FireFlex FLX-PC User manual

FM-060M-0-84B

Vacuum / Pressure Controller Model FLX-PC®

Operation Manual

Page ii

FLX-PC® Vacuum / Pressure Controller

Operation Manual

FM-060M-0-84B

Manufactured by FIREFLEX Systems Inc.

1935. Lionel-Bertrand Blvd

Boisbriand, Quebec (Canada) J7H 1N8

Tel: (450) 437-3473 Toll free: (866) 347-3353

Fax: (450) 437-1930

Web Site: http://www.fireflex.com - E-Mail: [email protected]

Page iii

FLX-PC® Vacuum / Pressure Controller

Operation Manual

FM-060M-0-84B

Table of Contents

General Description ....................................................................................................................................... 1

Display in Normal Condition ......................................................................................................................... 1

LCD Display Intensity

Vacuum Pump Control .................................................................................................................................. 2

Supervisory Pressure

Forced Shutdown Reset

Low and High Pressure ................................................................................................................................. 2

Alarm Pressure .............................................................................................................................................. 2

Operation Mode .............................................................................................................................................. 2

Quick Detection of Sprinkler Opening ......................................................................................................... 2

Events History Log ........................................................................................................................................ 3

Pressure Units ................................................................................................................................................ 3

Trouble Condition .......................................................................................................................................... 3

Specifications ................................................................................................................................................. 3

Useful Conversions ....................................................................................................................................... 3

Wiring Diagrams ............................................................................................................................................ 4

Page iv

FLX-PC® Vacuum / Pressure Controller

Operation Manual

FM-060M-0-84B

Copyright © 2018 FIREFLEX Systems Inc.

All Right Reserved

Reproduction or use, without express written permission from FIREFLEX Systems Inc, of any portion of this manual is prohibited.

While all reasonable efforts have been taken in the preparation of this manual to assure its accuracy, FIREFLEX Systems Inc

assumes no liability resulting from any errors or omissions in this manual, or from the use of the information contained herein.

FIREFLEX® is a registered trade mark from FIREFLEX Systems Inc. FLX-PC® is a registered trade mark from FIREFLEX Systems Inc.

FIREFLEX Systems Inc. reserves the right to make changes to this manual and the data sheets herewith at any time, without prior

notification.

Page 1

FLX-PC® Vacuum / Pressure Controller

Operation Manual

FM-060M-0-84B

General Description

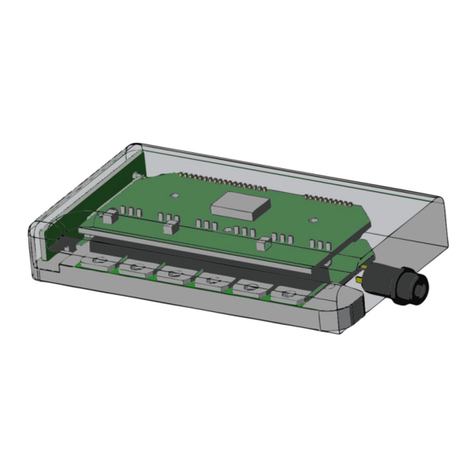

The FLX-PC® control unit is equipped with a microcontroller

based circuit that uses a piezoelectric type pressure sensor

to analyze the pressure in real time in a piping network and

perform various control operations. It includes a LCD type

display with 2 lines of 16 characters that displays the status

of the system. A single push-button on the side is used to

perform the various commands.

The FLX-PC® unit is powered by the release control panel

and consumes very little energy. Various pre-established

parameters allow to conduct supervisory and fire protection

system release via connections to the release control panel.

The FLX-PC® unit allows the control of the start-stop cycle of

the vacuum pump according to pre-established parameters.

CONTROL

PUSH-BUTTON

SERVICING CONNECTOR

19 20 21 22 23 24 25 26 27

10 11 12 13 14 15 16 17 18

1 2 3 4 5 6 7 8 9

P1

P2

P3

P4

ON

SW1-2

RV1

FACTORY SET

LCD CONTRAST ADJUSTMENT

PRESSURE TRANSDUCER

FACTORY SET

CONFIGURATION FOR

OPERATION MODE AND

FAST DETECTION

FACTORY WIRED

CONNECTION JACKS

1/2-NPT CONNECTION TOWARDS PIPING

LCD DISPLAY

FM-061H-2-8A

WIRING TOWARDS

JUNCTIONS BOX

Figure 1 - Internal arrangement of the FLX-PC unit

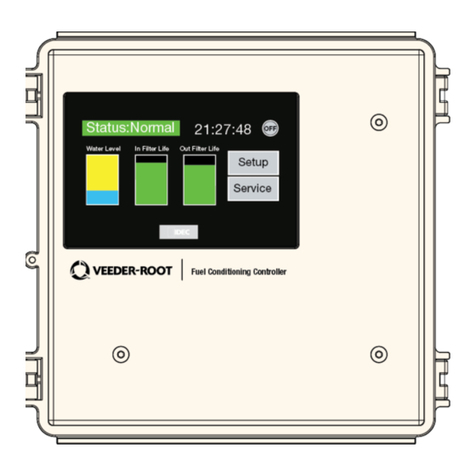

Display in Normal Condition

The system pressure is displayed in real time on the first line

(see PRESSURE UNITS CONVERSION section for a list of other

units of pressure).

-0.180 BAR

168:30:25 5:20

The second line shows information on the operation of the

vacuum pump. The hour meter on the left represents the

time (in hours: minutes: seconds) between the last two starts

of the pump; this gives an idea of the frequency of the pump.

The hour meter on the right represents the operation time of

the pump (in minutes: seconds) during its last start.

The limit of the time meter on the left is 9999:59:59. The one

on the right is 99:59. Each counter restarts at zero when the

limit is reached.

In the attached example, we can see that the pump starts

approximately once a week (the last two cycles of the pump

having been separated from 168 hours, 30 minutes and

25 seconds) and that the last startup time was 5 minutes,

20 seconds.

This information is useful for identifying a change of state in

the pipe network or a change in the performance of the

pump. In a normal state of supervision, the frequency and

duration of operation should be constant with time.

LCD Display Intensity

The brightness of the LCD display is kept at a low level. By

pressing the push-button momentarily, the display reaches its

full brightness; the full brightness will be kept for a period of

one minute.

The contrast of the LCD display is calibrated at the factory,

but can be changed via the RV1 adjustment potentiometer

located inside the case.

Page 2

FLX-PC® Vacuum / Pressure Controller

Operation Manual

FM-060M-0-84B

Vacuum Pump Control

The system is designed to maintain a level of vacuum in the

piping network between -0.150 BAR and -0.180 BAR. These

values are fixed and cannot be changed.

Supervisory pressure

The pump starts at -0.150 BAR and stops at -0.180 BAR.

-0.150 BAR +

When the pump is in operation, the sign [] appears to the

right of the first line.

Note: The vacuum pump will not operate if a trouble

condition is present on the FLX-PC® unit.

Forced Shutdown

The forced shutdown of the vacuum pump takes place when

the deluge valve is operated, an automatic sprinkler has

been activated or that the vacuum pump has worked for a

period of more than 35 minutes.

-0.180 BAR *

When the pump is shutdown, the sign [] is displayed to the

right of the first line.

To allow the vacuum pump to start, you must first correct the

situation and put the system in normal condition of operation.

Refer to the section B MECHANICAL SECTION of the

Operation and Maintenance Manual of the

FIREFLEX®VACTEC® system.

Once the system is back in operating condition, press and

hold the push-button for 5 seconds to restart the vacuum

pump. Release the push-button as soon as the pump starts

or until the sign [] disappears.

Note: The history display appears after 3 seconds; do not

release the push-button before the end of 5 seconds.

Low and High Pressure

A supervisory signal is transmitted to the release control

panel in the following situations:

-0.140 BAR

LOW PRESS.

When the vacuum level reaches -0.140 BAR. This can

happen if the vacuum pump does not work. Refer to the

section D VACUUM SUPPLY of the Operation and

Maintenance Manual of the FIREFLEX®VACTEC® system to

correct the situation.

If the vacuum level reached -0.220 BAR, this indicates a high

level of vacuum and this situation is abnormal. Refer to the

section D VACUUM SUPPLY of the Operation and

Maintenance Manual of the system FIREFLEX®VACTEC® to

correct the situation.

-0.220 BAR

HIGH PRESS.

Note: Supervisory signals are kept latched for a period of

5 seconds.

Alarm Pressure

Note: This section do not applies to vacuum single interlock

pre-action systems.

An alarm pressure signal is transmitted to release control

panel when the vacuum level reaches -0.130 BAR.

-0.130 BAR

ALARM PRESS.

Note: Alarm signal is kept latched for a period of 5 seconds.

Operation Mode

The FLX-PC® unit can be configured to match the different

types of interlock for a pre-action system, via switch SW1

located inside the case. This switch is configured at the

factory and should not be changed.

Quick Detection of Sprinkler Opening

The FLX-PC® unit can be configured so that it can quickly

detect an automatic sprinkler opening; this configuration is

done via the switch SW2 located inside the case. When this

mode is enabled, the letter [D] is displayed to the right of the

first line. This allows for a time of operation less than

5 seconds between the automatic sprinkler opening and the

opening of the deluge valve.

-0.160 BAR D

ALARM SPK

This operation is valid under the following conditions:

Sprinkler K Factor Network Capacity

K5.6(80) to K<11.2(161) 2000 US gal (7.57m3)

K11.2(161) to K<25.2(363) 3000 US gal (11.4m3)

K25.2(363) and bigger 4000 US gal (15.1m3)

An alarm pressure signal is transmitted to the release control

panel when a variation of the vacuum corresponding to the

opening of a vacuum sprinkler is detected.

Page 3

FLX-PC® Vacuum / Pressure Controller

Operation Manual

FM-060M-0-84B

Events History Log

The last 50 events are kept inside the FLX-PC® unit for

consultation.

To access this information, press and hold the push-button

for 3 seconds then release the push-button.

***VER: 1.0.0***

1000:45:33 HRS

The first line indicates the version of the software of the

FLX-PC® unit.

The second line shows the total operating time of the vacuum

pump. When the hour counter reaches the value of

9999:59:59, the counter returns to 0:00:00.

Note: When the 24VDC supply is removed from the

FLX-PC® unit, the hour counter returns to 0:00:00.

Press the push-button momentarily to scroll through each of

the events in history up to a maximum of 50 events. The list

will go back to the first event at the end of the last event.

***VER: 1.0.0***

1 PUMP STOP

The display will automatically return to its normal condition

after 10 seconds of inactivity of the push-button.

Note: When the 24VDC supply is removed from the

FLX-PC® unit, all events are cleared from the history.

Pressure Units

The pressure is initially displayed in BAR. It can also be

displayed in KPA, PSI or BAR/PSI. This last unit will display

the BAR when in a vacuum and the PSI under positive

pressure.

To change the unit, press and hold the push-button for

10 seconds then release the push-button.

BAR

The current unit will be displayed. Press the push-button

momentarily to scroll through the various units.

KPA

PSI

BAR/PSI

Once the unit has been selected, the display will

automatically return to its normal condition after 10 seconds

of inactivity of the push-button; the change of units will be

completed.

Note: When a unit is changed, the hour counter returns to

0:00:00 and all events are cleared from the history.

Trouble Condition

A trouble signal is transmitted to the release control panel

when the FLX-PC® unit is not powered or a defect of the

microcontroller is present.

Note: The vacuum pump will not operate if a trouble

condition is present on the FLX-PC® unit.

Note: When the 24VDC supply is removed from the

FLX-PC® unit, the hour counter returns to 0:00:00 and all

events are cleared from the history.

The opening of the FLX-PC® unit must only be performed by

a qualified technician. No operation requires to remove the

front cover.

Specifications

Voltage supply range: 20 to 28VDC

Maximum current consumption: 40mA under normal

supervisory condition; 75mA under alarm condition

Contacts rating: 30VDC, 1A (resistive)

Pump control rating: 30VDC, 45mA

Inputs rating: 30VDC, 2mA

Pressure range: -14.7 to 175PSI (-1 to 12.1BAR)

Piping connection size/material: 1/2-NPT, C836 Brass

Useful Conversions

BAR KPA PSI

-0.220 -22 -3.19

-0.180 -18 -2.61

-0.150 -15 -2.18

-0.140 -14 -2.03

-0.130 -13 -1.89

0 0 0

12.07 1207 175

Page 4

FLX-PC® Vacuum / Pressure Controller

Operation Manual

FM-060M-0-84B

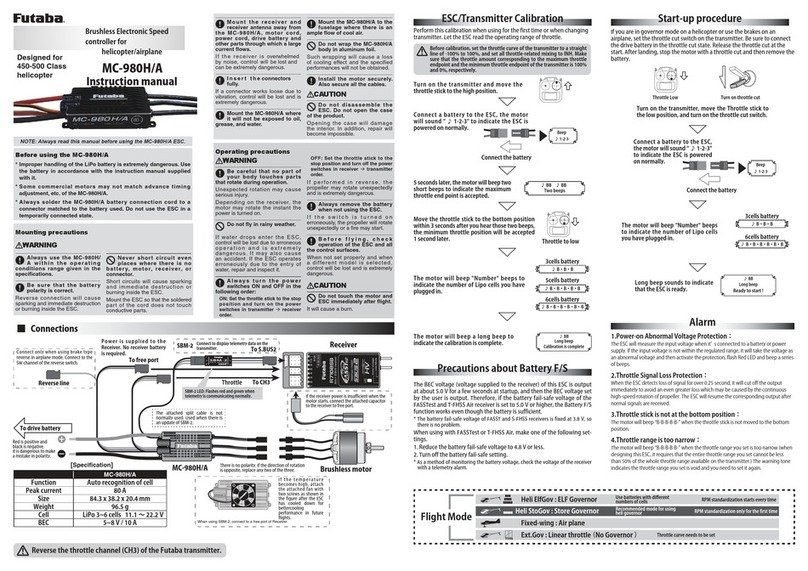

Electrical Wiring

The electrical connections to the FLX-PC® unit are rooted to

the release control panel via a built-in junction box and

connected at the factory.

Connections to the FLX-PC® unit allow powering the unit, the

connection among other devices of the system, the

transmission of alarm, supervisory and trouble control signals

towards the release control panel and ultimately control of

the vacuum pump.

The FLX-PC® unit is powered via a non-resettable power

source from the release control panel. Alarm, supervisory

and trouble signals are connected to the release control

panel through dry contacts of the FLX-PC® unit. Control

contacts of the system come from the devices of the fire

protection system. The vacuum pump control is made via a

24VDC isolation relay whose contacts activate the contactor

that controls the vacuum pump.

The connections are all done via the connections of terminals

P1, P2 and P3 jacks. These jacks are spring-loaded and can

accept only a single wire. Terminals P2 and P3 are thus

redundant in order to not allow connection of more than one

wire in the same jack.

2019

P3 2221 2423 25 26 27

1110

P2 1312 1514 16 17 18

21

P1 43 65 7 8 9

MAIN VLAVE

DELUGE VALVE

OPENING

+24VDC

COM

VACUUM PIUMP

START/STOP

2019

P3 2221 2423 25 26 27

1110

P2 1312 1514 16 17 18

EOLR

EOLR

HIGH PRESSURE

ALARM

LOW PRESSURE

SUPERVISORY

HIGH PRESSURE

SUPERVISORY

TROUBLE

ALARM

SUPERVISORY

TYPICAL WIRING TOWARDS AN ALARM

CIRCUIT AND A SUPERVISORY CIRCUIT

FM-061H-2-9A

EXTERNAL CONNECTIONS

EXTERNAL

CONNECTIONS

ALARM

EOLR

SUPERVISORY

EOLR

LOW

PRESSUREALARM

HIGH

PRESSURE

TROUBLE

EQUIVALENT CIRCUIT

Figure 2 - Wiring diagrams

Table of contents