THERMA Trapzilla TZ-1826 Installation and operating instructions

A THERMACO® Technology

For additional information on Trapzilla or other Thermaco products,

please visit www.trapzilla.com or call at 1-800-633-4204.

Copyright ©2018 Trapzilla®Thermaco, Inc. • P.O.Box 2548 • Asheboro, NC 27204

Toll Free: (800) 633-4204 • Phone: (336) 629-4651 • Fax: (336) 626-5739

Installation & Maintenance Instructions

For Trapzilla®TZ-1826

Part# MNL-TZ-1826

AEF

*Please consult Thermaco, Inc. for specic models tested,

certied and/or listed by these organizations.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANG LE PRO JECTION

®

Conforms to ASME Standard

ASME A112.14.3-2000

Please consult Thermaco, Inc. for specic models tested,

certied and/or listed by these organizations.

®

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 3

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 2

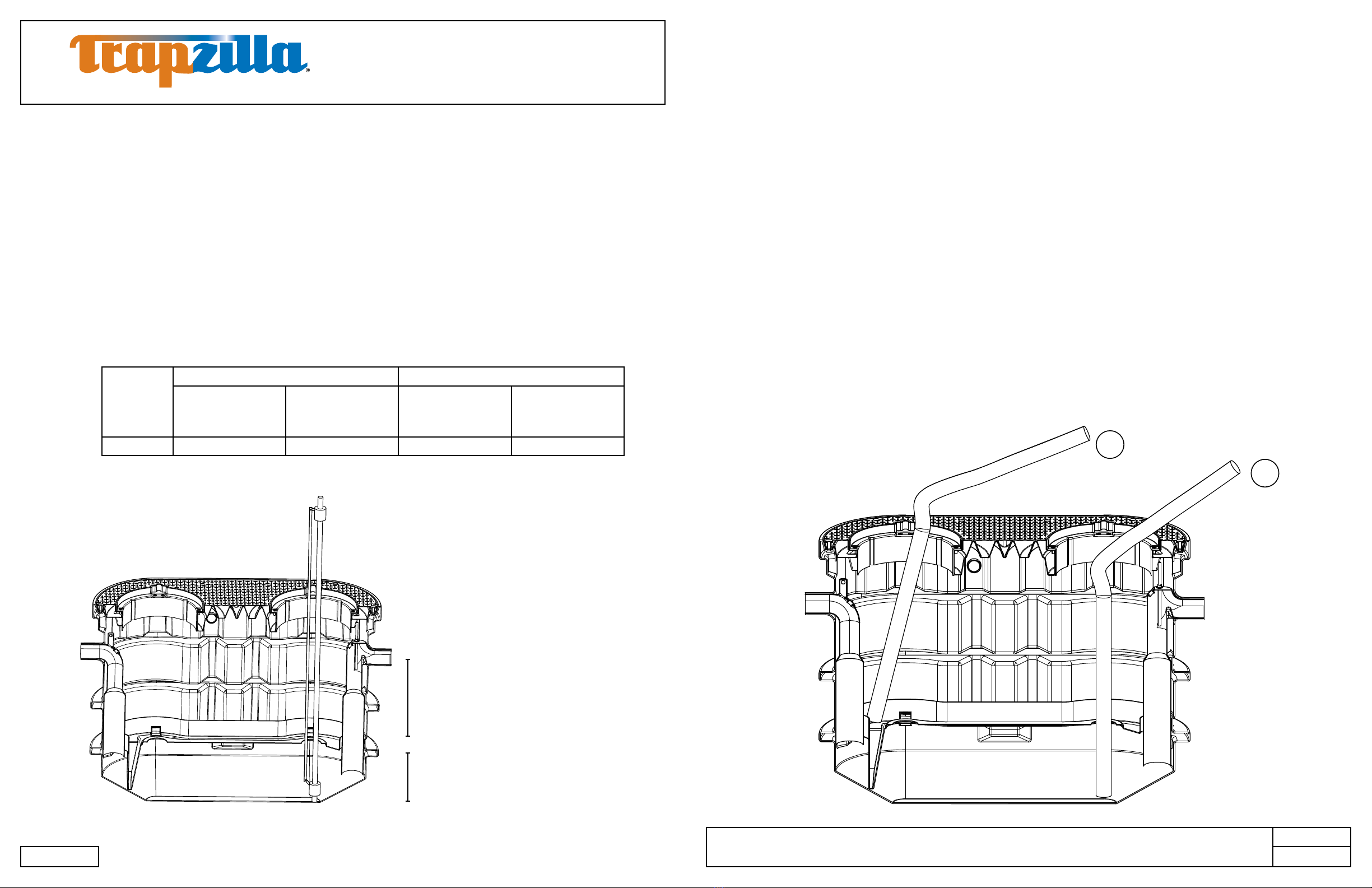

1. System Overview

The Thermaco, Inc. Trapzilla®Supercapacity

Grease Interceptor collects free-floating

grease & oils contained in kitchen drain water

ows. As most food service facility managers

already know, grease buildup inside a

building’s grease containment system is a

major cause of problems due to exterior drain

line blockages. These problems jeopardize

normal operations as well as create health

and safety hazards within the facility itself.

The proper installation of a Trapzilla®

Supercapacity Grease Interceptor can

reduce or eliminate grease problems and

costly sewer surcharges and nes through

efcient separation and retention of free-

oating grease & oils.

The Trapzilla offers patented at separation

curve technology. This means that the unit does not lose grease separation efciency as it lls with

retained grease. Thus, the Trapzilla stores large quantities of grease without losing efciency. The

unique compact design of the Trapzilla allows for installation into most facilities. Options are available

that enable a Trapzilla unit to be installed on the oor, suspended from the ceiling or in-ground outside

the facility.

Trapzilla units are designed to treat high ows of kitchen drainwater with large grease storage capacity

within a small footprint unit. These units are easy to maneuver into position and just as easy to plumb.

Hydromechanical grease interceptors, automatic recovery units, grease removal devices and other

similar plumbing devices receiving kitchen ows from sinks, oor drains, woks and other food bearing

sources may generate odors. There are many factors inuencing odor evolution and dissemination.

These include room ventilation, kitchen menu, ambient temperatures, ware washing practices, grease/oil

input, daily input uid volume, sanitizers, installation plumbing design and product maintenance/upkeep.

Odors are usually prevented by good area ventilation, frequent uid inputs, good product maintenance

practices and proper product installation. Additional steps, including aeration, chlorination, pH control,

improved area ventilation and additional maintenance may be needed at some sites.

*Devices formerly referred to as grease traps are now called hydromechanical grease interceptors.

Contents

1. System Overview.................................................................................................................................... 3

2. Models and Options................................................................................................................................ 4

2.1 Models ........................................................................................................................................... 4

2.2 Options .......................................................................................................................................... 5

3. Plumbing Installation .............................................................................................................................. 6

3.1 Plumbing Considerations Prior to Installation................................................................................ 6

3.1.1 Locating the Unit................................................................................................................... 6

3.1.2 Inlet/Outlet Piping ................................................................................................................. 6

3.1.3 Flow Controls........................................................................................................................ 6

3.1.4 Venting the Outlet ................................................................................................................. 6

3.1.5 High Head Height Applications Over Six (6) Feet (1.95 m) .................................................. 6

3.2 Vessel Vent Connection.................................................................................................................. 7

3.3 Plumbing Congurations ................................................................................................................ 8

3.3.1 One TZ-1826 ......................................................................................................................... 8

3.3.2 Installing Multiple Trapzilla Units in Parallel........................................................................... 9

3.3.3 Installing Multiple Trapzilla Units in Series............................................................................. 10

4. Above-Ground Installation ...................................................................................................................... 11

4.1 Components for Above-Ground Installations.................................................................................. 11

4.2 Instructions for Assembling and Attaching External Brace ............................................................. 12

4.3 Instructions for Installing Multiple Trapzilla Units Above-Ground.................................................... 12

4.3.1 Installing TZ-1826-SSA with TSS-95-SSA in Series .............................................................. 12

4.3.2 Construction of Riser for TSS-95-SSA installation in series with TZ-1826-SSA.................... 13

4.3.3 Installing Multiple TZ-1826-SSA in Series ............................................................................. 13

4.3.4 Installation of Pipe Hangers with Above-Ground Units .......................................................... 14

5. In-Ground Installation Instructions.......................................................................................................... 15

5.1 Single TZ-1826 Installed In-Ground ............................................................................................... 15

5.2 TZ-1826 with Optional ECA-TZ-29 Extension Collars .................................................................... 16

5.3 Concrete Specications for In-Ground Installation ......................................................................... 17

5.4 Concrete Calculations for TZ-1826 Models/Components* ............................................................. 17

5.5 Trimming and Setting the ECA-TZ-18 Single-Piece Extension Collar ............................................ 18

6. Unit Maintenance.................................................................................................................................... 20

6.1 Measuring Grease/Solids Levels.................................................................................................... 20

6.2 Pumping/Servicing Unit .................................................................................................................. 21

7. Limited Warranty and Remedy ............................................................................................................... 22

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 5

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 4

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PROJEC TION

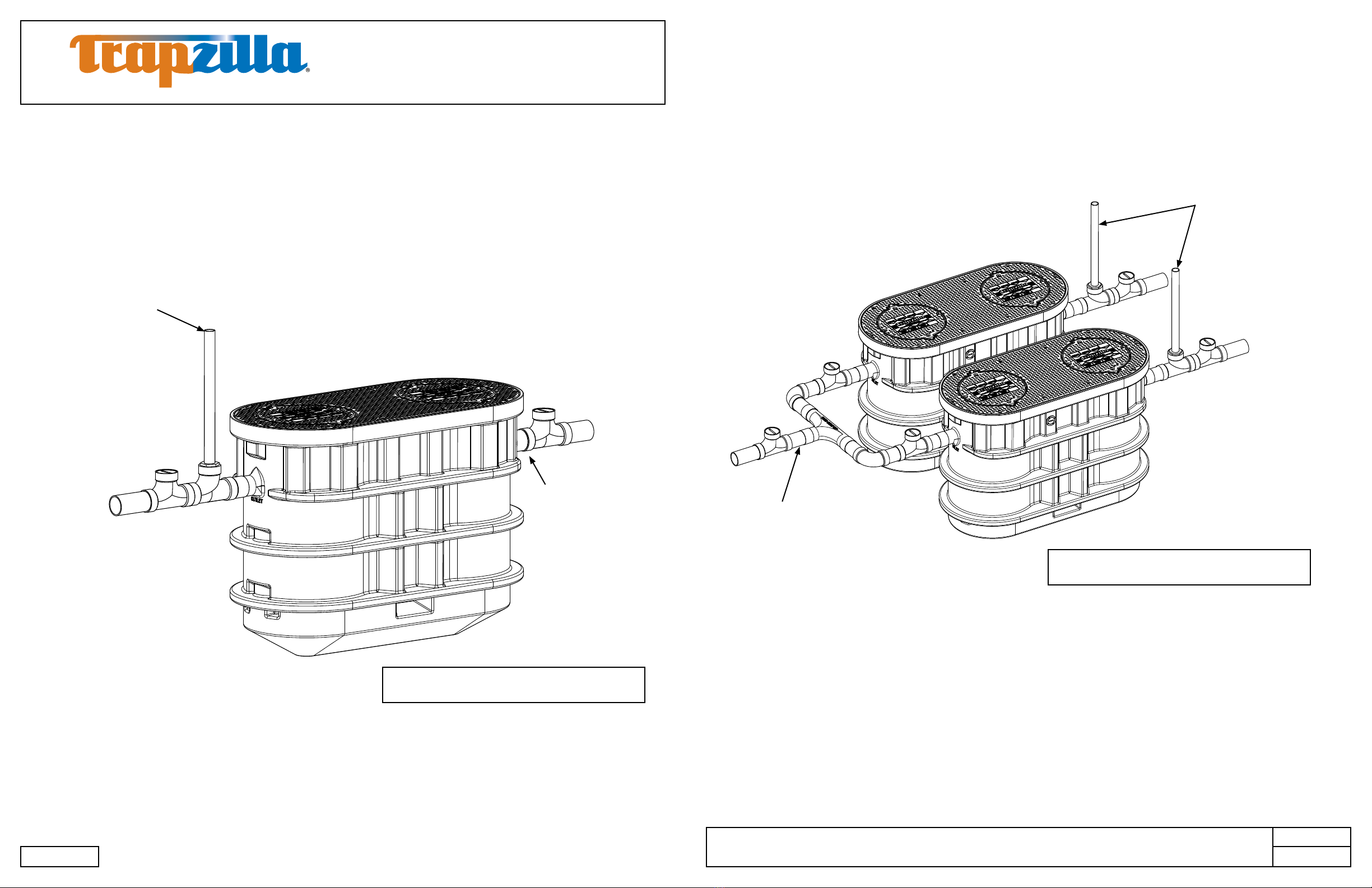

TZ-1826

1,826 pounds of grease storage, PDI and ASME rated

at 100 gpm. Equipped with 4” inlet/outlet, 2” vessel vent

connection, and 4” Low-Head Flow Control Accessory to

limit ow to 100 gpm.

Comes with: Extension Collar Adapter Lid Assembly with

two 18” tall extension collars and two 22” diameter lids.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739

Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO.

C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PROJECT ION

TZ-1826-SSA

1,826 pounds of grease storage, PDI and ASME rated

at 100 gpm. Equipped with 4” inlet/outlet, 2” vessel vent

connection, and 4” Low-Head Flow Control Accessory to

limit ow to 100 gpm.

Comes with: Extension Collar Adapter Lid Assembly with

two 18” tall extension collars, two 22” diameter lids,external

brace (not pictured) and SSA-1826 Support Stand.

*Models available with 6” Inlet/Outlet, add sufx -6 to model.

2. Models and Options

Thermaco offers different models and options specically designed to assist the owner/installer meet

site conditions while complying with local pretreatment and plumbing code.

2.1 Models

2.2 Options (Some options must be purchased separately)

FTCA-22

Optional 22” diameter cover available for

In-Ground installations. Provides a non-slip,

diamond patterned aluminum replacement for

the standard STC-22 cover. Each TZ-1826

would require two (2) FTCA-22 covers.

SSA-1826

Support Stand for TZ-1826 for Above-Ground

Installations. Must be fully supported, not to

be installed over grates.

*Included with TZ-1826-SSA Models

ECA-TZ-29

(purchase separately)

Optional, eld-modiable extension

collars available to provide

additional depth for existing kitchen

drainage piping.

• TZ-1826-ECA Models ship with

two (2) built-in 0-18” extension

collars.

• ECA-TZ-29 adds 0-29” depth

to -ECA model.

• Contact Thermaco before

installing any Trapzilla more

than 60” below grade from

center of outlet pipe or in

location where water table will

ever rise above bottom of unit.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PROJE CTION

0-18” Built-In

Extension ECA-TZ-29

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO .

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PROJE CTION

21.13 in

[53.7 cm]

R10.56 in

[26.8 cm]

R11.56 in

[29.4 cm]

1.50 in

[3.8 cm]

23.10 in

[58.7 cm]

ANGLE STIFFENERS

Bottom View

Top View

Side View

DIAMOND PLATE SURFACE

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PROJ ECTION

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 7

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 6

3. Plumbing Installation

3.1 Plumbing Considerations Prior to Installation

3.1.1 Locating the Unit

The system should be visible and easily accessible for maintenance and inspection. Options are available

to install the Trapzilla in a basement, suspended from a ceiling or in-ground in an exterior location. Make

sure adequate room is provided around the unit to allow easy access for a pump truck operator. Make

sure the height above the Trapzilla access cover is enough to properly service the system.

3.1.2 Inlet/Outlet Piping

The inlet and outlet piping connections require exible sleeve pipe couplings. Keep outlet piping as

straight as possible. Thermaco, Inc. recommends installation of Two-Way Cleanouts on both the Inlet and

Outlet of Trapzilla Interceptors and Solids Separators in accordance with all applicable laws, regulations

and codes. These cleanouts should match the size of the Inlet and Outlet Piping (i.e. for 4” Inlet/

Outlet piping, a 4” cleanout should be used). Use only “sweep” connections. Do not reduce the pipe

sizing on the outlet piping. Do not install “P” trap on outlet connection of system. (Note: The system

already has a internal gas trap)

3.1.3 Flow Controls

Trapzilla systems are supplied with a Low-Head Flow Control module (LHFC). This should be connected

to the inlet of the Trapzilla unit in situations where ow rate needs to be restricted to the ASME rated

ow or when vented ow control is required by local code.

3.1.4 Venting the Outlet

An outlet vent or approved air admittance valve of at least 1/2 the diameter of the system’s outlet

connection must be present as close as possible to the Trapzilla outlet to prevent possible siphonage

problems. The Vent on the Outlet piping is to be installed in accordance with all applicable laws,

regulations and codes. Failure to provide a vent for the system voids Thermaco’s Limited Warranty for

the system.

3.1.5 High Head Height Applications Over Six (6) Feet (1.95 m)

For installations where there is head height of greater than 6 feet (1.95 meters), Thermaco, Inc.

recommends installation of a code-approved Vented Flow Control Assembly (Thermaco VFCA not

included with Trapzilla).

Note: Drawing for reference only. Equipment must be installed in compliance with all applicable laws, regulations

and codes, including plumbing codes. Installation should be performed by a qualied plumber.

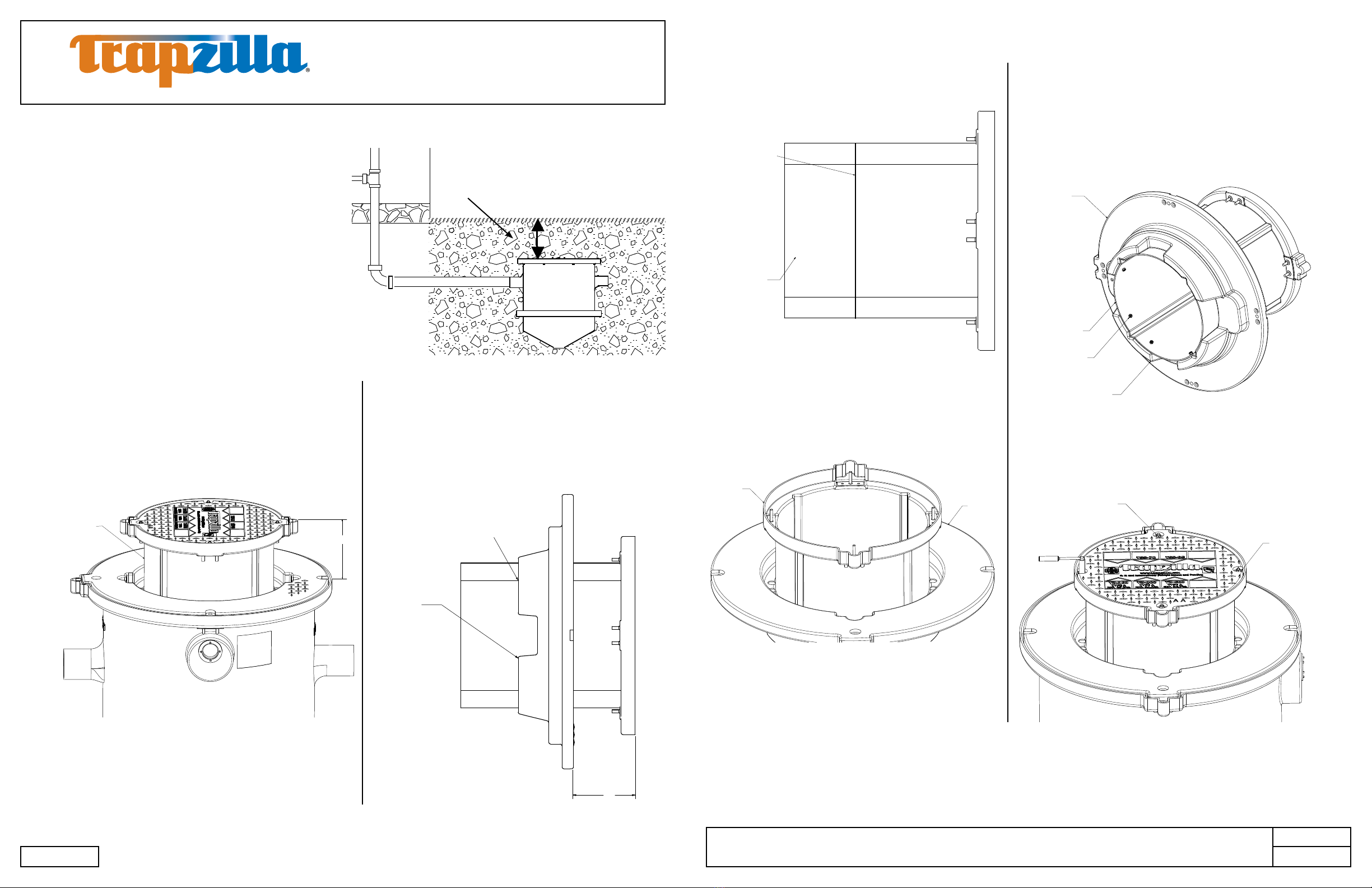

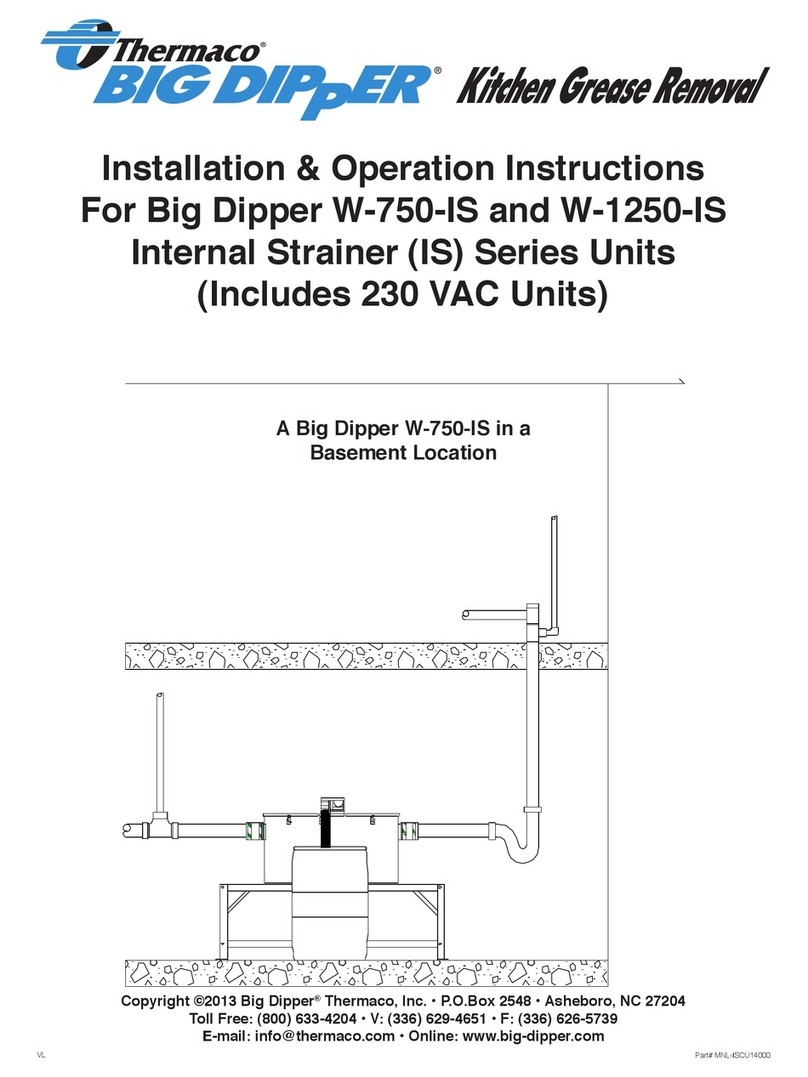

3.2 Vessel Vent Connection

Venting of the Trapzilla tank is recommended by the manufacturer and required for in-door installations.

• Vent the tank through the provided 2” NPT threaded connector on the side of the tank (This vent may

be located above the outlet or on the side of the tank depending on model).

• Remove and discard the plug and connect appropriate vent lines as indicated below (for 2” vent

connection, use 2” pipe).

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANG LE PROJ ECTION

Vessel Vent Connection

Can be connected to the outlet vent,

facility vent, or independently vented to

atmosphere

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 9

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 8

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PRO JECTION

3.3 Plumbing Congurations

3.3.1 One TZ-1826

Each Trapzilla unit is shipped with a Low Head Flow Control module (see LHFC box for additional

instructions). When applicable, this needs to be installed to the inlet of the Trapzilla and connected to

a code-approved air intake. Thermaco, Inc. recommends installation of Two-Way Cleanouts on both

the Inlet and Outlet of Trapzilla® in accordance with all applicable laws, regulations and codes. These

cleanouts should match the size of the Inlet and Outlet Piping (i.e. for 4” plumbing, a 4” cleanout should

be used). A Vent on the Outlet piping is also to be installed in accordance with all applicable laws,

regulations and codes.

*Use a Two-Way Cleanout before and after all

Trapzilla Installations

Outlet

Inlet

*Cleanout

*Cleanout

Outlet Vent

(Connect to

facility vent)

Note: Drawing for reference only. Equipment must be installed in compliance with all applicable laws, regulations

and codes, including plumbing codes. Installation should be performed by a qualied plumber.

Low-Head Flow Con-

trol (not pictured) to

be installed as close

as possible to inlet

when necessary.

3.3.2 Installing Multiple Trapzilla Units in Parallel

Trapzilla Grease Interceptors should be installed in parallel with a Trapzilla Flow Splitter (MFSH-44 or

MFSH-66) diverting the ow. Place Two-Way Cleanouts before, between and after the units as shown

below, including before and after the ow splitter. Make sure to connect an outlet vent after each Trapzilla

Grease Interceptor. A Low Head Flow Control (LHFC) is shipped with each unit, and if needed should

only be installed after the rst Cleanout and before the Flow Splitter.

*Use a Two-Way Cleanout before and after all

Trapzilla Installations

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PRO JECTION

Outlet

Inlet

*Cleanout

*Cleanout

Outlet Vents

(Connect to

facility vent)

Low-Head Flow Con-

trol (not pictured) to

be installed as close

as possible to inlet

when necessary.

*Cleanout

*Cleanout

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 11

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 10

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PRO JECTION

3.3.3 Installing Multiple Trapzilla Units in Series

Alternatively, two Trapzilla Grease Interceptors, Solids Separators or a combination may be installed in

series. A single Trapzilla Solids Separator and Trapzilla Grease Interceptor should always be installed

in series. Place Two-Way Cleanouts before, between and after the units as shown below. Make sure

to connect an outlet vent after the Trapzilla Grease Interceptor. A Low Head Flow Control (LHFC) is

shipped with each grease interceptor and should only be installed after the rst Cleanout and before

the rst grease interceptor.

*Use a Two-Way Cleanout before and after all

Trapzilla Installations

Outlet

Inlet

*Cleanout

*Cleanout

Outlet Vents

(Connect to

facility vent)

Low-Head Flow Control (not

pictured) to be installed as

close as possible to inlet of

rst grease interceptor.

*Cleanout

Note: Drawing for reference only. Equipment must be installed in compliance with all applicable laws, regulations

and codes, including plumbing codes. Installation should be performed by a qualied plumber.

The SSA-1826 Support Stand is a one-piece assembly with a conical center that sits on the oor.

It does not add appreciable height to the assembly.

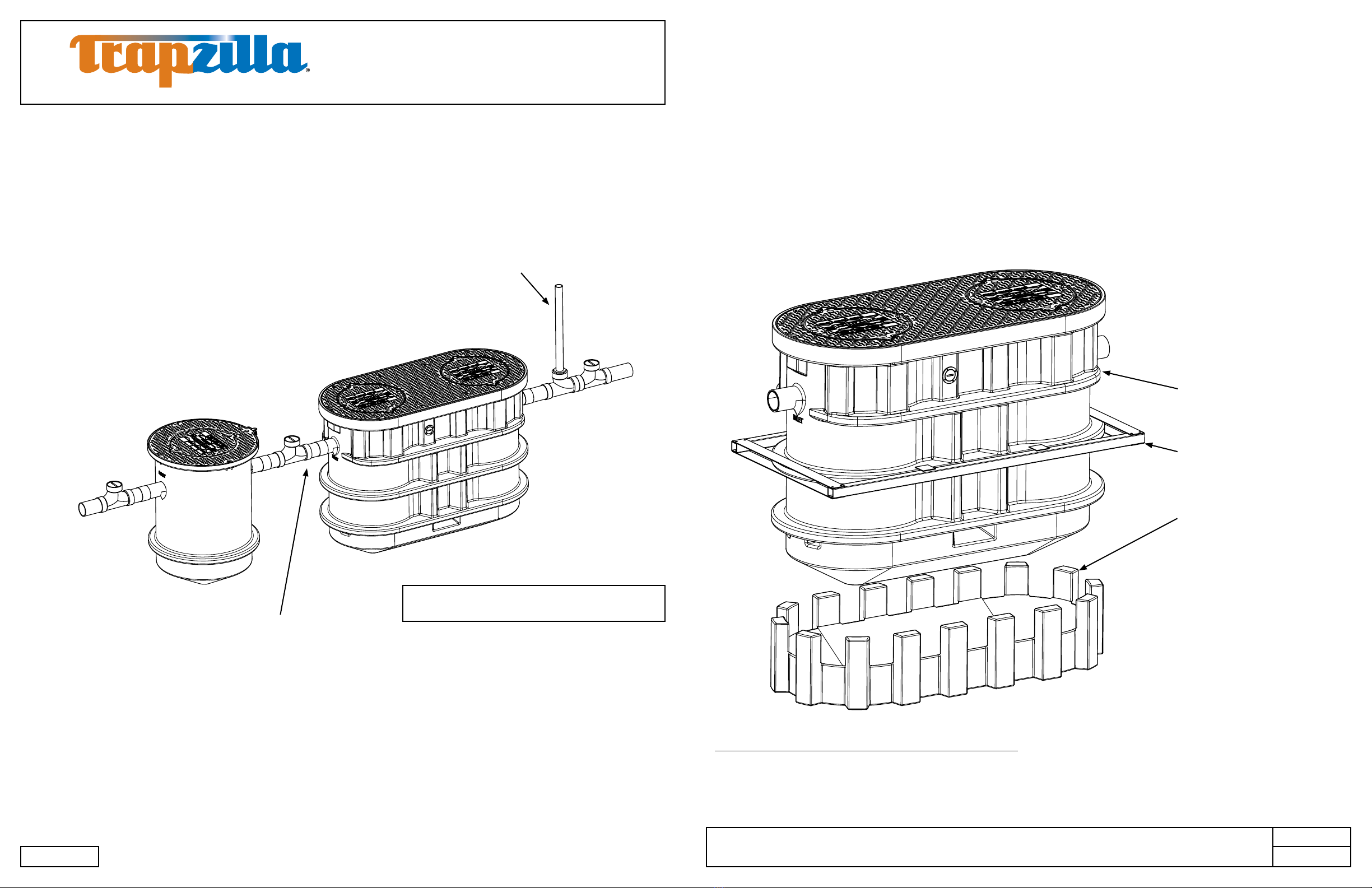

4. Above-Ground Installation

4.1 Components for Above-Ground Installations

Using a model-specic Support Stand, a Trapzilla unit may be installed directly on top of the oor in a

location such as a basement or mechanical room.

TZ-1826-SSA comes with SSA-1826 and external brace for above-ground installations. All TZ-1826

units come with built-in 18” Risers which must be cut down and secured in eld.

The External Brace must be installed in above-ground installations or the warranty will be voided.

NOTE: SUPPORT STAND

MUST BE INSTALLED OVER

A CONTINUOUS SURFACE.

NON-CONTINUOUS

SURFACES SUCH AS GRATES

ARE NOT SUITABLE FOR

SUPPORT.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANG LEPR OJECTION

TZ-1826

External Brace

(installation instructions on

next page)

SSA-1826

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 13

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 12

4.3.2 Construction of Riser for TSS-95-SSA installation in series with TZ-1826-SSA

For the installation of a TSS-95-SSA prior to the TZ-1826-SSA, a riser must be constructed to raise the

smaller unit by 8” and provide full support for the weight of the interceptor and its contents.

4.3.3 Installing Multiple TZ-1826-SSA in Series

When installing multiple Trapzilla units in series, the change in elevation from the inlet to the outlet of a unit

requires that each preceding unit be installed 1.5” higher than the unit after it. For above-ground units,

pressure treated plywood may be placed fully beneath the support stand to create the height difference.

All installations inside of a building must have a vessel vent installed and be piped to atmosphere.

4.2 Instructions for Assembling and Attaching External Brace

4.3 Instructions for Installing Multiple Trapzilla Units Above-Ground

4.3.1 Installing TZ-1826-SSA with TSS-95-SSA in Series

When installing a TZ-1826-SSA Interceptor with a TSS-95-SSA Solids Interceptor in series, the change

in elevation from the outlet of one of these smaller units to the inlet of the TZ-1826-SSA to the requires

that the preceding unit be installed 8” higher than the unit after it.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PR OJECTION

8" ELEVATION DIFFERENCE

(MINIMUM) BETWEEN TSS

AND TZ TO ENSURE FLOW

AND TO COMPENSATE FOR

HEIGHT DIFFERENCES. A

RISER MADE FROM TREATED

LUMBER OR CONCRETE MAY

BE USED.

LAMINATED

PLYWOOD

RISER

FRAMED FLOOR RISER

WITH PLYWOOD TOP

FOR CONTINUOUS

SUPPORT

36" SQUARE MINIMUM

Note: Drawing for reference only. Equipment must be installed in compliance with all applicable laws, regulations

and codes, including plumbing codes. Installation should be performed by a qualied plumber.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PRO JECTION

1.5" ELEVATION DIFFERENCE

(MINIMUM) BETWEEN FRONT

UNIT AND REAR UNIT TO

ENSURE FLOW AND TO

COMPENSATE FOR HEIGHT

DIFFERENCES

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PR OJECTION

PLYWOOD STACK RISER

ASSEMBLE SHEETS OF PRESSURE

TREATED PLYWOOD (MINIMUM

36 INCHES [92CM] SQUARE) TO

THE DESIRED HEIGHT. SECURE

EACH LAYER TO THE ONE BELOW

WITH CORROSION RESISTANT

SCREWS.

FRAMED FLOOR RISER

CONSTRUCT A FLOOR SUPPORT FRAME

(MINIMUM 36 INCHES [92CM] SQUARE) FROM

PRESSURE TREATED LUMBER OF 2 IN [50MM]

NOMINAL THICKNESS AND OF THE DESIRED

HEIGHT. SPACE FRAME MEMBERS NO MORE THAN

10 IN [25CM] APART. COVER THIS STRUCTURE

WITH PRESSURE TREATED PLYWOOD. SECURE ALL

JOINTS WITH CORROSION RESISTANT SCREWS.

1

2

3

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANG LE PRO JECTION

RAIL

PLATE

UPPER SUPPORT RIB

CENTER SUPPORT RIB

LOWER SUPPORT RIB

1. PLACE ONE RAIL ON

EACH SIDE OF TZ-1826

WITH TABS ON TOP AND

BOTTOM OF CENTER

SUPPORT RIB.

2. PLACE ONE PLATE ON TOP

OF CENTER SUPPORT RIB AND

ONE ON THE BOTTOM ON EACH

END OF THE TZ-1826. ALIGN

HOLES IN THE PLATES AND RAILS. 3. INSERT 2 BOLTS

INTO HOLES AT EACH

CORNER. ADD NUTS

AND TIGHTEN TO

COMPLETE ASSEMBLY.

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 15

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 14

4.3.4 Installation of Pipe Hangers with Above-Ground Units

Trapzilla units installed indoors, above-ground require the use of pipe hangers (purchased separately)

to properly support plumbing and reduce stress on connections with unit. Thermaco recommends the

use of four (4) Zinc-plated Steel Loop Style hangers with 1000 lbs. work load limit for a single Trapzilla

installation with two (2) hangers placed before inlet side cleanout and two (2) hangers placed after nal

cleanout.

Place each pair of hangers 35” apart (space-permitting) and no closer than 5” from any joint. When

multiple units are installed place one (1) additional pipe hanger in between each unit, leaving 5” distance

from unit and cleanout. Follow pipe hanger manufacturer’s instructions for physical installation.

5. In-Ground Installation Instructions

5.1 Plumbing Instructions for Single TZ-1826 Installed In-Ground

A Trapzilla unit may also be installed in the ground inside or outside of the facility. For instances

where the facility drainage piping requires an extension collar that is more than the 18” provided

by the built-in extension, the ECA-TZ-29 Extension Collar Assembly may be installed to align the

Trapzilla inlet with the drainage piping. Thermaco, Inc. strongly recommends surrounding the

in-ground Trapzilla with concrete to provide additional structural strength and to offset buoyancy

effects. For Buoyancy Calculations & suggested concrete fill quantities please see page 17.

In-Ground Installations inside of a building must have a vessel vent installed and be piped to

atmosphere.

Note: Drawing for reference only. Equipment must be installed in compliance with all applicable laws, regulations

and codes, including plumbing codes. Installation should be performed by a qualied plumber.

Outlet Vent -

extend to grade

and cover or con-

nect to facility

Vessel Vent -

to atmosphere

Built-in 18”

extension collars

Trapzilla cover -

placed on top-most

extension collar, to

be accessible from

ground level

Grade

Two-way cleanout

before and after

each unit, extend to

grade.

Concrete surround-

ing unit body and

extension collar.

Inlet Outlet

5/8”-11 Rods

Loop-Style

Pipe Hanger

35” between

hangers

5” between hangers

and any joints

Unit must be supported by

Trapzilla Support Stand Assembly.

No Trapzilla unit may be hung

using pipe hangers.

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 17

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 16

5.3 Concrete Specications for In-Ground Installation

In order to offset the effects of buoyancy caused by groundwater (high water tables), strengthen the

sideload of the unit, and prevent movement of the unit in the event of shifting earth, Thermaco, Inc.

recommends concrete be poured around the entirety of Trapzilla®units installed in-ground in the amounts

of concrete specied in the table below. The concrete must to be poured continuously and completely

surrounding the Trapzilla®body (and Extension Collars if applicable) to ensure proper strength and

security at a compression strength of 4000 psi (C28/35).

5.4 Concrete Calculations for TZ-1826 Models/Components*

Amount of Concrete

Trapzilla Model Weight in lbs. (Kg) Volume in Cubic Yards (m3)

TZ-1826 3950 1.0

ECA-TZ-29 (each) 600 0.20

5.2 Plumbing Instructions for TZ-1826 with Optional ECA-TZ-29 Extension Collars (purchased

separately)

In some cases, TZ-1826 may be installed in locations where built-in extension collar will not reach grade.

In these cases, the two-piece ECA-TZ-29 Extension Collar (purchased separately) may be used to make

lid accessible at ground level. Follow instructions included in ECA-TZ-29 packaging for installations.

Each TZ-1826 would require two (2) ECA-TZ-29 if pipe depth requires.

* In-ground installation instructions only applicable for units installed where center of outlet pipe is

no more than 60” below grade. For all installations deeper than this, Thermaco must be contacted

to verify site conditions and provide further instructions for proper installation. Failure to abide by

this instruction will result in voiding the warranty of the unit.

In-Ground Installations inside of a building must have a vessel vent installed and piped to at-

mosphere.

Note: Drawing for reference only. Equipment must be installed in compliance with all applicable laws, regulations

and codes, including plumbing codes. Installation should be performed by a qualied plumber.

ECA-TZ-29

Two-piece extension

collar with 4-29” of

extension. Connect

bottom piece to built-

in extension collar

and use original lid

provided.

Built-in

extension

Follow instructions

on pages 18-19 to

set built-in extension

collar. When pos-

sible adjust height

of built-in extension

collar before trimming

ECA-TZ-29.

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 19

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 18

5.5 Trimming and Setting the ECA-TZ-18 Single-Piece Extension Collar

In-Ground Trapzilla Models ship with a built-in,

single-piece, 18” extension collar that must be

trimmed and then set to the correct height to

bring the Solid Top Cover to grade.

Follow the steps below to set the extension

collar prior to backfilling the hole with

concrete.

Amount of extension collar needed to bring

Solid Top Cover to grade.

Step 2: Remove the extension collar adapter ring from the

unit with the extension collar still in place. On the underside

of the cover, mark the excess extension collar length at the

bottom of the four (4) “skirt” portions of the adapter ring.

Check the extension collar height dimension frequently

during this marking to ensure that the collar has not moved.

Extend this mark between the gaps in the “skirt” so that the

collar is marked all around.

Step 1: With the Trapzilla unit installed in its permanent

location, raise the telescoping extension collar to nished

grade or oor level. Measure the height from the top of the

unit to this nished extension collar height and record this

dimension.

Note: If the oor will have a tile covering, allow for the tile

thickness when determining the extension collar height.

8.25"

Extension collar

Skirt

Mark excess extension collar length

at the four (4) "skirt" portions of

the adapter ring.

8.25

Step 5: Working from the bottom of the assembly, install

eight (8) self-drilling, self-tapping screws (provided) through

the extension collar wall and into the adapter ring. Two of

these screws should be installed in each of the four (4) skirt

areas of the adapter ring. Check the extension collar height

dimension frequently during this operation to ensure that the

collar has not moved. Note: Use caution when tightening

these screws to ensure that they do not strip.

Step 6: Place the adapter ring/extension collar assembly

onto the Trapzilla unit. Position the small cover onto the

extension collar. Secure the adapter ring and the small

cover with the brass nuts and at washers provided. Seal

the gap between the 18” extension collar and extension

collar adapter ring using a silicone sealant.

Step 3: Remove the extension collar from the adapter ring

and, with an appropriate saw, cut along the line created in

Step 2 to remove the excessive extension collar.

Step 4: Reinsert the extension collar into the adapter ring

ensuring that the cover alignment key on the extension

collar is aligned with its recess in the adapter ring.

Reset the extension collar height to the dimension

determined in Step 1.

Line marking the bottom

of the "skirt" (adapter

ring has

been removed

for clarity)

Excess part of

extension collar

to be discarded

after cutting

along line

Reinsert extension collar into adapter

ring to insure alignment.

Adapter ring

Extension collar

Modified extension collar

Self-tapping screws

8 Places

Adapter ring

"Skirt"

5/16-inch Hex Nut

4 Places

5/16-inch Washer

4 Places

Note: Tighten down the flat

washers and brass nuts using

a 5/16-inch socket and rachet.

Do not over tighten.

Note: Drawing for reference only. Equipment must be installed in compliance with all applicable laws, regulations

and codes, including plumbing codes. Installation should be performed by a qualied plumber.

IMPORTANT: Excess extension collar must be trimmed on all units. Do not allow

additional extension collar to extend beyond bottom of adapter ring. On units

where extension collar is completely recessed, the extension collar should still

be secured and the excess extension removed as in step 3.

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 21

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 20

6. Unit Maintenance

6.1 Measuring Grease/Solids Levels

Due to its unique design, Trapzilla is capable of retaining high quantities of grease in a compact footprint.

Therefore, unlike traditional interceptors, Trapzilla can hold an extraordinarily high percentage of its

volume in grease without losing separation efciency. To determine the current levels of grease/solids

in your Trapzilla grease interceptor, follow the instructions below.

1. Remove four nuts/washers securing the 22” Solid Top Cover.

2. Place a grease/sludge dipstick into the center of the opening, making sure that it goes through the

hole in the horizontal bafe.

3. Once the dipstick has found its natural resting place at the lowest point in the conical shaped bottom,

take the measurement.

4. Remove dipstick and compare grease/sludge levels to the corresponding unit in the charts below.

Grease Solids

Total

Capacity

(depth):

Ready to

pump at

(depth):

Total

Capacity

(height):

Ready to

pump at

(height):

TZ-1826 25” 20” 13.5” 10.75”

Take solids/sludge measurement from

bottom of unit upward and compare to

chart above.

Take grease measurement from top of

liquid level downward and compare to

chart above.

Note: Drawing for reference only. Equipment must be installed in compliance with all applicable laws, regulations

and codes, including plumbing codes. Installation should be performed by a qualied plumber.

6.2 Pumping/Servicing Unit

Periodically, the Trapzilla® unit will need to be serviced which involves pumping out all accumulated

grease and solids. Pumping frequency may be set at a regular interval by sewer district (every 30-90

days). If not, determine pumping frequency using instructions in 6.1 to periodically measure grease/

solids levels to determine appropriate timing for pumping. Follow instructions below to pump/clean out

TZ-1826.

1. Each lid has four brass nuts securing the lid. Remove the four brass nuts from the bolts and fully

remove the 22” lid to pump out. It is not necessary to remove adapter lid to pump out Trapzilla.

2. Begin by taking the grease from the top of the main chamber until all grease is removed.

3. Upon reaching the horizontal bafe, you will see a hole through which you may access the rest of

the grease and the solids. Be sure to lower the hose all the way to the bottom of the Trapzilla unit

on the outlet side so that solids may be entirely removed. The conical shape and natural grade of

the unit will allow solids and grease to run to outlet side of unit.

4. Have kitchen run water into unit to ush any remaining solids to the outlet end of the unit.

5. If necessary, use a water hose with spray nozzle to rinse off inside of unit.

6. Secure lids in place and instruct kitchen to run water into unit until full.

DO NOT use mechanical crust breaking devices to break down any mat that has formed inside the

Trapzilla unit.

DO NOT use grinding augers in maintenance of the Trapzilla unit.

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANGLE PRO JECTION

1

1

2

2

3

3

4

4

A A

B B

C C

D D

THIS DRAWING CONTAINS PROPRIETARY AND PATENTED MATERIAL. THIS DRAWING MAY NOT BE REPRODUCED IN WHOLE OR PART WITHOUT

WRITTEN CONSENT FROM THERMACO, INC. POSSESSION OF THIS DRAWING DOES NOT CONSTITUTE THE RIGHT TO MANUFACTURE.

POSSESSION OF THIS DRAWING DOES CONSTITUTE AN IMPLIED NONDISCLOSURE AGREEMENT BETWEEN THERMACO, INC. AND THE HOLDER OF

THIS DRAWING. DO NOT DESTROY THIS DRAWING, IT IS THE SOLE PROPERTY OF THERMACO, INC. AND MUST BE RETURNED UPON REQUEST.

MATERIAL (UNLESS NOTED)

FINISH (UNLESS NOTED)

646 GREENSBORO STREET

PO BOX 2548, ASHEBORO, NC 27203

VOICE 336-629-4651 FAX 336-626-5739 Decimals

.XX +/- .03

.XXX +/- .015

Unless otherwise specified

Dimensions are in inches

Tolerances

Angular

+/- 1°

CHECKED SIZE REV. NO. DWG NO.

PART NO. C

SCALE RELEASE DATE SHEET OF

ENGINEERING

DRAWN DATE

THIRD ANG LE PRO JECTION

2

3

©2018 Thermaco, Inc. All rights reserved • Patented/Patents Pending • Specications subject to change without notice

Thermaco, Inc. • 646 Greensboro St. • Asheboro, N. C. 27204-2548 • (336) 629-4651 MNL-TZ-1826 23

A THERMACO® Technology

Trapzilla®Grease Interceptor

Installation and Operations Manual

TZ-1826 Models

AEF

MNL-TZ-1826 22

7. Limited Warranty and Remedy

Thermaco, Inc. warrants to the original user that the equipment manufactured by Thermaco and delivered

with this warranty (the “Product”) shall be free from material defects in workmanship and materials during

the lifetime of the plumbing system in which the Product is initially installed.

Any claim under this warranty must be made in writing to Thermaco at 646 Greensboro Street, Asheboro,

NC 27203 promptly after discovery of the defect and the Product must be delivered, prepaid, to

Thermaco, together with proof of purchase and a return authorization number issued by Thermaco. If

Thermaco determines that the Product is defective, Thermaco’s sole obligation, and the purchaser’s

sole and exclusive remedy, is the repair or replacement, at Thermaco’s option, of the defective Product.

This warranty shall not cover any defect or damage resulting directly or indirectly from: (i) failure to

properly install, operate or maintain the Product in accordance with Thermaco’s instructions, including,

without limitation, use in excess of rated ow, installation deeper than manufacturer’s recommendation

or in conjunction with unapproved components, use to remove emulsied fats and oils or use that fails

to comply with applicable laws, regulations or codes; (ii) damage in transit, handling or installation; (iii)

modications, adjustments, or alterations of the Product; (iv) disassembly of components other than as

required for prescribed maintenance; or (v) any other causes not arising out of defects in workmanship

or materials. Thermaco shall not be responsible for damage to Products resulting from ultraviolet light

exposure, vault ooding, sewer line back-up, pumping or lift station failure, ambient water ow, freezing, or

other sources of water damage. Costs for any service, adjustment, removal, repair, packing, or otherwise

incurred with respect to the Product prior to submission for warranty are the responsibility of purchaser.

No distributor, sales representative or other person is authorized to make any warranty statements

on behalf of Thermaco regarding Products other than as provided herein. This statement of warranty

supersedes any quote, brochure, or other statement or document with respect to warranty of Thermaco

products.

EXCEPT AS EXPRESSLY SET FORTH ABOVE,THERMACO MAKES NO REPRESENTATIONS,

WARRANTIES OR GUARANTEES, EITHER EXPRESSED OR IMPLIED, INCLUDING, WITHOUT

LIMITATION, AS TO MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, WHETHER

OR NOT THERMACO HAD KNOWLEDGE OF PURCHASER’S PARTICULAR REQUIREMENTS OR

NEEDS, OR WITH RESPECT TO ODOR GENERATION OR OTHER INCIDENTALS RELATING TO

USE OF THE PRODUCT.

The sole and exclusive remedy with respect to this warranty or any other claim relating to defects or any

other condition or use of Products, however caused, and whether such claim is based upon warranty,

contract, tort, strict liability or any other theory, is LIMITED to the repair or replacement of the Product,

excluding any cost to remove or install the Product or, at Thermaco’s option, repayment of the purchase

price. IN NO EVENT SHALL THERMACO BE LIABLE, WHETHER IN CONTRACT, WARRANTY, TORT

(INCLUDING NEGLIGENCE), STRICT LIABILITY, INDEMNITY OR ANY OTHER LEGAL THEORY,

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. UNDER NO CIRCUMSTANCES WILL THE

AGGREGATE LIABILITY OF THERMACO FOR ANY CAUSE OF ACTION RELATED TO THE PRODUCT

COVERED HEREBY EXCEED THE NET PURCHASE PRICE RECEIVED BY THERMACO FOR THE

PRODUCT.

Note: Do not Pressure/Hydrostatic test our units.

Table of contents

Other THERMA Industrial Equipment manuals

THERMA

THERMA Big Dipper IS Series Installation instructions

THERMA

THERMA Internal Strainer Series Installation instructions

THERMA

THERMA Big Dipper 51000 Series User manual

THERMA

THERMA Big Dipper 51000 Series User manual

THERMA

THERMA Big Dipper 40000 Series User manual

THERMA

THERMA Big Dipper 51000 Series User manual