OPERATION and MAINTENANCE

B20HPC-SKE-V25 1 of 75

Chino, CA 91710

reedpumps.com

INTRODUCTION............................................................................................................. 2

WARRANTY.................................................................................................................... 3

WARRANTY CLAIM FORM....................................................................................................................... 4

SAFETY .......................................................................................................................... 5

SAFETY ALERT SYMBOLS AND SIGNAL WORDS ................................................................................ 5

LOCKOUT /TAGOUT ............................................................................................................................... 6

GENERAL SAFETY GUIDELINES............................................................................................................ 6

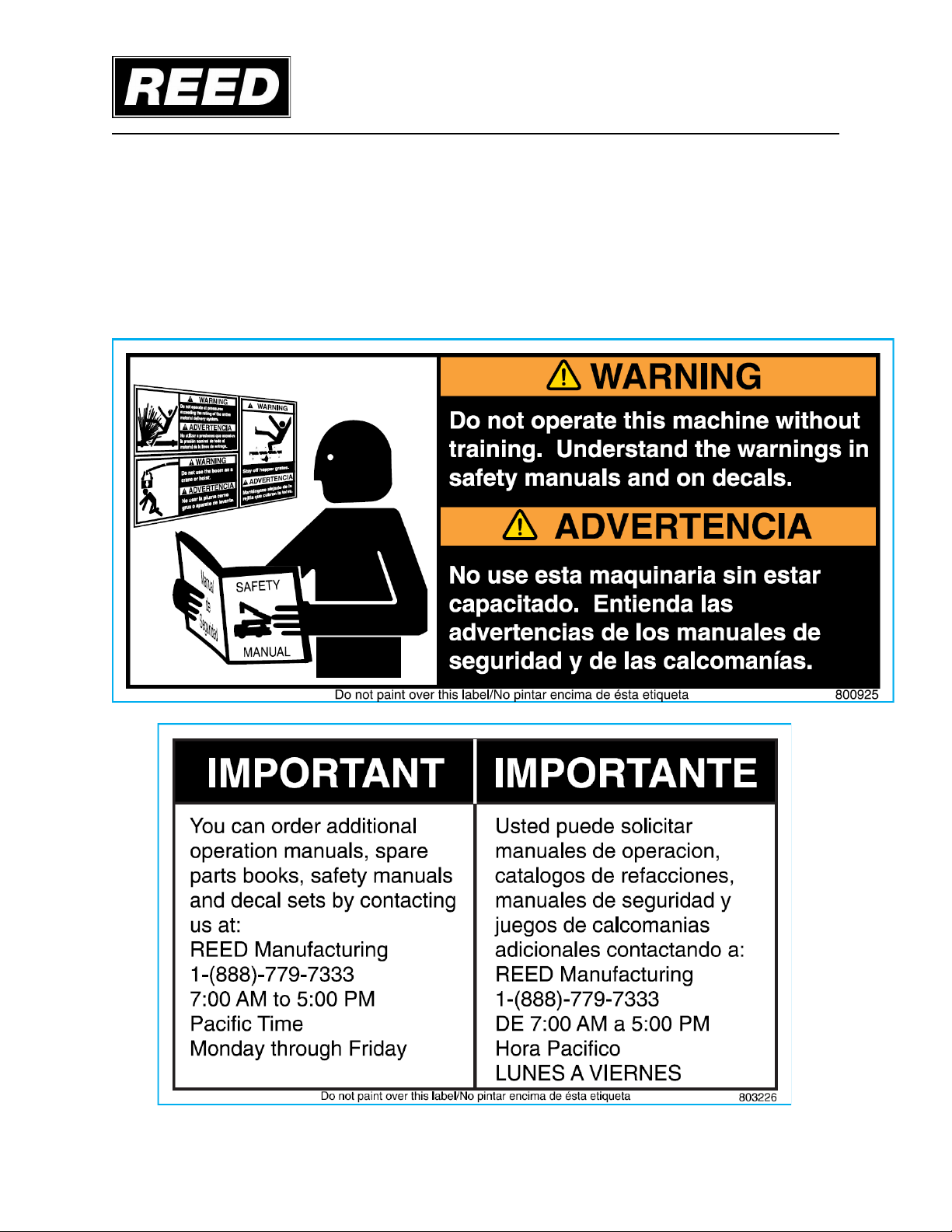

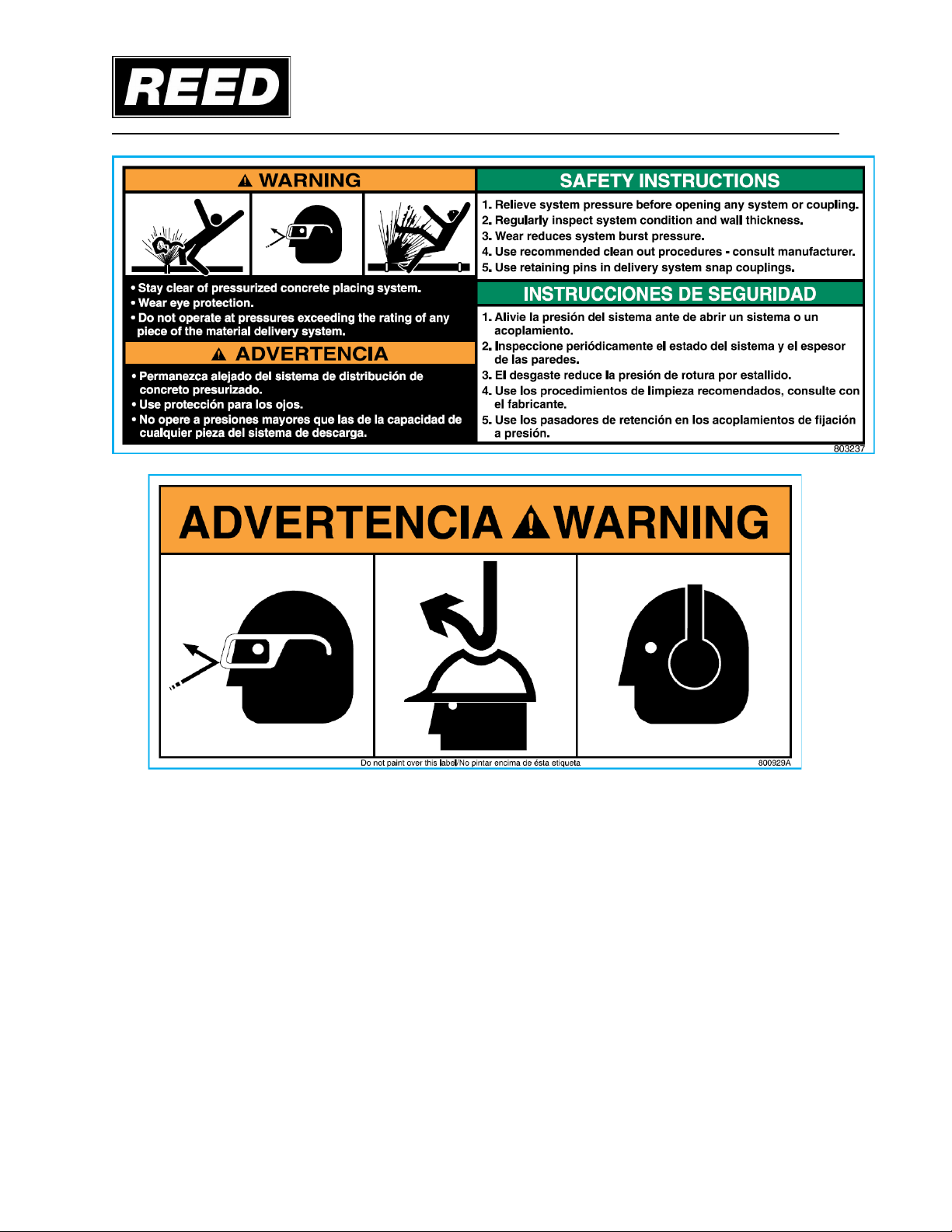

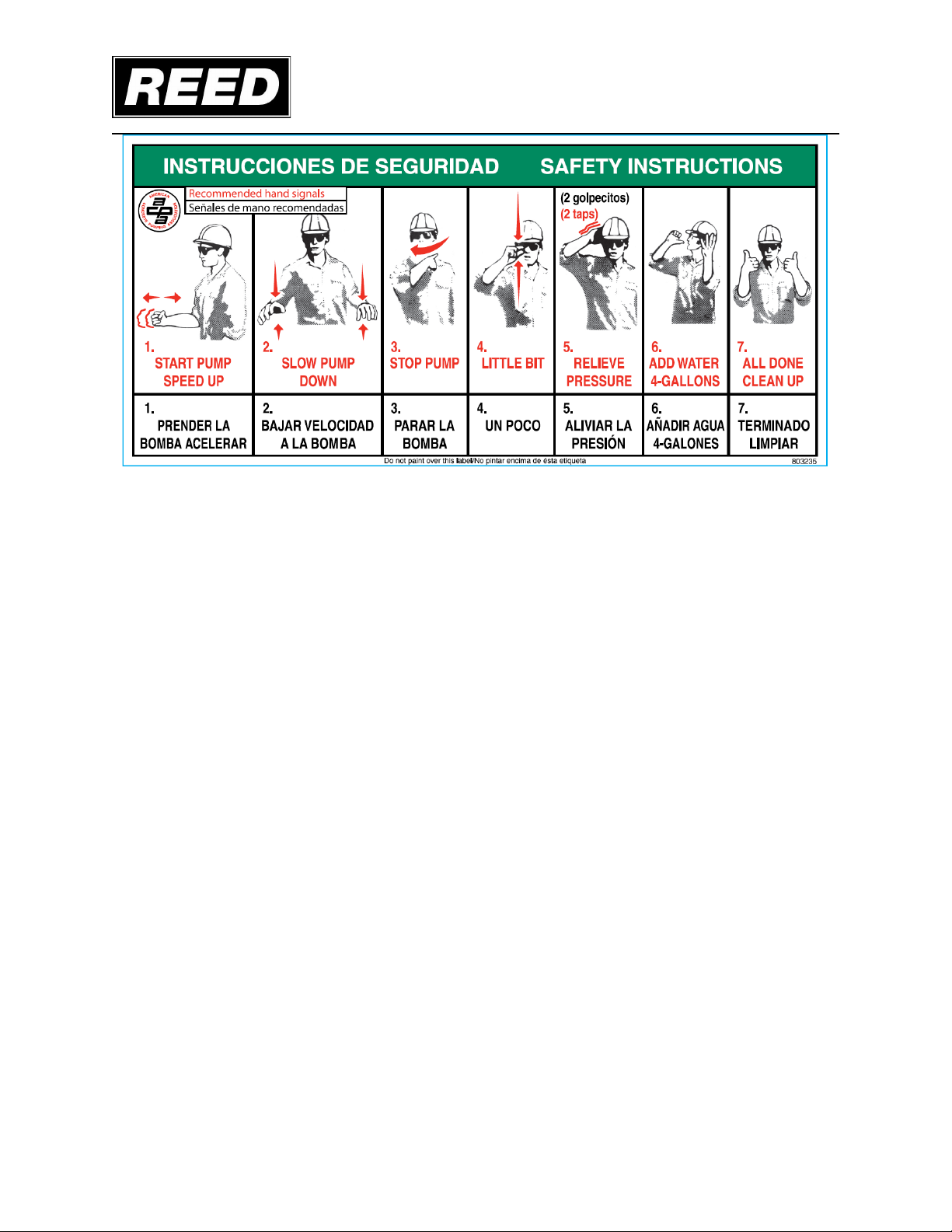

SAFETY DECALS ..................................................................................................................................... 7

OPERATION ................................................................................................................. 17

OPERATOR QUALIFICATIONS ............................................................................................................. 17

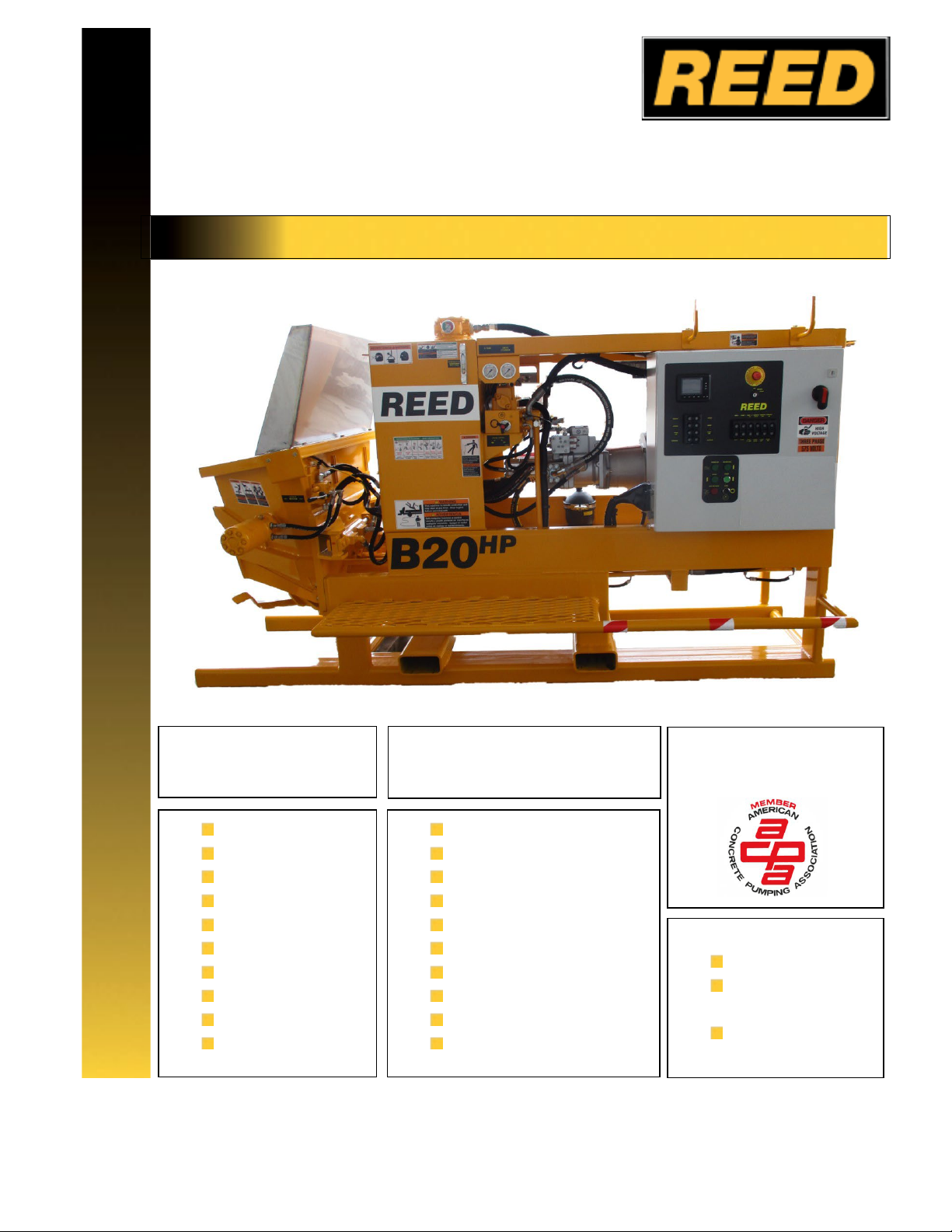

PRODUCT DESCRIPTION ..................................................................................................................... 18

HYDRAULIC SYSTEM DESCRIPTION .................................................................................................. 19

B20 SKE ELECTRIC FAMILIARIZATION................................................................................................ 26

MAIN ELECTRIC CONTROL BOX FAMILIARIZATION .......................................................................... 27

CONTROLS ............................................................................................................................................ 29

PLC MAIN CONTROLS...................................................................................................................................29

PLC MAIN CONTROLS...................................................................................................................................30

SCREEN OPERATION INSTRUCTIONS ........................................................................................... 35

REMOTE CONTROL FAMILIARIZION............................................................................................................44

OMINEX RADIO REMOTE..........................................................................................................................45

PRIMING ................................................................................................................................................. 48

PUMPING................................................................................................................................................ 49

CLEANING .............................................................................................................................................. 51

MAINTENANCE ............................................................................................................ 52

RECOMMENDED MAINTENANCE PRACTICES................................................................................... 52

GENERAL MAINTENANCE AREAS ....................................................................................................... 54

LUBRICATION ........................................................................................................................................ 56

ADDING HYDRAULIC FLUID.................................................................................................................. 62

COMPONENT REPLACEMENT ............................................................................................................. 67

S-TUBE, WEAR RING, AND WEAR PLATE....................................................................................... 67

PUMP MAINTENANCE SCHEDULEAND CHECKLISTS ...................................................................... 68

NOTES.......................................................................................................................... 75