Fire Pro FPC-5V2 User manual

FPC-1 | P a g e

Operation and User Manual

FPC-5V2

Panel Fire Protection Controller

Issue April 2019

Version 2

FPC-5V2 April 20191 | P a g e

INDEX

1. Overview.....................................................................................................................2

2. Summary of Technical Characteristics...................................................................2

3. Technical Features...................................................................................................2

4. Assembly of unit........................................................................................................4

5. Installation guidelines ..............................................................................................6

6. Specifications............................................................................................................7

7. Testing and Commissioning....................................................................................7

8. FPC5-V2 Module Assembly ....................................................................................9

9. Adaptor plate/junction box coupling required......................................................9

10. FPC5-V2 Module Connection to Condensed Aerosol Generators ................10

11. Kiwa Declarations...................................................................................................11

FPC-5V2 April 20192 | P a g e

This Operation & User Manual provides information on the FPC-5V2 fire protection module

and how it is connected to the various FirePro Condensed Aerosol Generators.

Autonomous fire suppression unit

Primary power source: 3Vdc battery.

Battery monitoring feature with LED - indication.

Manual or Automatic battery status indication.

Single input detection loop.

Linear heat detector cable or a bimetallic sensor

connections

Figure 1: FPC-5V2 module.

The FirePro fire protection module detects fire by using either a linear heat detector

cable or a bimetallic sensor and activates the condensed aerosol fire suppression

generators automatically in electrical cabinets and similar enclosures.

Figure 2: Fire detection devices.

Input detection terminal (J7 on the PCB) is available for connecting the linear heat

detector cable or a bimetallic sensor. Output terminal (J6 on the PCB) can be used to

connect the condensed aerosol fire suppression generator. Both J7 & J6 terminals

are not electrically polarized.

+

-

Figure 3: Interconnecting the fire detection devices.

FPC-5V2 April 20193 | P a g e

The fire protection module FPC-5V2 is powered by an internal 3V battery capable of

providing the necessary amperage to activate a condensed aerosol fire suppression

generator.

The FPC-5V2 module is equipped with a battery monitoring feature. The battery status

is indicated by the three LEDs located on the front of the unit.

oThe green LED flashes every four seconds, indicating that the battery is in

good operating condition and is able to activate the aerosol generator when

required.

oThe yellow LED is illuminated when the battery voltage level has dropped but

is still able to activate the aerosol generator when required.

oThe red LED is illuminated when the battery is unable to activate the aerosol

generator and it is necessary to replace the battery immediately.

oWhen no LED is illuminated, either the battery is installed in reverse polarity or

it is fully discharged, or the unit is set in manual mode.

Press Switch

LED’s Status

Press Switch

+

-

Figure 4: Battery status indicator.

The fire protection module FPC-5V2 can monitor the battery in both automatic

and manual mode. Automatic mode means that the battery monitor function of

the unit is operating continuously. Manual mode means that the battery

monitor function of the unit does not operate continuously but only operates by

pressing and holding the press switch located on the front of the unit above

the LED. Automatic mode and Manual mode operation can be adjusted by

changing the position of the "SW2" switch on the electronic PCB. When the

switch is in the ON - position the unit is in Automatic mode. When the switch is

in the OFF - position the unit is in Manual mode.

FPC-5V2 April 20194 | P a g e

Step 1: Remove the top safety

the electronic PCB.

Knob “A”

Knob “B”

FPC-5V2

Front Section FPC-5V2

Main Body

Figure 5

Step 2: Pass the Condensed Aerosol Generator wires through the FPC-5V2 main body.

It is important to pass the Condensed Aerosol Generator wires from the same opening

of the adaptor plate/junction box coupling.

Figure 6

Step 3: Install the FPC-5V2 main body to the Condensed Aerosol Generator by turning

Figure 7

Step 4:

the electronic PCB.

Bimetallic

Sensor

Linear Heat

Detector Cable

+

-

Figure 8

FPC-5V2 April 20195 | P a g e

Step 5: Install the CR2 battery on the battery holder "J4".

Figure 9

Step 6: Use a multimeter to make sure that there is no voltage at terminal "J6" on the

electronic PCB. If there is a voltage reading, this means that the fire detection part of the

unit has been activated, which will trigger the activation of the condensed aerosol

generator when connected. Address this issue first and then proceed to the next step.

Figure 10

Step 7: Connect the Condensed Aerosol Generator wires

electronic PCB.

Figure 11

Step 8: To adjust the position of the "SW2" switch for Automatic or Manual monitoring

mode operation, unscrew the electronic PCB from the front section of the FPC-5V2

module.

Press Switch

Figure 12

Step 9: Place the front section of the FPC-5V2 module into the main body of the FPC-

5V2. Insert and tighten safety Knob "A" to assemble the unit.

FPC-5V2 April 20196 | P a g e

Figure 13

The Linear Heat Detector cable that is connected to the FPC-5V2 module must be installed

inside and on the ceiling of the electrical panel enclosure .

Figure 14 Typical installation

The FPC-5V2 module equipped with a bimetallic sensor must be installed in such a way so

that the bimetallic sensor is as close to the ceiling inside the electrical panel enclosure.

Figure 15 Typical installation

FPC-5V2 April 20197 | P a g e

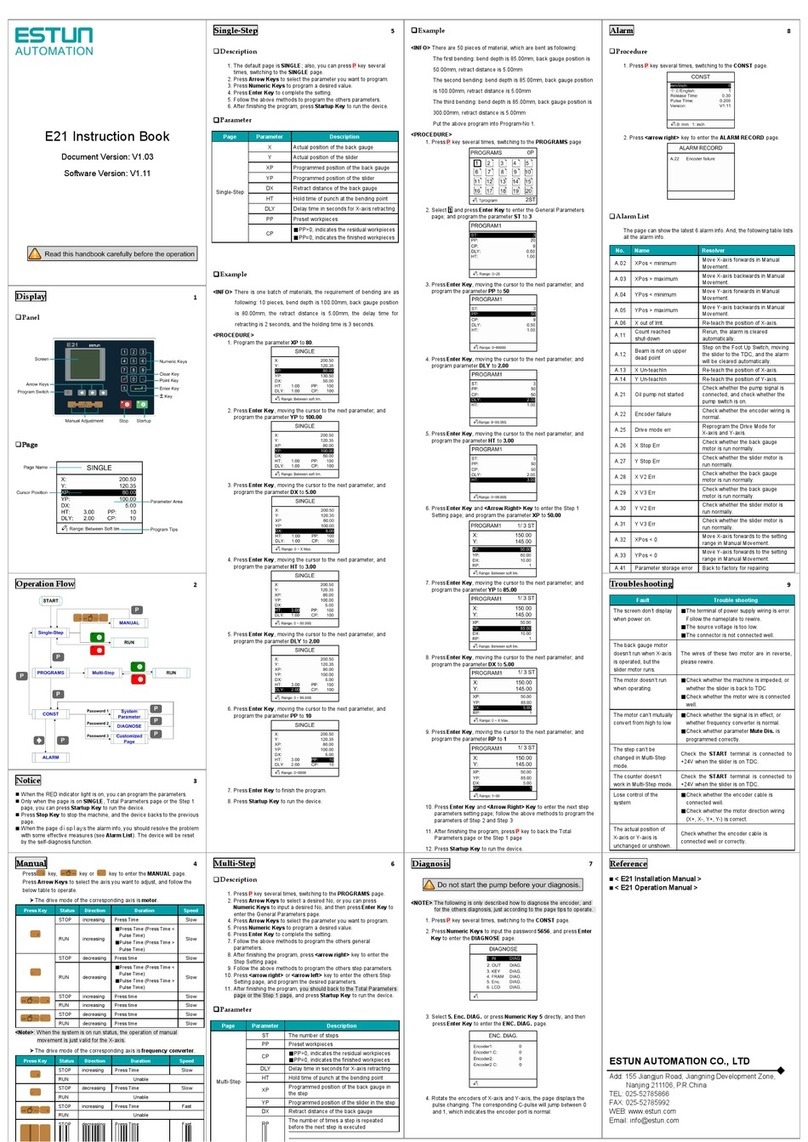

FPC-5V2

Terminals

Description

I/P terminal

J7

Linear Heat Detector cable max 10m length

I/P terminal

J7

Linear Heat Detector cable max 10m length

O/P terminal

J6

Condensed Aerosol Generator 1

O/P terminal

J6

Condensed Aerosol Generator 1

Battery

3Vdc Lithium battery (CR2 (3V))

I/P Rating

IP30

Enclosure Heat

Resistance

Withstands for a short period heat of up to 180oC

degrees

Table1: Specifications

For Testing, Commissioning and Simulation purposes, the Condensed Aerosol Generator is

disconnected from the fire protection module FPC-5V2 and replaced by an indication circuit

as per below diagram. The indication circuit includes a resistor and an LED (the indication

circuit must be installed as illustrated below since the LEDs feature polarity).

LED 1

165Ω to 180Ω

3.3Vdc

LED

165Ω to 180Ω

18 ma

0Vdc

Bimetallic

Sensor

Linear Heat

Detector Cable

+

-

+

-

LED 1

165Ω to 180Ω

+

-

+

-

Figure 16: Typical connection of the simulation LED

FPC-5V2 April 20198 | P a g e

Step 1: Remove any power source connected to the system (CR2 Battery).

Step 2: Connect the simulation LED circuit as described in figure 16.

Step 3: Apply the power source to the system (CR2 Battery).

Step 4: Create a short-circuit by using the two end-wires of the LHD cable (Linear Heat

Detector cable) or apply heat to the bimetallic sensor.

Step 5: Once the detection line is activated observe whether the LED illuminates.

Step 6: Cancel the short-circuit on the detection line (LHD cable) or wait for the bimetallic

sensor to cool down.

Step 7: Observe whether the LED is off.

Step 8: If no problem has been observed, remove the power source connected to the

system (CR2 Battery).

Step 9: By using an ohm-meter ensure that the ohmic resistance of the condensed aerosol

generators is b

Step 10: Replace the simulation LED circuit with the condensed aerosol generators.

Figure 17: Measuring the Condensed Aerosol Generator resistance

FPC-5V2 April 20199 | P a g e

-

Electrical

Gland for

LHD cable Knob “A”

Knob “B”

or Bimetallic

Sensor

Front Section

Main Body

Electronic

PCB CR2 Battery

Figure 18:

Adaptor plate applicable to Condensed

Aerosol Generator series: FP-20

Adaptor plate applicable to Condensed

Aerosol Generator series: FP-40, FP-80

Junction box coupling applicable to

Condensed Aerosol Generator series: FP-

100, FP-200, FP-500, FP-1200, FP-2000,

FP-3000, FP-4200, FP-5700,

Table 1:

FPC-5V2 April 201910 | P a g e

-

Figure 19: For Box type Condensed Aerosol Generators FP-1200, 2000, 3000, 4200, 5700

FP-20 FP-40,80 FP-100,200,500

Figure 19: For Cylindrical type Condensed Aerosol Generators FP-20,40, 80, 100, 200, 500

FPC-5V2 April 201911 | P a g e

Declarations

Number

K94463/05

Replaces

K94463/04

Issued

January 16th, 2017 first issue

Valid until

December 4th, 2019

Declaration of Conformity,

based on the requirements § 4.4.2, § 4.4.3 and § 7.15 of

CEN/TR 15276-1, regarding

FirePro

Ignition device for Non-Pressurized Condensed Aerosol Generators

•BTA ignition device (Bulb Thermal Activator)

•FPC-5 ignition device in conjunction with

oBi-metal switch

oHeat cable

oExtension cable for bi-metal switch and heat cable

Kiwa Nederland B.V.

Sir Winston Churchilllaan 273

Postbus 70

2288 AB Rijswijk

Tel. +31 88 998 44 00

www.kiwa.nl

Executed by:

Kiwa NCP

www.kiwafss.nl

Company

FirePro Systems Ltd

8 Faleas Street

Agios Athanasios Industrial

Area

Cy-4041 Limassol - Cyprus

Telephone +357 25379999

Email [email protected]m

Internet www.firepro.com

This declaration consists of 6 pages.

Publication of this declaration is allowed.

Note:

Publication of only this front page or parts of the declaration is considered as “not valid”.

STATEMENT BY KIWA

With this declaration, Kiwa declares that legitimate confidence exists that

the products supplied by

FirePro Systems Ltd.

comply with the technical specifications as laid down in this product

declaration.

Ronald Karel

Kiwa

Kiwa®declaration K94463/05

Page 2 of 6

FirePro Ignition device for Non-Pressurized Condensed Aerosol

Generators

Declaration

This product declaration is based on the functional requirement § 4.4.2, § 4.4.3 and test requirements § 7.15 of CEN/TR 15276-1.

Ignition device(s) other than the standard electrical ignition device have not been tested as a part of the Non-Pressurized Condensed

Aerosol Generators or separate component according § 7.

Generator specifications

The products mentioned below belong to this product declaration.

Type

Housing

Stainless steel

Activation Type

Number of outlets

Thermal

Electrical

FP20 SE

Cylinder

No

Yes

2

FP20 T

Cylinder

No

Yes

1

FP20 TH

Cylinder

Yes

No

1

FP40 S

Cylinder

No

Yes

2

FP40 T

Cylinder

Yes

Yes

1

FP80 S

Cylinder

No

Yes

2

FP80 T

Cylinder

Yes

Yes

1

FP100 S

Cylinder

Yes

Yes

1

FP200 S

Cylinder

Yes

Yes

1

FP500 S

Cylinder

Yes

Yes

1

Type

Housing

Red Coated Steel

Activation Type

Number of outlets

Thermal

Electrical

FP1200

Box

No

Yes

1

FP1200 T

Box

Yes

Yes

1

FP2000

Box

No

Yes

1

FP2000 T

Box

Yes

Yes

1

FP3000

Box

No

Yes

1

FP3000 T

Box

Yes

Yes

1

FP4200 T

Box

Yes

Yes

1

FP5700

Box

No

Yes

1

FP5700 T

Box

Yes

Yes

1

Type

Housing

Stainless Steel

Activation Type

Number of outlets

Thermal

Electrical

FP1200 S

Box

No

Yes

1

FP1200 TS

Box

Yes

Yes

1

FP2000 S

Box

No

Yes

1

FP2000 TS

Box

Yes

Yes

1

FP3000 S

Box

No

Yes

1

FP3000 TS

Box

Yes

Yes

1

FP4200 TS

Box

Yes

Yes

1

FP5700 S

Box

No

Yes

1

FP5700 TS

Box

Yes

Yes

1

Non-pressurized generator.

Kiwa®declaration K94463/05

Page 3 of 6

FirePro Ignition device for Non-Pressurized Condensed Aerosol

Generators

Application and use

Total flooding fire-extinguishing systems are used primarily for protection against hazards that are in enclosures or equipment that, in

itself, includes an enclosure to contain the extinguishant. Condensed aerosol generators can be used as a part of fire fighting systems in

buildings, plants or other structures. It covers total flooding systems primarily related to buildings, plant and other specific applications,

utilizing electrically non-conducting condensed aerosol fire extinguishants.

The following are typical of such hazards, but the list is not exhaustive:

a) Electrical and electronic hazards;

b) Telecommunications facilities;

c) Flammable and combustible liquids and gases;

Where aerosol generators are used in a potentially explosive application, the suitability of the generator to the atmosphere for the

determined life shall be assessed.

The fire extinguishing components shall be suitable for extinguishing fires of the following classes:

•Class A according EN2

•Class B according EN2

Conditions for application

•The numbers and types of the extinguishing components have to be determined in conformity with the guidelines and calculation

methods of the supplier.

•Distribution is to be done by supplier or companies authorised by the supplier.

•Before usage an instruction is to be given by a trainer or instructor for this product authorized by the supplier.

•The installation and maintenance of the fire extinguishing components have to take place according to the specifications of the

supplier/manufacturer, CEN/TR 15276-2 and/or evaluation guideline BRL-K23003.

Point of interest during use or limitation of use

The condensed aerosol extinguishing components should not be used on fires involving the following unless relevant testing by

accredited testing laboratories has been carried out to the satisfaction of the Authority:

•Temperatures for use of aerosol extinguishing agents shall be within the supplier’s listed limits.

•Local applications 1) of condensed aerosol extinguishing systems are not covered by this product declaration.

oLocal applications require a pre-engineered and pre-designed system which has been tested and approved for a specific

application by an authority such as Kiwa or by an accredited testing laboratory.

1) a local application is used for the extinguishment of surface fires in flammable liquids, gasses, and shallow solids, where the enclosure does not conform to the requirements for total flooding.

The above list may not be exhaustive.

Manual

At delivery the product should be accompanied by an operation manual in the English language, known and authorized by Kiwa.

Following minimum items shall be described:

•Type of aerosol generators;

•Design application density;

•Description of occupancies and hazards to be protected against;

•Specification of aerosol generators;

•Equipment schedule or list of materials for each piece of equipment or device, showing device name; supplier, model or part number

and description;

•System calculation;

•Enclosure pressurization and venting calculations;

•Description of fire detection, actuation and control systems.

•Requirements for inspection, maintenance and testing of an aerosol fire-extinguishing system and for the training of inspection and

maintenance personnel.

For specific details regarding the owner’s manual, see CEN/TR 15276-1.

Kiwa®declaration K94463/05

Page 4 of 6

FirePro Ignition device for Non-Pressurized Condensed Aerosol

Generators

Marking

The products should be marked with the Kiwa®-mark.

Place of the mark

Required specifications

Method of marking

•On the generator

•Name of the product and supplier

•Supplier’s type designation

•Production date and serial number

•Mass of aerosol-forming compound

•Temperature range

•Storage humidity range

•Service life

•Distances as specified in table 5

•Reference to the application

instructions

•Certification mark

•Fire Class A according EN2

•Fire Class B according EN2

•Non-erasable and non-detachable;

•Non-flammable;

•Permanent an legible

Recommendations for Customers

Check at the time of delivery whether:

•The supplier has delivered in accordance with the agreement;

•The mark and the marking method are correct;

•The products show no visible defects as a result of transport etc.

If you should reject a product on the basis of the above, please contact:

•FirePro Systems Ltd

and, if necessary,

•Kiwa Nederland B.V.

Consult the suppliers processing guidelines for the proper storage and transport methods.

Kiwa®declaration K94463/05

Page 5 of 6

FirePro Ignition device for Non-Pressurized Condensed Aerosol

Generators

Cross reference CEN/TR 15276-1, Fixed fire fighting systems - Condensed aerosol extinguishing systems -

Part 1: Requirements and test methods for components, February 2009

Chapter

Description

Demand 1)

Result

Remarks

4

Component requirements

4.4

Ignition device

4.4.2

Electrical ignition device

A

Pass

Standard electrical activator in

conjunction with thermal ignition

device, see 4.4.3

4.4.3

Thermal ignition device

A

Pass

Bi-metal switch, heat cable and

BTA ignition device (Bulb Thermal

Activator)

See 5.12.2, 5.12.3 and 7.15

See Kiwa declaration K90415 and

K97969

4.4.4

Other methods of ignition device

N/A

5.

Condensed aerosol generator requirements

5.12

Ignition device

5.12.2

Electrical ignition device

Standard electrical activator only

tested for function in conjunction

with the following ignition devices:

Bi-metal:

•60 ºC

Heat cable:

•68 ºC

See 5.12.3 and 7.15

The bi-metal switch and heat cable

are mandatory equipped with the

FPC-5 ignition device.

5.12.3

Thermal ignition device

A

Pass

Bi-metal switch:

•60 ºC

Heat cable:

•68 ºC

BTA ignition device (Bulb Thermal

Activator):

•57 ºC (glass bulb)

Other bulb temperatures are

available.

See information, instruction

& user manual § 9.

The bi-metal switch and heat cable

are mandatory equipped with the

FPC-5 ignition device.

See 7.15

Kiwa®declaration K94463/05

Page 6 of 6

FirePro Ignition device for Non-Pressurized Condensed Aerosol

Generators

Chapter

Description

Demand 1)

Result

Remarks

7.

Test methods

7.15

Ignition performance test

A

Pass

25 samples of the complete

ignition devices:

•Bi-metal switch,

•Heat cable and

•BTA ignition device (Bulb

Thermal Activator)

The bi-metal switch and heat cable

are mandatory equipped with the

FPC-5 ignition device.

Bi-metal switch is tested including

an extension cable for bi-metal

element with a maximum length of

10 meters and up to 3 bi-metal

switch elements in multiple

(parallel) configuration.

Heat cable is tested with a

maximum length of 10 meters

including the length of the

extension cable. Variations are

allowed.

All operate as intended.

1) A = Applicable N/A = Not Applicable Not tested

DISCLAIMER

FirePro Systems makes no representations or warranties of any kind, either express or implied,

statutory or otherwise, including but not limited to warranties of merchantability, fitness for a

particular purpose, of title, or of non-infringement of third party rights, including the intellectual

property rights of others.

Any information provided by FirePro Systems, relevant to the system engineering of the project is

indicative and for guidance purposes only.

ompatible with the

equipment used in the system. Furthermore, the responsibility for the preparation and/ or approval

of a project, subject to its specifications/ technical features and its related documentation, designs

or drawings adherence (e.g. design documentation, construction, as-built drawings, circuit

diagram, cable lengths and voltage drop calculations, etc.) to local, national and international laws

and regulations, falls entirely within the scope of the contractor/ consultant assigned for the

installation and commissioning.

LIMITATION OF LIABILITY

In no event, regardless of cause, shall FirePro Systems be liable for any indirect, special,

incidental, punitive or consequential damages of any kind, whether arising under breach of

contract, tort (including negligence), strict liability or otherwise, even ifadvised of the possibility of

such damages.

NOTE

FirePro is constantly updating its products and systems to the state of the art and therefore

reserves the right to make changes in design, equipment and technology. You cannot

therefore base any claims on the data, illustrations or descriptions contained in thisliterature.

Table of contents

Other Fire Pro Controllers manuals