FIPA TR01.250 User manual

Operang instrucons

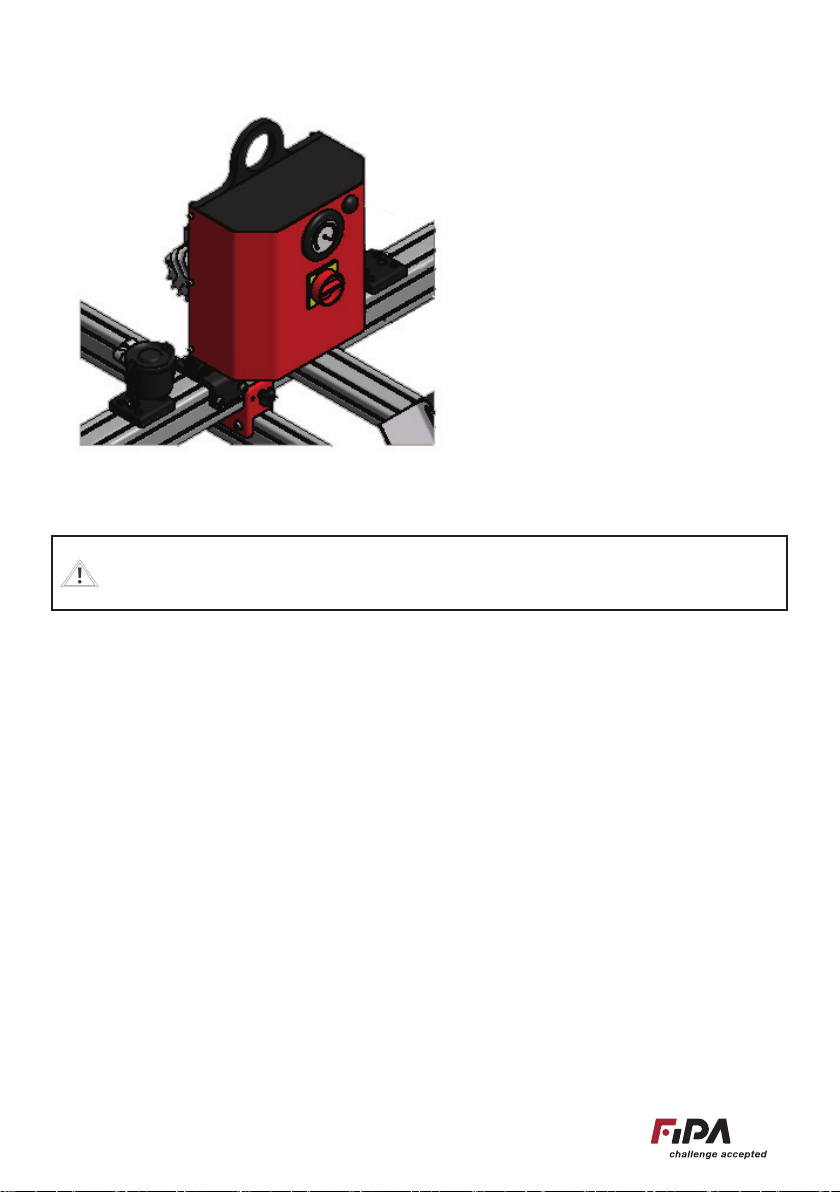

FIPA Spider vacuum traverse

TR01.250

TR01.500

EC Declaraon of Conformity

Ismaning, April 2016

Place and date

Rainer Mehrer,

CEO

The company:

FIPA GmbH

Freisinger Str. 30

85737 Ismaning

Germany

declares under its own responsibility, that the FIPA Spider vacuum traverse:

TR01.250

TR01.500

Table of contents

1. INTRODUCTION 4

2. SAFETY 5

3. PRODUCT DESCRIPTION 7

4. INSTALLATION AND COMMISSIONING 9

5. OPERATION 11

6. MAINTENANCE 13

7. TROUBLESHOOTING 15

8. SPECIFICATIONS 17

Symbols

Warning

Commissioning

FIPA Spider vacuum traverse

4

1. INTRODUCTION

necessary.

items, please contact our Technical Team.

Peripheral systems, installed alongside the FIPA Spider vacuum traverse, are not described in these

Rainer Mehrer,

CEO

The design and construcon of the vacuum traverse may not be modied under any

circumstances without approval from FIPA GmbH. Only genuine FIPA accessories and

spare parts may be used. Unapproved modicaons and/or the use of third party

accessories and spare parts can cause severe bodily injury during the liing process

and will result in the warranty being voided.

5

FIPA Spider vacuum traverse

2. SAFETY

Safety rules

>

>

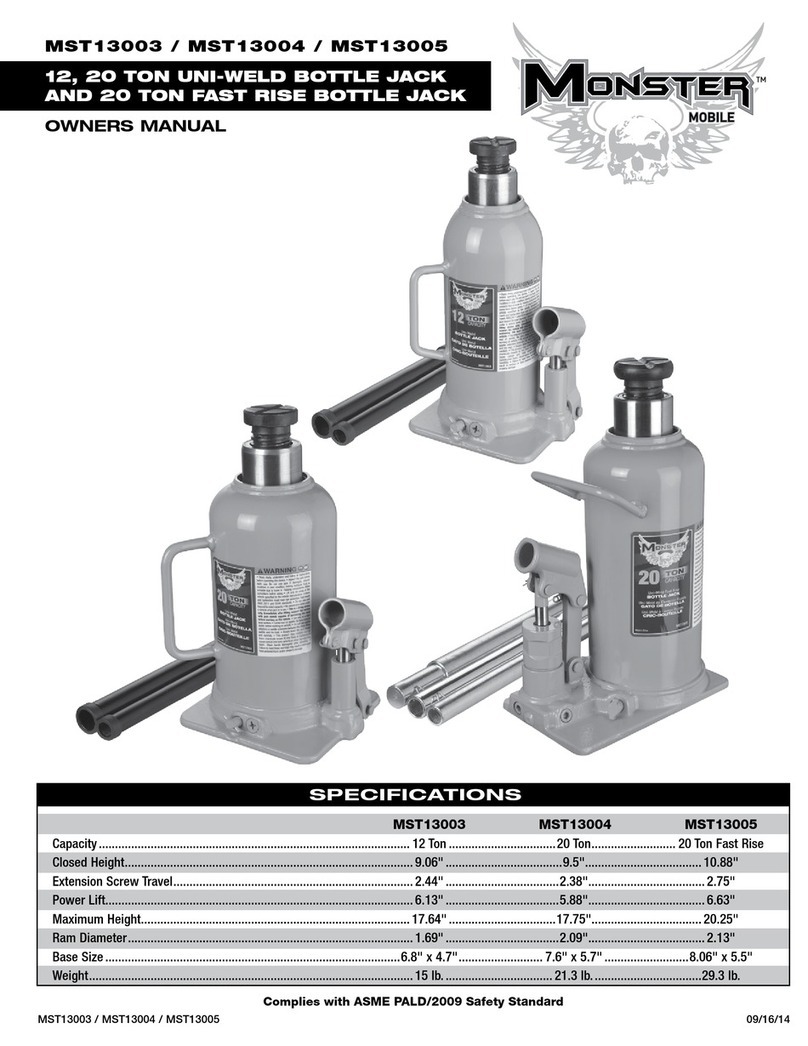

Type

TR01.250

TR01.500

>

>

>

>

>

>

>

>

> -

cated centrally between the vacuum cups .

>

>

>

>

> Never manually manipulate the vacuum traverse when raising or lowering.

>

>

>

FIPA Spider vacuum traverse

6

Observe the rules and regulaons of your naonal authories and instuons for

occupaonal safety and operaon of liing equipment.

Important informaon

>

>

>

>

>

7

FIPA Spider vacuum traverse

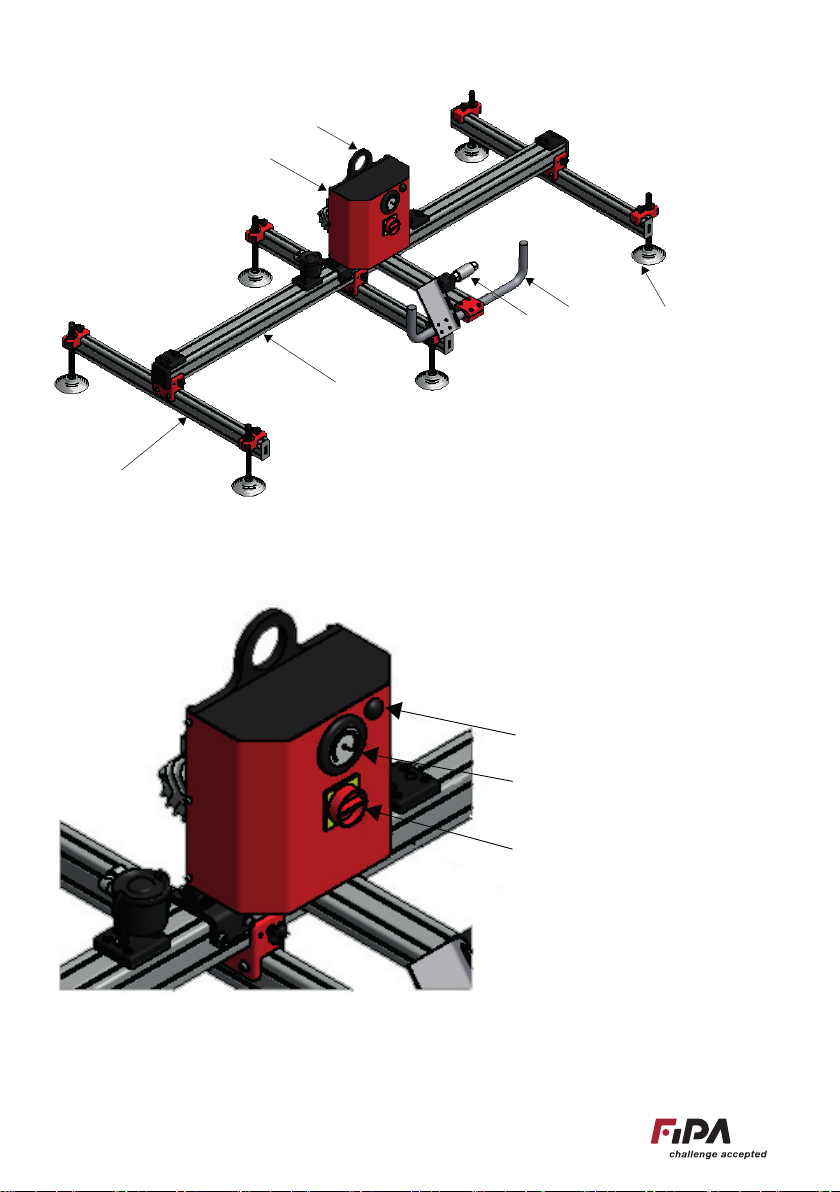

a

b

c

a

b

c

d

e

f

g

3. PRODUCT DESCRIPTION

aMain beam

bCross beam

c

d

eVacuum unit

fFastening eye, inner Ø 70 mm

gVacuum cup

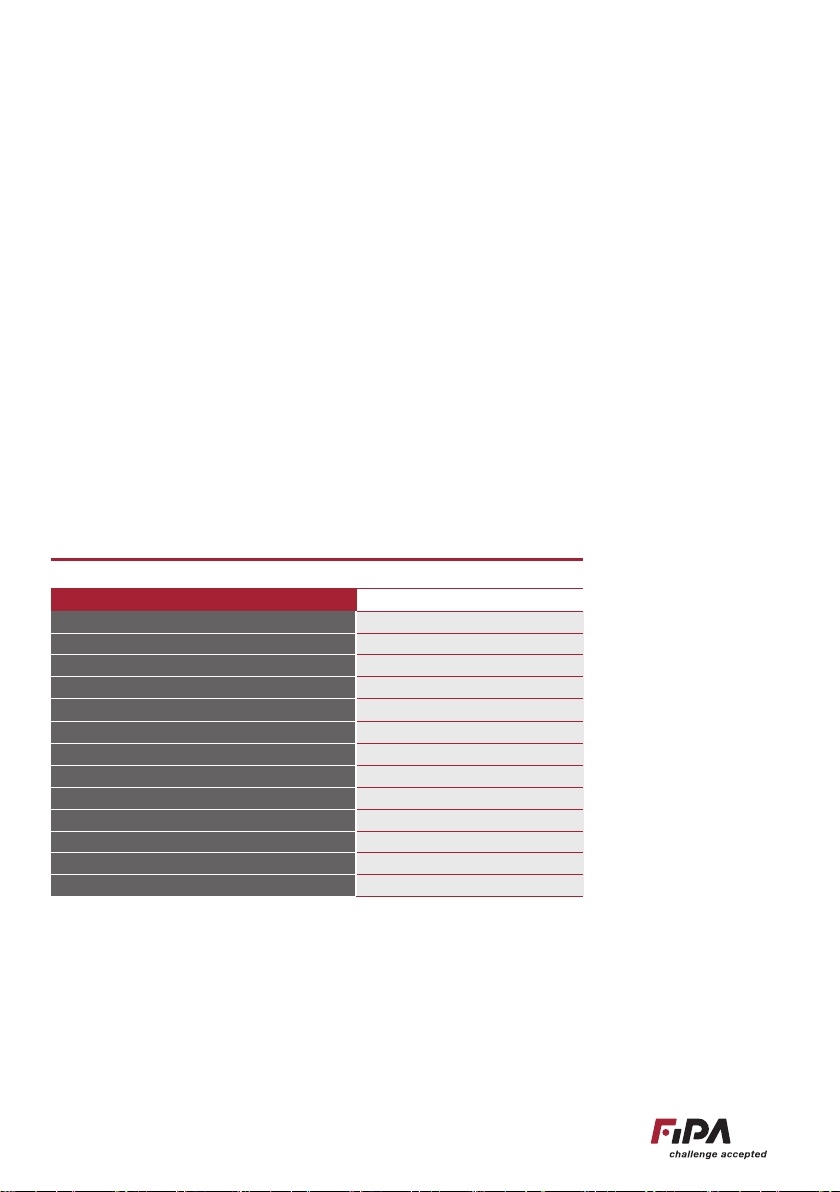

a

b

c

FIPA Spider vacuum traverse

8

a

a

b

a

b

a

9

FIPA Spider vacuum traverse

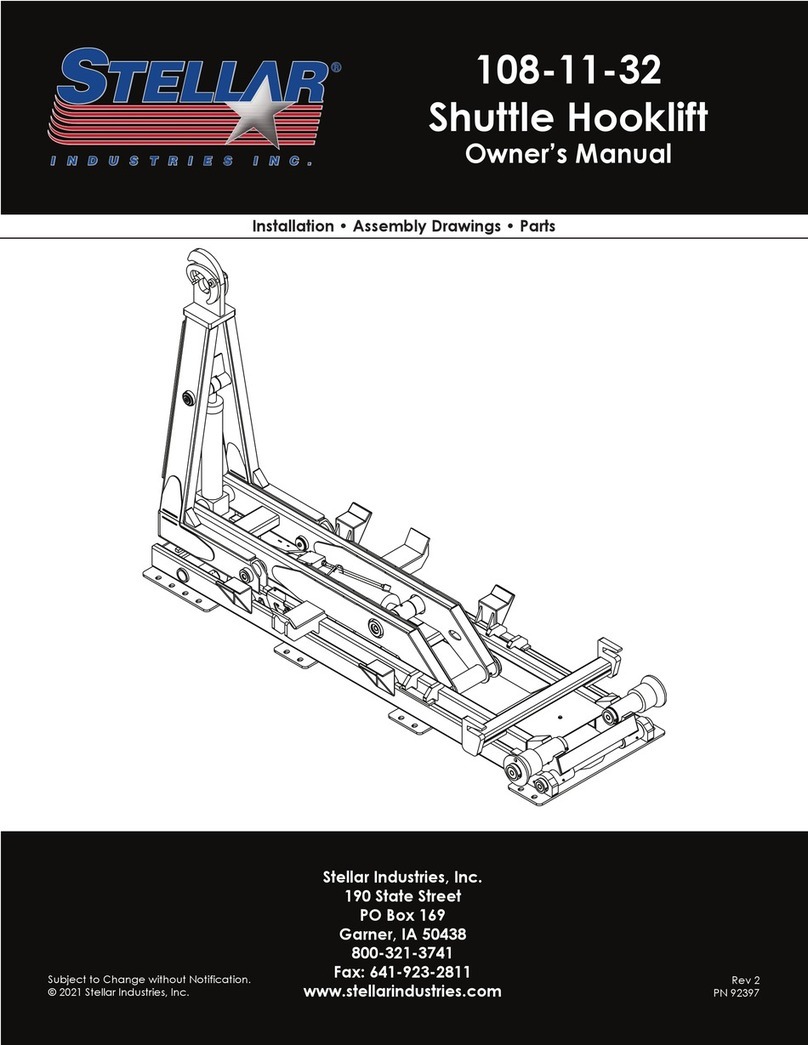

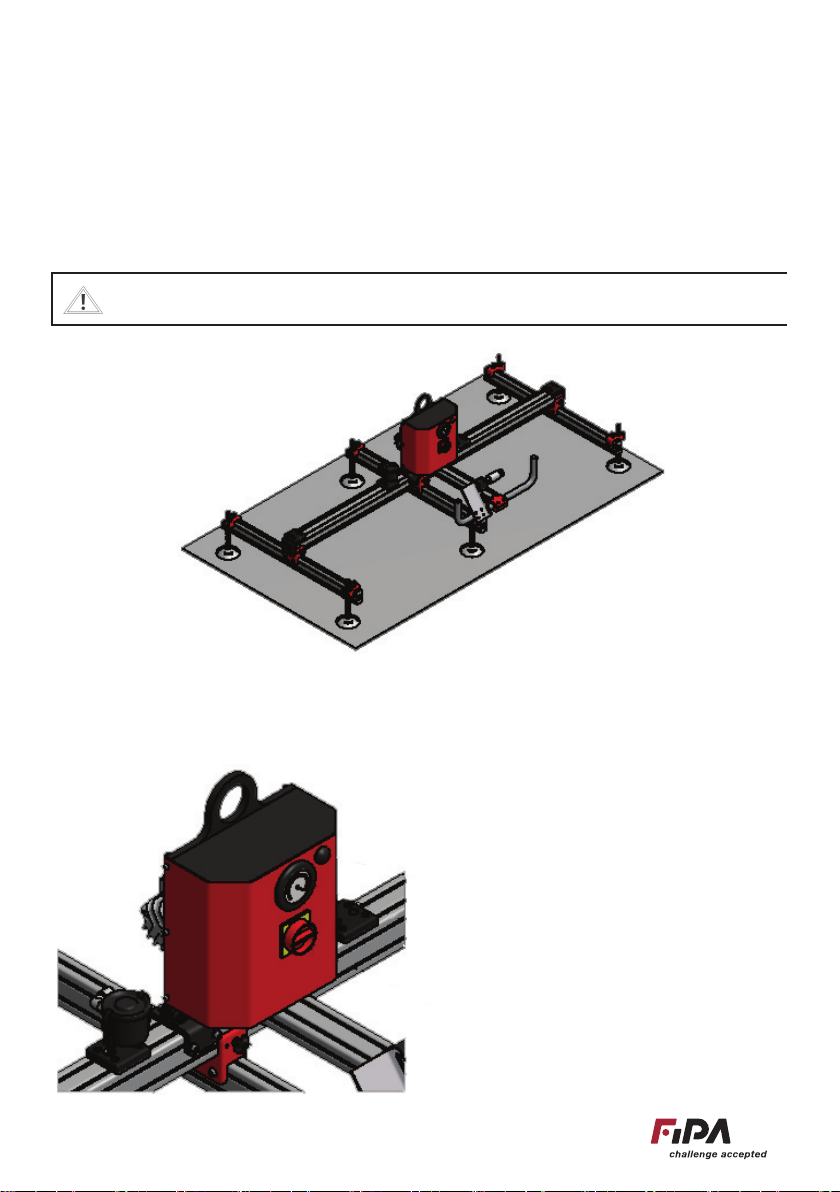

4. INSTALLATION AND COMMISSIONING

Safety instrucons for installaon

>

The electrical connecon may only be carried out by qualied personnel in compliance with the

applicable electrical standards.

Check that the supply voltage conforms to the data stated on the motor rang plate of the vacuum pump.

The FIPA Spider vacuum traverse has a two-pole and earthing-pin plug on the rear for connecng.

The vacuum traverse can thereby be connected to the chain hoist with a spiral cable.

Please note that the vacuum traverse only needs single phase electricity!

Technical data

Part No. DT.5C-1 / 50 Hz

Sucon power [m3/h] 5

Final pressure (absolute) [mbar/hPa] 120

Rated power 0.12

Voltage supply [V] 220 - 240

Current consumpon [A] 1

Speed [n/min] 2800

Noise level 1m 59

Weight 5.4

Vacuum inlet ø [mm] 9

Operang temperature at 20°C [°C] 65 - 70

Permissible ambient temperature [°C] 0 40°

Storage and transport temperature [°C] -20 - 50°C

PMax. Moisture (1000m above sea level) [%HR] 80

A three-phase variant is also available on request

The vacuum traverse must be operated in venlated areas to ensure that it funcons safely. It is

essenal to prevent hot air from building up in the work area.

Do not place any objects in the vicinity of the motor cooling impeller which could obstruct the

normal air ow.

FIPA Spider vacuum traverse

10

Important informaon

You will nd more detailed informaon about the use of the vacuum pump in the separate

enclosed operang instrucons for oil-free vacuum pumps.

Installaon of the vacuum traverse

>

>

elements must still be able to be operated in the highest position.

Test operaon and inial acceptance

>

>

The system must only be started aer a qualied electrician or electrically qualied

person has installed a safety device to the motor.

If no safety device is installed on the motor there is a risk of re!

11

FIPA Spider vacuum traverse

5. OPERATION

Device sengs

needle on the pressure gauge indicates a value

-600mbar

FIPA Spider vacuum traverse

12

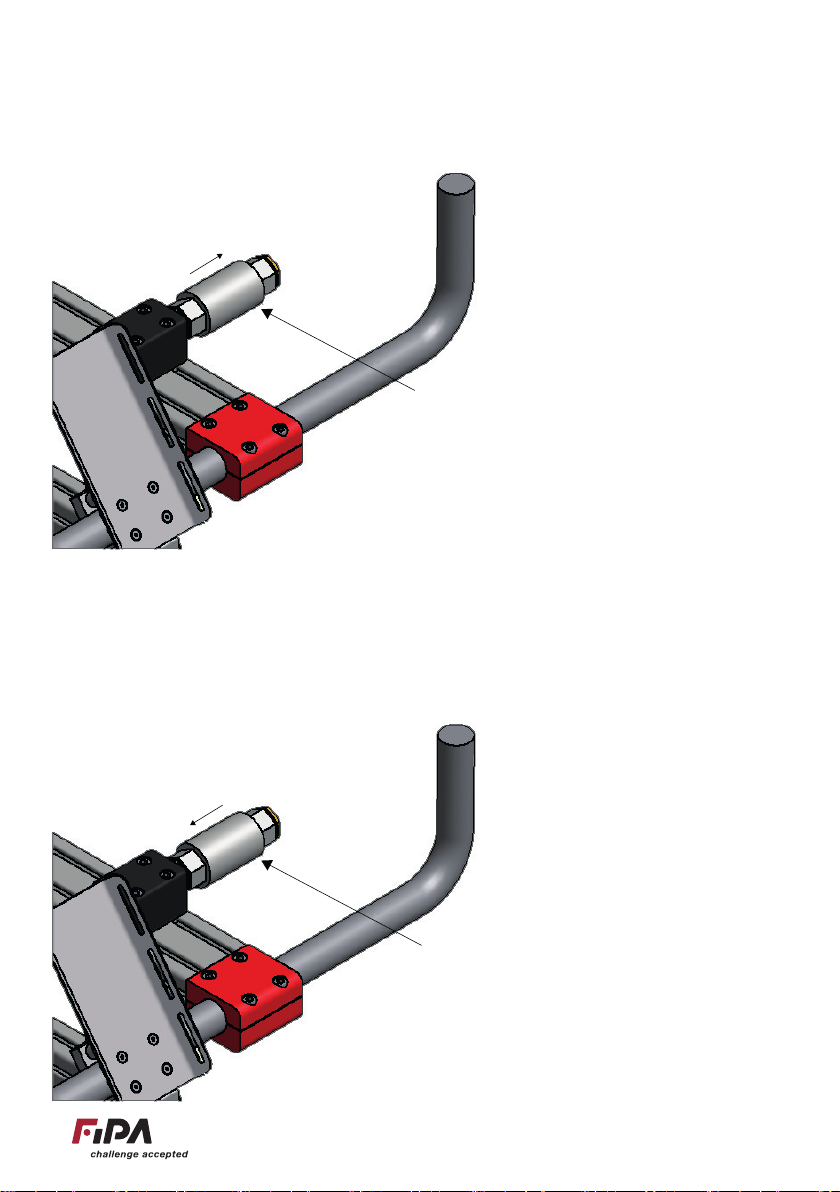

a

vent

a

suck

a

Risk of accident!

securely.

a

13

FIPA Spider vacuum traverse

6. MAINTENANCE

Warning! Only carry out maintenance if you have all the spare parts available.

>

again.

>

Maintenance of the vacuum pump

General informaon

>

>

>

>

FIPA Spider vacuum traverse

14

Maintenance

>

which the vacuum traverse is used. Only use genuine FIPA spare parts.

>

>

Maintenance of the vacuum traverse

Daily maintenance and inspecon

>

cleaned must be replaced.

>

Weekly maintenance and inspecon

>

>

>

>

>

Quarterly maintenance and inspecon

>

>

If parts are damaged, the vacuum traverse must not be used unl the fault has been reced.

Please contact our Technical Team!

>

>

>

>

Warning! An annual test is required by the accident prevenon regulaons (UVV). This

must be documented!

15

FIPA Spider vacuum traverse

7. TROUBLESHOOTING

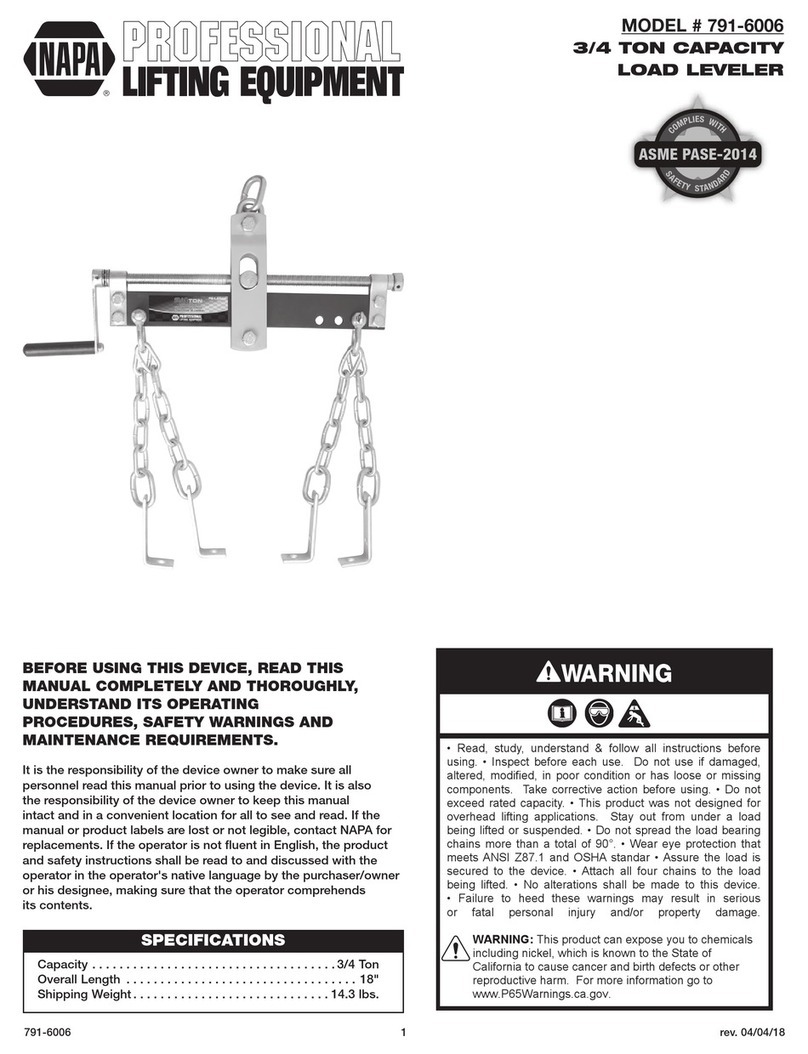

Fault: The load is not lied

Mount the cap correctly.

If you cannot recfy the fault yourself, please contact our Technical Team.

If the load is not lied, this can be due to the fact that a vacuum is not being generated or that

there is a leak in the system.

FIPA Spider vacuum traverse

16

Fault: The vacuum pump doesn't start.

Please contact our Technical Team.

Please contact our Technical Team.

Fault: Extraneous noise from the vacuum pump

Please contact our Technical Team.

Please contact our Technical Team.

Please contact our Technical Team.

Fault: Insucient vacuum is generated

Fault: The vacuum pump gets too hot

Please clean.

17

FIPA Spider vacuum traverse

8. SPECIFICATIONS

Dimensions of the FIPALIFT Basic vacuum traverse

649

896

2025

Ø 70

FIPA Spider vacuum traverse

18

Inspecon and maintenance documents

FIPA GmbH Company:

Freisinger Straße 30

D-85737 Ismaning

Date: _________________________

Serial Number: ________________________

Date: _____________________ __________________________

Comments

report number

Date / Signature

report number

19

FIPA Spider vacuum traverse

Comments

report number

report number

report number

report number

FIPA GmbH

Freisinger Strasse 30

85737 Ismaning / Germany

Telephone

962489-0

962489-11

FIPA Inc.

1855 Evans Road

Cary, NC 27513 / USA

919

651

9888

919

573

0871

FIPA Ltd.

2

1687036

2

1687037

This manual suits for next models

1

Table of contents

Other FIPA Lifting System manuals