Filtreco Combi drum 55 User manual

1www.filtreco.nl

It is

clear.

www.filtreco.nl

100324

User manual

Combi drum 55

(pump)

EN

ORDER NUMBER

3www.filtreco.nl

Introduction

Welcome to Filtreco: Filtration systems for koi ponds

Every koi lover knows the importance of good water quality. And that means having a good filtration

system for your pond. To keep your water clear, the choice is clear: Choose Filtreco. We know how much

you love your fish, and that is why we are the specialists that you can rely on. Your goal is to keep your

water clean, clear and healthy for your fish. But for clean water, you must choose the right filtration

system for your own specific situation. That's why Filtreco oers the widest selection of pond filters.

All with an unparalleled level of service, the lowest risk of malfunction and easy installation. Make no

mistake: when only the best quality will do, choose Filtreco. High-quality technology means quality of

life for your koi.

It is clear.

Introduction

This is the user manual for the Combi drum 55 (pump).

By purchasing this Filtreco filter, you have made an excellent choice. Please read this user manual carefully

before you start using this system. This will enable you to familiarise yourself with the system first. Any

work carried out on or with this system must always be performed in strict accordance with this user

manual.

To ensure safe, proper use, always adhere fully with the safety guidelines. Please keep this user manual

in a safe place and transfer it to the new owner in the event that the system changes ownership.

Filtreco

Nusterweg 69

NL-6136 KT Sittard

The Netherlands

CoC 14052952

VAT NL 58.28.235.B01

Filtreco is a WTH B.V. brand.

IBAN: NL39RABO0136750729

BIC: RABONL2U

+31 46 457 25 55

info@filtreco.nl

www.filtreco.nl

5www.filtreco.nl

Contents

Combi

drum

filters

Introduction ............................................................................................................ 03

Contents ................................................................................................................... 05

1. What's included .................................................................................................... 06

2. Product description ............................................................................................. 06

3. Assembling the filter ........................................................................................... 06

4. Instructions for use .............................................................................................. 06

5. Safety instructions ................................................................................................ 07

5.1 Danger of electrical shock in contact with water .......................................... 07

5.2 Pacemakers .......................................................................................................... 07

5.3 Guidelines for electrical installations ............................................................... 07

5.4 Safe use ................................................................................................................. 07

6. Placement and setup .......................................................................................... 08

6.1 Connecting the control box .............................................................................. 08

6.2 Connecting the electrodes and water level meter ........................................ 08

7. First use .................................................................................................................... 09

7.1 Sequence for first use ........................................................................................ 09

7.2 Adjusting water level meter ............................................................................. 09

7.3 Flush cycle ........................................................................................................... 09

8. Control box .............................................................................................................. 1 0

9. Control panel (malfunctions) ........................................................................... 1 0

10. Cleaning and maintenance ................................................................................ 1 2

11. Troubleshooting ..................................................................................................... 1 3

12. Winterising ............................................................................................................... 1 3

13. Wear parts ................................................................................................................ 1 3

14. Technical specifications ...................................................................................... 1 3

15. Wiring and power outages ................................................................................ 1 3

16. Technical diagram ................................................................................................. 1 4

17. Diagram for assembly in a pond ..................................................................... 1 5

6 Combi drum 55 (pump)

1. What's included

• PP basin

• PP drum with brushes

• 70 micron stainless steel panel

• PP duct

• Water level meter with 3 pins

• Drum motor

• Submersible pump

• Spray tube with 6 sprayers (the first of which has a higher

flow)

• 2x 2" inlets

• 4x 110 mm outlets

• 4x 110 mm drum bypasses

• 3x 1 1/2" drain with ball valve

• Control box

• Cover with safety lock

• 200LBiowheels

• 2airpans

2. Product description

The drum filter consists of a PP basin containing a PP drum with

mesh. The drum is pump-fed and installed beside the pond.

The inlets are below the water surface level, and the dirty water

is pump-fed through the floor drains or skimmers into the first

filtration chamber. On the outflow side, the water flows through

a slotted plate into the moving bed. Because the dirty water

flows through the drum, contaminants in the water cling to the

interior of the drum. As a result, less water can flow through the

mesh and the water level on the inside of the drum rises. The

water level meter detects this and initiates the flush cycle. This

cycle consists of activating the drum motor and spray pump.

This causes the drum to turn slightly more than one full rotation

and the sprayers flush the mesh clean. The flush water then

flows into the sewage along with the waste. The cycle repeats

as often as necessary.

3. Assembling the filter

The housing of the filter consists of a PP basin with one

partition. The partition is fitted with a silicone sealing strip at

the flange which separates dirty water from clean. There are

also 4 holes in the partition which are covered with a cap. In

case of a breakdown in the drum control, the covers can be

removed to enable the water to bypass the drum and flow past

it without being filtered. This enables you to still use the

biological filtration segment.

The basin is fitted with a removable waste drain. This can be

removed from the interior of the drum, which saves you the

trouble of having to disassemble the drainage line. The inclined

surface accelerates the water flow, causing the waste to be

carried along with it into the drain. There are also 4 brushes

installed on the inside of the drum which sweep away any algae

or other coarse particles that cling to the drain. The drum filter

is fitted with a removable spray tube made of PP, which is

equipped with flat jet nozzles. The sprayers feature a quick-

release system, making them easy to remove for cleaning. The

water level meter in the basin consists of 3 electrodes, 1 flush

level, 2 high-level safeties and 1 common electrode. The water

level for initiating the flush cycle is adjustable. Inside the basin

is a high-pressure submersible pump which supplies water to

the sprayers under high pressure during the flush cycle.

The drum motor is installed in a water-proof compartment inside

the biological filtration section. The shaft is enclosed by a

retaining ring in the installation plate. The shaft connects to

the drum via a flange with a pipe. To remove the drum, you can

simply detach this pipe-shaft connection, after which the drum

can be taken out. You do not have to disassemble the motor to

do this. The screens can be removed by detaching the tension

straps and unscrewing the cover panel to remove it.

4. Instructions for use

The Filtreco combi drum filter and all parts and accessories

that it comes with may only be used as follows:

• for cleaning garden ponds

• according to the user manual and technical specifications

• only with water temperatures between +4 ˚C and +35 ˚C.

• only suitable for transporting water

• not for commercial or industrial purposes

• not suitable for salt water

• never use without running water

• never use in combination with chemicals, foods or

flammable/explosive liquids

7www.filtreco.nl

5. Safety instructions

This system may cause bodily harm or damage to property if

you do not use it properly and in accordance with all safety

guidelines, or if you attempt to use it for any purpose other

than that for which it was designed. This system must never be

operated by children or anyone under the age of 16, or by anyone

who has a physical, mental or sensory impairment or lack of

experience and knowledge, unless they are under supervision

and have been instructed on the safe usage of the system and

informed of the dangers associated with it. Children must be

made aware that this system is not a toy. Cleaning and mainte-

nance must be performed by an adult user. This must never be

performed by a child, even if they are under supervision.

5.1 Danger of electrical shock in contact with water

If your system has not been connected properly and in

accordance with the safety guidelines, and a live electrical

current comes into contact with water, this can result in electrical

shock, causing serious injury and even death. Always switch o

the current on any water-bearing equipment before you come

into contact with the water.

5.2 Pacemakers

The cover has a magnetic switch. The magnetic field may interfere

with pacemakers.

5.3 Guidelines for electrical installations

The electrical installation must be carried out in accordance

with all national legislation and may only be performed by a

nationally certified electrician. A person is considered an

electrician if they have the appropriate training, knowledge,

experience and certification, and are capable of assessing and

conducting the necessary work. The job of an electrical specialist

also includes recognising any possible hazards and complying

with all applicable regional and national standards, regulations

and provisions of law.

• For your own safety, always consult a professional electrician

in case of any problems.

• This system can only be connected to a power supply that

matches its electrical specifications. All specifications for

this system can be found in this user manual.

• The system must be protected by a residual current device

with a fixed residual current of max. 30 mA.

• Use only extension cables and power dividers that are

splash-proof and whose cable diameters are the same as

the ones supplied with the system.

• Do not allow the plug connections to come into contact

with water or moisture.

• Connect the system only to a power outlet that has been

installed according to industry standards and does not

contain a dimmer.

5.4 Safe use

• Never use this system in connection with faulty electrical

cables or a defective housing.

• Never pull on the cables to adjust the placement of the

system. Ensure that the electrical cables are not pulled

tightly.

• Lay the cables through a secure duct to avoid damage and

make sure no one can trip or fall over them.

• Only open the housing of the motor or other electrical

components if this is necessary as instructed by the user

manual.

• Only perform maintenance and other tasks on the system

as described in this user manual.

• In case of any problems that you are unable to resolve,

please contact Filtreco.

• Only use original spare parts in combination with this system.

• Do not attempt to modify the technical features or

specifications of this system in any way.

• The connector cables cannot be replaced. In case of a broken

cable, the entire system or aected part must be replaced

entirely.

• When using in the open air, a roof must be placed above

the control box and a rain-proof cover must be placed above

the motor.

• Over-voltage in the mains can cause the system to

malfunction.

• Do not inhale the spray mist from the sprayer system. The

spray mist may contain harmful bacteria.

• If the cover is lifted, the flush system stops working. Once

the flush cycle has completed, allow some time before

opening the cover.

8 Combi drum 55 (pump)

6. Placement and setup

If you plan to install this system in a way that deviates

significantly from the recommendations in this user manual,

allow for a specialist to inspect the installation to ensure that

all technical specifications have been met.

The combi drum filter must always be placed in a level position.

The bottom of the filter must be completely supported. It is

recommended to place the system on a flat cement floor. When

positioning the filter, ensure that there is adequate space on all

sides so that you have room to perform maintenance. In order

for the filtration system to work properly, the filter must always

be placed above the water level.

Any greater deviation will result in an inaccurate measuring

of the water level. If the water level rises by more than 2 cm,

the water will overflow via the duct into the sewage system.

To prevent this, position the short electrode so that it is 1 cm

below the surface on the upper side of the drain. To maintain a

constant water level, you can install an automatic filling station

with overflow function for your pond.

For optimal water flow, use all 4 outlet connections. It is

recommended to use flexible rubber sleeves and joints when

connecting the water lines. These can compensate for small

dierences in dimensions and also absorb vibration.

Install slide valves or ball valves in front of and behind the filter,

so that the filter can be emptied during maintenance.

The drainage duct can be connected to a sewage connection

with a 110 mm diameter. Make sure that the duct is positioned

at an adequate incline. It is recommended to install a pipe with

a flexible rubber sleeve. These can compensate for small

differences in dimensions and also absorb vibration. They can

also be detached to remove the drainage duct.

Always use high-quality pipes with an adequate wall thickness.

Ideally, use 45 degree elbow connectors.

Lay the pipes at a downward angle so that they can be fully

emptied during the winter to protect them against frost.

Note! Electrical shock hazard. Use of this electrical system or

installation in connection with a (swimming) pond may result

in severe injury or death.

Only use this system in accordance with national and regional

regulations.

Always use suitable transport and lifting equipment when

transporting and assembling this system.

6.1 Connecting the control box

Ensure that the control box is not plugged in to the mains

power supply! Open the control box!

Hang up the box on 4 screws aligned with the grooves on the

back of the box. Space between the holes in the wall: w = 280 mm

x h= 251 mm. Remember that the length of the cable for the

electrical equipment is 3 metres. Be careful when opening the

box and remember that the screws you must loosen to open

the door should not protrude when you turn the box open. The

same goes for when you close the box.

6.2 Connecting the electrodes and water level meter

Ensure that the control box is not plugged in to the mains power

supply! Open the control box!

Turn the gland caps on the underside of the box and slide them

over the corresponding cable. Run the cable through the

cable gland into the box, leaving adequate length. Then twist

the gland caps closed again. Connect the electrodes as shown

below using a suitable screwdriver. The labels on the electrodes

match the codes on the connection inside the box.

9www.filtreco.nl

7. First use

Before using the combi drum filter for the first time, it is

advisable to thoroughly clean the pond manually and flush the

pipelines if possible. The reason for this is to prevent the newly

started filter from immediately experiencing an interval break-

down.

Note! Electrical shock hazard.

• Always switch o the current to the system before coming

into contact with the pond water.

• Secure the system to prevent it from unintentionally being

switched on.

• Never connect the system to a power supply that is fitted

with a dimmer.

• Do not use the system in combination with a switch that

has a timer function.

• Only switch on the control box if the submersible pump

is below the water level and the electrodes are below the

surface.

7.1 Sequence for first use

• Remove the cover from the filter.

• Check all the water inlet and outlet connections.

• Check the line from the pump to the spray tube to ensure

it is hand-tight.

• Open the valves on the outflow side.

• Open one valve in the in-flow line.

• Switch on the pump.

• Adjust the flow of the pump to point downwards in case

the desired water level quickly reaches the high level.

• Check all the water inlet and outlet connections again.

• Plug the connectors into the corresponding power sockets:

The plug for the spray pump goes into the power socket labelled

"spray pump".

The plug for the drum motor goes into the power socket labelled

"drum motor".

The plug for the water pump(s) goes into the power socket

labelled "pond pump".

Any additional components connect into the power socket

labelled "spare".

Please make sure that the power sockets can support a total

output of 2500 W from "pond pump" and "spare" combined!

7.2 Adjusting water level meter

The water level meter consists of 3 stainless steel electrodes:

• The "high-level" electrode (the short coated electrode)

• The "flush-cycle" electrode: the short coated electrode

• The common electrode: the long uncoated electrode

The flush-cycle electrode is set to the highest level by default.

This means that the flush cycle is initiated when the water level

drops by approximately 90 mm before the low level is reached.

If you would like for the flush cycle to take place sooner, you

can unscrew the cable gland and place the electrode lower.

Afterwards, tighten the cable gland again.

Note! The other two electrodes do not have an adjusting function.

7.3 Flush cycle

If the pond's water quality is such that the flush cycle lasts less

than 3 minutes, then the flow into the water inlet must be reduced

to ensure that the cycle lasts for more than 3 minutes. After the

contamination in the pond has decreased, the throttling in the

drainage duct can be gradually reduced as long as you allow

for the flush cycle time mentioned above.

10 Combi drum 55 (pump)

8. Control box

The control box consists of a housing with:

• 5powersockets,namely:

- Pond pump 1 for pond pump 1

- Pond pump 2 for pond pump 2

- Spare for any extra pond pump or other electrical

equipment

Note! These 3 power sockets have a combined total output

of 2500 Watts!

- Spraypumpforthehigh-pressuresubmersiblepump-max.

1000 Watts

- Drum motor for the drum motor - max. 100 Watts

- Main switch to switch the power supply to the box on

and o

9. Control panel (malfunctions)

The control panel is situated behind a locking hatch. It is easy

to unlock this hatch and open it upwards. Always close the

hatch carefully after every use.

1 Start/Stop:

Makes it possible to start and/or stop the flush cycle. This button

can be used either in manual or in automatic mode.

2 Reset Error:

Resetting an error/outage. If the error is actually resolved, it is

possible for the system to work normally again. If the error is

reset but still continues to exist, the Error LED will immediately

light up again.

3 Change Mode:

By pushing this button, you can switch back and forth between

Auto(matic) and Manual mode. In Manual mode, you can start

or stop one flush cycle by pressing Start/Stop. The flush cycle

will never start automatically in Manual mode. In Auto mode,

the flush cycle is initiated if the flush level is activated (electrodes

detect contamination) based on an increased water level.

4 Change Flush Time:

By pressing the Change Flush Time button, you can change the

flush time of the spray pump.

5 Power LED:

The Power LED glows green when the system is connected to

power (Main Switch is on).

11www.filtreco.nl

6 Error LED:

This LED glows red whenever an error or outage occurs. This

may indicate any of the following errors:

System Error:

Error in the control box (relay, electrodes, automation,

motherboard).

- The water pumps are switched o.

- No flush cycle is possible.

• The Main Switch is switched o

• Pull all the plugs out of the box

• Unplug the system's power supply cable

• Switch the F1 automat o and then on again

• Close the box and reconnect it to power

• Switch the Main Switch on again

• If the error continues, contact Filtreco

Level Error:

The water level in the filter has become too high. More water is

being pumped into the filter than is flowing out of it.

- The water pumps are switched o.

- No flush cycle is possible.

• Remove the cover and look for what's causing the problem.

• Check the inlet and outlet lines.

• If the outer end of the high-level electrode is above water

again:

- place the cover on the filter

- press "Reset Error"

- The mode will then switch to Manual

• Press "Start" to initiate the manual flush cycle.

- The "Flush" LED turns green

- Check to make sure the spray pump and motor are working

- If the motor is not working, check whether its plug is

connected

- If the spray pump is not working, check whether its plug

is connected

- When the flush cycle is complete, the "Flush" LED

switches o again.

- Remove the cover and check whether the water level

has reached the required operating level again

- Repeat the steps above if necessary

- If this continues to happen, you must decrease the inflow

capacity to the filter or increase the outflow capacity

from the filter.

Door Error:

The cover (contact) is not closed. The cover is not installed or

is not closed properly.

- The water pumps are switched o.

- No flush cycle is possible.

• Check whether the cover is closed properly

• Press "Reset Error" to return to the manual cycle

• The "Door" LED switches off and the "Manual" LED

switches on

• Press "Change Mode" to return to automatic mode.

If the error continues, check whether the magnet is still in place

under the holder for the cover. If so, then perform the following

steps:

• Switch o the "Main Switch"

• Disconnect the power plug from the mains

• Open the box

• Check whether the DR+ and DR- cables are properly

connected

Interval Error:

This occurs when 50 flush cycles have occurred in a row with

a pause of less than 3 minutes between each cycle. This may

occur when the water is heavily contaminated.

- The water pumps are switched o.

• Set the flush-cycle electrode to the highest level. Now, a

flush cycle will be initiated later.

• Check the outflow lines to see whether they are clogged.

• Check the sprayer heads and clean them if needed.

If this does not help, reduce the incoming flow until the most

heavy contamination is eliminated.

7 Auto Mode LED:

The LED glows then the system is in automatic mode.

8 Manual Mode LED:

The LED glows when the system is in manual mode.

12 Combi drum 55 (pump)

9 LEDs for the selected time interval:

Depending on how dirty the water is, you can choose between

5 dierent flush times.

The normal flush time can be used for average water conta-

mination. If the pond is very clean and hardly contains any

contaminants, such as in the winter time, you can switch to the

"eco" or "smart" setting. This reduces your water consumption. If

the water is heavily contaminated and you would like to flush

the screen more frequently, you can choose the "super" or

"turbo" setting.

You can change the selected flush times in Manual mode by

pressing "Change Flush Time".

The sprayer does not begin spraying until 1.5 seconds after the

motor starts. This ensures that only the soiled portion of the

screen is sprayed.

The Eco setting has a spray time of 5.5 seconds (quarter turn).

The Smart setting has a spray time of 8 seconds (half turn).

The Normal setting has a spray time of 11 seconds (1 turn).

The Super setting has a spray time of 22 seconds (2 turns).

The Turbo setting has a spray time of 33 seconds (3 turns).

Make sure that there is an interval of at least 3 minutes between

flush cycles, otherwise the drum will experience an interval error.

Confirm your choice by pressing "Change Mode". Your choice

is now saved. In manual mode, you can change this again if you

wish.

10 Safety Switch:

If the 'Safety Doorswitch E' is switched on, the system is supplied

with electrical current. After you use 'Safety Doorswitch E', the

system will always start in Manual mode. If you want to open

the control box, you must switch o 'Safety Doorswitch E' or

else the door cannot be opened. This is an additional safety

feature.

10. Cleaning and maintenance

Note! Electrical shock hazard! This can result is severe injury

or death.

When performing cleaning and maintenance, always take the

following measures:

• Always switch o the power supply and secure it from

being accidentally switched back on before you come into

contact with the water or perform any maintenance work

on the system.

• General cleaning - 1x each month:

- Switch o the "Main switch" and unplug the system from

the mains power supply.

- Remove any coarse waste (such as algae) on the

inside of the drain.

- Clean the brushes inside the drum.

- Clean the inside of the drum.

- Clean the door security blocks.

- Clean the water level meter electrodes.

• Cleaning the sprayer heads - 2x per month:

- Remove the sprayer head by turning it to the left

to unscrew it from the quick-release fastener.

- Remove the gasket from the holder.

- Remove the right-angle sprayer from the connector.

- Clean it.

- Install the gasket and sprayer back into the holder.

- Turn the holder onto the clamp bracket.

13www.filtreco.nl

• Complete cleaning:

- Switch o the "Main switch" and unplug the system from

the mains power supply.

- Close the inlet and outlet spouts and drain the water

through the valve until the filter is empty.

- Remove the drain and clean it thoroughly.

- Remove the drum and brushes and clean them

under running water.

- Remove the spray pump and clean it thoroughly.

- Clean the entire inside of the filter.

• Disassemble the drum as follows:

- Disassemble the spray tube by unscrewing the

connector and removing the drain from the tube clamp.

- Disassemble the drain by loosening the bolts.

Be careful not to lose the gasket and gasket rings!

- Turn the drum until the bolt from the shaft connection

is on top. Remove this bolt.

- Slide the drum slightly towards the partition until the

tube is separated from the shaft and then carefully lift

the drum at an angle upwards out of the silicone seal. Lift

the drum out of the filter basin. Carefully set the drum

down to prevent damage to the screen.

• Assemble the drum as follows:

- Carefully lower the drum into the filter and

set its flange on the shafts of the partition.

- Press the silicone seal into the flange of the drum on

all sides, using your hand.

- Slide the drum with the flange side over the shaft.

- Turn the drum around the shaft until the hole in the shaft

is positioned underneath the hole in the tube. Reinsert

the M8 x 15 bolt and screw it tightly.

11. Troubleshooting

Error codes related to the Error LED are found in chapter 9.

The following issues may occur:

• No water flow:

- Check whether the (slide) valves are open.

- Check whether the water pumps are connected.

- Check whether the inlet or outlet is clogged.

• Insucient water flow:

- Check whether the inlet or outlet is clogged.

- There are not enough inlet connections installed.

- The circulation pump does not have enough capacity.

- There is dirty water and particles in the clean water side

outside the drum: check the seal between the partition

and the flange of the drum.

• The high-pressure pump does not work:

- The plug is not plugged into the right power socket (spray

pump).

12. Winterising

To ensure proper functioning of the system, do not allow the

water temperature to decrease below +4 degrees Celsius.

Measures that you can take:

• Place a cover or lid over the drain.

• The control and motor cannot withstand freezing

temperatures. Be sure to place them in a location that is

protected from rain and frost.

In case water temperatures drop below +4 degrees Celsius or

there is a chance of freezing, discontinue using the system.

• Drain the system and clean it according to the instructions

• Allow the surrounding pipes to drain

• Leave the valves open

• Protect the pipes and other components from frost if

necessary.

13. Wear parts

The following parts may be subject to wear:

• Silicone drum seal Order number 100754

• Retaining ring Order number 100757

• Brush Order number 100759

• Drum screens Order number 100702

14. Technical specifications

• Operating voltage: Vac 230V

• Plug: 16 A Euro plug

• Total power output: 3680 Watts

• Cable length: 3 m

• Drum diameter: 40 cm

• Drum length: 60 cm

• Max. flow: 55 m3/h

• Weight: 150 kg

• Height above water level: completely

• Min. water level: As stated

• Max. water level: As stated

• Number of panels: 2

• Number of sprayers: 6

15. Wiring and power outages

If the control box is further away than the 3-metre cable length,

use a CE-approved splash-resistant extension cable to reach

the motor and the spray pump.

The cables for the water level meter cannot be extended using

a power cable. This may cause the system to malfunction.

Original Filtreco cables can be ordered separately. Any damage

to the control box caused by your own wiring or third-party

extension cables is not covered by warranty.

If following a power outage, the power circuit it reactivated, the

control box will revert to its previous mode (the mode which

was activated for longer than 10 seconds): automatic mode in

automatic mode and manual mode in manual mode. The

previously selected flush time will also be reactivated.

14 Combi drum 55 (pump)

16. Technical diagram

15www.filtreco.nl

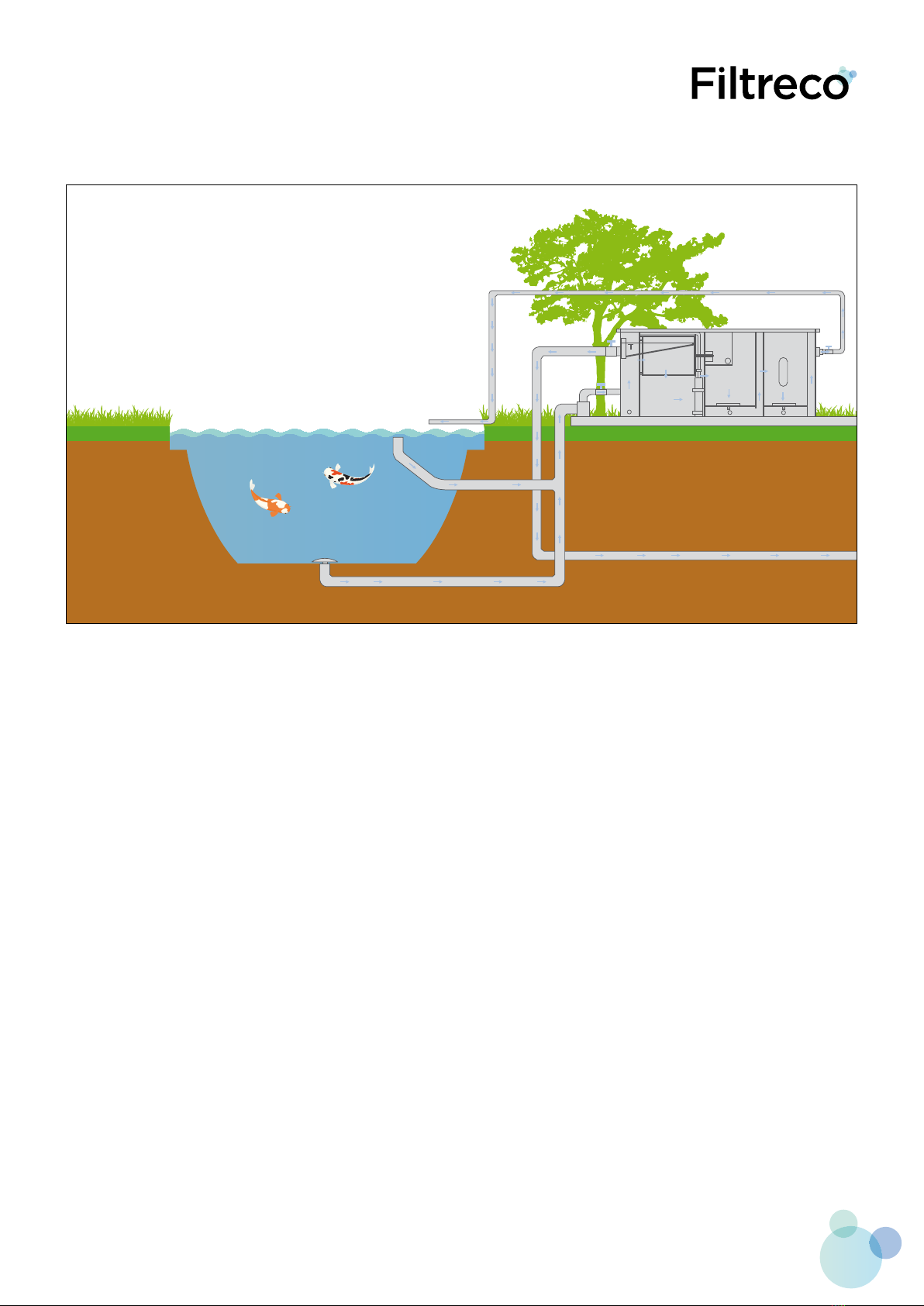

17. Diagram for assembly in a pond

P

16

Filtreco

Nusterweg 69

NL-6136 KT Sittard

The Netherlands

CoC 14052952

VAT NL 58.28.235.B01

+31 46 457 25 55

info@filtreco.nl

www.filtreco.nl

Filtreco is a WTH B.V. brand.

This manual suits for next models

3

Table of contents

Other Filtreco Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Atlantic Ultraviolet

Atlantic Ultraviolet Mighty Pure MP16A owner's manual

SunSun

SunSun CBG-500 Operation manual

Hayward

Hayward XStream Filtration Series owner's manual

Contech

Contech DownSpout StormFilter Operation and maintenance

Teka

Teka Airfilter MINI operating instructions

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual

STA-RITE

STA-RITE VERTICAL GRID DE FILTERS S7D75 owner's manual