Table of Contents 3

© Travis Industries 4161018 100-01436

Overview..........................................................................2

Listing Details...................................................................2

IAS (ICBO) Approval ....................................................2

EPA Approval...............................................................2

National Fireplace Institute...........................................2

Installation Warnings ....................................................4

Operating Warnings......................................................4

Installation Options...........................................................5

Heating Specifications......................................................5

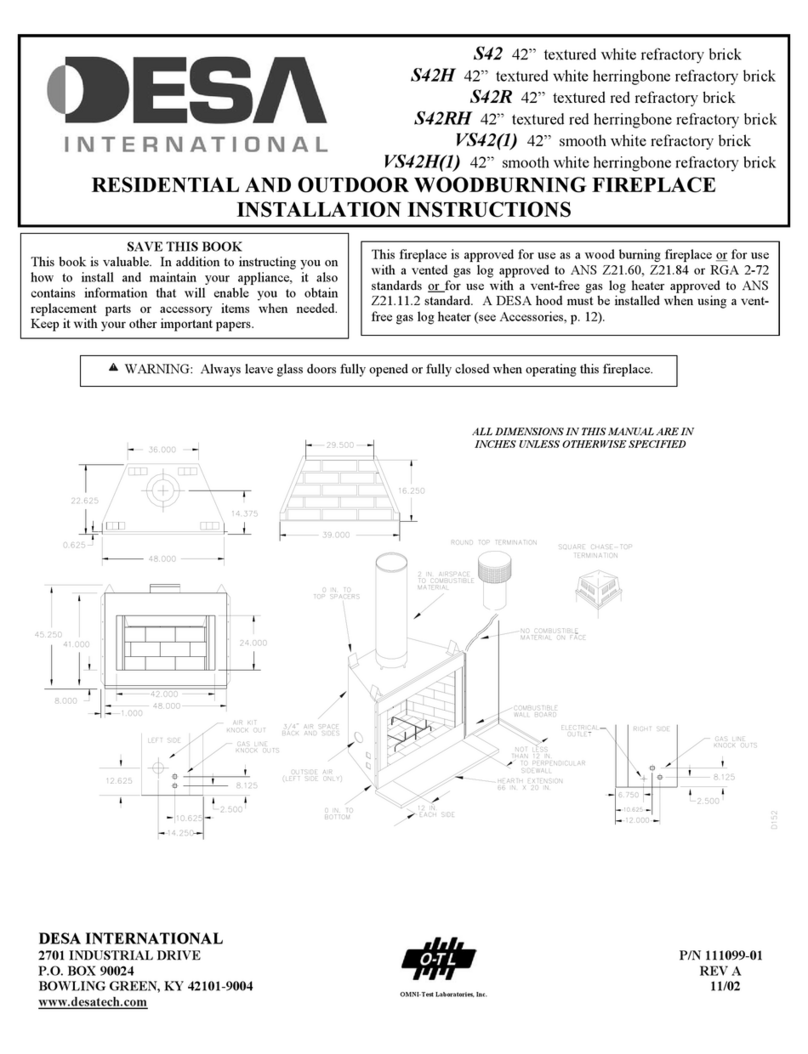

Dimensions ......................................................................5

Packing List......................................................................6

Items Shipped with the Face............................................6

Recommended Order of Installation.................................6

Installation Recommendations for Cold Environments.....7

Insulated Chimney is Strongly Recommended.............7

Use Cooling Air “P” Trap on Air-Cooled Chimney.........7

Use Intake Air “P” Trap and Insulated Intake Duct .......7

Daily Requirements for Homeowners ...........................7

Other Items...............................................................7

Fireplace Placement Requirements .................................8

Clearances to Fireplace................................................8

Fireplace Placement.....................................................9

Fireplace Framing ............................................................10

Minimum Framing Dimensions.....................................10

Framing Dimensions at 45° ..........................................10

Raised Fireplaces.........................................................11

Approved Chimney...........................................................12

Air Cooled Chimney Requirements (8” Inner Dia., 12” Outer

Dia.)..................................................................................13

Part Numbers (available through Travis Industries)......13

Anchor Plate Installation...............................................13

Cooling Duct Installation...............................................14

Air Cooled Chimney - Clearances to Combustibles......15

Air Cooled Chimney – Installation and System Height .16

Air Cool Chimney - Offset Requirements (30° Elbows) 17

Firestops ......................................................................17

Chimney Offset Chart...................................................17

Insulated Chimney Requirements (7” Inner Diameter).....18

Security ASHT+ Part Numbers (available through Travis

Ind.)..............................................................................18

Security ASHT+ - Clearances to Combustibles........18

Security ASHT+– Anchor Plate Installation ..............18

Insulated Chimney – Alternative Manufacturers...........19

Anchor Plate Installation...........................................19

Insulated Chimney – Installation and System Height....20

Insulated Chimney - Offset Requirements (30° Elbows)

.....................................................................................21

Firestops ......................................................................21

Chimney Termination Requirements................................22

Electrical Line Hookup .....................................................23

Wiring Diagram.............................................................23

Fireplace Junction Box.................................................24

External Wiring Installation...............................................25

External Wiring Installation (continued)............................26

Back Side of the Combustor Temp Display..................26

Air Intake Installation........................................................27

Air Intake Locations......................................................28

Non-Combustible Framing (included)...............................29

Facing Requirements.......................................................30

Facing Requirements (continued)....................................31

Mantel Requirements.......................................................32

Hearth Requirements.......................................................33

Finalizing the Installation..................................................34

Index ............................................................................36