7www.filtreco.nl

5. Safety instructions

This system may cause bodily harm or damage to property if

you do not use it properly and in accordance with all safety

guidelines, or if you attempt to use it for any purpose other

than that for which it was designed. This system must never be

operated by children or anyone under the age of 16, or by anyone

who has a physical, mental or sensory impairment or lack of

experience and knowledge, unless they are under supervision

and have been instructed on the safe usage of the system and

informed of the dangers associated with it. Children must be

made aware that this system is not a toy. Cleaning and mainte-

nance must be performed by an adult user. This must never be

performed by a child, even if they are under supervision.

5.1 Danger of electrical shock in contact with water

If your system has not been connected properly and in accor-

dance with the safety guidelines, and a live electrical current

comes into contact with water, this can result in electrical

shock, causing serious injury and even death. Always switch o

the current on any water-bearing equipment before you come

into contact with the water.

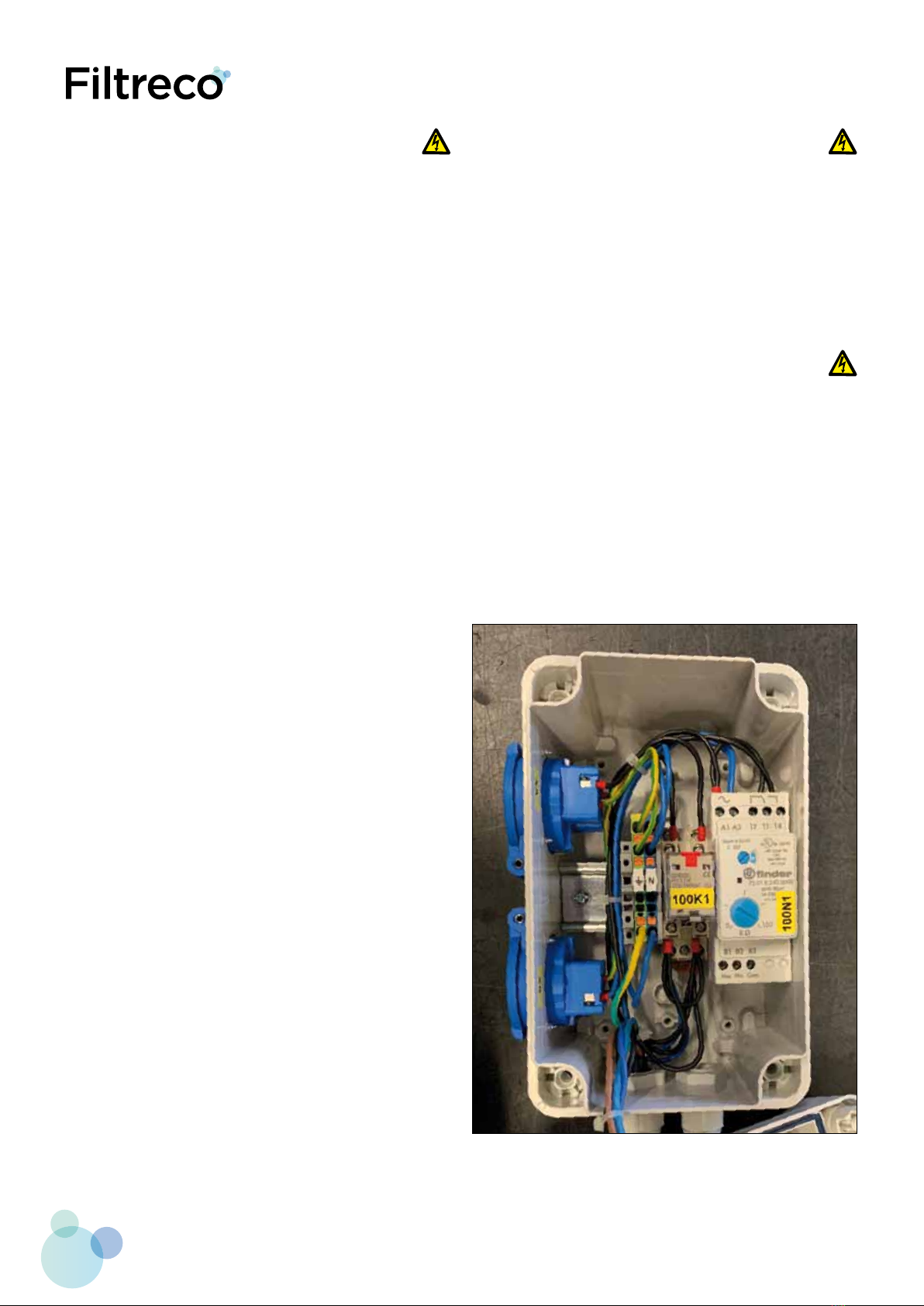

5.2 Guidelines for electrical installations

The electrical installation must be carried out in accordance

with all national legislation and may only be performed by a

nationally certified electrician. A person is considered an

electrician if they have the appropriate training, knowledge,

experience and certification, and are capable of assessing and

conducting the necessary work. The job of an electrical specialist

also includes recognising any possible hazards and complying

with all applicable regional and national standards, regulations

and provisions of law.

• For your own safety, always consult a professional electrician

in case of any problems.

• This system can only be connected to a power supply that

matches its electrical specifications. All specifications for

this system can be found in this user manual.

• The system must be protected by a residual current device

with a fixed residual current of max. 30 mA.

• Use only extension cables and power dividers that are

splash-proof and whose cable diameters are the same as

the ones supplied with the system.

• Do not allow the plug connections to come into contact

with water or moisture.

• Connect the system only to a power outlet that has been

installed according to industry standards and does not

contain a dimmer.

5.3 Safe use

• Never use this system in connection with faulty electrical

cables or a defective housing.

• Never pull on the cables to adjust the placement of the

system. Ensure that the electrical cables are not pulled

tightly.

• Lay the cables through a secure duct to avoid damage and

make sure no one can trip or fall over them.

• Only open the housing of the motor or other electrical

components if this is necessary as instructed by the user

manual.

• Only perform maintenance and other tasks on the system

as described in this user manual.

• In case of any problems that you are unable to resolve,

please contact Filtreco.

• Only use original spare parts in combination with this system.

• Do not attempt to modify the technical features or

specifications of this system in any way.

• The connector cables cannot be replaced. In case of a broken

cable, the entire system or aected part must be replaced

entirely.

• If used in the open air, a protective roof must be installed

above the control box.

• Over-voltage in the mains can cause the system to

malfunction.

• Do not inhale the spray mist from the sprayer system. The

spray mist may contain harmful bacteria.

• Once the flush cycle has completed, allow some time before

opening the cover.