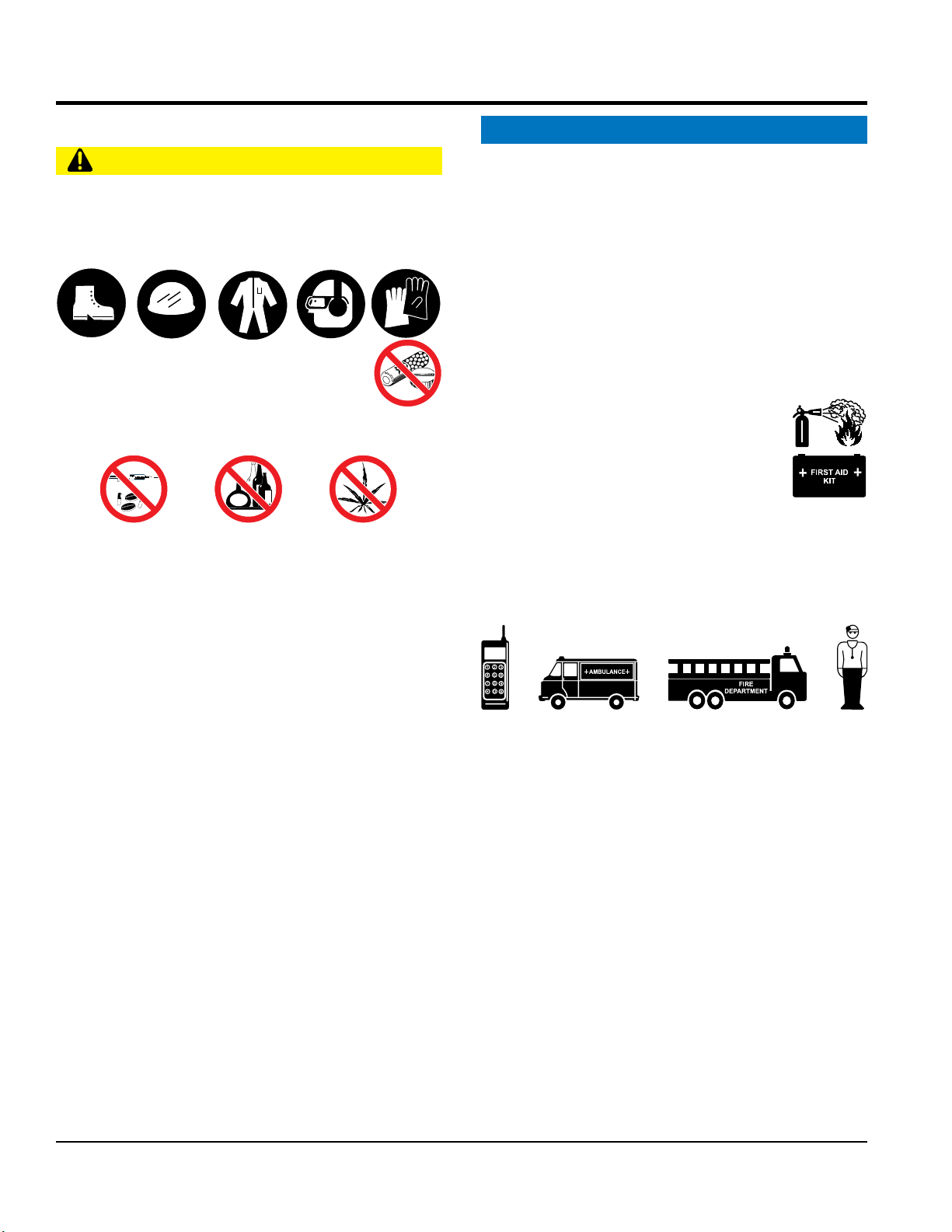

SAFETY INFORMATION

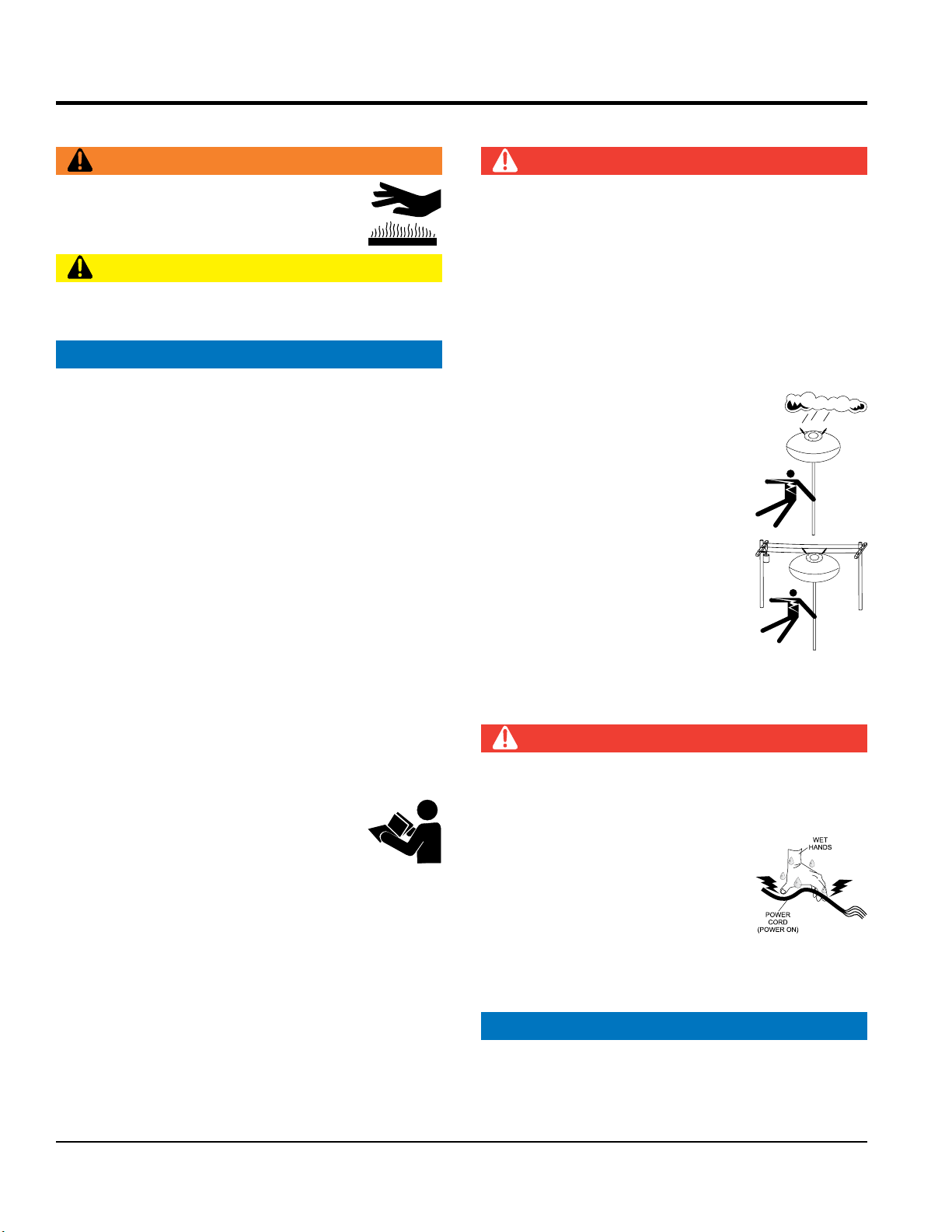

To prevent serious burns, touch

or unzip the balloon envelope when the

lamp is on.

CAutiON

ALWAYS keep the balloon away from sharp objects and

excessive amounts of heat.

NOTICE

To prevent balloon deformation, use lighting

system in strong winds.

place the balloon inside its protective cover

until the lamp has had a sufficient amount of time to cool

down. This will prevent the balloon’s nylon cover from

being burned (touching the lamp surface).

ALWAYS place the balloon inside its protective cover

after each use. This will prolong the life of the balloon

material, keeping it protected from harsh environmental

elements.

Replace balloon immediately if damaged. A damaged

balloon will not inflate properly, and may become more

damaged by touching the hot lamp surface.

use excessive force when zipping and unzipping

the balloon. Be gentle with the zipper mechanism. If the

zipper is broken, the balloon will become unusable.

If using a generator to power lighting system,

refer to applicable generator manual safety

information section.

Lighting system is equipped with a ground pin on the

power plug. For your protection, ALWAYS

grounding path.

insert the AC power plug into a

2-prong receptacle to operate lighting system.

When applying power to the lighting system,

ALWAYS

connect the AC power plug to a 3-prong receptacle that

is grounded. The possibility exists of

if the lighting system is

not grounded.

operate lighting system or

handle any electrical equipment while

standing in water, while barefoot, while

hands are wet or in the rain.A dangerous

could occur, causing

ALWAYS make sure the area above

the lighting system is open and clear

of overhead power lines and other

obstructions. Contact with overhead

power lines or other obstructions could

result in equipment damage,

let power cords or cables

use or

for cuts in the insulation

grab or touch a live power

cord or cable with wet hands. The

possibility exists of

Make sure power cables are securely connected.

Incorrect connections may cause

damage to the lighting system.

NOTICE

ALWAYS

make certain that proper power or extension

cord has been selected for the job. See Cable Selection

Chart in this manual.