FIOR & GENTZ NEURO VARIO-SPRING User manual

Systemknöchelgelenk

System Ankle Joint

Druckdatum: 2018-09

Der Inhalt dieser Produktbeilage wird regelmäßig aktualisiert und ist beim Einsatz des Produktes unbedingt zu beachten.

Sie finden diese Produktbeilage auch im Download-Bereich unserer Website unter www.fior-gentz.de/downloads. Seite 2

Date printed: 2018-09

This manual is regularly updated and should be strictly followed.

You can also find this manual in the download section on our website at www.fior-gentz.com/downloads. Page 16

DE

GB

16

Content Page

GB

1. Declaration of Conformity 17

2. Warranty 17

3. Safety Information 17

4. Safety Instructions 17

4.1 Classification of the Safety Instructions 17

4.2 All Instructions for a Safe Handling of the NEURO VARIO-SPRING System Ankle Joint 18

5. Application 20

6. Joint Function 20

7. Scope of Delivery 20

8. Load Capacity 20

9. Tools for Assembling the System Joint 21

10. Assembly/Lamination Dummies 21

11. Assembly Instructions 21

11.1 Mounting the Functional Unit 22

11.2 Mounting the System Stirrup 22

11.3 Mounting the Cover Plate 22

11.4 Checking the System Joint's Free Movement 23

11.5 Basic Alignment 23

11.6 Securing the Screws 23

12. Adjustment Options on the Orthosis 24

12.1 Adjustable Alignment 24

12.2 Adjustable Range of Motion 24

12.2.1 Filing the Range of Motion 24

12.2.2 Fine Adjusting the Range of Motion 24

12.2.3 Securing the Adjusting Screw 24

12.3 Reading Joint Angles 25

13. Converting the NEURO VARIO-SPRING into a NEURO VARIO-CLASSIC

System Ankle Joint 25

14. Advice on Production Techniques 25

14.1 Parallel Alignment of System Joints 26

14.2 Mounting to the System Side Bar/System Anchor 26

15. Maintenance 26

15.1 Repairing the Bearing Nut Bore 26

15.2 Replacing the Sliding Washers 27

15.3 Cleaning 27

16. Disposal 27

17. Spare Parts 28

18. Accessory Parts 29

19. Information for the Treatment Documentation 31

17

1. Declaration of Conformity

We declare that our medical devices as well as our accessories for medical devices are in conformity with the

requirements of the Medical Devices Directive 93/42/EEC. Therefore, the FIOR &GENTZ products bear the CE marking.

2. Warranty

The warranty only applies if the product is used under the described conditions and for the intended purpose.

The warranty expires if the product is used differently, if it is combined with other components or materials or

if it is mounted according to a different production technique than the one recommended by the FIOR &GENTZ

Orthosis Configurator. A combination with products from other manufacturers requires a written consent by the

seller. The warranty and guarantee expire if the product is mounted several times. For further information, we

refer to our General Terms and Conditions of Business Transactions, Sales, Delivery and Payment.

3. Safety Information

This manual is addressed to orthotists. That is why the content basically confines to features of the product. It

does not contain any notes about dangers which are obvious to orthotists. Please note that the product is not

supposed to be combined with other components or materials than with those recommended by the FIOR& GENTZ

Orthosis Configurator.

To achieve maximum safety, please show the patient and/or the care team how to use and maintain the product

correctly. Enclosed to this manual you will find a patient information which has to be given to the patient and/

or the care team.

For information reasons and for the safety of your patient, please note all information provided in this manual

including notes, tables and illustrations. In particular, note the safety instructions indicated by DANGER, WARNING,

CAUTION and NOTICE that are listed and explained in the following paragraph. Ignoring this information may

lead to patient injuries and property damage.

4. Safety Instructions

4.1 Classification of the Safety Instructions

DANGER Important information about a possible dangerous situation which,

if not avoided, leads to death or irreversible injuries.

WARNING

Important information about a possible dangerous situation which,

if not avoided, leads to reversible injuries that need medical treatment.

CAUTION

Important information about a possible dangerous situation which,

if not avoided, leads to light injuries that do not need medical treatment.

NOTICE

Important information about a possible situation which,

if not avoided, leads to damage of the product.

All serious incidents connected to the product shall be reported to the manufacturer or the responsible

authorities.

18

4.2 All Instructions for a Safe Handling of the NEURO VARIO-SPRING System Ankle Joint

DANGER

Potential Trac Accident Due to Limited Driving Ability

Advise the patient to gather information about all safety and security issues before driving

a motor vehicle with orthosis. The patient should be able to drive a motor vehicle safely.

WARNING

Risk of Falling Due to Improper Handling

Inform the patient about the correct use of the system joint and potential dangers especially

with regards to:

- moisture and water as well as

- excessive mechanical stress (e.g. due to sports, increased activity or weight gain).

WARNING

Risk of Falling Due to Loosely Attached Cover Plate

Mount the cover plate to the system joint according to the assembly instructions in this

manual. Secure the screws with the specified torque and the corresponding adhesive and

make sure that no sliding washers are damaged in the process.

WARNING

Risk of Falling Due to Permanent Higher Load

If patient data has changed (for example, due to weight gain, growth or increased activity),

recalculate the load capacity of the system joint. For this purpose, use the Orthosis Configurator

or contact Technical Support.

WARNING

Risk of Falling Due to Improper Shoe

Advise the patient to wear a shoe to which the orthosis is adjusted in order to avoid joint

dysfunction.

WARNING

Risk of Falling Due to Incorrectly Adjusted Adjusting Screw

Adjust the adjusting screw according to the information in this manual. Do not make a fine

adjustment of more than 10° and secure the adjusting screw with the securing pin and the

corresponding adhesive.

WARNING

Damage to the Anatomical Joint Due to Incorrect Position of the Joint’s Mechanical Pivot

Point

Determine the mechanical pivot points correctly in order to avoid a permanent incorrect

load on the anatomical joint. Please refer to the online tutorials on our website or contact

Technical Support.

19

WARNING

Jeopardising the Therapy Goal Due to Lack of Free Movement

Check if the system joint moves freely in order to avoid restrictions of the joint function.

Use suitable sliding washers according to the information in this manual.

WARNING

Jeopardising the Therapy Goal Due to Incorrectly Filed System Stirrup

Do not file the system stirrup too far. This applies especially to the dorsiflexion stop, otherwise

the forefoot lever is not activated. As a result, the patient is only stabilised insuciently by the

orthosis and the gait worsens. In order to avoid this, always file the system stirrup:

- gradually into the required stop angles and

- only so far that no more than a 10° fine adjustment is possible.

NOTICE

Limitation of the Joint Function Due to Improper Processing

Errors in processing can impair the joint function. Pay particular attention to:

- correctly connecting the system side bar/system anchor with the system case in accordance

with the production technique;

- greasing the joint components only slightly and

- adhering to the maintenance intervals.

20

5. Application

The NEURO VARIO-SPRING system ankle joint is exclusively for use for orthotic fittings of the lower extremity.

It must be handled by a professionally trained user. You will find more information about this product under

paragraph 6 Joint Function.

Every mechanical joint influences the orthosis' function and thus also the function of the leg. All FIOR &GENTZ

system joints were developed for everyday life activities such as standing, walking and running but not for

extreme loads due to sports such as climbing and parachuting.

Depending on the type of orthotic fittings and the patient’s individual physical abilities, driving a motor vehicle

safely should be guaranteed. This is subject to national laws and checked by authorised medical bodies. It is

recommended to modify the motor vehicle to the patient’s special needs (e.g. automatic transmission) so that

the driving ability is given even without a functioning orthosis.

6. Joint Function

The basic function of the NEURO VARIO-SPRING system ankle joint s to provide motion control with a dorsi-

flexion assist. The range of motion in dorsiflexion can be adjusted by filing the system stirrups and additionally

by using the adjusting screws. The dorsiflexion-assist effect can be changed by replacing the functional unit or

the pin and pressure spring.

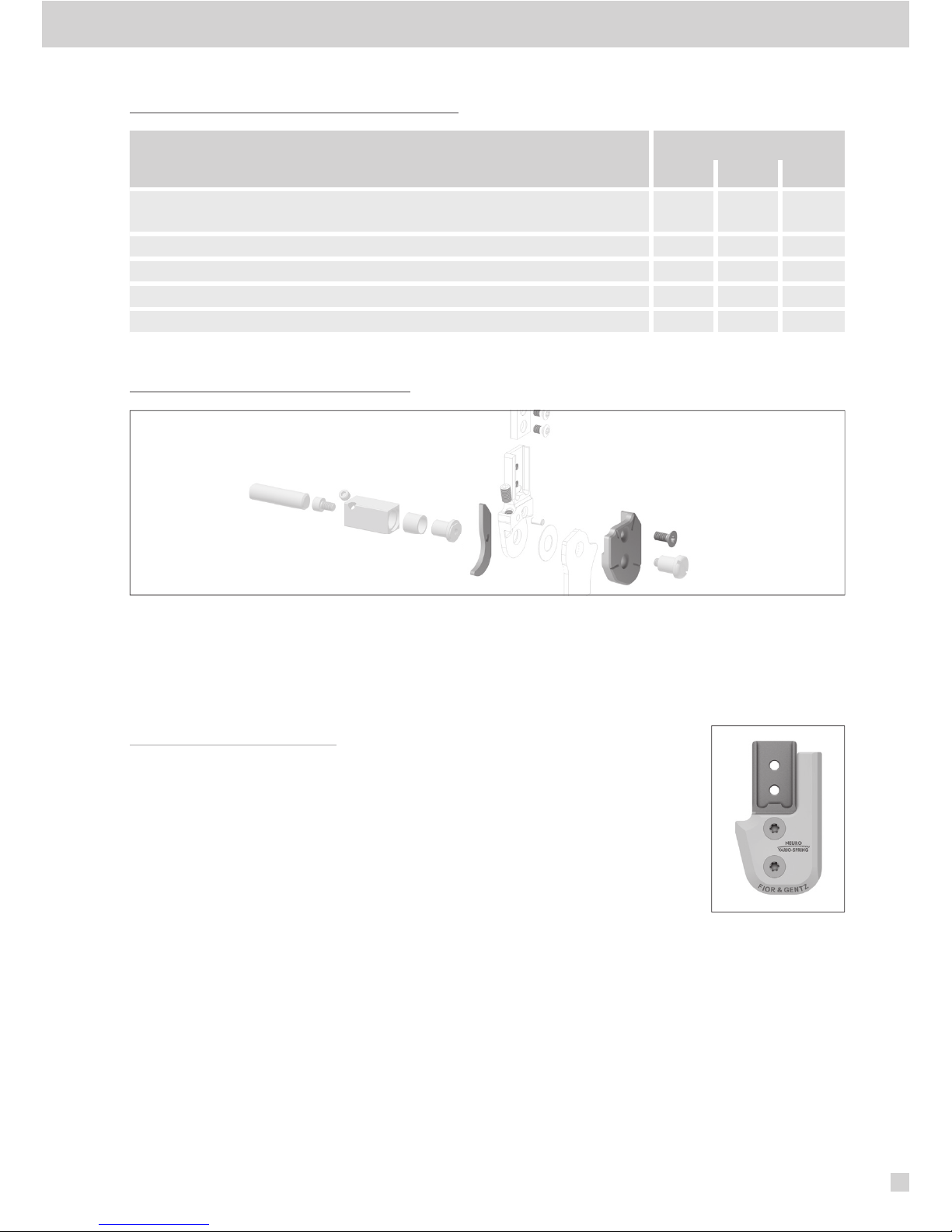

7. Scope of Delivery

The scope of delivery includes the following articles:

Description Quantity

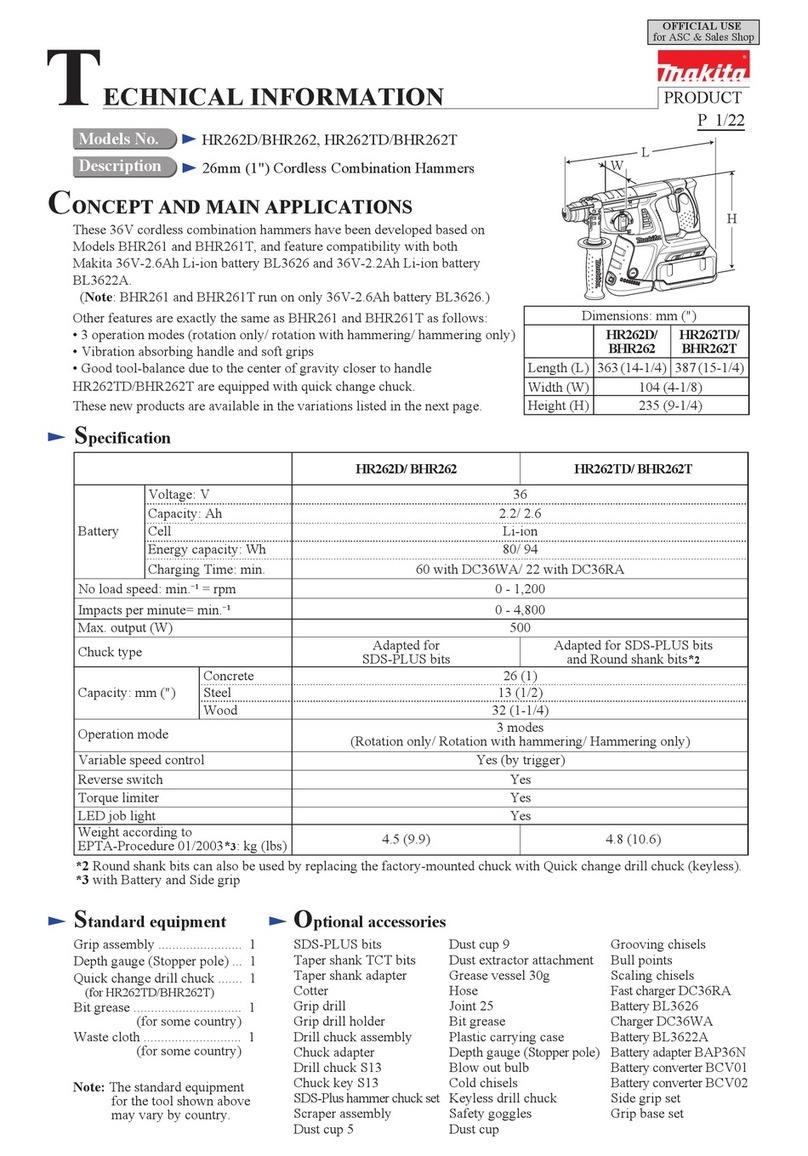

NEURO VARIO-SPRING system ankle joint (fig. 1) 1

securing pin (fig. 2) 1

AGOMET F330, 5g (fig. 3) 1

orthosis joint grease, 3g (fig. 4) 1

assembly/lamination dummy (fig. 5) 1

Corresponding system stirrups in different designs and for different production techniques have to be ordered

separately.

8. Load Capacity

You can find all relevant patient data for your selected system joint in the configuration you performed with the

Orthosis Configurator and/or on your completed orthotic treatment sheet.

fig. 1

fig. 3 fig. 4 fig. 5

fig. 2

21

9. Tools for Assembling the System Joint

Tools

System Width

14mm 16mm 20mm

T20 hexalobular screwdriver

as well as T20 hexalobular bit xxx

screwdriver for slotted screws with the blade size 3.5 x 0.6mm x x x

torque screwdriver 1-6Nm x x x

pin punch x x x

assembly aid for cover plate - x x

10. Assembly/Lamination Dummies

Assembly/lamination dummies are included in the scope of delivery of the system joint. You can find the article

numbers as well as the corresponding tools for the parallel alignment in our product catalogue System Joints

and Articulated System Side Bars.

11. Assembly Instructions

The system joint is delivered fully assembled (fig. 7). All functions are checked beforehand.

You have to disassemble the system joint for mounting it in the orthosis and for mainte-

nance. When disassembling the system joint, make sure not to interchange the different

parts with each other or with parts of other system joints. Clean all system components.

In order to clean the threads in the cover plate, use the Super Clean LOCTITE7063

(articleno.: WZ7063) to remove any insulating wax residues. To ensure optimum func-

tionality, please follow the assembly instructions below:

fig. 7

fig. 6

22

11.1 Mounting the Functional Unit

Start the assembly of the NEURO VARIO-SPRING system ankle joint by mounting the

functional unit. Proceed as follows:

1. Assemble the functional unit consisting of ball (1), pin (2) and pressure spring (3) in

the correct order (fig. 8).

2. Screw in the pressure screw (4) tightly in order to secure the functional unit in the

cover plate's spring duct.

11.2 Mounting the System Stirrup

Mount the system stirrup corresponding to the system width and production technique

to the NEURO VARIO-SPRING system ankle joint. Proceed as follows:

1.

Grease the axle bore of the system stirrup as well as the friction

surfaces of the bearing nut and the first sliding washer with the

delivered orthosis joint grease.

2. Put the bearing nut into the intended opening of the joint's upper

part. The bearing nut has to be placed completely into the opening.

- correct position of the bearing nut (fig. 9);

- incorrect position of the bearing nut (fig. 10).

3. Place the first sliding washer slightly greased on both sides onto the

joint's upper part (fig. 11).

4. Mount the system stirrup (fig. 12).

11.3 Mounting the Cover Plate

Then, mount the cover plate of the NEURO VARIO-SPRING system

ankle joint. Proceed as follows:

1. Clamp the assembly aid for cover plate into a vice.

2. Place the cover plate with the ball on the pin of the assembly aid for

cover plate and compress the pressure spring by pulling the cover

plate in your direction until the cover plate fits into the assembly aid

for cover plate.

3.

Remove the assembly aid for cover plate with the cover plate from

the vice (fig. 13).

4.

Apply spray adhesive on one side of the second sliding washer and adhere it to the cover plate (fig. 14). Grease

the other side of the sliding washer slightly with the delivered orthosis joint grease.

fig. 11 fig. 12

fig. 13

fig. 8

4

3

2

1

fig. 9 fig. 10

The assembly aid for cover plate can only be used for a NEUROVARIO-SPRING system ankle joint with

a system width of 16mm or 20mm. A NEURO VARIO-SPRING system ankle joint with a system width

of 14mm can be mounted effortlessly without the assembly aid.

fig. 14

23

Place the sliding washer in a way that prevents it from being damaged

when mounting the cover plate. If you have nevertheless placed the

sliding washer incorrectly (fig.15-16), remove the particles and place a

new sliding washer.

5.

Mount the cover plate using the assembly aid for cover plate by plac-

ing it sideways on the system stirrup (fig.17).

6.

Screw in the first countersunk flat head screw (axle screw, S1; fig.18)

according to the torque given in the table (see paragraph 11.6).

7. Now, screw in the second countersunk flat head screw (S2; fig. 19)

according to the torque given in the table (see paragraph 11.6).

8.

Remove the assembly aid for cover plate from the mounted cover plate

by grasping the assembly aid for cover plate at the top and carefully

pulling it up and then sideways from the functional unit.

11.4 Checking the System Joint's Free Movement

Check if the system joint moves freely. If the system joint runs with lateral

play, mount the next thicker sliding washer. If it does not move freely

(it is jammed), mount the next thinner sliding washer. For more informa-

tion about the sliding washers see paragraph 15.2.

11.5 Basic Alignment

When mounting the system ankle joint, mind the correct adjustment of the dorsiflexion stop as it is decisive for

the entire alignment of the orthosis. Correct the dorsiflexion stop, if necessary.

11.6 Securing the Screws

After the orthosis has been produced and tried on and before it is given to the patient, secure the screws for the

cover plate with a torque which corresponds to the system width (see table and cover plate of the system joint) and

LOCTITE 243 medium strength (article no.: KL2000). Let the adhesive harden (final strength after approx. 24 hours).

Position of the Screw (Fig. 19)

System Width

14mm 16mm 20mm

S1 (screw 1, axle screw) 4Nm 4Nm 4Nm

S2 (screw 2) 4Nm 4Nm 4Nm

fig. 16fig. 15

Jammed sliding washer particles cause lateral play in the system

joint and a damaged sliding washer could lead to restrictions of

the joint function.

The screws of the cover plate are not secured with the necessary torque at delivery.

fig. 18

fig. 17

fig. 19

S2

S1

24

12. Adjustment Options on the Orthosis

The NEURO VARIO-SPRING system ankle joint can be individually adjusted to the

patient's pathological gait with the help of two adjustment possibilities (fig. 20).

12.1 Adjustable Alignment

When producing an orthosis with the NEURO VARIO-SPRING system ankle joint,

the alignment of the orthosis has to be adjusted to the patient's pathological gait

using the adjusting screw (fig.20). Furthermore, changes in the pathological gait

can be treated flexibly. The position of the adjusting screw cannot change due to

a securing pin installed in the system joint (see paragraph 12.2.3).

12.2 Adjustable Range of Motion

The range of motion is the angle of rotation between two defined limita-

tions of movement.

12.2.1 Filing the Range of Motion

The range of motion of the system ankle joint in dorsiflexion can be

adjusted by filing. For this purpose, the system stirrup is marked with

lines which serve as orientation (fig.21). If the system stirrup is filed to

20°, the system joint becomes free moving in dorsiflexion.

12.2.2 Fine Adjusting the Range of Motion

The range of motion is roughly adjusted by filing the system stirrup. Use the adjusting screw of the system joint

to fine adjust the range of motion at a maximum of 10 more degrees (fig. 20). When screwing in the adjusting

screw too much (more than 10° fine adjusting), the surface pressure between adjusting screw and system stirrup

can become so high that the screw is compressed and loses its function.

12.2.3 Securing the Adjusting Screw

When the adjusting screw turns or loosens, it must be secured again with

the securing pin. Please follow the assembly instructions below:

1. Unscrew the adjusting screw out of the thread (fig. 20).

2. Demount the cover plate and drive out the premounted securing pin

with a pin punch (fig. 22).

3. Turn the worn position of the securing pin by about 90° (fig. 23) and

put it in again (fig. 24).

4. Mount the cover plate (fig. 25).

5. Now, screw the adjusting screw into the desired position (fig. 25).

fig. 20

15°

20°

10°

2°

4°

6°

8°

fig. 21

For more detailed information about the adjustment of the range of motion please refer to the

publications in the download section on our website at www.fior-gentz.com/downloads.

fig. 22 fig. 23

fig. 24 fig. 25

90°

25

6. Additionally, secure the adjusting screw with LOCTITE 243 (article no.:KL2000). Let the adhesive harden

(final strength after approx. 24 hours).

12.3 Reading Joint Angles

The lasered degree markings on the system stirrup and the lasered line

on the cover plate (fig.26) show the angle of the system joint towards

the system stirrup. When handing over the orthosis, you can check the

individual normal posture (the orthosis' basic alignment) by the markings.

You can read as well as record the joint angle indicated at this time. By

doing so, you can easily compare later adaptations or deviations of the

individual normal posture with your documentation.

The distances between the degree markings for each system width can

be seen in the following table.

Degree Marking

System Width 14mm 16mm 20mm

Degree 2° 2° 2°

13.

Converting the NEURO VARIO-SPRING into a NEURO VARIO-CLASSIC System Ankle Joint

You can convert the system joint in order to use the orthosis without dor-

siflexion assist. The joints' upper parts of the NEURO VARIO-SPRING and

NEURO VARIO-CLASSIC system ankle joints are identical in construction.

Disassemble the functional unit of the NEURO VARIO-SPRING system

ankle joint and mount the cover plate of the NEURO VARIO-CLASSIC

system ankle joint (fig.27). When ordering the cover plate, note and

respect the corresponding system width.

14. Advice on Production Techniques

Use the system components determined by the Orthosis Configurator when

producing an orthosis and mind the recommended production technique.

If the securing pin is deformed after the driving, put in a new one (article no.:GS4007). If

necessary, cut the new pin with a sharp knife so that it does not protrude. An additional security

pin is included in the delivery.

fig. 26

You will find more information about the individual normal posture on the internet at

www.fior-gentz.com.

You will find detailed information about our production techniques in the section “Orthosis Production”

under “Online Tutorials” and “Producing the Orthosis” on our website www.fior-gentz.com.

fig. 27

26

14.1 Parallel Alignment of System Joints

You will find the necessary tools for the parallel alignment of the system joints on the positive cast in our latest

product catalogue System Joints and Articulated System Side Bars.

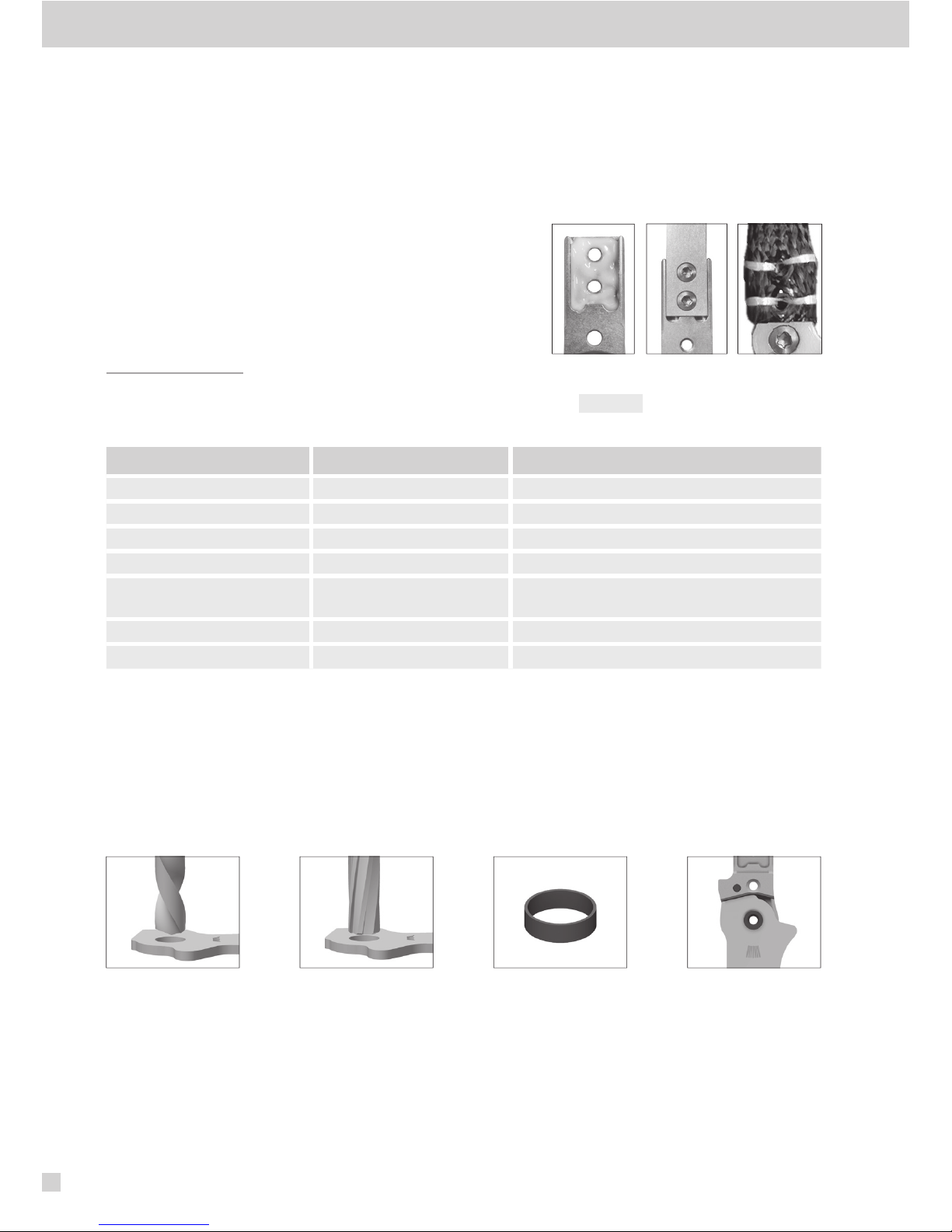

14.2 Mounting to the System Side Bar/System Anchor

Depending on the production technique, the system side bar/system

anchor must be adhered and screwed or sewed together with the

system joint (fig.28-30). You will find further information concerning

the different production techniques on the internet or in the manual

System Side Bars and System Anchors (article no.: PB1000-SA).

15. Maintenance

We recommend checking the system joint’s functionality and wear every 6 months.

Check the following parts in particular:

Joint Part Problem Measure

pressure spring fatigue of spring force replacing

pin wear replacing

bearing nut wear replacing

securing pin wear replacing, see paragraph 12.2.3

bore for bearing nut of

system stirrup oversize inserting repair bushing,

see paragraph 15.1

sliding washers wear replacing, see paragraph15.2

adjusting screw wear replacing

15.1 Repairing the Bearing Nut Bore

If the bore for the bearing nut is worn out at the system stirrup, bore (fig.31) and ream (fig.32) it with a reamer

(see product catalogue System Joints and Articulated System Side Bars) in order to insert a repair bushing

(boring and reaming measurements see table). For a centred boring and reaming, clamp the system stirrup firmly.

After inserting the repair bushing made of bronze (fig. 33), the bore has the specified size again. The joint system

is now free of play (fig.34).

fig. 34fig. 33fig. 32fig. 31

fig. 29

fig. 28 fig. 30

27

Boring and Reaming Measurements [mm]

System

Width

Bearing Nut

Outer Ø

Repair

Bushing

Inner Ø

Repair

Bushing

Outer Ø

Ø

Measurement

for Boring

Ø

Measurement

for Reaming

Art. No.

Repair Bushing

14mm 8.5 8.5 9.6 9.3 9.6 H7 BR1009-L025

16mm 9.6 9.6 10.5 10.2 10.5 H7

BR1110-L030

20mm 10.5 10.5 11.5 11.2 11.5 H7

BR1211-L030

15.2 Replacing the Sliding Washers

If the premounted sliding washers wear out, they have to be replaced by new ones with the same thickness. The

article numbers of the premounted sliding washers are on the back page of this manual. The last three digits of

the article number stand for the thickness of the sliding washer, e.g. GS1407-040. The thickness of this sliding

washer is 0.40mm. In total, the sliding washers are available in five dierent thicknesses. The thickness of a sliding

washer is indicated by the markings. For example, a sliding washer with two grooves is 0.40mm thick, whereas a

sliding washer with one notch is 0.55mm thick (fig.35). Note and respect that when reordering.

15.3 Cleaning

While using the orthosis, the system joint has to be cleaned if needed and during regularly carried out mainte-

nance. For this purpose, disassemble the system joint and clean the soiled system components with a dry cloth.

16. Disposal

Dispose of the system joint and its individual parts properly. The product must not be disposed

of with the residual waste (fig.36). Please comply with the applicable national laws and

local regulations for the proper recycling of recyclable materials.

0.45mm 0.50mm 0.55mm 0.60mm

0.40mm

fig. 35

fig. 36

For proper disposal, it is necessary to demount the system joint from the orthosis.

28

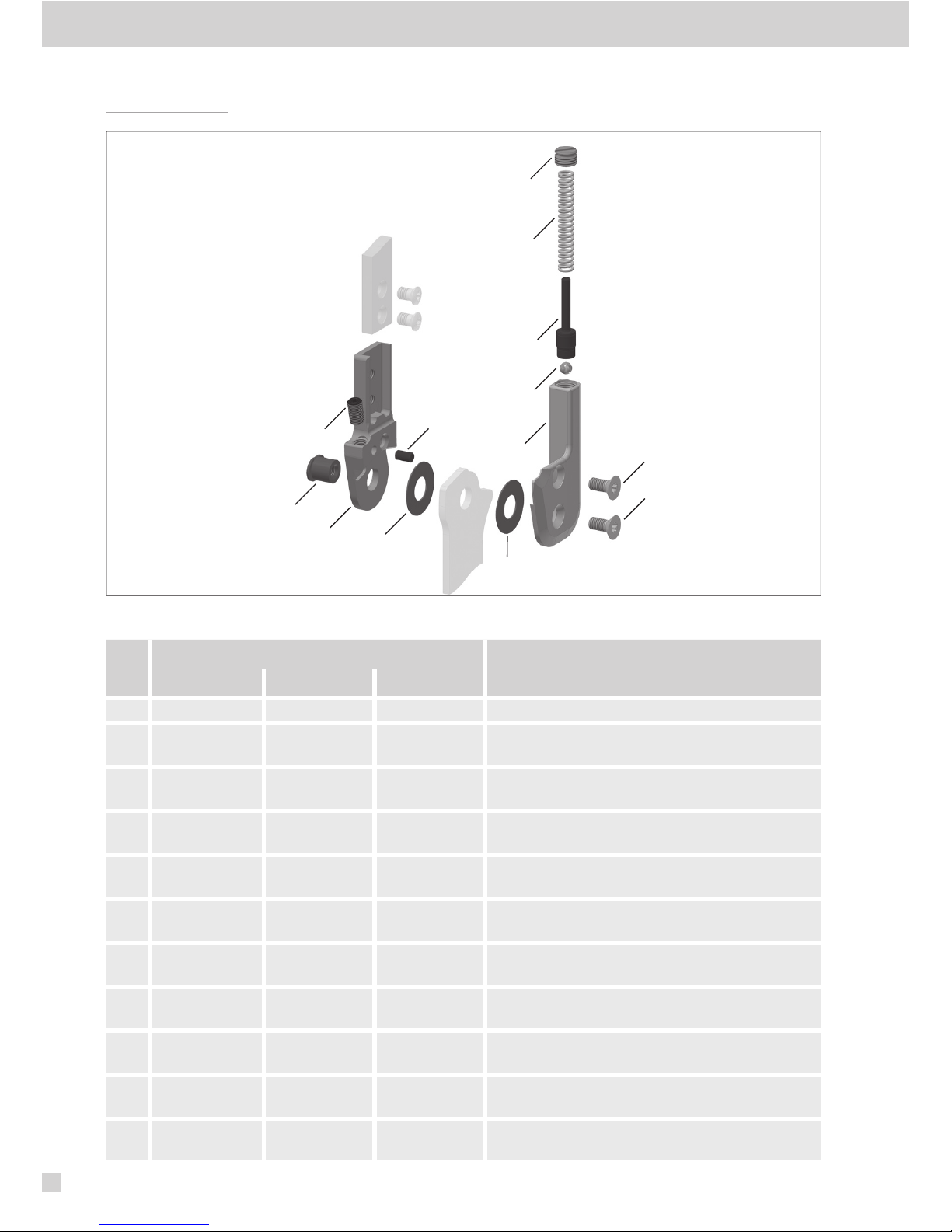

17. Spare Parts

Item

Article Number for System Width

Description

14mm 16mm 20mm

1 SB8559-L0620 SB9669-L0760 SB1069-L0810 bearing nut

2 SF0412-L/ST SF0413-L/ST SF0415-L/ST upper part, left lateral or right medial, straight,

steel (with adjusting screw)

2 SF0412-R/ST SF0413-R/ST SF0415-R/ST upper part, left medial or right lateral, straight,

steel (with adjusting screw)

2 SF0412-L/TI SF0413-L/TI SF0415-L/TI upper part, left lateral or right medial, straight,

titanium (with adjusting screw)

2 SF0412-R/TI SF0413-R/TI SF0415-R/TI upper part, left medial or right lateral, straight,

titanium (with adjusting screw)

2 SF0432-L/ST SF0433-L/ST SF0435-L/ST upper part, left lateral or right medial, bent

inwards, steel (with adjusting screw)

2 SF0432-R/ST SF0433-R/ST SF0435-R/ST upper part, left medial or right lateral, bent

inwards, steel (with adjusting screw)

2 SF0432-L/TI SF0433-L/TI SF0435-L/TI upper part, left lateral or right medial, bent

inwards, titanium (with adjusting screw)

2 SF0432-R/TI SF0433-R/TI SF0435-R/TI upper part, left medial or right lateral, bent

inwards, titanium (with adjusting screw)

2 SF0432-8L/ST SF0433-8L/ST SF0435-8L/ST upper part, left lateral or right medial, bent

outwards, steel (with adjusting screw)

2 SF0432-8R/ST SF0433-8R/ST SF0435-8R/ST upper part, left medial or right lateral, bent

outwards, steel (with adjusting screw)

1

24

10

11

9

3

8

7

6

5

2a

4

fig. 37

29

Item

Article Number for System Width

Description

14mm 16mm 20mm

2 SF0432-8L/TI SF0433-8L/TI SF0435-8L/TI upper part, left lateral or right medial, bent

outwards, titanium (with adjusting screw)

2 SF0432-8R/TI SF0433-8R/TI SF0435-8R/TI upper part, left medial or right lateral, bent

outwards, titanium (with adjusting screw)

2a SC9605-L08ST SC9606-L10ST SC9606-L10ST adjusting screw

3 GS4007 GS4007 GS4007 securing pin

4 GS2009-* GS2210-* GS2611-* sliding washer*

5 SC2108-L04 SC2109-L05 SC2110-L05 pressure screw

6 FE1634-02 FE2836-02 FE2752-02 pressure spring, golden

7 SF0342-75 SF0343-72 SF0345-81 pin

8 KU1005-ST KU1005-ST KU1005-ST ball

9 SF0462-L/AL SF0463-L/AL SF0465-L/AL cover plate, left lateral or right medial

9 SF0462-R/AL SF0463-R/AL SF0465-R/AL cover plate, left medial or right lateral

10 SC1405-L10 SC1405-L11 SC1405-L12 countersunk flat head screw, hexalobular socket

11 SC1405-L10 SC1405-L11 SC1406-L12 countersunk flat head screw, hexalobular socket

(axle screw)

5-11 SF4972-L/AL SF4973-L/AL SF4975-L/AL functional unit NEURO VARIO-SPRING, left

lateral or right medial

5-11 SF4972-R/AL SF4973-R/AL SF4975-R/AL functional unit NEURO VARIO-SPRING, left

medial or right lateral

* Sliding Washers

Article Number for System Width

14mm 16mm 20mm

Ø = 20mm Ø = 22mm Ø = 26mm

GS2009-040 GS2210-040 GS2611-040

GS2009-045 GS2210-045 GS2611-045

GS2009-050 GS2210-050 GS2611-050

GS2009-055 GS2210-055 GS2611-055

GS2009-060 GS2210-060 GS2611-060

18. Accessory Parts

You will find a big variety of accessory parts in our latest product catalogue System Joints and Articulated

System Side Bars.

When reordering, note and respect the thickness of the sliding washers (explanation see paragraph15.2).

31

19.

Informationen für die Versorgungsdokumentation/Information for the Treatment

Documentation

Bitte heften Sie diese Produktbeilage zu Ihrer Versorgungsdokumentation!

Add this manual to your treatment documentation!

Patientendaten/Patient´s Data

Name

Name

Straße

Address

PLZ, Wohnort

Postcode, City

Telefon privat

Home Telephone

Telefon geschäftlich

Telephone at Work

Kostenträger

Insurance

Mitgliedsnummer

Insurance No.

Behandelnder Arzt

Attending Physician

Diagnose

Diagnosis

Die Angaben der Produktbeilage beziehen sich auf den aktuellen Stand bei Drucklegung. Produktangaben sind

Richtwerte. Technische Änderungen vorbehalten.

Alle Urheberrechte, besonders die Rechte der Verbreitung, Vervielfältigung und Übersetzung, bleiben ausschließlich

der FIOR &GENTZ Gesellschaft für Entwicklung und Vertrieb von orthopädietechnischen Systemen mbH vorbehalten.

Nachdrucke, Kopien sowie sonstige Vervielfältigungen elektronischer Art dürfen auch auszugsweise nicht ohne

schriftliche Genehmigung der FIOR &GENTZ Gesellschaft für Entwicklung und Vertrieb von orthopädietechnischen

Systemen mbH vorgenommen werden.

The information in this manual is valid at the date of printing. The contained product information serves as a guideline. Subject

to technical modifications.

All rights, particularly the distribution, copy and translation of this manual or any part of it, in paper or as electronic document,

must be authorised in writing by FIOR &GENTZ Gesellschaft für Entwicklung und Vertrieb von orthopädietechnischen Systemen

mbH. Reprints, copies and any other electronic reproduction, even partial, must be authorised in writing by FIOR &GENTZ

Gesellschaft für Entwicklung und Vertrieb von orthopädietechnischen Systemen mbH.

PB4000-SF-09/2018

Montierte Gleitscheiben-Version

Mounted Sliding Washer Version

1. GS ____________ - ________

2. GS ____________ - ________

Beinseite

Leg Side

links/left rechts/right

Der Qualitätsstandard der Firma FIOR & GENTZ ist durch eine unabhängige Zertifizierungsgesellschaft

nach den internationalen Normen ISO 9001 und ISO 13485 geprüft und bescheinigt worden.

The quality standard of the FIOR & GENTZ company has been controlled and certified by an independent certification

organisation according to the international standards ISO 9001 and ISO 13485.

Gesellschaft für Entwicklung und Vertrieb

von orthopädietechnischen Systemen mbH

Dorette-von-Stern-Straße 5

21337 Lüneburg (Germany)

info@fior-gentz.de

www.fior-gentz.com

+49 4131 24445-0

+49 4131 24445-57

Table of contents

Popular Power Tools manuals by other brands

Milwaukee

Milwaukee M12 AL-0 Original instructions

SCHUNK

SCHUNK KSO 65 Installation and operating instruction

Ribimex

Ribimex PRS499 quick start guide

EINHELL

EINHELL TE-MS 18/210 Li Original operating instructions

AutoTeks

AutoTeks BUILDEX Operator's manual and maintenance instructions

Geo Knight

Geo Knight Digital DK20 16x20 manual