This document applies to installation, maintenance and

troubleshooting of the Thermal Cycler DiceTM Real Time System III .

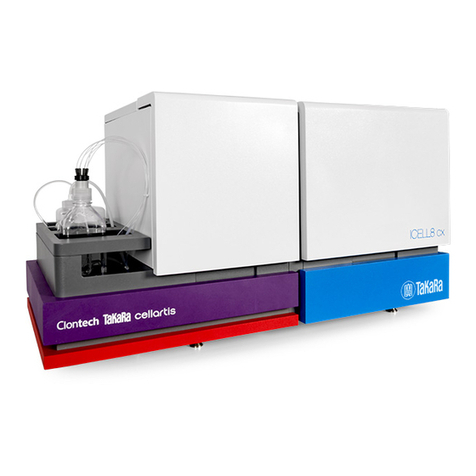

Thermal Cycler Dice Real Time System III (Cat.# TP950)

Thermal Cycler Dice Real Time System III with PC (Cat.# TP970)

Thermal Cycler Dice Real Time System III with PC/MRQ (Cat.# TP980)

Thermal Cycler Dice Real Time System III (Cy5) with PC (Cat.# TP990)

<Software of TP951 main body >

Thermal Cycler Dice Real Time System III LCD application software version 1.00

Thermal Cycler Dice Real Time System III Software version 6.00 for PC

(Cat.# TP952)

OS:Microsoft®Window®7 (32bit) / Windows®8.1 (64bit)

* Not confirm on the Windows®8

Microsoft®Office 2007 / 2010 / 2013

NOTICE

L47 Real-Time PCR Quantification Method

The purchase of this product includes a limited, non-transferable license for all fields other than human

or veterinary in vitro diagnostics under specific claims of U.S. Patent Nos. 6,174,670, 6,569,627,

6,303,305, and 6,503,720, owned by the University of Utah Research Foundation and licensed to Idaho

Technology, Inc. and Roche Diagnostics GmbH.

* Thermal Cycler Dice is a trademark of TAKARA BIO INC.

* Microsoft, Windows, Windows Vista, Excel and PowerPoint are registered trademarks of Microsoft

Corporation.

* FAM and ROX are trademarks of Applera Corporation or its subsidiaries in the US and/or certain

other countries.

* SYBR is a registered trademark of Molecular Probes, Inc.

* All marks are the property of their respective owners. Certain trademarks may not be

registered in all jurisdictions.

Copyright© 2015 by TAKARA BIO INC., KUSATSU, Shiga, Japan

Rev. J