FINO 86000 Operation manual

FINO Stereo-Mikroskop

86000

86001

Original FINO

Germany

Gebrauchsinformation•User Information•Mode d’emploi

Información sobre el uso•Informazioni d’uso

Gebruiksaanwijzing•Instrukcja stosowania

FINO

•der feine Unterschied•the fine difference•la fine différence•la fina diferencia•la fine differenza

86000 86001

mit Stativ mit Gelenkarm

with table stand with articulated arm

avec trépied de table avec un bras articulé

con el pie de sobremesa con el brazo articulado

con stativo con braccio snodato

met statief met scharnierarm

se stativem s kloubovým ramenem

med stativ med ledad arm

állvánnyal csuklós karral

Version 1/2016. Read the operating instructions before commencing with any work!

1. Fields of application 3

2. Device setup 3

3. Safety precautions 4

4. Getting started 4

• Prior to commissioning • location

5. Handling 4

• Using with a stand (item no. 86000)

• Using with a joint arm (item no. 86001)

• Working with an LED ring light

6. Service and maintenance 7

7. Storage 7

8. Technical data 7

9. Delivery forms 7

10. Guarantee 7

11. Disposal 8

CONTENTS

2

1. Fields of application

For optimum control over all laboratory work. The

adjustable magnification enables maximum micro-

metre (μm) precision. Fine-tuning of the objective

height using the round adjustment screws provided

on both sides.

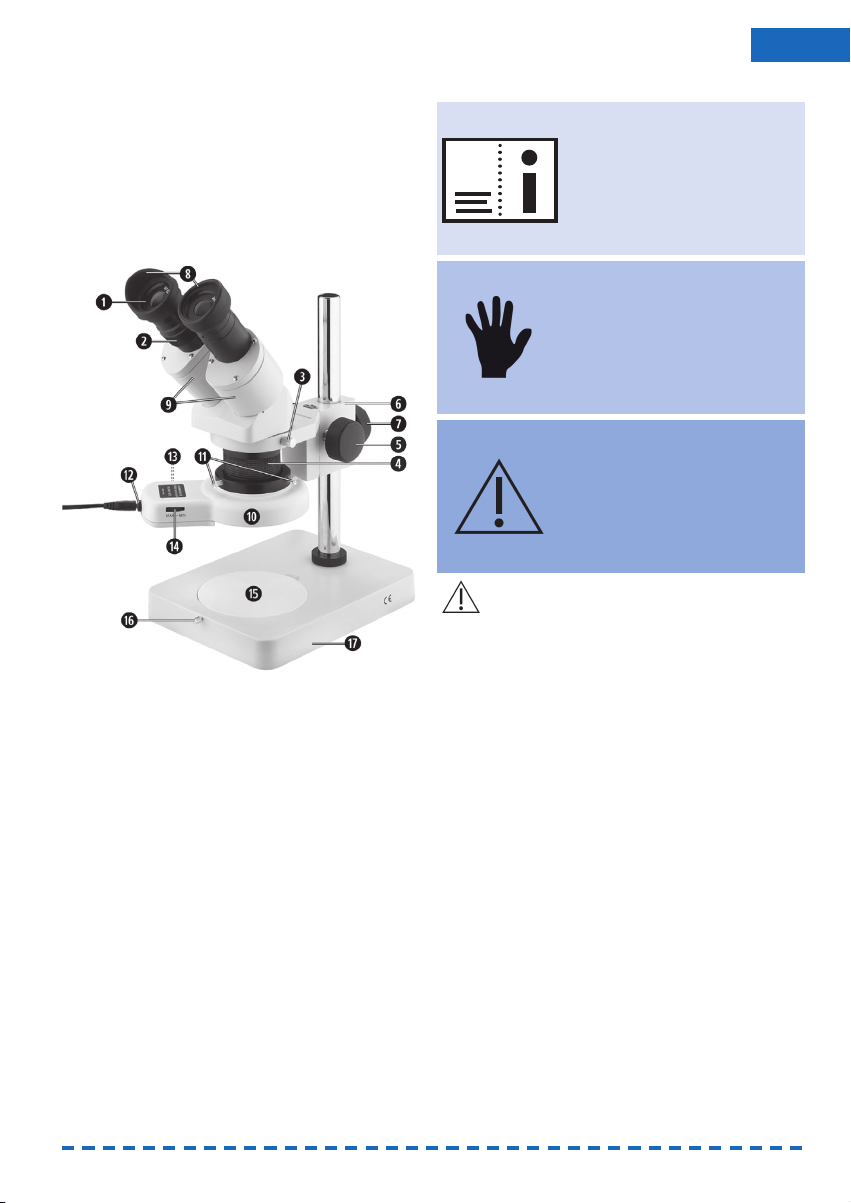

2. Device setup

1Ocular

2Dioptre compensation

3Clamping screw for microscope head

4Objective tube

5Drive knob for height adjustment

6Drive box with stand compartment

7Locking knob (for locking when using

the table stand)

8Ocular viewfinders

9Objectives

10 Episcopic illumination (ring light)

11 Plastic screws for episcopic illumination

(ring lights)

12 Socket for connecting the mains adapter cable

13 On/off switch for episcopic illumination

(ring light)

14 MAX-MIN control

15 Specimen stage

16 Clamping screw for specimen stage

17 Table stand

3. Safety precautions

Warning! Failure to observe this safety

information can result in electric shock! Keep

the device out of the reach of children.

• Only connect the episcopic illumination

(ring light) of the device to a properly

connected mains socket with a mains voltage of

230 V/50 Hz using the mains adapter supplied.

• Check the mains adapter, power cable and

device for damage prior to operation.

• If damage is identified, take the device

out of service and ensure that it cannot be put

back into operation. Have the device repaired

by an authorised specialist or by FINO GmbH.

• Do not open or repair the adapter housing,

otherwise safety is not ensured and the warranty

with become void.

• Protect the device against damp and

moisture.

• The mains adapter includes protection against

overheating and switches itself off automatically

after four hours of continuous operation. The

device must be allowed to stand for approx. one

hour before it may be switched on again.

3

ENU

It is essential to read the instructi-

ons for use carefully prior to ope-

ration and to keep these readily

available.

This symbol indicates safety pre-

cautions where non-compliance

can lead to risks for persons.

This symbol indicates safety pre-

cautions where non-compliance

can lead to damage of the device

and its function.

Information on disconnecting from the mains:

• Unplug the mains adapter from the mains socket

in order to fully disconnect the device from the

mains.

• So that the mains adapter can be unplugged

immediately in an emergency, position the device

so that access to the mains socket is never

obstructed.

• When the device is not in use, disconnect the

mains adapter from the mains socket in order

to exclude the risk of fire, prevent unintended

activation, and save energy.

• Do not touch the mains adapter when your hands

are wet as this could cause a short circuit or

electric shock.

• Disconnect the mains adapter directly from

the socket; do not pull on the power cable.

• Do not squash the power cable, knot it,

or tie it to another cable.

• When laying the power cable, ensure that

no-one can trip over it.

4. Getting started

4.1 Prior to commissioning

Before first operation check the item for transport

damages. Claim any transport damages immediately

with the supplier.

Check the device for its proper condition. In

particular, check the mains connection for

damage, such as pinching, cracks or ageing! Do not

commence operation if the mains connection is

damaged! Check the nominal voltage of the device

prior to connecting to the mains. The voltage given

on the type plate must correspond to the local mains

voltage. The mains connection plug is to be plugged

into a grounded, protected mains socket.

4.2 Location

Only operate the device in enclosed areas

that are not exposed to environmental

factors. Install the device on a dry, even surface.

Select the location so that the device is not exposed

to high temperatures, direct sunlight, strong vibra-

tions, blows or impacts.

5. Handling

5.1 Using with a stand (item no. 86000)

The device is supplied almost entirely pre-assem-

bled.

• Raise the microscope knob a few centimetres

using the drive knob (5).

• Loosen the clamping screw for the microscope

head (3) and turn the microscope knob so that

the oculars (1) are facing the user. Secure the

clamping screw (3) again.

• Place both ocular viewfinders (8) on the oculars

(1).

• Unscrew the protective cap from the objective

tube (4) by turning it anticlockwise.

• Look through both oculars (1) and adjust the ocu-

lar distance in line with the interpupillary distance

by turning the objectives (9) inwards or outwards.

• For the required contrast in each case, select

either the black or the white side of the specimen

stage (15). To secure the stage, turn the clamping

screw (16) tightly by hand.

• Place the specimen to be viewed under the

microscope on the specimen stage.

• In the case of larger specimens, the distance

setting selected using the drive knobs at the side

may not be sufficient.

Adjust the distance using the locking knob (7).

Guide values:

W= Widefield; Oculars 10x (supplied), other magni-

fications optionally available.

• Required magnification (1x or 2x) by turning the

objective tube (4) by 90° in each case.

• For fine adjustment, use the drive button (5) to

modify the distance to the object in order to

achieve maximum image precision.

• Set dioptre compensation (2) to suit individual

requirements.

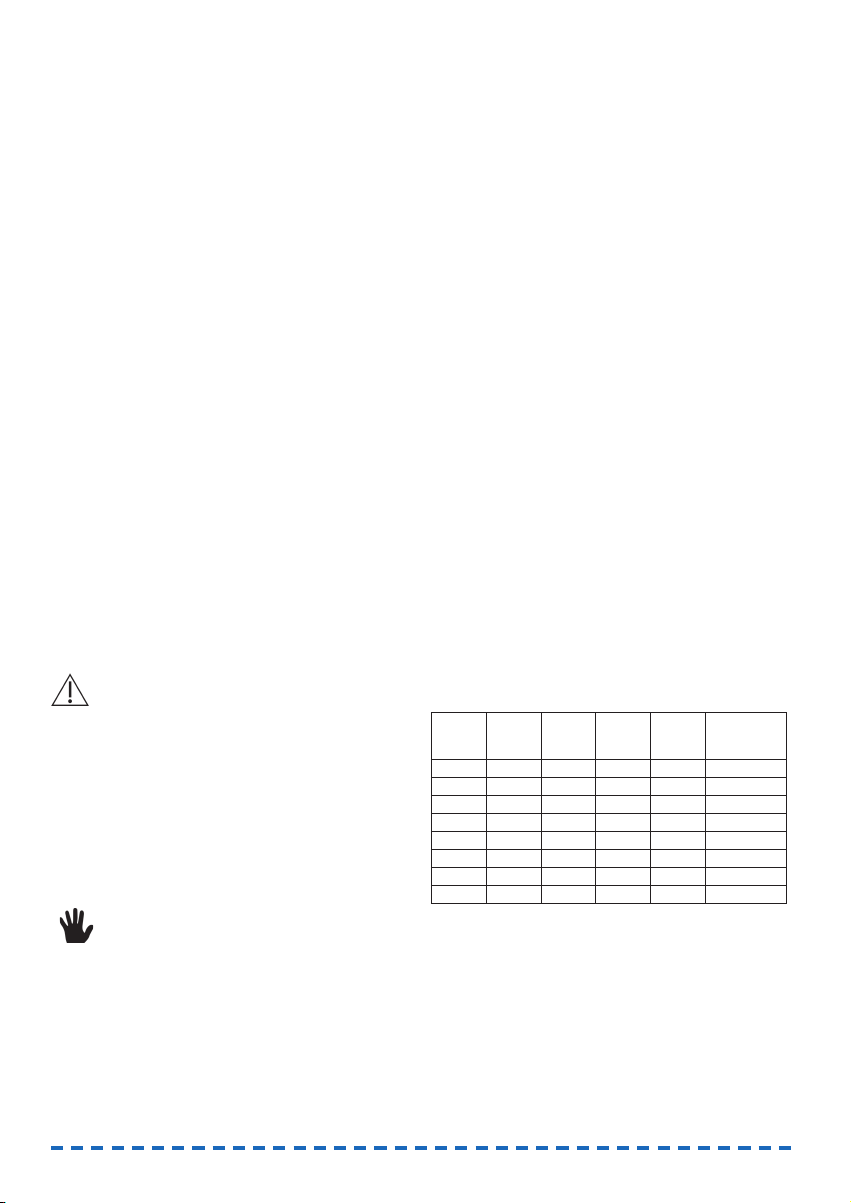

Objective

magnification

Ocular

magnification

Overall

magnification

Working

distance(mm)

Field of view

ø (mm)

Field number =

Field of view ø

(mm) x objective

magnification

1x W 5x 5x 79 20 20

2x W 5x 10x 84 10 20

1x W 10x 10x 83 19 19

2x W 10x 20x 83 9,5 19

1x W 15x 15x 83 12,4 12,4

2x W 15x 30x 83 6,2 12,4

1x W 20x 20x 83 9,6 9,6

2x W 20x 40x 82 4,8 9,6

4

• The working distance and field of vision can be

further increased using the optional FINO add-on

lens with 0.5x reducing optics (item no. 86006).

The add-on lens can be screwed onto the quick-

action revolver.

5.2 Using with a joint arm

(item no. 86001)

The joint arm can be screwed on securely at the

workstation or secured flexibly using the table clamp

supplied. For both types of attachment, choose a

smooth, stable, horizontal surface for assembly.

Fixed assembly of the joint arm:

The screws must be drilled directly into the work

surface and leave drill holes.

• In the area selected for assembly, mark four drill

holes at a distance of 45 mm and pre-drill the

holes for the screws supplied:

• For easier assembly, remove the screw-on-flange

from the lower end of the joint arm. To do so,

unscrew and remove both socket head screws

from the side of the flange using the socket

wrench supplied and remove the flange from the

pivot of the joint arm.

• Assemble the screw-on-flange on the worktop

using the screws supplied.

• Carefully reinsert the pivot into the screw-on-

flange at the lower end of the joint arm, screw in

both socket head screws again, and tighten using

the socket wrench. The tightening torque of the

screws determines the ease of the swivel move-

ment of the joint arm.

Flexible assembly of the joint arm using the table

clamp:

The work surface is not damaged.

• Unscrew the four pre-assembled machine screws

from the table clamp supplied.

• For easier assembly, remove the screw-on-flange

from the lower end of the joint arm. To do so,

unscrew and remove both socket head screws

from the side of the flange using the socket

wrench supplied and remove the flange from the

pivot of the joint arm.

• Align the drill holes of the screw-on-flange over

the drill holes of the table clamp and screw the

screw-on-flange tightly onto the table clamp

using the socket wrench and machine screws

supplied.

• Attach the table clamp at the required location

on the worktop.

• Carefully reinsert the pivot into the screw-on-

flange at the lower end of the joint arm, screw in

both socket head screws again, and tighten using

the socket wrench. The tightening torque of the

screws determines the ease of the swivel move-

ment of the joint arm.

Attaching the FINO stereo microscope to the joint

arm:

• Unscrew the locking knob for locking when using

the table stand (7), and place to one side.

• Loosen the clamp screw for the microscope head

(3) and remove the microscope head from the

drive box (6).

• On the upper joint of the joint arm, you will find

a small horizontal ball-and-socket joint with a

threaded bolt and a pre-assembled hex nut.

Screw the drive box (6) of the microscope onto

this threaded bolt.

5

ENU

• With the drive box seated horizontally, secure

using the hex nut.

• Place the microscope head back into the drive

box and seat securely using the clamp screw (3).

Joint adjustment

The joint arm has a friction joint that is addi-

tionally supported at the centre and in the foot by

internal springs.

In order to adjust the joint arm, the wing nuts on the

joint arm must not be opened. The wing nuts are

used for basic adjustment of the friction and for

occasional readjustment.

Note:

The foot joint is adjusted using the quick-

release lever. The quick-release lever can transmit

forces that are so strong that the joint is completely

blocked. In this case, it is essential that the quick-

release lever is opened slightly prior to adjusting the

joint arm, as the joint arm will otherwise be dama-

ged.

Tip:

If the lever is pulled a little to the side away

from the joint, the lever can be moved to any requi-

red position without opening the joint.

Using the microscope:

• Place both ocular viewfinders (8) on the oculars

(1).

• Unscrew the protective cap from the objective

tube (4) by turning it anticlockwise.

• Look through both oculars (1) and adjust the ocu-

lar distance in line with the interpupillary distance

by turning the objectives (9) inwards or outwards.

• Place the specimen to be viewed under the

microscope on the specimen stage.

• In the case of larger specimens, the distance

setting selected using the drive knobs at the side

may not be sufficient.

Adjusting the distance using the joint arm (see

section on joint adjustment).

Guide values:

W= Widefield; Oculars 10x (supplied), other magnifi-

cations optionally available.

• Required magnification (1x or 2x) by turning the

objective tube (4) by 90° in each case.

• For fine adjustment, use the drive button (5) to

modify the distance to the object in order to

achieve maximum image precision.

• Set dioptre compensation (2) to suit individual

requirements.

• The working distance and field of vision can be

further increased using the optional FINO add-on

lens with 0.5x reducing optics (item no. 86006).

The add-on lens can be screwed onto the

quick-action revolver.

Objective

magnification

Ocular

magnification

Overall

magnification

Working

distance

(mm)

Field of view

ø (mm)

Field number =

Field of view ø

(mm) x objective

magnification

1x W 5x 5x 79 20 20

2x W 5x 10x 84 10 20

1x W 10x 10x 83 19 19

2x W 10x 20x 83 9,5 19

1x W 15x 15x 83 12,4 12,4

2x W 15x 30x 83 6,2 12,4

1x W 20x 20x 83 9,6 9,6

2x W 20x 40x 82 4,8 9,6

6

5.3 Working with an LED ring light

LED episcopic illumination (ring light) is supplied for

illumination of the specimen to be examined under

the microscope.

Use:

• Unscrew the three plastic screws (11) out of the

LED episcopic illumination (ring light) (10) only

until these screws no longer extend into the

opening for the objective tube (4).

• Push the LED episcopic illumination (ring light)

(10) over the objective tube (4) as shown in the

illustration under 2. Device setup, and carefully

tighten the three plastic screws (11).

• Plug the mains adapter supplied into a properly

connected socket and connect the connector of

the adapter cable with the socket (12) on the

LED episcopic illumination (ring light).

• Set the on/off switch for LED episcopic

illumination (ring light) (13) to position "I".

• Set the required illumination using the

MAX-MIN control (14).

• After use, set the on/off switch (13) to the "0"

position and switch off the LED episcopic

illumination (ring light).

6. Service and maintenance

• Do not use aggressive chemical substances,

solvents or scouring agents to clean the surface.

• After use, cover the device with the dust-

protection hood supplied in order to keep

dust and dirt to a minimum.

• Remove dirt using a soft, slightly moistened

cloth.

• Use a lens cleaning cloth to clean the oculars (1).

Be very careful when cleaning the oculars as their

surfaces can scratch easily.

7. Storage

Cover the device with the dust-protection hood

supplied.

Store unit in a dry and dust-free place.

8. Technical data

8.1 With stand, item no. 86000

Metal stand, column length 18.0 cm; Flat base 20.0 x

15.0 cm; Widefield oculars (pair) WF 10x; Revolver 1x

and 2x for magnification 10x/20x; LED episcopic illu-

mination (ring light) 100-240 V, 50/60 Hz; 3.6 W;

Power cable 2 m.

8.2 With joint arm, item no. 86001

Metal joint arm 85.0 cm; Widefield oculars (pair) 10x;

Magnification 10x/20x; LED episcopic illumination

(ring light) 100-240 V, 50/60 Hz; 3.6 W; Power cable

2 m.

9.Delivery forms

9.1 With stand, 1 unit, item no. 86000

FINO stereo microscope complete with stand; LED

episcopic illumination (ring light); Widefield oculars

(pair) 10x; Ocular viewfinders; Dust protection hood

and power cable.

9.2 With joint arm, 1 unit,

item no. 86001

FINO stereo microscope complete with spring-joint

arm; Table clamp; Screw-on-flange; Four screws;

Socket wrench; LED episcopic illumination (ring

light); Widefield oculars (pair) 10x; Ocular viewfin-

ders; Dust protection hood and power cable.

Accessories

FINO LED episcopic illumination

(ring light) 1 pc. 86011

FINO widefield oculars (pair) WF 5x 1 pc. 86002

FINO add-on lens 0.5x 1 pc. 86006

10. Guarantee

Our technical recommendations of application are

based on our own experiences and tests and should

only be regarded as guidelines. It rests with the skills

and experience of the user to verify that the products

supplied by us are suitable for the intended proce-

dures. Our products are undergoing a continuous

further development. We reserve the right of

changes in construction and composition. It is

understood that we guarantee the impeccable quali-

ty of our products.

7

ENU

11. Disposal in accordance with

EU guideline 2002/96/EU

This equipment may not be disposed in

domestic waste! Please contact the manu-

facturer or your dealer!

11.1 Registration Number

WEEE-Reg.-No. DE 3092617

Important!

FINO GmbH has prepared these instructions to help

users operate the unit and to make it easier to take

the unit into operation for the first time and then use

it. FINO GmbH cannot be held liable for damages

due to improper use or due to modifications made to

the device itself. The warranty will be voided if the

unit is used for any purpose other than its proper

intended purpose. FINO GmbH has a policy of conti-

nuously developing and improving its products. FINO

GmbH reserves the right to make changes or impro-

vements to the products described in this document

or to the document itself without prior notice. FINO

GmbH offers no guarantees for the completeness or

correctness of this document.

8

9

ENU

FINO GmbH

Mangelsfeld 18

D-97708 Bad Bocklet

Tel +49-97 08-90 94 20

Fax +49-97 08-90 94 21

This manual suits for next models

1

Table of contents