANCE:

- The UV bulb should be replaced every 12 months.

- Clean the quartz sleeve every 6 months.

- Change the quartz sleeve as needed.

Two models of UV lights have been used on the Medipac systems, which are detailed below.

part#

SUUVOO02024

UV Bulb, SPV-410

part#

SUUVOO02025

UV Quartz Sleeve, SPV-410

part#

EQUVOO00896

UV SPV-410

part#

EQUVOO01907

UV Pro-Max 10

part#

SUUVOO02023

UV Bulb, Pro-Max 10

part#

SUUVOO02022

UV Quartz Sleeve, Pro-Max 10

Table of contents

Other Better Water Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Bluebird

Bluebird Torriozo user manual

Astral Pool

Astral Pool SEL BLUE EVO Installation and user manual

Pure Water

Pure Water PW90 Programming guide

Ro-Man

Ro-Man Fresh 3 installation guide

Clear Water

Clear Water mineralpure R-50 installation manual

Bio-Tek

Bio-Tek BioSure Professional EOS7177-PQ Installation & operation manual

WaterTech

WaterTech Reionator Pro RX10 owner's manual

Aqua Medic

Aqua Medic platinum line plus Operation manual

Alfalaval

Alfalaval S 821 manual

B. Braun

B. Braun Aquaboss CCS Instructions for use

unGer

unGer nLite Hydro Power HP06T Installation & operating instructions

Pureit

Pureit Marvella RO+UV instruction manual