FIPA FIPALIFT Smart Series Manual

Operang and maintenance instrucons

FIPALIFT Smart

SH.BAS.SMA.80

SH.BAS.SMA.100

SH.BAS.SMA.120

SH.BAS.SMA.140

EC declaraon of conformity

Ismaning, den November 2015

Datum und Ort/Date and place

Rainer Mehrer,

Geschäsführer/CEO

Company:

FIPA GmbH

Freisinger Str. 30

85737 Ismaning

Germany

www.pa.com

declares under its sole responsibility that the FIPALIFT Smart:

SH.BAS.SMA.80

SH.BAS.SMA.100

SH.BAS.SMA.120

SH.BAS.SMA.140

referred to in this declaraon are being produced according

to the following regulaons:

2006/42/EG (Machinery Direcve)

2006/95/EG (Low Voltage Direcve)

2004/108/EG (EMC-Guideline)

Table of contents

1. INTRODUCTION 4

2. SAFETY 5

3. PRODUCT DESCRIPTION 7

4. INSTALLATION AND COMMISSIONING 8

5. OPERATION 12

6. MAINTENANCE 15

7. TROUBLESHOOTING 15

8. SPECIFICATIONS 18

Symbols

Warning

Important information

Commissioning

Check

FIPALIFT Smart

4

1. INTRODUCTION

The FIPALIFT Smart tube lier is a liing device whose liing force and moon are based on vacuum.

The device can be adapted to a variety of applicaons. Consequently it is possible to li various

objects, such as sheet metal, wooden panels, glass panels, doors, windows, crates, boxes, sacks,

barrels and drums. Any applicaon is possible.

The FIPALIFT Smart tube lier has been developed to be ergonomic and uid to work with, allowing

you to easily li and move heavy loads. It is extremely me-ecient in that a drawn out process to

secure the load is not necessary.

The operang manual contains a descripon of the safety rules, installaon, operaon, maintenance

and troubleshoong as well as the technical data. Special versions of the FIPALIFT Smart tube lier

are not described. Informaon about these products can be obtained from our Technical Sales

Department (+49 89 962489-0).

The device supplied may only be used for liing objects for which it is designed in accordance with

your enquiry and order conrmaon. If you intend to use the liing equipment for other objects,

please contact our Technical Sales Department.

Peripheral systems installed alongside the FIPALIFT Smart tube lier are not described in these

operang instrucons. Please take note of the separate descripons for these system parts.

FIPA is constantly striving to develop and improve the design and construcon of its liing

equipment. Therefore FIPA reserves the right to make modicaons to the design and technical

conguraon without noce.

All informaon in these operang instrucons corresponds to the features at the me of publicaon.

Prinng errors are possible.

Rainer Mehrer,

CEO

The design and construcon of the tube lier may not be modied under any circum-

stances without approval from FIPA GmbH. Only original FIPA accessories and spare parts

may be used. Unapproved modicaons and/or the use of third party accessories and

spare parts can cause severe bodily injury during the liing process and will result in the

warranty being voided.

5

FIPALIFT Smart

2. SAFETY

Read these operang instrucons carefully before inial commissioning and note the following

safety rules. The FIPALIFT Smart tube lier may only be operated and maintained by personnel

who have read these operang instrucons and fully understand the content. Display the operang

instrucons near the tube lier so as to be easily accessible and make operators aware of them.

Safety regulaons

> The unit may not be operated or maintained by persons under the inuence of alcohol,

medicaons aecng awareness, such as sleeping tablets or strong painkillers or other drugs.

Other condions such as circulatory problems or dizziness are criteria that disqualify persons

from operang this system.

> It is within the operator's scope of responsibility to ensure that no physical injury can arise

during work.

> Wear safety boots during operaon.

> When working with the tube lier, never allow yourself to be distracted and never distract

the operator. Lapses of concentraon lead to accidents.

> Do not work with loads that are heavier than the design of the device allows.

> Only use the tube lier to li loads that are packaged so that they cannot come apart when

lied.

> Do not place the vacuum cup on surfaces with loose areas, such as address labels or covers

that could come loose.

> Do not place the vacuum cup on surfaces that are so slippery that the load could slide o the

vacuum cup (slip eect).

> Take parcular care when handling objects with sharp edges, such as sheet metal.

> Never use the FIPALIFT Smart tube lier to li loads that contain hazardous or explosive sub-

stances. IEnsure beforehand that work can be undertaken safely.

> Posion the vacuum cup vercally above the centre of gravity of the object to be lied.

> The tube lier with a lied load may only be operated so that if the load were to fall, it would

not cause injury to persons.

> Never move lied loads over persons. Persons may not stand below the lied load.

> Do not set down the lied load if doing so would cause injury to persons or damage to objects.

> The vacuum cup may not be aached to people or animals.

> Never li objects for longer than 60 seconds with the tube lier's vacuum cup. Doing so

causes the vacuum pump to overheat and may cause damage and/or impair its funcon (this

does not apply to tube liers that are operated with a mul-chamber ejector).

> Never manually manipulate the tube lier when raising or lowering.

> Always adjust the balancing height according to the load.

> A lied load may not be le unaended.

> The standard tube lier may not be operated in a potenally explosive environment. Electrical

and mechanical components can produce sparks that can ignite vapours. A specially modied

device is required for this kind of applicaon. Please contact our Technical Sales Department.

FIPALIFT Smart

6

Observe the rules and regulaons of your naonal authories and instuons for

occupaonal safety and operaon of liing equipment.

Important informaon

> It is important to read the enre manual thoroughly before installing and commissioning the

system and familiarise yourself with the system.

> The tube lier should only be operated with gentle hand movements on the control handle in

order to avoid violent movements when liing.

> The device must be switched o during servicing and cleaning and must be secured against

being switched back on.

> The vacuum pump must be handled with parcular care as it is sensive to shocks and

vibraons.

> The vacuum pump may not be started up without an air lter.

7

FIPALIFT Smart

3. PRODUCT DESCRIPTION

Upper

swivel joint

Liing tube

Vacuum hoses

Control unit

Filter unit

Vacuum pump

Protecve coang

Liing unit

Filter holder

Filter cover

Filter holder

Upper swivel joint

Silencing box

Control unit

Non-return valve

Balancing buon

Release lever

Control lever

Air connecon

Connecon for vacuum hose

Cable bushing

Bellows vacuum cup

Lower swivel joint

Corner joint

Suspension eye

Plasc adapter

Balancing valve

Handgrip

Silencer

Filter housing

Filter cover

Ejector with integrated

Non-return valve

Plasc adapter

Vacuum meter

Suspension eye

Compressed air vacuum pump / connecon side

Compressed air vacuum pump / filter side

On/off pushrod

Compressed air connecon

FIPALIFT Smart

8

4. INSTALLATION AND COMMISSIONING

Ensure that the delivered tube lier matches the delivery note. If any parts are missing, please

contact our Technical Sales Department. Many problems during installaon and the test run can be

avoided if this manual is read thoroughly before installaon. For safety reasons, it is imperave to

have detailed knowledge about the equipment. The FIPALIFT Smart tube lier is used together with

an electrical vacuum pump (or side channel blower) or with a pneumac pump (mul-chamber

ejector according to the Venturi principle). Strictly observe the instrucons for the pumps.

Safety instrucons for installaon

> The employee responsible for installaon of the FIPALIFT Smart tube lier must ensure that

the suspension structure (e.g. the FIPA crane system or the FIPA jib crane or similar) is of su-

cient size to hold the dead weight of the tube lier including maximum load plus an adequate

safety factor.

> The electrical installaon must be undertaken by a qualied electrician.

Installaon of the tube lier

> The liing unit is fastened to the suspension eye. Make sure that the fastening elements are of

sucient size and adequately secured if necessary.

> Once the liing unit has been mounted, the vacuum cup should be 100 mm above the oor.

If the vacuum cup is closer to the oor, the tube should be shortened or the suspension sys-

tem moved higher. If the vacuum cup is further from the oor, the tube must be extended or

the suspension system lowered.

Ensure that the tube lier can be reached by operang personnel even at its highest posion and

that the desired operang height is achieved. If this is not the case, the length of the liing tube

must be adjusted and/or the height of the suspension.

Instrucons for shortening the liing tube

Remove the protecve coang from the control unit, remove the black tape and unscrew the liing

tube from the plasc adapter. Measure out the length of the liing tube by which it needs to be

shortened in order to make the FIPALIFT Smart tube lier the correct height above the oor.

9

FIPALIFT Smart

Step 1: Cut the liing tube to length and cut away the wire coil.

Step 2: Cut away any excess material and orange-coloured adhesive tape. If you proceed as shown in

the gure, the wire coil will not come away from the material.

Step 3: Remove about 20 mm of orange-coloured adhesive tape from the wire coil.

Step 4: Remove about 2 turns of the white cord from the cut ends.

Step 5: Screw the liing tube back onto the plasc adapter.

Step 6: Then wind reinforced adhesive tape (FIPA item number SH.SPP.ALL.0034) around the liing

tube and the plasc adapter. The adhesive tape must be ghtly tensioned.

Step 7: Pull the protecve cover back over the tube.

Selecng the vacuum pump

The selecon is highly dependent on the consistency of the load to be lied; liing trials may be

required. For the correct design, please contact our Technical Sales Department (+49 89 962489-0).

The pumps are not included in the delivery and must be ordered separately.

The following pumps are available from FIPA and are approved for the FIPALIFT Smart tube lier:

Technical data

Item no. DT.25B-1 DT.25B-3

Sucon power at 50 Hz [m3/h] 25 25

Sucon power at 60 Hz [m3/h] 29 29

Final vacuum [%] 88 88

Power supply at 50 (60) Hz [V] 220 - 240 Delta: 220-255 (220-266)

Star: 380-440 (380-460)

Current consumpon at 50 (60) Hz [A] 5.8 (6.2) Delta: 3.8-4.2 (4.4-4.2)

Star: 2.2-2.4 (2.5-2.4)

Rated power at 50 Hz [kW] 0.75 0.75

Rated power at 60 Hz [kW] 0.9 0.9

Noise level at 50 Hz [dB(A)] 65 65

Noise level at 60 Hz [dB(A)] 67 67

Operang temperature at 50 Hz [°C] 65 - 70 65 - 70

Operang temperature at 60 Hz [°C] 70 - 75 70 - 75

Weight [kg] 29 28.5

Accessories Spare part kit KIT-DT.25B*

FIPALIFT Smart

10

Technical data

Item no. DT.40B-1 DT.40B-3 DT.60C-3

Sucon power at 50 Hz [m3/h] 40 40 60

Sucon power at 60 Hz [m3/h] 46 46 70

Final vacuum [%] 88 88 88

Power supply at 50 (60) Hz [V] 220 - 240 Delta: 220-255 (220-266)

Star: 380-440 (380-460)

Delta: 230 (265)

Star: 400 (460)

Current consumpon at 50 (60) Hz [A] 9.8 (9) Delta: 7 (7.1-7)

Star: 4 (4.1-4.0)

Delta: 5.91 (5.6)

Star: 3.4 (3.23)

Rated power at 50 Hz [kW] 1.5 1.5 1.5

Rated power at 60 Hz [kW] 1.8 1.8 1.8

Noise level at 50 Hz [dB(A)] 68 68 70

Noise level at 60 Hz [dB(A)] 70 70 72

Operang temperature at 50 Hz [°C] 75 - 80 75 - 80 70 - 73

Operang temperature at 60 Hz [°C] 80 - 85 80 - 85 72 - 75

Weight [kg] 40 37.5 66

Accessories Spare part kit KIT-DT.40B* Spare part kit KIT-DT.60C

Diagrams

> Sucon power depending on vacuum level at 50 Hz > Sucon power depending on vacuum level at 60 Hz

Sucon power [m3/h]

100

80

60

40

20

0

Vacuum level [%]

DT.60

90 5070 30 10 0

DT.25

DT.40

Sucon power [m3/h]

100

80

60

40

20

0

DT.60

Vacuum level [%]

90 5070 30 10 0

DT.25

DT.40

Installaon of the electrical vacuum pump

> The vacuum pump must be posioned as close as possible to the liing unit in order to keep

the length of the vacuum hose as short as possible. If the FIPALIFT Smart tube lier is intended

to li loads as quickly as possible, it is especially important that the vacuum hose between the

vacuum pump and the liing unit is not too long. A longer vacuum hose reduces the possibili-

es of the liing unit ulising the full capacity of the vacuum pump. It is recommended that

the hose between vacuum pump and liing unit is not longer than 30 m. If a longer hose is

necessary, please contact our Technical Sales Department.

11

FIPALIFT Smart

> The vacuum pump must be installed in a well venlated area as it radiates heat. Ensure that

there is free space at least 300 mm around the pump and that no loose objects can cover the

pump's venlaon openings.

> If the pump is not installed on the oor, ensure that it is installed securely in such a way that it

cannot fall down or p over.

> Make sure that the belt cover is installed.

> The electrical installaon may only be undertaken by a qualied electrician.

> Remove the cover from the pump's vacuum inlet.

> The pump may only be operated when the lter is connected.

> Check the direcon of rotaon using the direconal arrow on the electric motor and check

whether air is coming out of the silencer. The pump can be damaged if it is run in the wrong

direcon.

> If several FIPA tube liers are installed, the vacuum pumps must be labelled in order to make

clear which pump is connected to which tube lier.

> The electrical cable must be laid through the cable bushings provided for such purpose.

(Please see the gure on page 7).

> It is imperave also to note the operang instrucons for the respecve pumps.

The system may only be started up aer a qualied electrician or electrically qualied

person has installed a safety device on the motor. If no safety device is installed on the

motor there is a risk of re!

Installing the vacuum hose and air lter on the vacuum pump.

> The air lter should be installed in an easily accessible place and it should also be clearly

idened which liing device the lter is connected to. To start with, the vacuum hose must

be hung in the suspension system which the liing unit is installed on (e.g. the FIPA crane

system or the FIPA jib crane or similar). Secure the vacuum hose to the top swivel joint of the

liing unit and to the air lter.

> Also secure the vacuum hose between the air lter and the vacuum pump. NOTE! The arrow

on the air lter points in the direcon in which the hose leads to the vacuum pump.

> Ensure that the vacuum hose is not pinched anywhere along its enre length or that it cannot

come into contact with things that could damage it.

Installing the compressed air operated vacuum pump (mul-chamber ejector)

> Hang a compressed air hose in the suspension system which the liing unit is installed on

(e.g. the FIPA crane system or the FIPA jib crane or similar). A G1/2 compressed air hose is

recommended.

> Secure the compressed air hose to the vacuum pump's compressed air connecon. The

compressed air connecon has a G1/4 internal thread.

> Ensure that the supplied compressed air is free of impuries and water. A water separator and

a solids lter must be installed between compressor and vacuum pump.

> The liing speed of the FIPALIFT Smart tube lier with compressed air operated vacuum pump

is insucient when the compressed air supplied is not at least 630 litres/minute at a pressure

of 6 bar. Restricons, such as compressed air hoses that are too small or 90° angles in the line

must be avoided.

FIPALIFT Smart

12

Test operaon and inial acceptance

> Li a load with a surface that is fully impermeable to air. Leave the load suspended on the

liing unit and observe the enre unit for hissing sounds to ensure that no leaks have occurred

during installaon.

> Li a load of around 5 kg with a surface that is impermeable to air. Leave the load freely

suspended on the tube lier and then switch o the vacuum pump. The load and liing unit

should now slowly sink down to the oor. If this should not be the case, please contact our

Technical Sales Department.

> Li a load with a surface that is fully impermeable to air and that is the maximum permied

weight for this model. See the "Troubleshoong" secon if the load cannot be lied.

> Aer the FIPALIFT Smart tube lier has been installed on a suitable crane system, a sign stang

the maximum permied load must be aached to the control unit. The maximum permied

load must be equal to the maximum load of the installed tube lier and the maximum load of

the liing system. Please note that these signs are not provided by FIPA.

5. OPERATION

Device sengs

Seng the no-load neutral posion

The no-load neutral posion is calibrated

with the balance buon, see gure.

Adapng for right-hand and le-hand use

Take the release lever from its xing and let

it click in to the le or right of the handle.

13

FIPALIFT Smart

Use

Operang handle

1. Operang handle in outer posion:

- The liing unit is in its highest posion with load.

- Without the liing unit is moved into its preset neutral posion.

2. Operang handle in half-pressed posion:

- The load is raised or lowered according to pressure on the lever.

3. Operang handle in fully pressed posion:

- With load, the liing unit is lowered rapidly and the load is released once it has reached a solid base.

- Without load, the liing unit is lowered rapidly.

Gripping the load from above

Push the operang handle in fully and place the vacuum

cup on the load to be lied. Release the lever fully or

parally to raise the load.

Gripping the load from the side

> Rotate the vacuum cup forwards if the load is to be held

from the side.

> Do not li the load with surfaces that have loose areas.

These area can come loose, get sucked into the vacuum

cup and the load could then fall!

> Only li loads that are so stable that they cannot come

apart when lied.

Grip the load from the side when the upper side does not have a suitable gripping surface.

FIPALIFT Smart

14

Rotang the load

> The enre control unit with the load can be rotated.

> The load can be freely rotated even if the control unit is

held sll.

The opon of rotang the load while the control unit remains xed is especially useful when it is

necessary to manoeuvre the load in narrow gaps.

Releasing the load

With the release lever

> Press the release lever and the load is released and can

drop freely.

> Only use the release lever when you have ensured that a

free-falling load cannot cause injury to persons.

> Only use the release lever when the load cannot be dam-

aged by a free fall.

The release lever can be used, for example, when the load is dropped into a deep container.

It may also be necessary to use the release lever for parcularly light loads.

With the handle

> Press the handle in fully and the load will be released

once it reaches a solid base.

15

FIPALIFT Smart

6. MAINTENANCE

The maintenance instrucons must be followed precisely in order to ensure that the system works

safely and that the liing characteriscs are not impaired. If faults are detected in the system, these

must be reced immediately before the FIPALIFT Smart tube lier can be started up again.

> The device must be switched o during servicing work and secured against being switched

back on.

> Only FIPA original spare parts are to be used for maintenance and repairs. FIPA original spare

parts are matched to the necessary loads and forces of the tube lier. Using other spare parts

can lead to serious defects and to the warranty being voided.

Daily maintenance and inspecon

> The lter must be checked every day in dusty or dirty usage condions. Shake out the lter

and clean with the vacuum cleaner. Damaged lters or lters that can no longer be cleaned

must be replaced.

Weekly maintenance and inspecon

> Test to check whether a power failure would cause the load to fall rapidly:

Step 1: Start vacuum pump.

Step 2: Li a load with a surface that is fully impermeable to air and with a weight of around 5 kg.

Step 3: Switch o the vacuum pump and at the same me push the control handle upwards.

Step 4: The load should slowly sink to the oor. If the load falls too quickly, the tube lier may

not be used unl the fault has been reced. Please contact our Technical Sales Department.

> Check if the lter is blocked or damaged.

> Check if the vacuum cup is damaged.

> Check if the liing tube is damaged.

> The liing tube gets longer over me. Check the length of the liing tube and ensure that the

vacuum cup does not touch the oor. If necessary, shorten the vacuum hose, see page 8.

Quarterly maintenance and inspecon

> Check that the suspension eye and the crane system which the FIPALIFT Smart tube lier is

aached to are in good condion.

If parts are damaged, the tube lier may not be used unl the fault has been reced.

Please contact our Technical Sales Department!

> Check that the nuts and bolts of the fastening system are ght and secured if necessary.

> Check that the vacuum hose and the liing tube are air-ght and not caught on anything.

FIPALIFT Smart

16

7. TROUBLESHOOTING

Fault: The load is not lied or is lied more slowly than normal.

Is the air lter blocked?

Shake out the lter and clean with the vacuum cleaner. Replace the lter if it is damaged.

Is the lter unit's end cap correctly installed?

Tighten the cap correctly.

Does the system have any leaks? Place the vacuum cup on an air-ght, at board. Pull the control

handle up and check vacuum hose, connecons, air lter, upper swivel joint, liing tube, control

unit and vacuum cup for hissing noises.

Seal leaks or replace components which are not air-ght.

Is there dirt in the vacuum cup?

Remove dirt from the vacuum cup.

Is the vacuum hose caught anywhere?

Seal leaks or replace vacuum hose.

Carry out a test to check whether a power failure would cause the load to fall rapidly.

(See "Weekly maintenance")

Is the load being lied too heavy? Check that the weight corresponds to the liing capacity of

the delivered FIPALIFT Smart tube lier.

If you cannot recfy the fault yourself, please contact our Technical Sales Department.

If the load is not lied, this can be due to the fact no vacuum is produced in the liing

tube and/or the vacuum cup. The cause is usually a leak in the load or in the liing

unit.

Fault: The load is lied very slowly to start with, but then more quickly as the height increases.

Is there a leak in the liing tube?

It is imperave to replace the liing tube.

Is there a leak in the vacuum hose?

Seal leaks or replace vacuum hose.

17

FIPALIFT Smart

Fault: The load is not lowered slowly during the power failure test.

See "Weekly maintenance".

Please contact our Technical Sales Department.

Fault: It is impossible to set the desired no-load neutral posion.

Unfasten the control unit from the liing tube.

Check that no dirt has collected in the balancing valve.

Remove the dirt.

Fault: The vacuum pump doesn't start.

Please contact the company responsible for the electrical installaon or our Technical Sales

Department.

Fault: Extraneous noise from the vacuum pump.

Shut the vacuum pump down and contact our Technical Sales Department.

FIPALIFT Smart

18

8. SPECIFICATIONS

FIPALIFT Smart dimensions

2500

2902

G1

Ø 19

19

FIPALIFT Smart

Filter unit

Terminal clamps

Fing

Filter element

Wing nut

Spindle

Housing

Ø 51

Ø 9

230

165

30

Ø 210

350

Groove

Cover

Flat washers

FIPALIFT Smart

20

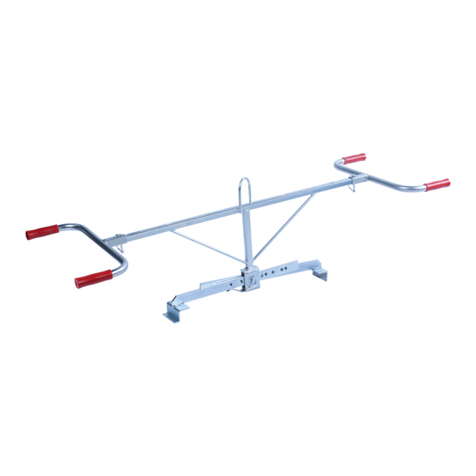

Liing tube and suspensions

Suspension single

Liing tube

Protecve coang

Adapter plate

Plasc adapter

Gasket

Suspension double

This manual suits for next models

4

Table of contents

Other FIPA Lifting System manuals