erlab Captair Flex S Series User manual

User Manual

TM

Please consider the environment before printing this document

User Manual

Captair®Flex™

S-M-SD-XLS

Kunshan erlab D.F.S Co.,Ltd

100 Liu Shi Jing Road Kunshan Development Zone PengLang Jiangsu Province

Tel : +86 (0) 512 5781 4085 - Fax . : + 86 (0) 512 5781 4082 - E-mail : Sales.china@erlab.com.cn

01/2010 - T

echnical data are not contractual. erlab®CHINA reserves the right to modify the present document without prior notice.

User Manual

TM

2

Congratulations!

By choosing Captair® Flex™ ductless filtering fume hoods, you have

chosen an efficient, reliable way to ensure safety.

Your Captair® Flex™ filtering fume hood guarantees that you are

protected when working with chemicals that pose an inhalation risk for

the user.

Your fume hood functions based on the recirculation of filtered air, which

makes it possible to use high-efficiency filters to trap toxic particles

and molecules and to recycle this air within the laboratory. The air

downstream from the hood’s modular filtration column, which uses the

new Flex™ technology, is thus free of all chemical pollutants.

Nevertheless,theeffectivenessofthissystemisdirectlydependent

upon it being used correctly and monitored by its users. Your

laboratory may also benefit from ergonomic, economic, and ecological

advantages provided by the Captair® Flex™ fume hood throughout its

life cycle.

Do you want to work in a 100% safe environment year after year?

A careful reading of this manual is a must!

Designed to protect the user,

the environment and your budget.

User Manual

TM

3

€

€

Your new Captair®Flex™ ductless filtering fume hood

offers several advantages from day one:

Benefit from the use of an immediately

available unit, easy to relocate.

Captair®Flex™ filtered enclosures can be moved depending

on the protection needs of the laboratory and can be easily

relocated without disturbing room air balance.

Eliminate installation costs

The installation of a captair®Flex™ filtered enclosure is

quick and easy. There is no need for a ductwork linked

to an air supply / air extraction system, in comparison to

traditional ducted systems. A single electrical outlet is all

that is needed to make it work Its setting up can be realized

at any time, without any complex forward planning. Do not

hesitate to compare this cost to a traditional ducted fume

hood cost.

Protect the environment

Since no ductwork is required, a captair®Flex™ filtered

enclosure totally eliminates the direct discharge of

pollutants into the atmosphere and therefore contributes

to the protection of the environment. Furthermore, a

captair®Flex™ filtered enclosure does not generate any

pollution linked to energy production unlike a traditional

ducted fume hood.

Achieve significant energy savings

Ductwork air balance is essential to the proper operation of

a traditional ducted fume hood however; it is also the source

of very important energy consumption. In fact, captair®

Flex™ filtered enclosures do not generate any energy costs

associated with the use of expensive extraction systems

or conditioned air supplies. Operational costs remain at a

minimum even when taking into account filter changes.

User Manual

TM

4

Contents

Introduction Page 2

Page 5

Page 27

Page 35

Page 52

Protecting yourself

Getting started

Maintenance

Warning

- Monitoring air face velocity

- Manually detecting filter saturation

- Automatically detecting filter saturation

- Replacing the filters

- The revolving system

- Cleaning and maintenance

- Via the E.S.P. program (Erlab Safety Program)

- Via AFNOR NF X 15-211: 2009 standard

- Flex™ technology

- Description of the control box

- First start-up

- Navigating the digital display screen

User Manual

TM

5

Getting started

- Flex™ technology

- Description of the control box

- First start-up

- Navigating the digital display screen

User Manual

TM

6

By combining molecular and particulate filtration

technologies,erlab® was able to devise the new Flex™

modular filtration column technology.

This single device can thus be configured to meet the

protection needs of your laboratory.

This flexibility was made possible by creating stackable,

one-size-fits-all filtration cartridges—an innovation

that is key to your new Captair® Flex™.

This innovation developed by the erlab® R&D

laboratory offers unprecedented flexibility, adaptability,

and savings.

Your device can be quickly reconfigured and can be

easily used for other applications.

Possible configurations for your Captair® Flex™ fume hood

FLEX™ TECHNOLOGY

A modular filtration column which provides

unprecedented adaptability and flexibility.

N’hésitez pas à tout moment à entrer en contact avec votre agent

ESP pour configurer avec lui la solution de protection adéquate à vos

besoins

You may contact your E.S.P. agent at any time

to confirm the safety parameters

related to the use of your device!

Manipulated chemicals/ Applications

1

5

3

4

2

6

7

4

8

1

5

3

4

2

6

7

4

8

256 mm

Carbon filter

Fan

256 mm

H14 HEPA filter

Fan

340 mm

Carbon filter

H14 HEPA filter

Fan

445 mm

Carbon filter

Carbon filter

H14 HEPA filter

Fan

Carbon filter

Carbon filter

H14 HEPA filter

Fan

Carbon filter

H14 HEPA filter

Fan

Carbon filter

Carbon filter

Fan

Liquids

For dilutions, titrations,

extractions, transfers, …

Solids

For sievings, grindings,

weighings, formulations,

compressions…

Liquids & solids

For dissolutions, filtration,

extractions, …

Handlings in

clean rooms

Up to class ISO 5 rooms

1C

1P

1P 1C

1C 1P

1P 2C

2C 1P

2C

Class 2 according to the

NF X 15-211 :2009 standard

Class 1 according to the

NF X 15-211 : 2009 standard

Class 1 according to the

NF X 15-211 : 2009 standard

Class 1 according to the

NF X 15-211 : 2009 standard

Class 2 according to the

NF X 15-211 :2009 standard

Class 2 according to the

NF X 15-211 :2009 standard

User Manual

TM

7

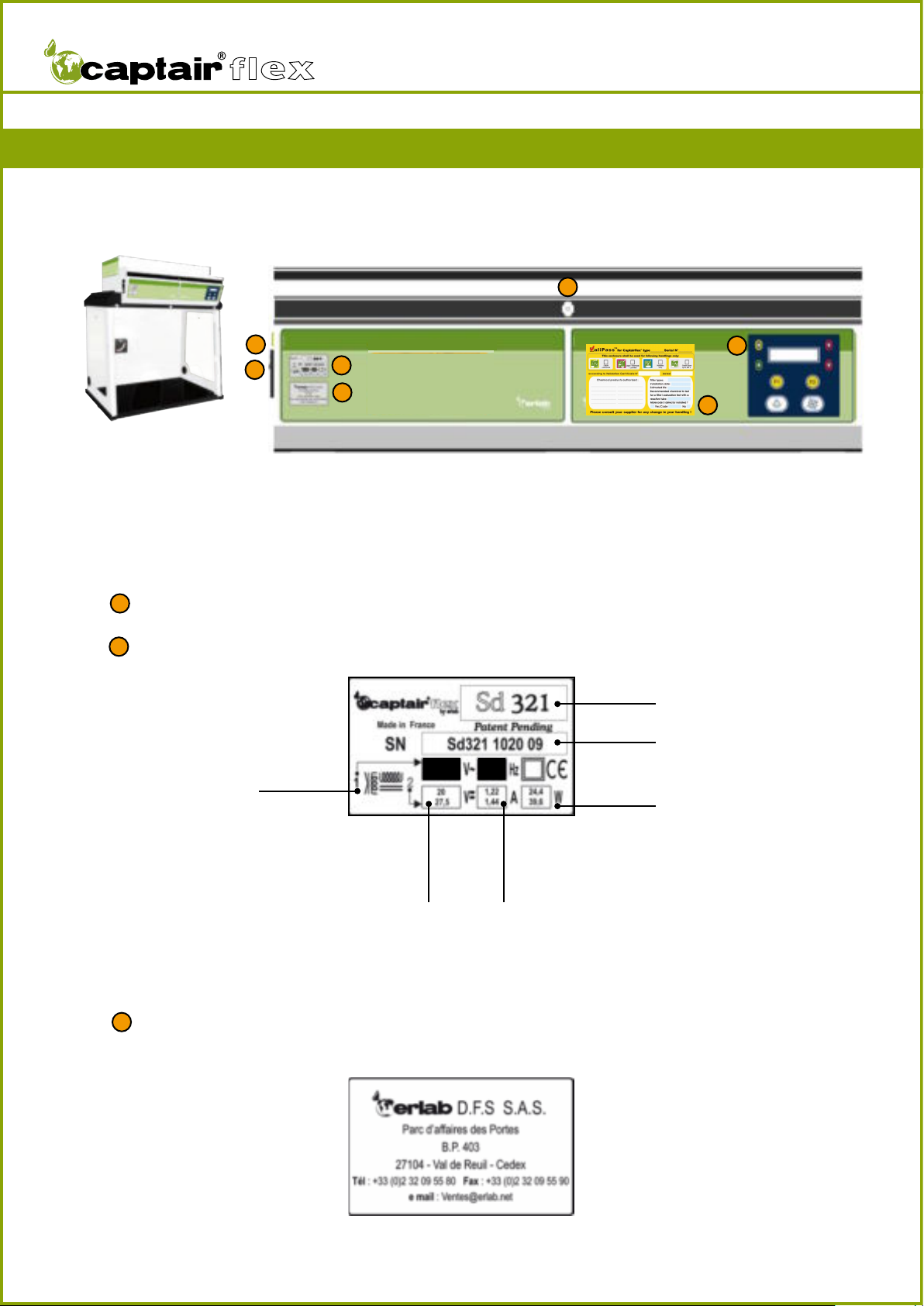

Master switch

Model label

Name of the manufacturer or their representative

1

2

3

12

3

4

5

6

Fume hood model

Fume hood serial number

Power in Watts

IntensitySupply

voltage

Supply voltage

and frequency

supported

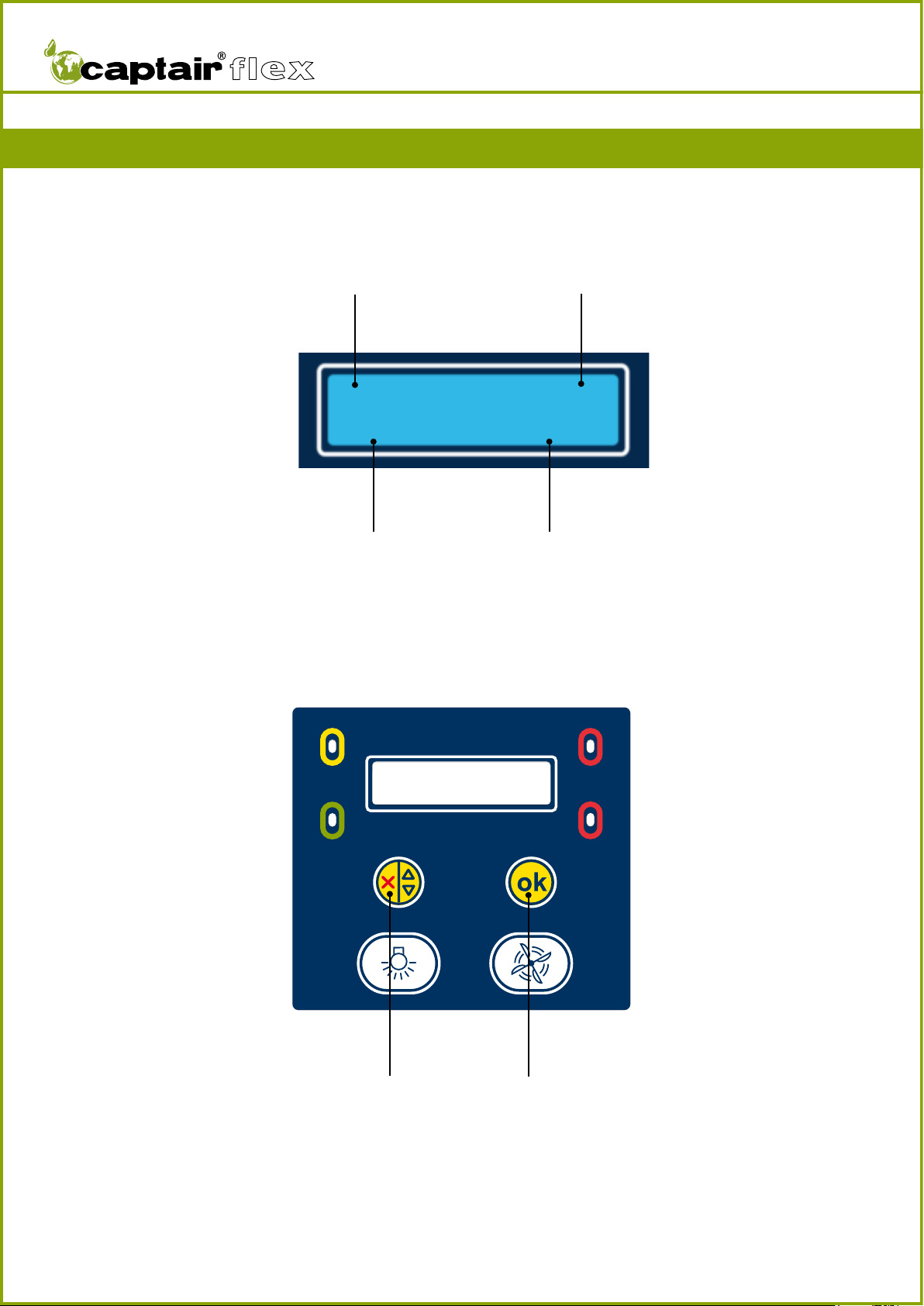

DESCRIPTION OF THE CONTROL BOX

7

100-240 47-67

User Manual

TM

8

4

5

6

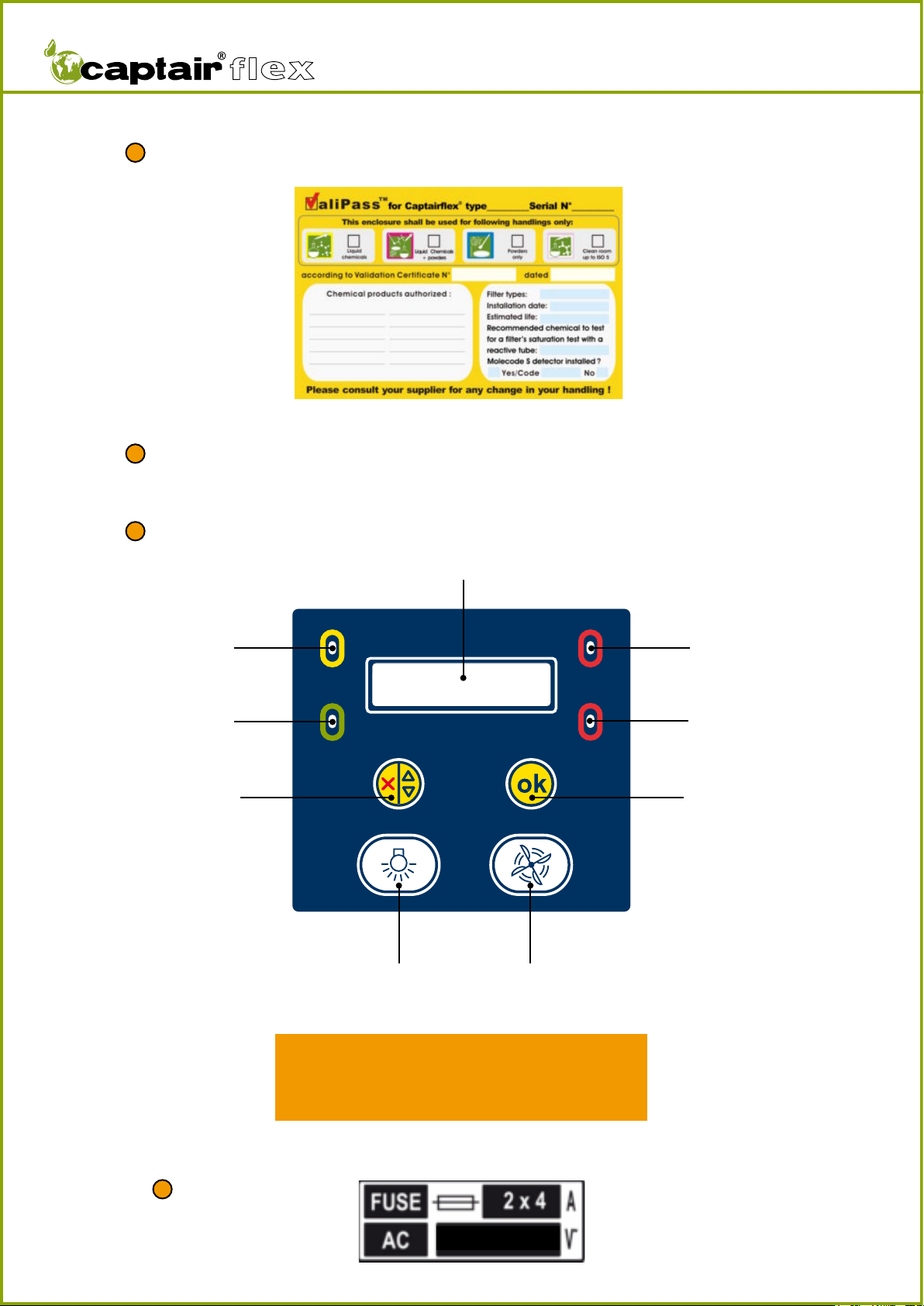

Valipass® form: Refer to the Valiquest® section for details.

Control panel

Sampling port for the manual filter saturation test or for an ambient air sensor when

the machine is equipped with the Molecode™ S option.

Yellow indicator light

Green indicator light

Red indicator light

Red indicator light

Digital display screen

Confirmation buttonNavigation button

Ventilation

switch

Internal light

switch

For information on the various scenarios related

to the triggering of the device’s indicator lights and

audible alerts, refer to the EVENT ALERTS section

of the FIRST START-UP chapter.

7Fuse tag.

100-240

User Manual

TM

9

Default screen display

Information related to the filters

Month and year during which

the main filter was installed

Number of fans installed

in the device.

Operating time of the device

based on the cycle setting of

the Timer™

Filter FANS: XX

MM/Year HH:MN

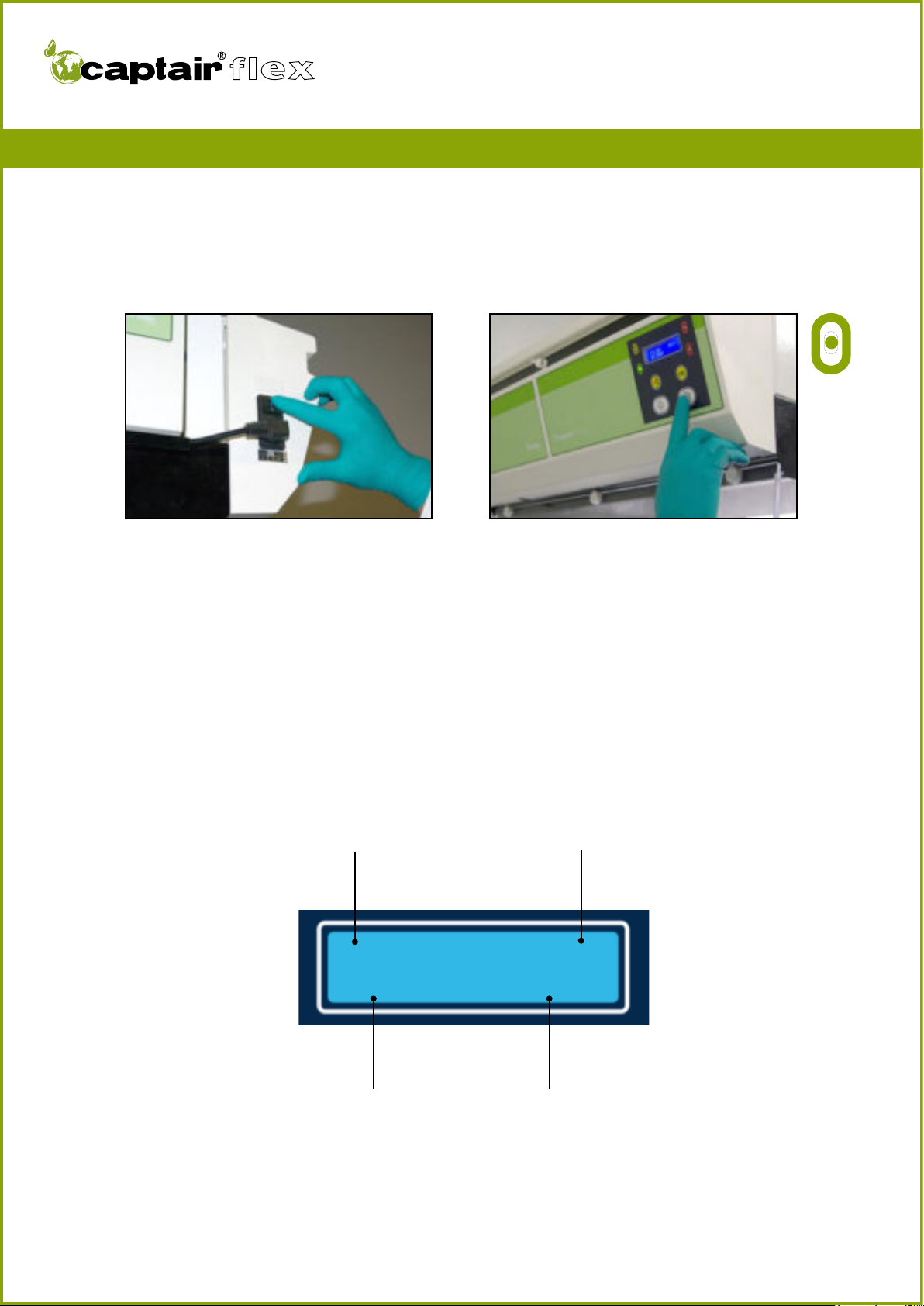

Turn on the device using the switch located on the left side of the control panel.

Activate the device’s ventilation system using the ventilation button located underneath

the digital display screen.

The green indicator light comes on and the screen displays the DEFAULT SCREEN DIS-

PLAY.

The Timer™ begins to count down based on its factory settings (60 hours).

You have carefully followed the steps described in the assembly instructions and your

Captair® Flex™ fume hood is ready to use.

FIRST START-UP

User Manual

TM

10

The Timer™

The Timer™ keeps track of the amount of time that your Captair® Flex™ fume hood

has been in operation in order to remind the user when it is necessary to carry out a

periodic filter saturation test.

The default setting (factory setting) is 60 hours (as required by NF X 15-211: 2009 stan-

dard).

An alarm will alert the user to check that the filter is still able to function properly.

A pre-warning alarm may go off between 0 and 10 hour(s) before the Timer™ alarm

(according to factory settings).

Activation / Deactivation:

It is possible to activate or deactivate the Timer™ and its pre-warning alarm.

To make use of this functionality please refer to the section on “Navigating the digital

display screen.”

In order to guarantee that your device functions properly and in order to ensure your

safety, your Captair® Flex™ fume hood is equipped with a monitoring system linked to

the air flow parameters and to the device’s Flex™ technology.

Event 1:

Fan control problem

Event conditions:

The fume hood does not reach the proper number of rotations per minute (RPMs) wi-

thin a period of ten seconds after the ventilation system has been started.

This section describes all of the audible and visual alerts triggered by the alarms included

in your Captair® Flex™ fume hood.

Solution:

Contact your maintenance service as quickly as possible.

FAN

CONTROL FAILURE

Display screen

Event alerts

Alarm type

Yellow indicator light on, constant

Intermittent audible alarm

User Manual

TM

11

Event 2:

Fan out of order

Event conditions:

The rotation speed of the fan is less than 700 RPM.

FAN

OUT OF ORDER

Display screen Alarm type

Solution :

Contact your maintenance service as quickly as possible.

Solution :

Press the navigation and confirmation buttons simultaneously and release them to deacti-

vate the alarm.

The red indicator light will stay on.

The concentration at the exhaust of a filter nearing its saturation point can build up very

quickly. Consider replacing the filter.

Event 3:

Solvent detected in the sampling chamber

Event conditions:

The detection limit of the Molecode™ S unit has been reached.

FILTER

NEAR END OF LIFE

Display screen Alarm type

Red indicator light on, constant

Continuous audible alarm

Yellow indicator light on, constant

Intermittent audible alarm

User Manual

TM

12

Event 4:

Solvent detected 2

Event conditions:

The detection limit of the Molecode™ S unit has been surpassed.

CHANGE

FILTER(S)

Display screen Alarm type

Solution :

It is necessary to replace the filter.

Please contact your maintenance service.

Solution :

Press the navigation and confirmation buttons simultaneously and release them to deacti-

vate the alarm.

Identify the source of the pollution.

Event 5:

Pollutant detected in the ambient air of the laboratory

Event conditions:

The ambient air sensor on the front detects that pollution is likely in the ambient air of

the laboratory.

LABORATORY

POLLUTION

Display screen Alarm type

Red indicator light on, constant

Continuous audible alarm

Red indicator light on, blinking

Continuous audible alarm

User Manual

TM

13

Event 7:

Pre-warning alarm maintenance

Event conditions:

If the Timer™’s pre-warning alarm is activated, this alarm is triggered when the counter’s

value is less than the pre-warning value.

FILTER TEST

H / MN

Display screen Alarm type

Solution :

Press the navigation and confirmation buttons simultaneously and release them to deacti-

vate the alarm.

Consider checking whether or not the filter is saturated.

Refer to the maintenance section of this manual.

Event 8:

Maintenance

Event conditions:

The value of the Timer™ is equal to zero.

FILTER

TEST

Display screen Alarm type

Solution :

Press the navigation and confirmation buttons simultaneously and release them to deacti-

vate the alarm.

Consider checking whether or not the filter is saturated.

Refer to the maintenance section of this manual.

Yellow indicator light on, blinking

Intermittent audible alarm

Red indicator light on, constant

Continuous audible alarm

User Manual

TM

14

DEFAULT SCREEN DISPLAY

Information related to the filters

Month and year during which

the main filter was installed

Number of fans

installed in the device

Operating time of the device

based on the cycle setting of

the Timer™

Filter FANS: XX

MM/Year HH:MN

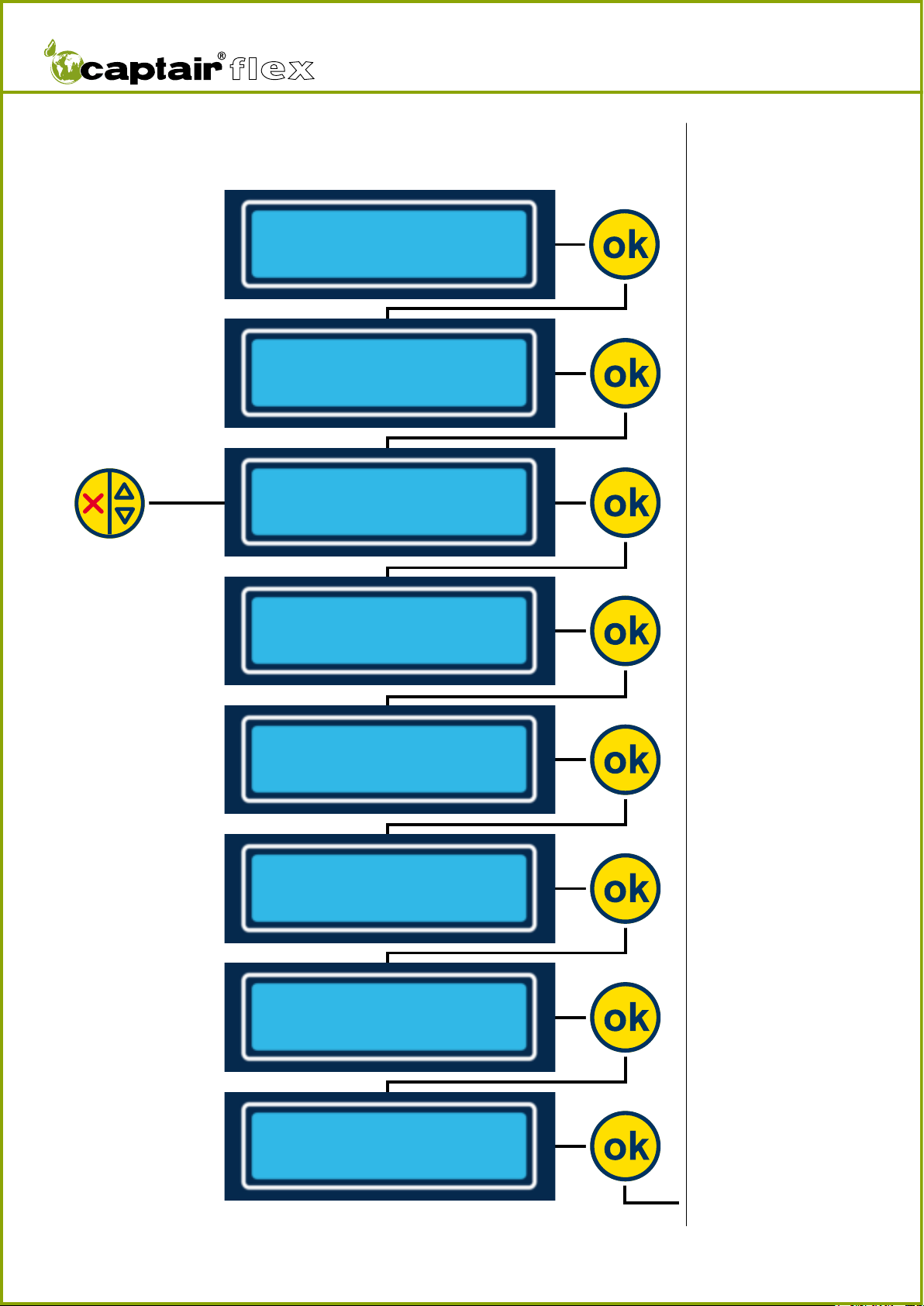

ACCESSING THE MENUS

To access the menus of the screen, press down

on the navigation and confirmation buttons

simultaneously.

The menus will appear when the buttons are

released.

NAVIGATING THE DIGITAL DISPLAY SCREEN

User Manual

TM

15

Notes:

Allows the user to view the sta-

tus of the fume hood. Press the

confirmation button to access

the contents of the menu.

Allows the user to modify the

parameters of the screen display

language.

Press the confirmation button to

access the contents of the menu.

Allows the user to update

information after testing for filter

saturation.

Press the confirmation button to

access the contents of the menu.

Allows the user to modify the

limit settings of the Molecode™

S detection sensor.

Press the confirmation button to

access the contents of the menu.

Allows the service engineer to

set the ventilation flow rate.

Protected by an access code.

Press the confirmation button to

access the contents of the menu.

Allows the user to activate or

deactivate the Timer™. Press the

confirmation button to access

the contents of the menu.

Allows the service engineer to

access the device’s configuration.

Protected by an access code.

Press the confirmation button to

access the contents of the menu.

Allows the user to exit the main

menu.

Press the confirmation button to

display the default screen display.

1 Main Menu

MAIN MENU

>Hood State

1-1

Hood State

>Set Language

1-2

Set Language

>Test filter

1-3

Test filter

>Set Threshold

1-4

Set Threshold

>Set Setpoint

1-5

Set Setpoint

>Set Timer

1-6

Set Timer

>Man. Menu

1-7

Man. Menu

>Exit

1-8

User Manual

TM

16

Notes :

This number corresponds to the

number of fans detected by the

device.

It may be between 1 and 4 de-

pending on the Captair® Flex™

model in question. (Refer to the

technical specifications listed at

the end of the manual.)

Indicates the presence or

absence of the Molecode™ S

option on your device.

This number indicates the

sensitivity on the Molecode™

S detection sensor included on

your device. If the device is not

equipped with a Molecode™, the

contents of this screen are not

visible.

RPM: rotations / minute.This

number indicates the rotation

speed of each fan. It may be

between 0 and 3000 depen-

ding on the Flex™ technology

installed in your device and on

the factory settings.The rotation

speed must be the same for each

fan installed, +/- 5%.

Display the Hood Stat menu.

1-1 Hood State

1-1-1

1-1-2

1-1-4

1-1-3-1

Threshold Sensor

Value : XXX

Number of fan

XX

RPM

01:XXXX 02:XXXX

03:XXXX 04:XXXX

Solvent Sensor

YES

MAIN MENU

>Hood State

1-1-3-2

Solvent Sensor

NON

User Manual

TM

17

By default the screen displays the

name of the factory-set naviga-

tion language. Other possible

display languages: French, Spanish,

German, and Italian.

Notes:

Allows the user to modify the

language displayed on the screen.

Confirm the chosen language to

save the selection.

Display the current navigation

language.

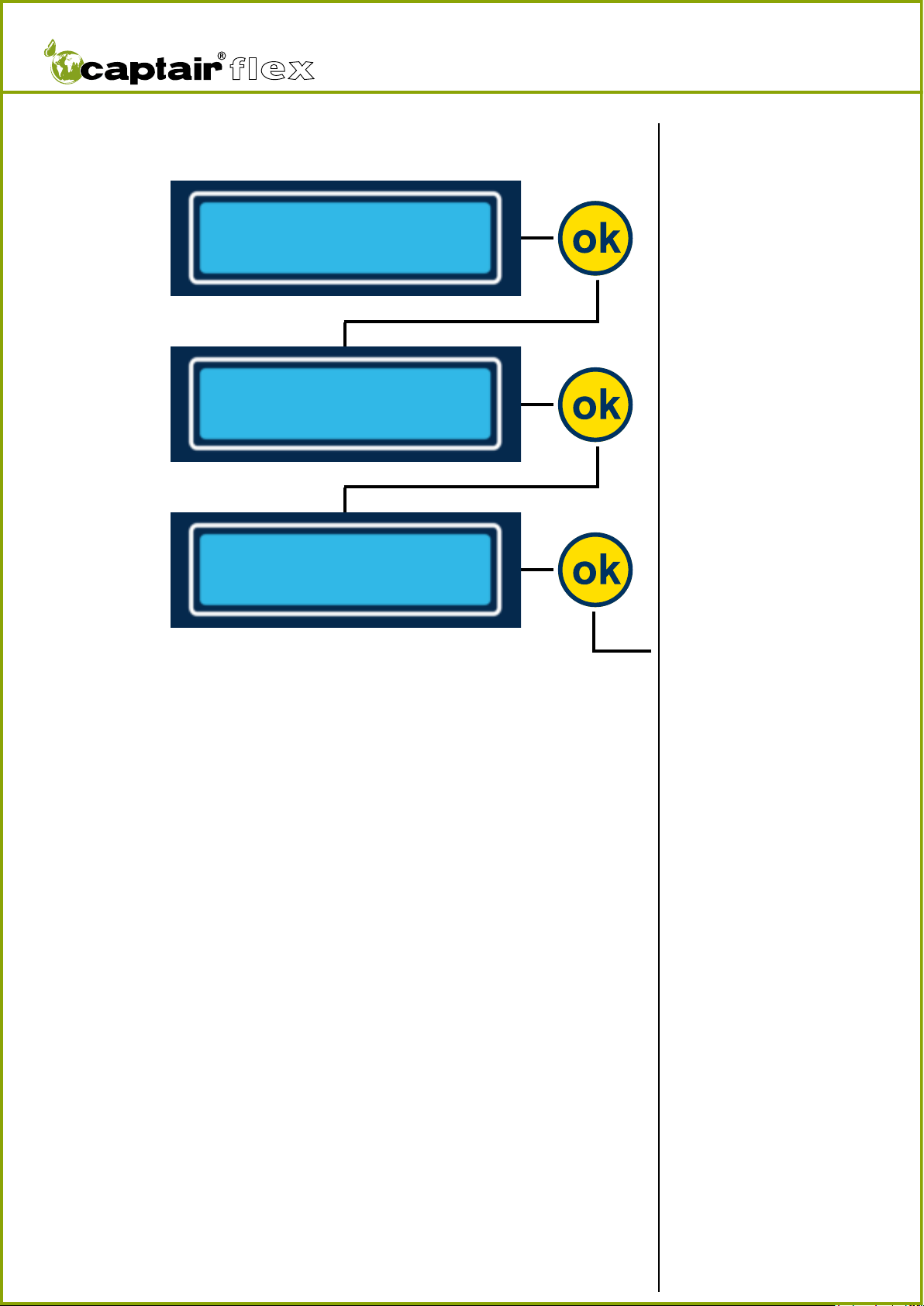

Display the Set Language

menu.

Display the Set Language

menu.

Confirm the chosen language to

save the selection.

Confirm the chosen language to

save the selection.

Confirm the chosen language to

save the selection.

Set Language

1-2

1-2-1

Actual Language

English

Change Language

English

Change Language

French

Change Language

Spanish

Change Language

German

Change Language

Italian

Hood State

>Set Language

1-2-2-1

1-2-2-2

1-2-2-3

1-2-2-4

1-2-2-5

User Manual

TM

18

Notes:

N.B.: accessing this menu

interrupts the ventilation

system of your device. It is

strongly recommended to

access this menu after the

filter saturation tests have

been performed. Press the

confirm button to proceed

to the next step.

Displays the sensitivity value

of the current sensor as sto-

red in the device’s memory

or previously modified.

If the Molecode™ S is not

installed on the device,

screens 1-3-5, 1-3-6, and 1-3-7

do not display.

Allows the user to adjust the

sensitivity value of the unit after

a new filter has been installed.

Scroll through the numbers using

the scroll button and confirm

each digit using the confirmation

button.

Confirm the previously selected

value.

Displays the month, year, and

operating time of the device after

a new filter has been installed in

the Manufacturer menu.

Parameter reset menu after a

new filter has been installed.

Allows the user to confirm

the installation date of the

new filter and to reset the

Timer™ if the Timer™ is ac-

tivated according to factory

settings. If the Timer™ is

not activated,“H:Mn” is not

displayed on the screen.

Allows the user to indicate the

new filter installation date.

Display the Test filter menu.

Test filter

1-3

1-3-1

Test filter

New filter

New filter

Month/Year H:Mn

Confirm ?

Month/Year H:Mn

Date : MM XX

YY XXXX

Threshold Sensor

Value : XXXX

Threshold Sensor

Value : XXXX

Confirm

Value

Set Language

>Test filter

1-3-7

1-3-6

1-3-5

1-3-4

1-3-3

1-3-2

Display the 1-3-2-1 menu

User Manual

TM

19

Notes :

N.B.:Accessing this menu inter-

rupts the ventilation system of

your device. Press the confirm

button to proceed to the next

step.

After verifying the condition of

the filter via a saturation test,

display the installation date and

operating time of this filter.

By pressing the confirm button,

the Timer™ is reset according to

the factory configuration if the

Timer™ is activated.

Display the Test filter menu.

Test filter

1-3

1-3-2-1

Test filter

Good Filter

Good Filter

Month/Year H:Mn

Confirm ?

Month/Year H:Mn

1-3-2-2

1-3-2-3

User Manual

TM

20

Notes:

N.B.: accessing this menu inter-

rupts the ventilation system of

your device. Press the confirm

button to proceed to the next

step. IMPORTANT: this menu

only appears if the device is

equipped with a Molecode™ S.

Displays the sensitivity value of

the Molecode™ S unit as confi-

gured in the factory or previously

modified. Scroll through the

numbers using the scroll button

and confirm each digit using the

confirmation button.

Allows the user to confirm the

selected value.

Display the Set Threshold

menu

Set Threshold

1-4

1-4-1

Threshold Sensor

Value : XXXX

Confirm XXXX ?

1-4-1

Test filter

>Set Threshold

This manual suits for next models

3

Table of contents

Other erlab Laboratory Equipment manuals