Fimer VSN700 User manual

Solar Monitoring

VSN700 Data Logger

Product manual

EN

2

ATTENTION –AIMPORTANT SAFETY INSTRUCTIONS

This document contains important safety instructions that must be followed during the installation and maintenance of the equipment.

ATTENTION –ASAVE THESE INSTRUCTIONS

Keep this document in a safe place near the inverter for easy access during installation, operation and maintenance.

ATTENTION –AThe installer must read this document in its entirety before installing or commissioning this equipment. In addition to

what is explained below, the safety and installation information provided in the product manual must be read and followed. For more

detailed information regarding proper installation and use of this product, refer to the product manual located at www.fimer.com.

ATTENTION –AThe product must be used in the manner described in the document. If this is not the case the safety devices

guaranteed by the inverter might be ineffective.

ATTENTION –AAll pictures and illustrations shown in this document are indicatives and must be intended as support for installation

instruction only. Actual product may vary due to product enhancement. Specifications subject to change without notice. The latest

version of this document is available on the FIMER website.

EN

3

Table of Content

1. Labels and Symbols 4

2. Not included in the supply 4

3. Field of use, general conditions 4

4. System overview 5

5. Installation 7

5.1.1 Tools 7

5.1.2 Materials and Test Equipment 7

6. Commissioning 10

6.3.1 Set a static IP address 11

7. Adding an FIMER weather station 14

8. Interfacing VSN700-05 with SCADA systems 17

8.3.1 Set a Static IP Address for the data logger 17

8.3.2 Configure the serial interfaces 17

8.3.3 Communication with devices by SCADA or monitoring system 19

9. Troubleshooting 21

10. Data logger specifications 23

EN

4

Operators are required to read this manual and scrupulously follow the indications reported in it, since FIMER cannot be held responsible

for damages caused to people and/or things, or the equipment, if the warranty conditions are not observed.

ATTENTION –AThis manual contains important safety instructions that must be followed during installation and maintenance of

the equipment.

ATTENTION –AThis manual must be considered as an integral part of the equipment, and must be available at all times to everyone

who interacts with the equipment.

1. Labels and Symbols

In the manual, the danger or hazard zones are indicated with signs, labels, symbols, or icons.

In the manual and/or in some cases on the equipment, the danger or hazard zones are indicated with signs, labels,

symbols or icons.

Generic hazard - Important safety information. This points out operations or situations in which staff must be

very careful.

Hazardous voltage - This points out operations or situations in which staff must be very careful due to

hazardous voltage.

Positive pole and negative pole of the input voltage (DC)

This points out that it is mandatory to carry out the described operations using the clothing and/or personal

protective equipment provided by the employer.

This points out that the examined area must not be entered or that the described operation must not be carried

out.

NOTE –DThe choice of the inverter model must be made by a qualified technician who knows about the installation conditions, the

devices that will be installed outside the inverter and possible integration with an existing system.

2. Not included in the supply

FIMER accepts NO liability for failure to comply with the instructions for correct installation and will not be held responsible for systems

upstream or downstream the equipment it has supplied. It is absolutely forbidden to modify the equipment. Any modification, manipulation,

or alteration not expressly agreed with the manufacturer, concerning either hardware or software, shall result in the immediate cancellation

of the warranty.

The Customer is fully liable for any modifications made to the system.

Given the countless array of system configurations and installation environments possible, it is essential to check the following: sufficient

space suitable for housing the equipment; airborne noise produced depending on the environment; potential flammability hazards.

FIMER will NOT be held liable for defects or malfunctions arising from: improper use of the equipment; deterioration resulting from

transportation or particular environmental conditions; performing maintenance incorrectly or not at all; tampering or unsafe repairs; use

or installation by unqualified persons.

FIMER will NOT be held responsible for the disposal of: displays, cables, batteries, accumulators etc. The Customer shall therefore

arrange for the disposal of substances potentially harmful to the environment in accordance with the legislation in force in the country of

installation.

3. Field of use, general conditions

FIMER shall not be liable for any damages whatsoever that may result from incorrect or careless operations.

You may not use the equipment for a use that does not conform to that provided for in the field of use. The equipment MUST NOT be used

by inexperienced staff, or even experienced staff if carrying out operations on the equipment that fail to comply with the indications in this

manual and enclosed documentation.

3.1 Intended or allowed use

This device is monitoring equipment designed for data collection and low-voltage connection to inverters, weather stations, string

combiners, and other photovoltaic equipment.

EN

5

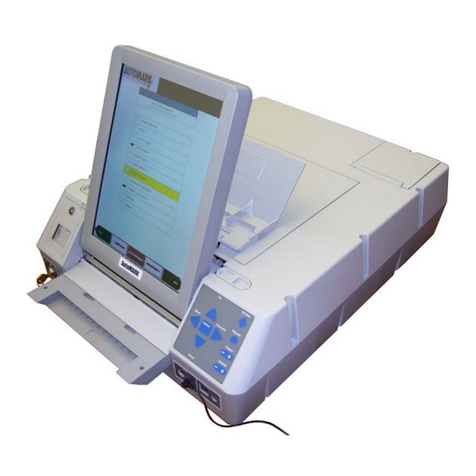

4. System overview

The VSN700 series data loggers are a lightweight solution for remote data acquisition, which enables PV system owners to benefit

from advanced energy reports. The data logger collects and analyzes energy generation data from all connected FIMER (and legacy

Power-One) solar inverters and other supported devices. System performance and energy information are logged into a database on the

Aurora Vision® Plant Management Platform where it can be retrieved and used for analysis via any standard web-browser on an Internet

connected device.

The installer logs on to the Aurora Vision website to register the VSN700 series data logger and ensures that the logger is correctly

passing information to the servers. The installer provides a URL to the end user for access to Aurora Vision Plant Viewer. The installer can

also monitor all of their sites through a web-browser using Aurora Vision Plant Portfolio Manager.

The VSN700 in conjunction with the Aurora Vision solution brings the following benefits:

• Safeguard Your Investment and Maximize Your Return

• Improved Solar Energy System Efficiency

• Lower Life Cycle Costs

• Real-time and Historic Data Presented Using Web-based Devices

• Alarm Functions and Device Communication Failure

• Remote Access to all Data Using Internet Technology

VSN800-XXPower supply

VSN700

Weather station

(optional with most models)

Access to all recorded data

is via web-based interface

with enhanced productivity tools

INTERNET

Aurora Vision

®

Inverter monitoring

EN

6

4.1 Commercial and Utility Application with VSN700-05

String Inverter or Central Inverter VSN700-05 VSN800-14

IP or Modbus TCP

RS-485

INTERNET

Plant Portfolio Manager

Scada

Plant Viewer

The information in this document applies to all VSN700 Data Logger models. This guide provides instructions for installing the data logger

hardware to work directly with FIMER (or legacy Power-One) solar inverters and for setting up the Aurora Vision management system for

remote data access.

The VSN700 consists of a data logger/gateway, a universal AC/DC power supply adaptor, and optionally comes with a DIN rail

mounting kit. The data logger connects to a Local Area Network (LAN) with an Ethernet RJ45 connection. Typically it connects to a

Digital Subscriber Line (DSL) or Cable modem through a router to get access to the Internet. In summary, any kind of Internet connection

will work.

4.2 VSN700 Data Logger models

The data logger comes in three models. The feature differences are provided in the table below.

Model Supported Devices and Features

VSN700-01-XX

(Residential)

Monitor up to 5 x FIMER (or legacy Power-One) single-phase and/or small three-phase (Trio 5.8/7.5/8.5)

string inverters.

VSN700-03-XX

(Commercial)

Monitor up to 10 x FIMER (or legacy Power-One) string inverters and 1 x FIMER VSN800 Weather

Station. String inverters can be single-phase or three-phase.

VSN700-05-XX

(Max)

Monitor any FIMER (or legacy Power-One) solar inverters.

Monitor other supported FIMER and 3rd party devices; including, meters, combiners, and weather stations.

Includes a Modbus TCP server and converts proprietary Power-One inverter data maps into SunSpec

compliant Modbus data maps for easier SCADA system integration.

EN

7

5. Installation

Qualified personnel with appropriate training and experience must perform the installation of the VSN700. Follow standard safety

precautions during all procedures. Appropriate personal protection equipment (PPE), such as safety gloves and safety glasses is

recommended.

WARNING –BDuring normal operation, dangerous voltages flow through many parts of the system, including: terminals, all I/O

Modules (Inputs and Outputs) and their circuits. All Primary and Secondary circuits can, at times, produce lethal voltages and

currents. Avoid contact with any current-carrying surfaces. Installation may also require close proximity to high-voltage high-current

wires, so proper caution should be exercised when installing these devices.

WARNING –BMake sure all power is switched off before performing installation. These servicing instructions are for use by

qualified personnel only. To reduce the risk of electric shock, do not perform any servicing other than that specified in the operating

instructions unless you are qualified to do so.

5.1 Preparation

Make sure you have the following tools and materials prior to starting installation.

5.1.1 Tools

• Standard Electrician’s Toolkit

• Personal Protective Equipment (Gloves, Goggles, Clothing)

5.1.2 Materials and Test Equipment

• Twisted-Pair RS-485 Wire (Belden#3106A or equivalent).

NOTE –DDO NOT USE CAT5/6 CABLE FOR THE RS-485 DATA WIRE.

• Ethernet Cable to make Network Connection

• Laptop Computer with Internet Browser

• Second Ethernet Cable for Logger configuration

• Mounting Screws and/or Brackets

It is also useful to know if you need to perform Asset Registration or final End-to-End Data Checks after physical installation is complete.

If so, you will need a User ID / password to log in to Aurora Vision Plant Portfolio Manager, and additionally you will need Administrator

privileges to access the Administration tool in Aurora Vision. See the “Commissioning” section for details.

5.2 VSN700 installation

1. Check packaging for all components

• Data Logger

• Power Supply Adapter (not included with VSN700-05-00 model)

• DIN rail mounting kit for 35mm DIN rails (VSN700-05-00 model only)

2. Determine the indoor location of the VSN700.

For reliable operation, it is required that the data logger be located within 100m (330 ft.) of an Ethernet connection and within 1200m

(4000 ft.) of the inverter(s).

3. Mount the data logger.

The logger comes with flanges with pre-drilled holes for easy mounting. A DIN rail mounting kit comes with the VSN700-05-00 model

and can be optionally ordered with other models. All data logger versions require a weather protected site. The included power supply

requires an ambient temperature between 0oC and 40oC but the logger can operate between -40oC and 85oC.

4. Connect shielded twisted-pair wire to the RS-485 terminals on the inverter(s). If there are multiple inverters, wire the inverters in a daisy

chain configuration. Refer to your inverter manual for information on terminal locations and daisy chaining inverters. Use RS-485 data

wire with one twisted pair, one ground conductor, and a shield with drain wire (Belden#3106A or equivalent).

NOTE –DDO NOT USE CAT5/6 CABLE FOR THE RS-485 DATA WIRE.

5. For systems with multiple inverters, the RS-485 network must be terminated at the final inverter by a switch near the RS-485 terminal

block. The farthest inverter in the daisy chain must be terminated by setting the inverter termination switch to ON. For all other inverters

in the daisy chain, turn OFF the termination switch. Below are pictures of RS-485 terminals in various inverters, as well as locations of

the termination switch.

NOTE –DIn some environments you may experience poor RS-485 signal quality due to noise. If signal quality is a problem, double-

check that the last inverter in the chain is terminated and other inverters are not terminated. If problems persist, it may prove helpful

to attach a 120 Ohm 0.5 Watt resistor across screw terminals 1 and 2 on the data logger.

READ THE MANUAL –EIf you need more information, consult your inverter’s manual for locating the RS-485 terminals and the

termination resistor switch.

EN

8

6. Connect the other end of the shielded twisted-pair wire to Secondary RS-485 terminals on the data logger. Use the table below and the

figure on page the next page to make the proper connections. See the section on Adding an FIMER Weather Station for information on

connections for an attached weather station.

RS-485

Screw Terminal

Eth1 - For Device

Configuration

Eth0 - For Internet

Connection

RS-485 Connection Data Logger RS-485 Screw Terminal Connector Example Inverter RS-485 Pin Label

RS-485 Negative (-) 1-TR (Port 5)

RS-485 Positive (+) 2+TR (Port 4)

RS-485 Negative (-) 3----

RS-485 Positive (+) 4----

Ground 5RTN (Port 3)

VDC Power Only 6----

7. VSN700 models come packaged with an AC/DC power adapter. The DC output wires are pre-stripped and tinned for connecting to the

screw terminal of the data logger. Attach the conductor with the white label, which is positive 12 volts DC, to Port 6 of the data logger’s

screw terminal. Attach the other solid black DC ground conductor to Port 5 of the data logger’s screw terminal. See the figure below.

VSN700-05-00 models come with a DIN Rail kit for mounting directly onto a DIN rail within an inverter. After DIN Rail mounting, connect

the data logger directly to a 9V-24V (±10%) DC voltage source capable of supplying greater than 7.2VA. The logger will typically only

consume about 3VA during normal operation.

+12VDC

Power Supply

Example Inverter

Terminal Block

To Network via

Switch or Router

Screw Terminal Block

on Data Logger

EN

9

8. For models with an AC/DC adapter, connect the adapter to a standard power outlet. The power supply accepts a Universal AC input for

use worldwide and will come with a plug adapter that is specific for your region. An appropriate travel adapter can be used if connecting

to a different socket type.

9. Check the data logger’s power.

There is a pair of light emitting diodes (LEDs) on the side of the logger, opposite the RS-485/DC power terminal block. The LEDs flash

during system boot and then LED2 turns solid green when power is supplied and the system is ready.

5.3 Inverter communication

FIMER (and legacy Power-One) PVI and UNO inverter models use a proprietary communication protocol called Aurora Protocol. To

monitor these inverters with a VSN700-01 (Residential) or VSN700-03 (Commercial) Data Logger model, they must be attached to the

Secondary RS-485 port on the data logger.

FIMER PRO inverter models use Modbus RTU protocol and must be attached to the Primary RS-485 port VSN700-03 (Commercial)

Data Logger model. Modbus devices are not supported by the VSN700-01 (Residential).

The RS-485 ports on the VSN700-05 (Max) version are configurable for either protocol. Specific FIMER (and legacy Power-One) inverters

support both protocols and will have separate ports dedicated for each; consult your inverter’s manual for its capabilities. In any case, all

inverters (and other devices) connected in a particular daisy chain must use the same communication protocol and protocol settings. For

systems with multiple inverters, each inverter in a daisy chain must be manually assigned a different RS-485 serial address. Refer to the

inverter manual(s) for instructions on RS-485 wiring and setting the communication parameters like baud rate and RS-485 serial address.

Write down the serial number and RS-485 address for each inverter so you can determine which inverter is which on the monitoring

system.

EN

10

6. Commissioning

The following are the major steps required to make sure the system is operational and data is being passed to Aurora Vision servers:

1. Connect the data logger to your Ethernet network.

2. Configure the data logger through its web-based user interface.

3. Verify that you have a working Internet connection from the data logger to Aurora Vision’s servers.

4. Perform Asset Registration through the Administration page on Aurora Vision (reachable from Plant Portfolio Manager web

interface).

5. Verify end-to-end data transfer using the Aurora Vision Plant Portfolio Manager web portal.

Commissioning is not complete until you have performed the final two steps above over the Internet. However, these two steps do not

necessarily need to be performed as part of the hardware installation.

6.1 Connect to the Internet

Connect the data logger to the Internet through a local area network. Use standard Ethernet cable and connect it to the Ethernet RJ-45

port marked Eth0 (Internet) on the front of the data logger. The data logger can connect through any switch or router in your network.

NOTE –DThe data logger is by default set to DHCP and will try to acquire its IP-address from the DHCP server on your local network

(LAN). The data logger is designed for use on an Ethernet network and must be assigned an IP address (DHCP or static) to make it

accessible. If it is required to set a static IP for the data logger, your connection will not work until this address is set. If required, refer

to the section below on setting a Static IP address. Normally no ports should need to be opened in the network firewall. The data

logger will use port 443 outbound to transmit the data.

Verify that the data logger has an Ethernet connection. The Eth0 (Internet) LED can be used for detecting network link and network

traffic:

• Eth0 LED = GREEN = Link

• Eth0 LED = GREEN BLINK = Traffic

• Eth0 LED = OFF = No network link

NOTE –DIf no activity is seen on the LEDs, double-check all connections.

FIMER recommends a wired Internet connection because it is more reliable and requires less setup. If it is necessary to connect to a

wireless network, a wireless network bridge with an Ethernet port is required. Purchase and configure the wireless network bridge that

is compatible with the host wireless network. Ensure that the wireless connection is operational with a laptop before connecting it to the

Eth0 (Internet) port of the data logger.

NOTE –DFIMER does not provide Internet service or the cables required to connect the data logger to the Internet.

6.2 Configure the data logger

The installer must use a laptop with an Ethernet cable to communicate directly to the data logger’s web-based user interface for

configuration. The data logger’s web server has many options and capabilities, but here we only describe those necessary to get your

system up and running.

1. Configure the laptop’s Ethernet port to obtain a Dynamic IP address automatically through DHCP; typically, laptops are already

configured this way.

2. Connect the Ethernet cable between the secondary Ethernet port marked Eth1 (Local) on the data logger and the laptop computer.

3. Wait for the laptop to obtain an IP address from the data logger and then open an Internet browser window on the computer. Type in

the following URL in the address bar: http://172.17.17.1

4. The following Home page (or similar) will appear:

Tabs to perform configuration

operations

Section to set up devices connected to the

Data Logger RS-485/232 ports

NOTE –DDue to the constantly evolving nature of software, the images shown in this manual may be out of sync with the current user

interface. The options mentioned should still be accessible, but may be renamed or accessed in a different way than is described in

this manual. Check https://docs.auroravision.net for the latest version of this manual.

EN

11

Select the tabs across the top to perform configuration operations and select one of the ports in the Devices list to set up devices.

Verify all the icons for the data logger in the status area to the right are green. It may take some time for all the icons to turn green.

Status area

The MAC address (Logger ID) for the data logger is displayed at the top of the page. Be sure to write down the MAC address of the data

logger. The MAC address is needed later for Asset Registration.

6.3 Configure for devices

The Devices list on the Home page shows all the different devices connected through all the ports on the data logger. It is essential that

the devices you set up here match how devices are physically connected to your data logger.

By default, only the two RS-485 ports are set up. The primary RS-485 port is set to Modbus RTU and the secondary RS-485 is set to

Aurora Protocol (to SunSpec) Adapter.

The default settings support hardware connections where all inverters that use Aurora protocol are attached as an RS-485 daisy chain

to the Secondary RS-485 port. Optional weather stations and supported inverters that use Modbus RTU are connected to the Primary

RS-485 port. See Section 4 if you are adding a VSN800 Weather Station. See Section 5 for advanced configuration options if you are

using VSN700-05 (Max).

For the Secondary RS-485 connection, once inverters using the Aurora Protocol are properly addressed and wired in the RS-485 daisy

chain, inverters will automatically be discovered and displayed.

6.3.1 Set a static IP address

Setting a Static IP is only necessary if required by your network. In almost all cases you can skip this section.

1. Obtain Static IP address information for the site.

2. Select the Network tab. Set the Type (Network Connection Type) field to Static. The page allows you to type in the following information:

• IP address

• Subnet Mask

• Gateway

• DNS (separate primary and secondary DNS servers with a single space)

3. Press Update at the bottom of the page.

The data logger needs to be restarted before the network changes take affect. In the Home tab use the Reboot Logger button to reboot

the logger.

EN

12

6.4 Verify Internet connectivity to Aurora Vision servers

1. Verify that the Ethernet cable is connected between the data logger’s Eth0 (Internet) and your network.

2. The data logger acts as a router. From your laptop connected to Eth1 (Local), verify internet connectivity by opening up an Internet

browser window and connecting to www.auroravision.net.

3. The remaining steps for commissioning are performed via the Internet to check end-to-end communications. Proceed with one of the

following steps:

• If you are not responsible for these remaining steps, be sure to pass on the MAC address (Logger ID) information to the responsible

party. Remove the cable from Eth1. Installation is complete.

• If asset registration is already complete, proceed to the section on End-to-End Data Check.

• If asset registration is not complete, proceed to the next section on Asset Registration.

6.5 Asset registration

Asset registration is performed via the Administration tool in Aurora Vision. Asset registration assigns the MAC address of your logger to a

specific plant in Aurora Vision. Asset Registration can be performed before or after the on-site installation is complete. When you register

the data logger, all the assets (inverters and other devices) reporting to the data logger are also registered. A Plant must be created on

Aurora Vision using the Administration tool before the data logger can be assigned and registered to it. Note that access to Administration

tool requires an Aurora Vision User ID and password with Administrator privileges.

From the data logger’s user interface in the Logger ID drop-down menu, click the Register button to go to Asset Registration on the

Administration page of the Plant Portfolio Manager. If you are not using the data logger’s web-based user interface, go to https://admin.

auroravision.net/customeradmin. Select Administration > Register Logger and type in the MAC address of the data logger. Follow the

steps on the Asset Registration page to select the plant that the data logger will be associated with.

See the Plant Portfolio Manager Users Guide for help in using the Administration tool for asset registration. Go to https://docs.auroravision.

net for all the latest product documentation.

6.6 End-to-end data check

The last check is to make sure that data is actually being reported and is visible on the Aurora Vision portal. Wait 15 minutes and log on to

www.auroravision.net using a web browser on an Internet connected device. Within Aurora Vision, go to the Plants > Dashboard page

for the plant and open the Device Status panel. Verify that the energy readings agree with the inverter(s) and that all of the monitored

devices are communicating, as indicated by the Last Reported time.

6.7 Plant Viewer access for end users

The installer must supply the user with their unique Plant Viewer URL so they can monitor their system. To find the URL for a specific user’s

plant within Aurora Vision, follow these steps:

1. Log on to Plant Portfolio Manager at www.auroravision.net and go to Plants > Management.

2. Select the Plant from the asset list in the screen area to the left.

3. Once the correct Plant is displayed, select Plant Viewer from the Actions menu.

EN

13

4. A page is displayed to configure the user’s Plant Viewer options. Scroll down to the Published View section. The URL to provide to the

customer is in the Share URL field.

NOTE –DFor detailed information about plant sharing options see the Plant Portfolio Manager User Guide. Go to https://docs.

auroravision.net for all the latest product documentation.

EN

14

7. Adding an FIMER weather station

FIMER’s VSN800 Weather Station must be wired to the Primary RS-485 port on VSN700-03 (Commercial version). Weather stations

are not supported by VSN700-01 (Residential version). Weather stations can be attached to any port configured for Modbus RTU on

VSN700-05 (Max version).

1. Connect shielded twisted-pair wire to the RS-485 terminals on the weather station. Use RS-485 data wire with one twisted pair, one

ground conductor, and a shield with drain wire (Belden#3106A or equivalent).

NOTE –DDO NOT USE CAT5/6 CABLE FOR THE RS-485 DATA WIRE.

2. Connect the other end of the shielded twisted-pair wire to the Primary RS-485 terminals on the data logger. Use the table below and

the figure on the next page to make the proper connections.

RS-485 Screw Terminal

1 2 3 4 5 6

RS-485 and Power

Connections

Data Logger RS-485 Screw

Terminal Connector

Example Inverter

RS-485 Pin Label

Example VSN800-XX

RS-485 Pin Label

RS-485 Negative (-) 1-T/R ----

RS-485 Positive (+) 2+T/R ----

RS-485 Negative (-) 3---- RS-485 A(-)

RS-485 Positive (+) 4---- RS-485 B(+)

DC Ground 5RTN RS-485 GND and GND

VDC+ Power Only 6---- 24VDC

3. The VSN800 Weather Station can tap the power terminals on the data logger for its power source. Tapping off the data logger’s power

source is optional; any appropriate DC power source that meets the specifications of the weather station may be used. To use the data

logger’s power source for the weather station, connect shielded twisted-pair wire to the power terminals on the weather/environmental

station. For distances less than 400 feet between the data logger and the weather station we recommend using #22 AWG stranded

copper wire. For longer distances use a heavier gauge wire. Consult the VSN800 Weather Station datasheet for the minimum required

voltage and maximum allowed wire gauge. If unable to meet these specs because of voltage drop then a separate power supply closer

to the weather station must be used.

NOTE –DDO NOT USE CAT5/6 CABLE FOR THE POWER WIRES.

EN

15

4. Connect the other end of the shielded twisted-pair wire to the +9-24VDC and GND terminals (terminals 6 and 5) on the data logger. It

may be necessary to use a wire nut to attach the multiple wires to the GND terminal on the data logger.

Wire the weather station to the data logger as shown in the figure below.

+12VDC

Power Supply

Example Inverter

Terminal Block

To Network via

Switch or Router

Screw Terminal Block

on Data Logger

Example Weather

Station Terminal Block

EN

16

7.1 Configuration for a weather station device

The Devices list on the data logger’s Home page will show all the different devices connected through all the ports on the data logger. It is

essential that the devices you set up here match how devices are physically connected to your data logger.

The port configuration for the Primary RS-485 port on the Commercial version VSN700 (VSN700-03) must remain set to Modbus RTU

(default value) if adding an optional weather station.

Configure the Primary RS-485 port using the following procedure. Bring up the data logger’s web interface in the same manner as for

configuring inverters (connect an Ethernet cable from the data logger’s Eth1 (Local) port to a laptop and go to http://172.17.17.1).

To add the VSN800 weather station go to the Home tab and push the Find button for the Primary RS-485 port. Click on Start in the

window that pops up to begin the device discovery process. The default Modbus address for VSN800 Weather Station is 60. It is not

necessary to let the scan finish, once it has discovered the device the scan can be stopped and closed. The weather station will be

displayed as a SunSpec Compatible Device.

EN

17

8. Interfacing VSN700-05 with SCADA systems

This section describes how to interface external monitoring or SCADA systems with the VSN700-05 data logger and is intended only

for the Max version data loggers. This section does not apply to the Residential and Commercial versions. There are two important

aspects of the data logger that allow for easy integration into a SCADA system, the Aurora Protocol to SunSpec Adapter and Modbus

TCP communication.

8.1 Aurora Protocol to SunSpec Adapter

The data logger’s Aurora Protocol to SunSpec Adapter is a software adapter that has two main functions

• it continuously polls inverters that use the proprietary Aurora Protocol as fast as it can

• caches data gathered from these inverters in SunSpec compliant Modbus data maps.

NOTE –DThe SunSpec Alliance is a global trade alliance that aims to standardize how inverter data is stored.

This allows SCADA systems to use standard Modbus TCP read commands and a common SunSpec inverter data map to gather

information from any FIMER (or legacy Power-One) inverter that only supports Aurora Protocol.In addition, a SCADA system can send

a supported Modbus write command to a SunSpec inverter control register and the data logger sends the equivalent Aurora protocol

command(s) causing the inverter to execute a control action, such as grid disconnection or output power reduction.

NOTE –DNote that only inverters using the Aurora protocol have their data converted and cached in SunSpec compliant Modbus

data maps.

NOTE –DFor complete SunSpec specifications and open information standards, go to http://www.sunspec.org/specifications/.

8.2 Modbus TCP server

External monitoring or SCADA systems must communicate with the data logger using the Modbus TCP protocol. The data logger’s

Modbus TCP server/gateway converts and forwards onto the serial port(s) commands intended for Modbus RTU capable inverters

or other Modbus RTU protocol devices connected to the data logger. The device response is then converted and forwarded back to the

Modbus TCP client that sent the command.

The Modbus TCP server also communicates with the SunSpec Adapter allowing SCADA systems to gather data using Modbus TCP

protocol from inverters which use the proprietary Aurora protocol. When a Modbus TCP client sends read commands intended for an

inverter that is using Aurora protocol, the data logger’s Modbus TCP server will respond based on data that has been cached for that

inverter by the SunSpec adapter. When a Modbus TCP client sends a supported write command, the SunSpec adapter will send the

equivalent Aurora protocol command(s) to the inverter. If there are any problems with the command, an exception response will be sent

back to the Modbus TCP client. There is no confirmation that a write command is successful and that the inverter has performed the

control action; so, write commands should always be followed up shortly after with read commands to confirm the change(s).

8.3 Data logger configuration for SCADA or other monitoring systems

8.3.1 Set a Static IP Address for the data logger

Connect a PC to the Eth1 (Local) port of the data logger and browse to address http://172.17.17.1 to access the data logger’s web based

configuration UI. In the Network tab configure a static IP address for the data logger’s Eth0 port that is either within the same subnet as

the SCADA system or can be routed to/from the SCADA system. Use a single space between your primary and secondary DNS servers,

if applicable. Alternatively, the data logger can be set for DHCP if the DHCP server it receives its IP address from is configured to always

assign the same IP address to the data logger.

8.3.2 Configure the serial interfaces

Configure the serial port interfaces for the appropriate communication protocols based on the devices installed at the site. If using inverters

that only communicate using the Aurora protocol, then the serial interface they are connected to must be set for Aurora Protocol (to

SunSpec) Adapter for the inverter’s data to be accessible by Modbus TCP clients. Note that the ULTRA central inverter is only supported

via Modbus RTU or via the SunSpec Adapter options; it is not supported via the Legacy Aurora Protocol Adapter option. Setting the

interface for Modbus RTU will allow for better polling performance; however, advanced features like remote inverter firmware upgrade are

only available through the SunSpec Adapter option.

In the Home tab click the pencil icon and use the drop down menus to configure the Primary and Secondary RS-485 interfaces

based on the type of devices connected to these ports. Polling performance is better if half of the devices are connected to one of the data

logger’s RS-485 ports and half connected to the other, though this may not be practical depending on the physical locations of devices

or protocols used. Try to spread as many devices as possible across the two ports for better polling performance. The protocols used

on each interface can be changed on the Max version data logger. They can both be set for the same protocol or different protocols. All

devices daisy chained to a particular port must use the same communication protocol and settings as those set in the data logger for

that port, including baud rate and parity checking. Note that to monitor the ULTRA central inverter via Modbus RTU, the baud rate for the

interface on the data logger must be set for 19,200 bps.

Verify that both ports are configured to the appropriate baud rate and parity for the connected serial devices by clicking on the wrench

EN

18

icon next to each interface to access the Configure Interface menu(s). If communicating with inverters via Modbus TCP, open the

port(s) in the firewall associated with the RS-485 interface(s) by clicking the wrench icon next to the red X to open the Configure Global

Settings menu. The following image shows an example where one interface is configured for Modbus RTU and the other interface for

Aurora Protocol (to SunSpec) Adapter.

Save the changes by pressing the floppy disk icon.

The logger needs to be rebooted for the configuration changes to take effect. In the drop-down menu by Logger ID, click on Reboot, and

wait about a minute for the logger to fully reboot.

Now that the data logger has been configured, devices can be added to the logger either manually or by using the Find button(s). Devices

using Aurora protocol will be automatically discovered.

EN

19

8.3.3 Communication with devices by SCADA or monitoring system

The external monitoring or SCADA system communicates with the serial devices through the data logger’s Modbus TCP server/gateway.

The data logger’s Eth0 (Internet) interface and the external system need to be on the same network subnet or have a route set up in order

to communicate. The Modbus TCP ports must also be opened as previously described. The data logger forwards Modbus TCP traffic on

port 502 to the Primary RS-485 interface and traffic on port 503 to the Secondary RS-485 interface. For example, to communicate with

an inverter that uses Aurora protocol at RS-485 address 14 connected to the Primary RS-485 port which has been configured for Aurora

Protocol (to SunSpec) Adapter, the Modbus TCP command would be pointed to: <Eth0_IP_address>:502:14. To communicate with a

Modbus RTU device at RS-485 address 26 connected to the Secondary RS-485 port which has been configured for Modbus RTU, the

Modbus TCP command would be pointed to: <Eth0_IP_address>:503:26.

8.4 Adding 3rd party devices

If you are adding supported 3rd party devices to VSN700-05 (Max version), follow the steps below to manually add the device. Alternatively,

certain Modbus RTU devices can be auto-discovered using the Find button.

1. Go to the Home tab. Click on the Pencil icon across from Devices. The following screen appears:

2. The screen shows the current configuration settings for each port. To add a device select the Plus button on the RS-485 port that

the device is connected to. A window appears to enter device settings.

3. Select the Device Type from the pull-down menu.

4. Set the Slave Id field to the RS-485 serial address of the device.

5. Enter a Description to help you identify the device if you need to change configurations later.

6. Click the Add button.

7. The device will be added to the Devices page, listed under the RS-485 port that it is connected to.

EN

20

8. Press the Apply icon at the top to commit the changes.

9. After making changes, you are returned to the Devices page with the status indicators, as shown below. After sucessfully collecting

the first sample the indicator will turn green; click the black triangle next to the status indicator to verify the data collected is correct.

8.5 Modbus TCP client

In addition to Modbus TCP server functionality, the data logger is also capable of polling Modbus TCP devices using its Modbus TCP client

interface. The Modbus TCP device must be on (or be routed to/from) the same LAN that the data logger’s Ethernet interfaces (Eth0 and/or

Eth1) are connected to. The Modbus TCP interface must also be enabled by clicking the pencil icon and then using the dropdown menu to

enable it. Save this change using the Apply icon and then the logger must be rebooted. Once rebooted, manually add devices to the

Modbus TCP interface in a similar manner as described in the previous section. The type of device, its IP address, Modbus TCP server

port, and its RS-485 address (slave Id) need to be specified. The IP Port will typically be 502 and the Slave Id will typically be 1 unless the

device is behind a Modbus TCP gateway.

Table of contents

Popular Data Logger manuals by other brands

HYDROLOGICAL SERVICES

HYDROLOGICAL SERVICES ML1-420 Operation manual

EasyLog

EasyLog EL-SIE quick start guide

Dostmann Electronic

Dostmann Electronic LOG200 Series operating instructions

Hioki

Hioki 3639-20 instruction manual

Rotronic

Rotronic HL-1D quick guide

sauermann

sauermann KISTOCK KP 110-RF quick start guide