fine bubble MK1 NANO BUBBLER User manual

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

1

MK1 NANO BUBBLER™

Operation and Maintenance Manual

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

2

TABLE OF CONTENTS

Introduction ………………………………………………………………………………………………….3

Safety Terminology and Symbols ………….………………………………………………………4

Instructions ........................................................................................................4

Disposal of Packaging and Product ………………………………………………………….……..4

Warranty ……………………………………………………………………………………………….……….4

Spare Parts …………………………………………………………………………………………….………5

Transportation …………………………………………………………………………………….…………5

Storage ................................................................................................................6

System Applications ............................................................................................6

Installation ……………………………………………………………………………………………………..8

Determination of Installation Location ..............................................................10

Terms of Use and Installation…...........................................................................12

Operations .........................................................................................................13

Maintenance........................................................................................................14

Disposal................................................................................................................15

Technical Information…………………………..…………………………………………………………15

Typical MK1 Container Installation .....................................................................17

Trouble Shooting ….…………………………………………………………………………….………..23

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

3

INTRODUCTION

The purpose of this manual is to provide necessary information for

•Installation

•Operation

•Maintenance

NOTICE:

•Read this manual carefully before installing and using the product. Improper use of the product

can cause personal injury and damage to property and may void the warranty.

•Save this manual for future reference and keep it readily available at the location of the unit

CAUTION:

•Always specify the exact product type and part number when requesting technical information or

spare parts from the Sales and Service Department

Inexperienced Users

WARNING: This product is intended to be operated by qualified personnel

only. Be aware of the following precautions:

•Persons with diminished capacities should not operate the product unless they are supervised or

have been properly trained by a professional.

•Children must be supervised to ensure that they do not play on or around the product.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

4

SAFETY TERMINOLOGY AND SYMBOLS

About safety messages

It is extremely important that you read, understand, and follow the safety messages and regulations

carefully before handling the product. They are published to help prevent these hazards:

•Personal accidents and health problems

•Damage to the product

•Product malfunction

Hazard Level Indication

DANGER:

A hazardous situation which, if not avoided, will result in death or serious injury

WARNING:

A hazardous situation which, if not avoided, could result in death or serious injury

CAUTION:

A hazardous situation which, if not avoided, could result in minor or moderate injury

NOTICE:

A potential situation which, if not avoided, could result in undesirable conditions.

(A practice not related to personal injury)

INSTRUCTION

The instructions and warnings that are provided in this manual concern the standard version, as described

in the sales document. Special version Nano Bubbler™ may be supplied with supplementary instruction

leaflets. Refer to sales contract for any modifications or special version characteristics. For instructions,

situations, or events that is not considered in this manual or the sales document, contact the nearest

Service Centre.

DISPOSAL OF PACKAGING AND PRODUCT

Observe the local regulations and codes in force regarding sorted waste disposal.

WARRANTY

For information about warranty, see the sales contract and our standard warrantee.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

5

SPARE PARTS

WARNING:

Only use original spare parts to replace any worn or faulty components. The use of unsuitable spare parts

may cause malfunctions, damage, and injuries as well as void the guarantee.

CAUTION:

Always specify the exact product type and part number when requesting technical information or spare

parts from the Sales and Service Department.

TRANSPORTATION

Inspect the delivery

1. Check the outside of the package for evident signs of damage.

2. Notify our distributor within five days of the delivery date, if the product bears visible signs of

damage.

3. Unpack the unit - follow applicable steps:

•If the unit is packed in a carton, then remove the staples and open the carton.

•If the unit is packed in a wooden crate, then open the cover while paying attention to the nails and

straps.

•Remove the securing screws or the straps from the wooden base.

Inspect the unit

•Remove packing materials from the product. Dispose of all packing materials in accordance with

local regulations.

•Inspect the product to determine if any parts have been damaged or are missing.

•If applicable, unfasten the product by removing any screws, bolts, or straps. For your personal

safety, be careful when you handle nails and straps.

•Contact the local sales representative if there is any issue.

Transportation Guidelines

WARNING:

Observe accident prevention regulations in force.

Crush hazard - The unit and the components can be heavy. Use proper lifting methods and wear steel-toed

shoes. Always check the gross weight that is indicated on the package to select proper lifting equipment.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

6

Position and fastening

The Nano Bubbler™ unit can be transported only horizontally. Make sure that the Nano Bubbler™ unit is

securely fastened during transportation and cannot roll or fall over.

STORAGE GUIDELINES

The product must be stored in a covered and dry location free from heat, dirt, and vibrations.

NOTICE:

•Protect the product against humidity, heat sources, and mechanical damage

•Do not place heavy weights on the packed product.

•

Long term storage

If the unit is stored for more than 6 months, these requirements apply:

•Store in a covered and dry location.

•Store the unit free from heat, dirt, and vibrations.

•Rotate the Nano Bubbler™ shaft by hand several times at least every three months.

•Treat bearings and machined surfaces so that they are well preserved.

For questions about possible long-term storage treatment services, please contact your local sales and

service representative.

Ambient temperature.

The product must be stored at an ambient temperature from -5°C to +40°C (23°F to 104°F)

SYSTEM APPLICATIONS

MK1 Ultra-Fine Bubble (“UFB”) Nano Bubbler™ is used for the treatment of polluted open water

environment - such as lakes, marshes, rivers, inlets and bays or closed water environments, as for example

waste water tanks.

The method and terms for the restoration to start self-cleaning process closely depend on the cause and

state of pollution.

The basic function and performance are described as follows.

FUNCTIONAL PRINCIPLE

By using the water pumped in from the polluted water area to be treated and surrounding air, MK1 UFB

Nano Bubbler™ produces continuously large number of “activated” air bubbles of diameter < 100 nm

(“ultra-fine

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

7

bubbles”) and discharge them into the area. The mixture of activated ultra-fine bubbles and water

enriched the ultra-fine bubbles (“activated water”), resolves pollutants and microbes which cause

pollution, and molecules of bad smell.

As the result, the water environment is treated so that clean environment, that assures sustainable and

better lives, is restored. It is also possible to treat much worse environment by using proper additives.

SYSTEM PERFORMANCE

•One unit of MK1 type can treat an open water volume (ex. pond) of 10.000 m3 water (1 ha water

surface of 1 m depth). For larger volumes, please consult our nearest representative or consultant

for assessment of your water body.

•Activated ultra-fine bubbles are negatively charged. On the contrary, harmful microbes and

bacteria are positively charged. As the minus and plus charge pull each other, the ultra-fine bubbles

adhere to the microbes and the bacteria due to attractive force existing between them when they

meet with each other.

•The microbes and bacteria are forced to die because ultra-fine bubbles obstruct their activities after

adhesion. Then the activated air bubbles make harmful substances inactive or decompose.

•The molecules of activated water are ionized, and form groups of small clusters and water ions are

diffused to wide area in a short time resulting in the increase of dissolved oxygen which is

indispensable for useful living organisms.

•Hydroxyl ions included abundantly in activated ultra-fine bubbles and water, sterilize bad microbes

and bacteria effectively.

•Chemical materials such as NH4, P2O5, Compounds of Cr+6 and As- compounds are made inactive

due to active molecular motion of the activated water.

•Useful effects such as growth acceleration of plant and animals have been found.

Typical Results of Treatment:

Sludge: The sludge accumulated to the thickness of 30 cm can be resolved and disappear in about 45 days.

Harmful algae and microbes: Resolution starts in about 4 days.

Bad smell: Smell starts to reduce typically in about 4 days.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

8

INSTALLATION

Installation Precautions

WARNING:

•Observe accident prevention regulations in force.

•Use suitable equipment and protection.

•Always refer to the local and/or national regulations, legislation, and codes in force regarding the

selection of the installation site, and power connections.

The Nano Bubbler™ must be lifted and transported using the appropriate eyebolt or handle and never

using the power cord: if damaged, this may cause of a failure or more serious incidents.

Always fix a rope or a safety chain made with non-perishable material to the eyebolt or the Nano Bubbler™

handle. Always use the safety rope to raise, lower, move and anchor the Nano Bubbler™. Never use the

electric power cord and/or float to support the Nano Bubbler™.

Always remember to secure the safety rope used to lower the Nano Bubbler™ at the top, on the edge of

the floating buoy (or other floating object used to fix the Nano Bubbler™ on the water surface). The

buoy/floating platform must have minimum buoyancy of 40 kg to float the Nano Bubbler™.

Secure the electric power cord and the air delivery pipe to the safety rope. Make sure that air delivery pipe

intake is at least 600mm above the water surface. It is possible to use longer pipe and install the end with

on the shore/ground. When used in tank, ensure air pipe inlet is outside the tank.

Electrical Connection

ELECTRICAL HAZARD:

•Make sure that all connections are performed by qualified electrician and in compliance with the

regulations in force.

•Before starting work on the unit, make sure that the unit and the control panel are isolated from

the power supply and cannot be energized. This applies to the control circuit as well.

GROUNDING (EARTHING):

•Always connect the external protection conductor to ground (earth) terminal before making other

electrical connections.

•You must ground (earth) all electrical

Required power supply for the operation of main body is three phase 380 V, 1, 35 kW and 50Hz (or 220 V,

1, 35 kW and 60Hz for USA).

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

9

The electrical connection should always be conducted by qualified personnel, in compliance with local

regulations. Make sure the voltage and frequency of the mains power supply match those reported on the

plate of the motor-driven Nano Bubbler™. Make sure that the mains power supply has an efficient

grounding connection and conducting the grounding of the MK1 Nano Bubbler™. During installation, make

sure that the free end of the power cord is never immersed in water and is well protected against possible

infiltrations of water or moisture.

Special attention should be given to the integrity of the cables: even small leaks can cause infiltration in

the electric motor. In case of damage to the cables it is best to replace them rather than repair them: in

any case always contact qualified personnel. If using an extension, the junction must remain dry and the

cable must be sized appropriately.

Before conducting any maintenance and/or repair on the motor-driven Nano Bubbler™ disconnect it from

the mains power supply as if the motor is on standby following intervention of the thermal device or due

to incorrect positioning (jamming) of the float, it may suddenly restart. In case of excessive overheating of

the motor, the thermal device can stop the machine: the cooling time is about 15 minutes, after which the

Nano Bubbler™ turns on again automatically. You must always try to eliminate the cause that triggered the

intervention of the thermal protector (impeller blocked due to for foreign objects in the Nano Bubbler™,

coolant temperature too high).

It is always necessary to install an adequate electrical protection (adequately set circuit breaker and

differential switch with an operating current of less than 30 mA) that can provide an all-pole disconnection

from the mains with an opening distance between the contacts of at least 3 mm.

The maximum admitted shift between the actual voltage of the power supply and the rated value indicated

on the plate of the motor is of ±10% for three-phase.

Connection point should be located far enough from water region and the perfect prevention of electric

leakage is required.

If distance is more than 30 m and less 60 m from power supply to the Nano Bubbler™, an extension cables

up to 30 m can be used. A breaker with 8 A breaking current must be placed on an electric board and the

three-phase power cable of Nano Bubbler™ relates to each corresponding output terminal of the breaker.

Then, the extension cable at one end relates to the input terminals of the breaker and finally the extension

cable at another end relates to the three-phase power supply.

Note: Allowable current of the extension cable must be at least 16A.

If distance is more than 60 m from power supply to Nano Bubbler™, use a 1,5-kW regulator to compensate

for voltage drop. A breaker with 8 A breaking current must be placed on an electric board and the three-

phase power cable of Main body relates to each output terminal of the breaker. Then, each input terminal

of the regulator relates to the corresponding input terminal of the breaker and finally each input terminal

of the regulator relates to corresponding line of the three-phase power supply.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

10

Motor Rotation Direction Check

Before installing the Nano Bubbler™, make sure that the machine is not connected to the mains supply and

that the rotor turns freely: to so this, act on the impeller through the suction outlet.

Make sure the rotation direction is correct, i.e. clockwise looking from above of the machine (see the

arrow next on the Nano Bubbler™). To do this, before installation, start the motor for a few seconds

(connection and disconnection): if the rotation is correct, the Nano Bubbler™ rebounds in a clockwise

direction. When performing this test, make sure that the machine is at a safe distance from people,

animals or property. To change the direction of rotation, switch the two phases of the supply line.

DO NOT operate the machine in dry conditions.

Start the Nano Bubbler™ only when immersed in the liquid to Nano Bubbler™ out; heck the minimum

suction depth on the machine installed.

NOTICE:

For continuous operation of the Nano Bubbler™ the electric motor must be completely immersed in the

liquid.

DETERMINATION OF INSTALLATION LOCATION

Considering the volume of the object to be treated, water flow, and the purification capability of MK1

Nano Bubbler™, number of units and locations must be determined with the help of our consultants and

authorized representatives.

Typical indications are as follows.

•Set up the MK1 with the floating buoy/frame at centre in case of small pond.

•Set up one or more MK1 with the floating buoy/frames at five to ten meters from bank in case of

large river and lake.

•Set up one or more MK1 with the floating buoy/frames at upper stream when water flows.

•In a JoJo tank set up the MK1 should be placed on the bottom and the chain tightened. Insure that

the piping is secured to the chain. Depth not more than 2.5m.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

11

Installed How to install

Installation Set

1. Electrical splicing kit MX1

2. 2 x Pullies

3. Stain less steel chain.

4. 1 x Big Bouy.

5. 1x Small Bouy.

6. Air hose with float.

7. Cable for securing small boay or 10mm Rope.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

12

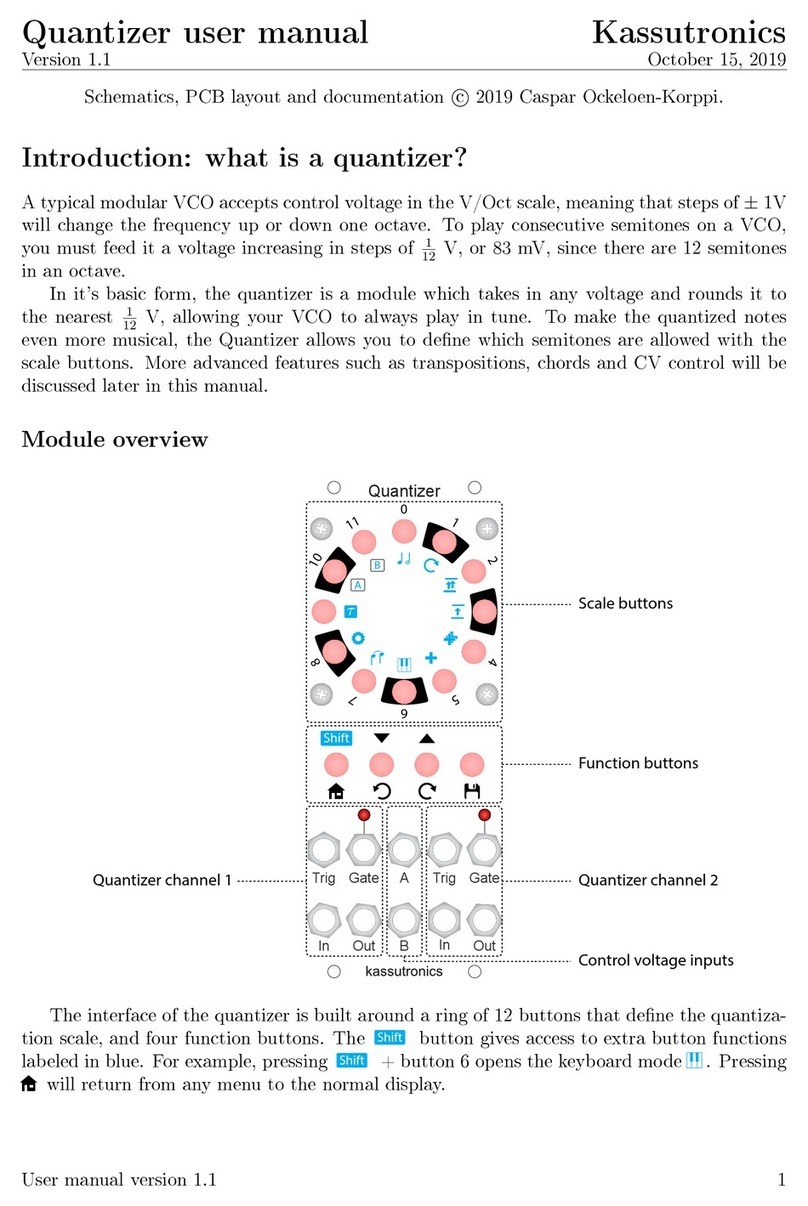

Place the MK1 in the centre of the pond/ dam that needs to be treated.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

13

TERMS AND USE OF INSTALLATION LOCATION

Installation with concrete anchor.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

14

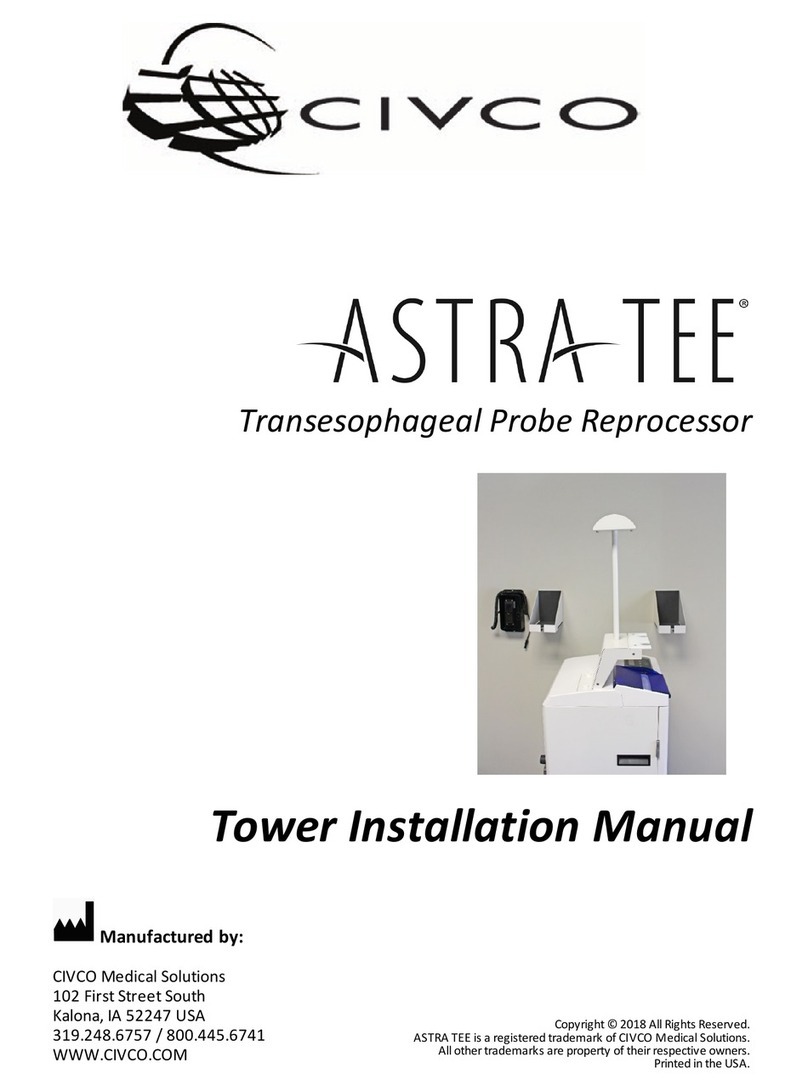

Installation with 2 anchor point.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

15

WARNING:

Improper use of the Nano Bubbler™ may create dangerous conditions and cause personal injury and

damage to property.

DANGER:

Do not use this Nano Bubbler™ to handle flammable and/or explosive liquids.

The MK1 Nano Bubbler™ has a vertical axis and is a mono-block single-impeller Nano Bubbler™ designed to

work “submerged” in fixed and mobile installations.

The machine is not suitable for liquids with the features below:

•Temperature range 0-40 °C;

•Density greater than 1000 kg/m3;

•Kinematic viscosity in the range 0,7-1,5 cSt);

•pH lower than 5 or greater than 8;

•Chemically and mechanically aggressive substances for the materials of the Nano Bubbler™;

•Flammable and/or explosive substances;

The maximum depth of immersion (with appropriate cable length) is 2.5m.

For continuous operation, in order to allow for proper cooling of the motor, the motor must be completely

immersed in the liquid (minimum depth of immersion 300 mm).

To avoid possible damage to the motor-driven Nano Bubbler™, the number of equally distributed

starts/per hour must be less than 30.

The bottom of the unit must be at least 1000mm above the sludge or bottom of the lake/dam/pond/tank.

The sound pressure, measured in the minimum depth that allows the Nano Bubbler™ to operate, is less

than 70 dB (A) when the Nano Bubbler™ is submerged the noise disappears.

OPERATIONS

Operations Start

Make sure that no person other than authorized and trained is operating the system. Before start of the

operation of the system, it must be verified that no person is in the water or close to the Nano Bubbler™

and all person outside of the water in safe distance from the power cables and power supply.

After safety measures are confirmed, switch on the power supply. MK1 Nano Bubbler™ starts to work and

ultra-fine bubbles are seen on the surface around the Nano Bubbler™. Recommended Nano Bubbler™

operation times:

•Normal operation mode: 6 hrs on, 6 hrs off

•Intensive mode (in case of heavily polluted liquid): 6hrs on, 2hrs off

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

16

Operation Control and Water Quality Inspection

Different from the test in water tank, in the open natural environment the quality of the water does not

improves always day after day. The cleaning process depends on many environmental parameters. For

example, if thick and hardened sludge exists at bottom of the pond, the water quality test data will change

to worse values in the beginning of the operations. This is because sludge starts resolve after a couple of

days depending upon its state and pollutant stored in the sludge, when start dissolving and diffusing it in

the water. After the sludge is completely dissolved in the water, data shows improvement again.

Therefore, it is important to understand what is happening in water by analyzing test results.

MAINTENANCE

ELECTRICAL HAZARD:

Disconnect and lock out electrical power before installing or servicing the unit.

WARNING:

•Maintenance and service must be performed by skilled, trained and qualified personnel only.

•Observe accident prevention regulations in force.

•Use suitable equipment and protection.

•Make sure that the drained liquid does not cause damage or injuries

Any work on the Nano Bubbler™ must be carried out by qualified personnel with adequate preparation

and suitable equipment.

In normal conditions of use they do not require any special maintenance. Disassembly is not required, even

of individual parts, since any tampering can jeopardize the performance of the machine. If there is a

danger of frost, you should empty the body of the Nano Bubbler™, then remove the machine from the

water and place somewhere dry. MK1 has an electric motor and is mechanically sealed when immersed in

by biodegradable hydraulic oil (Fina Biohidran SR 38 or similar).

Pay attention because this oil may be characterized by excess pressure and/or temperature with respect to

the external environment. Apart from that, the oil used does not have special risks and does not contain

substances harmful to health.

In case of direct contact, simply wash the affected area with water.

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

17

To ensure a long life to the motor-driven Nano Bubbler™s, it is necessary to subject them to periodic

maintenance. We recommend conducting the following checks every 250-300 hours of operation (every 3

months at normal daily operations):

•Check that the electric power supply is correct and that the current absorbed on the three phases is

balanced and not greater than the value featured on the plate.

•Check the electrical insulation of the motor; check that the level of noise and vibration is equal

the ones present in the conditions of the commissioning of the machine.

Have an electric motor and are mechanically sealed on the motor side when immersed in by biodegradable

oil: pay attention because this oil may be characterized by excess pressure and/or temperature with

respect to the external environment.

Under normal conditions the oil must be controlled every 3 months, in heavy-duty applications every

month. To fill the oil, please see attached video.

For the motor-driven Nano Bubbler™ to operate correctly is very important to use Food grade or similar

types of oil.

In the case of operation with muddy liquids or very dirty water, immediately after use or before prolonged

inactivity, clean the Nano Bubbler™ thoroughly by briefly operating with clean water in order to remove

residual solids that may clog the impeller and obstruct internal passages.

Before starting up the Nano Bubbler™ again, check that the shaft turns freely, i.e. is not blocked by

deposits or other causes and that electrical insulation of the motor and power cord are correct, that the oil

is intact and at the right level. During transport and storage keep the base resting on the relative suction

Nano Bubbler™, upright and with the cord wrapped around the frame of the motor.

DISPOSAL

There is no need for special disposal procedures, please refer to local requirements in terms of disposal,

recovery, re-use and recycling of materials. Check rotation direction.

TECHICAL INFORMATION

Fluids can also be used in bearings and chain drives, providing long service life and clean operation.

The value’s quoted above are typical of normal production. They do not constitute a specification.

Shelf Life: Product shelf life is 3 years from the date of manufacture when stored in sealed containers

under protected storage conditions*

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

18

* Protected storage conditions:

Include indoor or covered storage

Protected from contamination

Exposure to rain and snow and/or exposure to direct sunlight

ISO Grade

100

150

220

320

460

Viscosity, cSt @ ao o c SUS @ IOO O F)

cSt @too o c @ 210 0 F)

Viscosity index

D445

D445

105 (547)

12.0 (68)

142 (744)

14.6 (78)

225 (1189)

19.7 (100)

302 (1603)

23.8 (118)

424 (2264)

29.8 (146)

D2270

103

101

100

99

99

Flash Point, COC, o c ( O F)

D92

264 (507)

240 (464)

204 (399)

-36 (83)

43-37-0 (10)

184 (363)

198 (388)

Pour Point, o c ( O F)

D5950

-39 (-38)

-39 (-38)

-39 (-38)

-39 (-38)

Colour

D1500

<0.5

<0.5

<0.5

0.5

Water Separabiiity,

82 0 C (180 0 6), mc (min.)

D1401

4387-0

(10)

43-37-0 (10)

43-370 (15)

43-37-0 (20)

Rust Protection,

A- Distilled Water

BSynthetic Sea Water

0665

D665

Pass

Pass

Pass

Pass

pass

0.44

160 (353)

Pass

0.43

Pass

Foaming Resistance,

Sequence I

Anti-wear Protection:

Four Ball Wear, mm

(40 kg, 1200 rpm, 1 hr., 75 0 C)

D892

80/0

20/0

D4172

0.42

0.42

0.42

Extreme Pressure Protection:

Four Ball Weld. kg (1b)

D2783

126 (278)

160 (353)

160 (353)

160 (353)

Typical}

Performance

Data

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

19

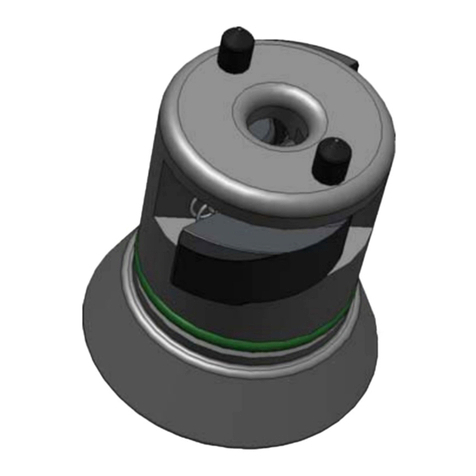

MK1 ™ ULTRA FINE BUBBLE NANO BUBBLER™

Power Source:

380V PH3 50Hz

240V PH1 50Hz

220V PH3 60Hz

Output:

1.350 Watts

2.8 Amps

Specifications:

Stainless Steel Housing

IP 68 Protection degree

950(H) x 300(W) x 200(L)

Weight: 37kg

Capacity:

18m / 80 g.p.m.

Bubble Size: 10 –300 nm

Average Size: 76 nm

Concentration:

220 000 000 bubbles

Bergrus Industrial Park, Unit 1-10, Porterville, Cape Town, 6810, South Africa

T: +27 (0)22 931 2240 E: info@finebubblewater.com W: www.finebubbletechnologies.com –Director & Founder Paul Botha

Strictly Confidential –Not to be copied without written consent by Fine Bubble Technologies (Pty) Ltd. ©Copyright 2018. All rights reserved.

20

TYPICAL MK1 CONTAINER INSTALLATION

Flow Chart

Table of contents

Popular Laboratory Equipment manuals by other brands

SKC

SKC Sioutas Cascade Impactor operating instructions

Steris

Steris Basil 1100 Operator's manual

Philips

Philips SCF287 manual

Fisher Scientific

Fisher Scientific 11-718 instructions

NuAire

NuAire LabGard NU-640-400 Operation and maintenance manual

Thermo Scientific

Thermo Scientific HESI-II Probe user guide

Hettich

Hettich ZENTRIMIX 380 R operating manual

ThermoFisher Scientific

ThermoFisher Scientific Thermo Scientific MicroClick instruction manual

Opticon

Opticon NLV-5201 user manual

TESTO

TESTO 872s instruction manual

Takara Bio

Takara Bio Thermal Cycler Dice Real Time System III Instrument manual

erlab

erlab Captair Flex S Series user manual