Fireye SureFire II HDHESI User manual

1 © 2020 Carrier

1. INTRODUCTION

This Instruction Manual contains a description of the type SureFire II™HDHESI Heavy Duty High Energy Igniter

construction, operation principle and the instructions for installation, start-up and service, including the industrial health

& safety recommendations.

Type HDHESI igniter is designed for direct ignition of gaseous or liquid fuels like light and medium oil, heavy oil

which can be steam, air or mechanically atomized.

The igniter creates 3 sparks per second of a very high energy of 24 Joules per spark, sufficient for self-cleaning

of the rod tip and for direct firing of heavy fuels in particularly difficult operating conditions e.g. in wet, dirty

(slag, ash, unburned fuel) environment.

In case of special fuels or difficult operating conditions consult Fireye before ordering.

This High Energy Igniter is intended for intermittent operation as Class 3 Special igniter.

The igniter is made of high quality materials, and its components are rigorously checked and tested prior to dispatch. No

moving parts and parts requiring adjustment ensure long and trouble-free operation at low service costs.

All of this makes HDHESI a reliable and effective source of direct ignition of gas burners and oil burners in heavy duty

applications.

Familiarization with the following instructions will reduce the possibility of equipment failure to a minimum and ensure

safe operation.

FIGURE 1. SureFire II™Heavy Duty HESI Igniter – main components.

SF-700

December 17/, 2020

SureFire II™

Heavy Duty

High Energy Spark Igniter

(24 Joules per Spark )

Instruction Manual

2 © 2020 Carrier

2. TECHNICAL SPECIFICATION AND OPERATION PRINCIPLE

HDHESI is a High Energy Igniter, working on the principle of cyclic discharging of a capacitive system by a spark

gap, generating 3 sparks of very high energy of 24 Joules per second on igniter rod tip.

Igniter construction

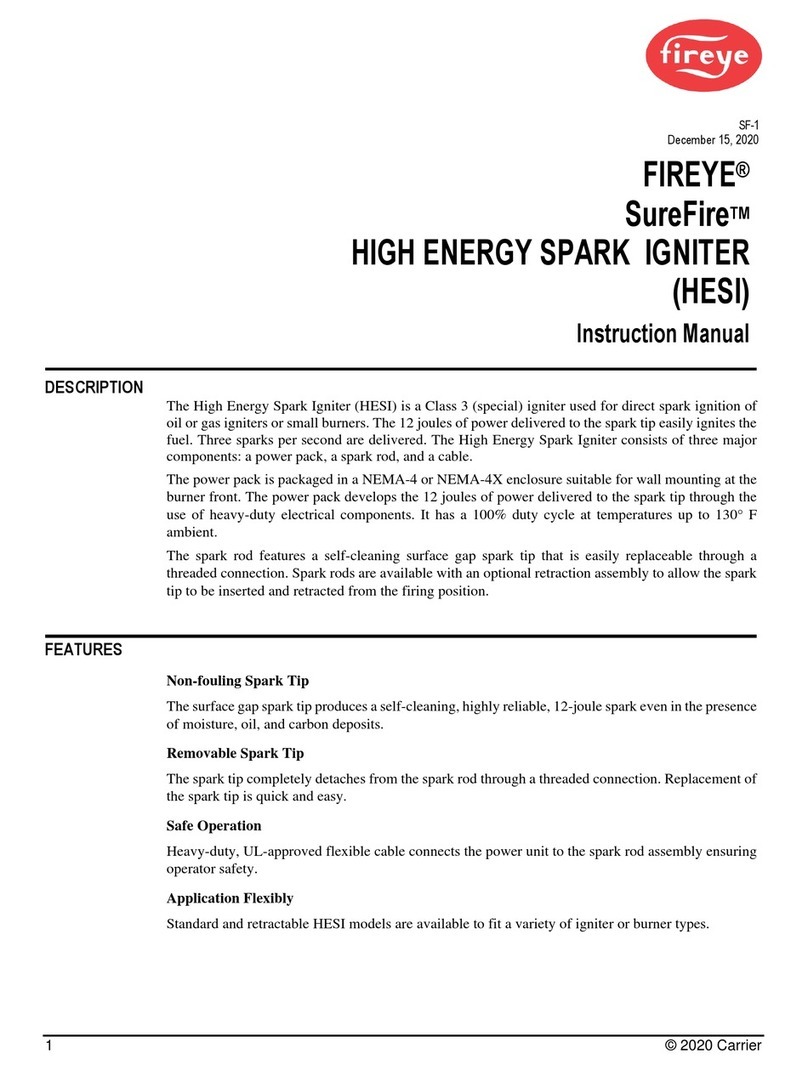

To order a complete HDHESI igniter please specify the following components (see Fig. 2):

– a Spark Rod: 16 mm outer diameter, with replaceable high resistant tip “class 60 Joules” of fixed gap between

electrodes, equipped with j. box IP67 and male cable connector, reference (insertion) length L = 0.8 to 5.0 m;

Part Number HE-ROD-24-xxx where “xxx” is the rod length L e.g. “1.3” means 1.3 m (see Fig. 2).

– the HV Cable: two wire, shielded, OD 15 mm², 4,5kV max, wire 1,5 mm², 5 m long (or 10 m), with female

cable connector on rod side; Part Numbers are: HEC-24-5 (optional 10 m long P/N HEC-24-10).

– the Power Pack: 230 or 115 VAC (selectable in power pack), rated for 3 sparks of 24 J each per second, with

a gland for ignition cable. Power pack printed board including HV transformer 230/115VAC/1150VAC, HV

capacitors, spark gap, circuit components, terminals is mounted in a carbon steel, powder coated IP66

enclosure;

Part Number HE-PP-24, includes: the door key, mounting lugs and a HV cable gland. Stainless Steel version

of Power Pack enclosure is available on request - contact Fireye.

Igniter operation

During the burner Trial for Ignition the HDHESI igniter is activated by connecting the power pack to a power

supply. Before it is connected check if the correct voltage has been selected on the Power Pack HV transformer

terminals (230VAC or 115VAC is prewired following the order spec). If not, make proper connections following

p. 4, wiring diagram Fig. 4 and Fig. 8. Once energized, the HV ignition transformer generates an 1150 VAC for

secondary circuit. This voltage is doubled to 2300V and rectified. HV capacitors are charged to the level at which

the spark gap causes energy discharge and the cycle is repeated. At the moment of discharge, current flows via HV

cable to the tip of the rod and creates a powerful spark of 24 Joules at the end of the rod tip (see Fig. 2, 4, 6),

between the central positive electrode and the grounded rod outer tube (negative electrode).

After the Trial for Ignition the SureFire II™HDHESI igniter must be disconnected from the power supply.

The circuit is equipped with discharging resistors which allows a quick discharge of capacitors, below 90

seconds, from when the igniter power supply is disconnected.

Only after this period the power pack enclosure can be opened, and service works can be undertaken.

The igniter is designed for continuous use, however the type of applications for which he is intended to be

used is intermittent operation. Following applicable standards, typical Trial for Ignition operating time is 5 - 10

seconds, repeatable in short periods. Operating time in such cases should not exceed time of few minutes. In order

to protect the device from unintentional continuous operation, adequate time delay protection must be

provided in the control system.

The igniter Power Pack can be equipped with a spark proof relay confirming the igniter operation. A rail mounted

current overflow indicator for mounting outside of the power pack, can be offered on request only.

Application features

The design of the unit provides a very stable and repeatable 3 sparks per second of 24J each.

Replaceable, high strength and durable rod tip does not require regular cleaning due to the high energy of the spark.

It is provided with a concentrically arranged electrodes which ensures a constant distance between them.

The use of replaceable tip, high quality materials used and lack of parts requiring adjustment ensures long operation

with low maintenance costs.

Basic principles on the HDHESI igniter use

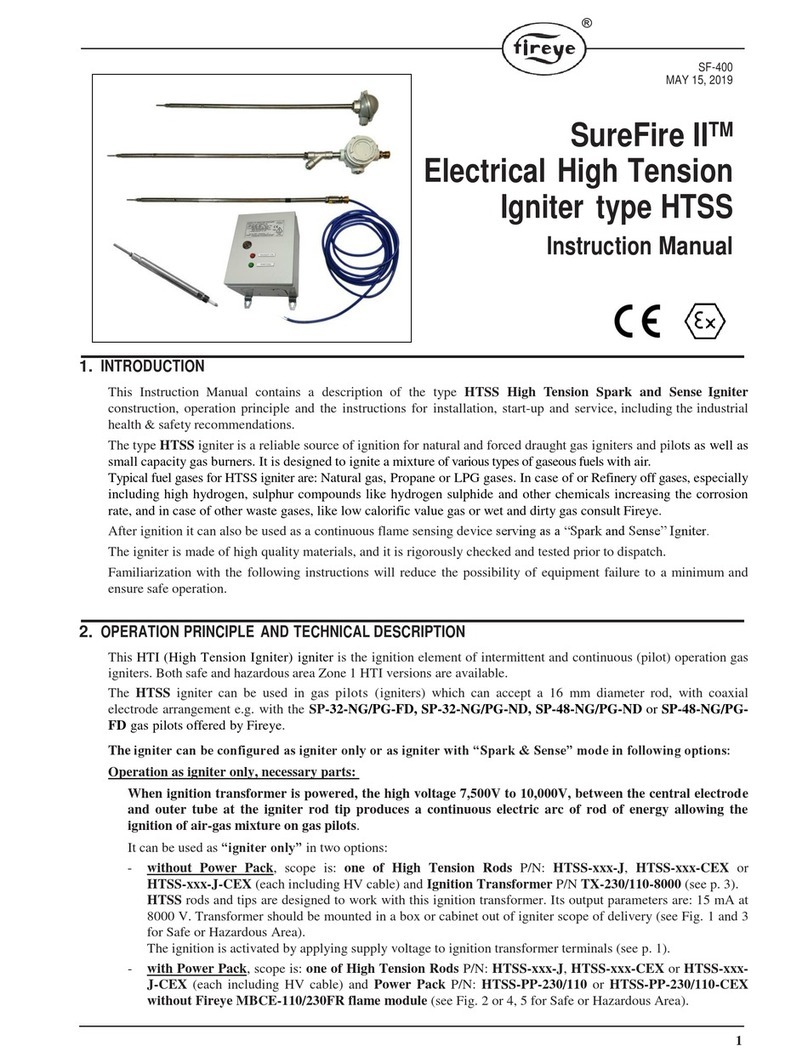

a) Rod should be mounted in a guide tube of diameter not less than 1”.

In case of very hot and/or dirty applications guide tube should be cooled/purged by air.

b) During ignition, igniter rod tip location should be at least 100 mm deep in the burner fuel cone (zone of the air-

fuel mixture), close to the nozzle of the burner (see Fig. 3).

c) After ignition the rod has to be retracted at least 400 mm back in such a way that rod tip should be hidden

at least 100 mm deep in guide tube (see Fig. 3).

d) Fireye offers coaxial retraction systems, refer to SF-2001 High Energy Igniter technical bulletin.

3 © 2020 Carrier

e) Strictly observe the temperature limits for individual parts of the igniter - see p. 3. In the case of expected

work at the limit of permissible operating temperatures, appropriate measures should be taken (e.g.

change of the mounting position and method of fixing, use of purge-cooling air).

f) In special or difficult applications, consult Fireye.

FIGURE 2. SureFire II™Heavy Duty HESI Igniter.

FIGURE 3. Use of SureFire II™Heavy Duty HESI Igniter on oil burner – basic principles of rod positioning.

4 © 2020 Carrier

FIGURE 4. Electric wiring diagram of Heavy Duty HESI Igniter.

NOTICE: CONNECT THE HDHESI IGNITER PARTS ACCORDING TO THE WIRING DIAGRAM IN

INSTRUCTION MANUAL.

WARNING: CHECK BEFORE CONNECTING THE IGNITER POWER PACK TO THE MAINS SUPPLY

WHAT SUPPLY VOLTAGE IS AVAILABLE ON SITE. CHANGE SUPPLY VOLTAGE FROM 230VAC

TO 115VAC IF NECESSARY.

NOTICE: POWER AND GROUNDING SHOULD BE CONNECTED IN ACCORDANCE WITH THE

IGNITER WIRING DIAGRAM (SEE FIG. 4), WITH PARTICULAR ATTENTION TO THE CORRECT

GROUNDING TO THE PLANT GROUNDING SYSTEM.

NOTICE: THE SAFETY INSTRUCTIONS IN THIS INSTRUCTION MANUAL SHOULD BE OBSERVED

DURING INSTALLATION, OPERATION AND MAINTENANCE.

WARNING: ALL WORK ON BURNER INSTALLATION MAY ONLY BE CARRIED OUT WEARING

PROTECTIVE CLOTHING, INCLUDING: PROTECTIVE UV-BLOCKING GLASSES, HARD HAT AND

GLOVES.

WARNING: STRICTLY OBSERVE THE TEMPERATURE LIMITS FOR A PILOT AND IGNITER ROD

MOUNTED INSIDE AND THE POWER PACK. IF THERE IS A RISK OF OVERHEATING, CHANGE

THE ROD POSITION OR USE COOLING AIR.

5 © 2020 Carrier

FIGURE 5. HESI Igniter Rod junction box wiring.

FIGURE 6. Heavy Duty HESI Igniter Power Pack layout

FIGURE 7. Connection of supply voltage 230VAC / 115VAC and HV cable to the rod on Power Pack board

6 © 2020 Carrier

3. TECHNICAL DATA

Power supply voltage; current: 230/115 VAC (50/60 Hz) switchable, at approx. 1.8/3.6 A, 220VA

Transformer output voltage: 1,150 VAC (RMS)

External protection: 8 A, fuse type D (both voltages)

Secondary circuit max. voltage: 2,300 VDC (output terminals to rod)

Method of operation: intermittent, 3 electrical sparks per second x 24 Joules each (72 Joules per

second)

Operation rating: 100% (see remarks in p. 2)

Operating temperature, IP rating:

– Power Pack P/N HE-PP-24 -40°C ÷ +65°C, IP66

– Rod P/N HE-ROD-24-xxx -60°C ÷ +80°C, IP67 junction box, +300°C rod tube continuously

– Rod Tip P/N HE-TIP-24-L +300°C tip continuously, over +1,000°C in flame for short period

(Trial for Ignition 5 – 10 seconds, repetitive in short periods)

– Cable P/N HEC-24-5 or HEC-24-10 -60°C ÷ +180°C

Rod outer diameter, outer tube material: 16 mm, 316 SS

Available rod insertion length L: 0.80 ÷ 5.00 m

Rod Tip P/N HE-TIP-24-L working length: 685 mm

HV cable: two wire, shielded, OD 15 mm, 4,5kV max, wire 1,5 mm²

Power Pack dimensions (L x W x H) : 250 x 360 x 155 mm

Weight of parts, material:

– Power Pack P/N HE-PP-24 9.8 kg, Carbon Steel powder-coated or Stainless Steel (option)

– Rod P/N HE-ROD-24-0.9 (0.9 m long)1.3 kg with rod tip, Cast Aluminum painted j.box, 316 SS tube

Rod weight adder approx. 0.75 kg per meter

– Rod Tip P/N HE-TIP-24-L 0.7 kg 316 Stainless and Heat Resistant steel

– Cable P/N HEC-24-5 or HEC-24-10 2.0 kg or 4.0 kg

Notes: 1. If the above parameters are different than those required please contact Fireye

2. For Imperial Units please refer to the Appendix 2 Unit Conversion Table

3. Device complies with the requirements of the European Directive 2011/65/EU (RoHS 2)

MARKING: The HDHESI 24 Joule igniter was independently tested and evaluated by the EMC Accredited Laboratory.

Assessment of compliance of the device with the essential requirements of the European directive no. 2014/30/EU was

carried out. Declaration of Conformity was issued, and igniter was CE marked accordingly.

FIGURE 8. How to switch supply voltage 230VAC to 115VAC on HDHESI Igniter Power Pack board

7 © 2020 Carrier

4. MOUNTING OF THE IGNITION DEVICE

4.1 The igniter function of HDHESI is activated by connecting the power pack to a power supply (230 or 115

VAC). So, before it is connected, check the supply voltage (230VAC or 115VAC) and check the connections

on transformer terminals. It should be wired following order spec. to 230VAC or 115 VAC. If they do not

match, change transformer supply wiring following wiring diagram Fig. 4 and Fig. 8.

4.2 The power supply should be connected in accordance with the igniter's schematic diagram of the power pack

board and igniter wiring diagram for power pack and rod (see Fig. 4), with particular attention to the correct

grounding to the plant grounding system, following the local codes.

4.3 Igniter must always be used in accordance with its intended purpose and following approved installation

documentation, operation algorithms and procedures as well as service manuals.

4.4 Check environmental conditions and ensure that the specified operating temperatures of components as in

p. 3 will not be exceeded.

4.5 During the rod mounting and aiming the conditions and recommendations mentioned in p. 2 should be observed

(see also below).

4.6 Rod should be mounted in a guide tube of diameter not less than 1” and a retraction for the HDHESI rod should

be used to retract igniter rod tip to the safe place after Trial for Ignition (please refer to SF-2001 High Energy

Igniter technical bulletin). The tube must allow the rod tip to reach the correct position in primary combustion

zone to ignite the fuel-air mixture and ensure correct operating temperature and tip protection (please follow

recommendations in p. 2 and Fig. 3).

When HDHESI ignition rod is being used in high temperature applications:

- always use retractor with min. stroke 400 mm to pull the tip back inside the guide tube,

- increase the guide tube length so that the rod tip is completely hidden in guide tube when

retracted,

- use purging / cooling air in the tube to cool the rod and push away a dirt.

4.7 Mounting of the igniter in a retractor: the igniter's rod should be placed inside the guide pipe and fixed in the

retractor clamps. Mounting of the igniter in a retractor must be done so as to enable adjustment of the rod tip

position relative to the burner's nozzle. See retractor Instruction Manual SF-2001 and burner manufacturer

recommendations.

4.8 The guide tube should not be placed in the flame.

4.9 The power pack enclosure should be positioned as close to the burner as possible to reduce cable lengths, as

energy is lost with increasing cable length. The control box must be in a location where the temperature does not

exceed at any moment its max. operating temperature. The box should be mounted with cable glands at the

bottom, to reduce moisture as well as dust and dirt ingress.

4.10Choose the correct glands depending on the cable type and environment demands. After installation, check if the

glands are correctly tightened.

4.11The HV cable should be placed away from any hot elements. It is shielded but not armored, so it should be

mounted in conduits, tubes or cable trays in order to reduce the possibility of damage.

NOTICE: CHECK IF THE LOCAL REGULATIONS ALLOW FOR DIRECT IGNITION OF PARTICULAR

BURNER TYPE OF A SPECIFIED TYPE OF FUEL AT A REQUIRED CAPACITY LEVEL USING AN ELECTRIC

SPARK IGNITER

NOTICE: ONLY QUALIFIED AND COMPETENT PERSONS AUTHORISED BY THE PLANT

MANAGEMENT OR MANUFACTURER, ACCORDING TO LOCAL LAW, ARE PERMITTED TO INSTALL,

MAINTAIN AND SERVICE HDHESI IGNITERS

NOTICE: MAKE SURE TO CONSULT THE MANNER OF MOUNTING THE IGNITER WITH THE

PRODUCT MANUFACTURER / DISTRIBUTOR

8 © 2020 Carrier

5. OPERATING INSTRUCTIONS

INDUSTRIAL HEALTH AND SAFETY ISSUES. STORAGE, HANDLING, TESTING:

5.1 The igniter, unless mounted on the burner, should be stored in a dry place, protected against mechanical

damage. Do not hit, step on igniter components.

5.2 The rod should be transported with care, avoiding impact against other objects or bending.

It should not be lifted by its ends to ensure no damage to rod, tip and connections.

5.3 Prior to starting the igniter it is necessary to check the condition of the cable, glands and connector for

mechanical damage and make sure that the power pack enclosure and rod j.box are properly closed and

glands are tightly fixed.

5.4 Powering the igniter's circuit should only be done after complete assembly of the rod, tip and only when

fitted in its operation-ready position at the burner. Check the proper insertion depth inside the burner as well

as the position of igniter rod tip against the gun nozzle - follow the burner Manual.

5.5 Check the correctness of connections of igniter’s components and protective grounding of the igniter rod

and power pack enclosure as well as circuit grounding. Powering the rod outside a burner should only be

done to test its operation.

5.6 The igniter supply should have effective grounding. Correct connection of the grounding of the igniter

should be checked first, then the line can be connected.

5.7 Do not touch, lift, carry the igniter rod or power pack when the igniter is energized or is not disconnected

from a potential source of electrical power.

5.8 Once assembled, the igniter can undergo the functional test. The rod should be positioned clear of

equipment, flammable materials and personnel. If these conditions are met, power can be applied, and device

switched on.

5.9 Do not open the power pack enclosure, disconnect rod tip or HV cable and grounding cables when the

equipment is energized or is not disconnected from potential source of electrical power supply.

5.10 Never use water to wash igniter components when it is connected to source of electrical power.

IGNITER START-UP AND OPERATION:

5.11 During the burner start-up the main voltage 230/115 VAC can be applied to the power pack, provided that

proper wiring conditions as in p. 5.3 to 5.6 have been verified, as well as the correct assembly of the igniter

has been inspected.

5.12 When starting the burner installation from cold conditions after a longer standstill, check the operation of

the ignition device itself without opening the fuel flow to the burner. When power applied:

- check that the retraction system functions correctly: whether the rod tip reaches its working point when is

inserted, and after retraction completely hides in guide tube away from flame zone.

- check if the rod movement is smooth without jams and obstructions, and safe for the operator. Adjust air

valves if necessary. Follow the retraction system instructions in SF-2001 High Energy Igniter bulletin,

- check the presence and repeatability of electrical sparks on the rod tip,

- no other sparking should be visible on rod connections, grounding points and cable glands. Should that be

the case, de-energize igniter immediately and follow the p. 7 instructions.

- in the case of no sparks present at the rod tip during energizing please refer to p. 7.

5.13 If, after above checking, sparks are strong and repeatable a full burner test with fuel can be performed. If

the spark is present but the igniter does not light the fuel, check fuel settings and the presence of fuel at the

nozzle. If the fuel settings are within the recommended range and during the Trial for Ignition the fuel is

present at the burner nozzle the rod position should be adjusted to ensure that the rod tip is in the correct

location. After moving the rod in new position, the test of ignition should be repeated.

5.14 If the flame is present, rod tip is in proper position, but there is no flame confirmation refer to p. 7.

5.15 The igniter’s use for direct ignition of oil fuel may take place only if sufficiently high atomization medium

(steam, air) and oil temperature as well as their proper pressure can be maintained.

5.16 It is recommended to ignite the burner at a low fuel flow and with a limited quantity of combustion air.

It is further recommended to use shut-off valves with a slow opening and fast closing capability.

9 © 2020 Carrier

WARNING: DO NOT PERFORM ANY MODIFICATIONS TO THIS EQUIPMENT AND

NEVER USE UNAUTHORIZED SPARE PARTS AS THIS WOULD RESULT IN A BREACH

OF THE APPROVALS CONDITIONS AND COULD PROVE HAZARDOUS TO YOUR

HEALTH AND LIFE !

6. PERIODICAL MAINTENANCE AND REPAIRS

The equipment manufacturer recommends a thorough inspection of the igniter every six months if possible, to

ensure long life and reliability.

CAUTION, DANGER HIGH VOLTAGE !

BEFORE ANY WORK ON IGNITER IS UNDERTAKEN, DISCONNECT THE POWER PACK

POWER SUPPLY AND WAIT 90 SECONDS.

ONLY THEN THE POWER PACK ENCLOSURE MAY BE OPENED OR CABLE AND ROD

DISCONNECTED.

STRICTLY FOLLOW THE RULES OF ELECTRICAL EQUIPMENT SERVICE !

INSPECTION OF THE IGNITER'S ROD:

6.1 Disconnect the power source, wait 90 seconds, then open the power pack enclosure and disconnect the HV cable

and igniter rod. Disconnect the rod and retractor and slide out from guide tube and retractor cylinder. Unscrew

the rod's tip.

6.2 Check the condition of the rod tip, central electrode, the ceramic insulator and tip thread joint. The parts must be

clean, not burnt, ceramic not broken and should not bear any traces of high temperature influence, erosion or

mechanical damage. If the rod's tip is damaged, it must be replaced. Clean the tip and remove all traces of erosion

and overheating.

6.3 Check the rod surface for mechanical damages or bending. The rod cannot be bent or squashed. The outer pipe

must not be burned or cracked. In case of excessive damage, replace the rod.

Open the rod junction box cover and check the condition of the cables and terminals. The inside of box and cables

must be clean and should not bear any traces of mechanical or thermal damages. In case of water ingress traces

check the condition of box gasket and tightness of glands and gasket from rod side. Check tip contact (socket) on

the rod side, insulator and thread as in p. 6.2. Clean if necessary.

6.4 In the event of any damage that may affect the safety and the rod performance - replace or return the part to the

manufacturer for repair.

6.5 Removal of the igniter rod and disconnection of the tip may only be done wearing protective gloves due to the

presence of hot surfaces.

INSPECTION OF THE POWER PACK:

6.6 Disconnect the power source and disconnect the HV cable as in p. 6.1.

6.7 Open the door of the power pack box and check the condition of connections on the power pack board terminals

as well as the condition of glands. Check electrical components on the board - HV transformer, capacitors and

other components for excessive wear, burn marks, loose cable connections and water ingress marks. In the case

of burn marks test the power pack or components, in case of water traces check the power pack tightness. Replace

components or whole power pack if necessary.

INSPECTION OF THE HV CABLE:

6.8 Check cable for nicks or kinks, check the connector. Make sure the cable connector is not damaged and

glands are not loose. In case of damages replace the cable set.

NOTICE: DURING THE INSPECTION HANDLE THE IGNITER WITH CARE. DO NOT

THROW OR BEND THE ROD. PROTECT FROM HITS, OTHER MECHANICAL

DAMAGES, MOISTURE AND DIRT.

10 © 2020 Carrier

7. TROUBLESHOOTING. ELIMINATION OF DEFECTS.

7.1 If the main voltage is present but no electrical sparks are generated at the rod's tip when there is correct voltage

at the HV ignition transformer input and output terminals (if it can be measured), perform the following:

a) Disconnect the power source.

b) Check if the power supply voltage comply with the transformer wiring – see p. 4.

c) Check the condition of the cable and electric connections for possible mechanical damage.

d) Check the condition of the rod, tip and it's screw joint for possible mechanical damage (as in p. 6.2) that

could cause internal electrical breakdown.

e) Follow the guidelines in points 6.3, 6.4 respectively.

f) After opening the door of the power pack box, check visually electrical connections on the board, check HV

transformer, capacitors and other components for burn marks. In the case of excessive wear or burn marks

replace the component.

g) Assembly the igniter, connect the power supply and grounding, make the functional test.

h) If no sparks are generated after the above measures have been taken, replace the original rod tip, reconnect

the power source and make the functional test again, following the rules in this manual.

i) If again no sparks are generated, replace the complete rod, and further the cable and repeat the functional test

each time.

j) If still no sparks are generated, replace the complete power pack and repeat the functional test. If the spark

will appear replace capacitors one by one in broken power pack and further replace the HV transformer.

k) After every step assembly the igniter, reconnect the power supply/grounding and repeat the functional test.

7.2 The main components can be checked the following way:

a) Rod Tip P/N HE-TIP-24-L: check on reference igniter rod.

b) Spark Gap P/N HE-SG-24: check on reference igniter power pack.

c) Transformer P/N HE-TR-1150: disconnect from capacitor C1 apply supply voltage. Measure output voltage

using high voltage probe – the RMS value should be 1,150V, peak 1,650V.

d) Capacitors P/N HE-CAP-10, -2, -05: use a multi-meter with capacitance measurement, disconnect GND bus

and measure capacitor capacity. It should be as per the capacitor specification.

7.3 If the main voltage is present but no electrical sparks are generated at the rod's tip and there is no voltage at the

HV ignition transformer output (if it can be measured), perform the following:

a) Check if the power supply voltage comply with the transformer wiring – see p. 4.

b) After opening the power packbox, check the presence of main supply on the HV transformer input and output

(use high voltage probe). If there is no voltage at transformer output replace the transformer. If there is no

equipment to measure transformer output replace the transformer by a spare one.

c) Assemble the igniter, connect the power supply and carry out the functional test following the above rules.

7.4 If the main voltage is present and the sparking is visible in other places: on rod connections, grounding points

and cable glands, perform the steps as above especially looking for bad connections, cracked cables, rods, bad

grounding connections. Try to identify and correct/replace faulty part. Repeat functional test after every

component replacement following the rules in this manual.

7.5 If there is no flame confirmation on flame safeguard system despite the proper igniter functioning and flame

presence on a burner, check the flame safeguard system and refer to this system manuals.

7.6 For any services and troubleshooting of Fireye retraction system module refer to Bulletin No SF-2001.

7.7 If, after all above measures have been taken, the HDHESI igniter does not work properly, or other igniter failure

occurs, please contact the manufacturer's service department.

7.8 Before any works on igniter circuit, replacing components always disconnect the supply and wait 90 sec. before

opening.

7.9 Before performing any functional tests connect the grounding and only then connect supply.

7.10 Each time before installation check the connection cable for mechanical damages.

11 © 2020 Carrier

8. SPARE PARTS, WARRANTY CONDITIONS

8.1 Igniter operation-consumable parts and suggested spare parts quantity:

- Rod Tip, 685mm long P/N HE-TIP-24-L - one for 4 igniters

- HV transformer 230/115VAC/1150VAC P/N HE-TR-1150 - one for 8 igniters

- Spark gap P/N HE-SG-24 - one for 8 igniters

- Capacitor, 3600 VDC/10μF P/N HE-CAP-10 - one for 8 igniters

- Capacitor, 3000 VDC/2μF P/N HE-CAP-2 - one for 8 igniters

- Capacitor, 3750 VDC/0.47μF P/N HE-CAP-05 - one for 8 igniters

- HV cable, with connector, 5 m long P/N HEC-24-5 - one for 8 igniters

Complete list of igniter spare parts Part Numbers is in Table 3.

8.2 HDHESI construction includes two wearing parts:

- Rod Tip, long P/N HE-TIP-24-L - lifetime 1,000,000 sparks

- Spark gap P/N HE-SG-24 - lifetime 200,000 sparks

ATTENTION: Above lifetime refers to laboratory test conditions.

In the real combustion chamber environment, these values are lower. In the case of the rod tip: work in high

temperature conditions, corrosive properties of fuel, impacts and mechanical damages and in the case of oil

fuel ignition oil residues and slag on the tip after its withdrawal (possible burning out), impacts on the slag -

can significantly reduce the tip's life.

In the case of the spark gap lifetime it is influenced by the high temperature, the power supply stability and

the mode of operation of the igniter.

8.3 The warranty (see page 16) does not apply to spark gap P/N HE-SG-24 and ignition rod tip P/N HE-

TIP-24-L as the life time of these parts depend on the quantity of ignition cycles and the conditions

they have to work under.

Each rod tip and spark tube has one month warranty to be checked on receipt or within 1 month, for damage

and tested for the proper functioning. Fireye should be notified of any failure. After 1 month, the warranty

on tip expires.

8.4 This guarantee covers delivered devices and materials under conditions of proper installation, start-

up, operation and maintenance, it means the use in accordance with applicable instructions and

manuals.

This is particularly applicable to overheated parts i.e. working above their maximum operating

temperature defined in Instruction Manual.

8.5 The defective device or part will be replaced or repaired at manufacturer’s option.

The warranty applies to and may be executed only on a failed device send to the manufacturer warehouse for

examination or warranty repair.

8.6 The manufacturer does not accept liability for damage to persons or property resulting from:

– mechanical damages, overheating,

– improper installation, operation, maintenance of igniter contrary to the instructions in the user manual,

– unauthorized igniter modifications or repairs made by unauthorized personnel,

– use of components or spare parts other than original.

8.7 During the guarantee period any repairs or parts replacements must be carried out by the manufacturer service

department, or the user, upon the service's notification and consent.

8.8 Replacement of the consumables can be user-performed only after expiration of the guarantee.

NOTICE: BEFORE THE GUARANTEE PERIOD EXPIRATION ANY REPAIRS OR

PART REPLACEMENT MAY ONLY BE CARRIED OUT BY AN AUTHORIZED

MANUFACTURER SERVICE.

AFTER WARRANTY SERVICE CAN BE CARRIED OUT ONLY BY QUALIFIED AND

COMPETENT PERSONS AUTHORISED BY THE PLANT MANAGEMENT OR AN

AUTHORIZED MANUFACTURER SERVICE.

12 © 2020 Carrier

9. STORAGE

SureFire II™HDHESI Electrical Igniter should be stored in a clean, dry environment and in its original packaging if

possible.

In the case of long length rods always keep them in a horizontal position by supporting both ends and in the middle. The

igniter should also be protected from contamination using the original packaging or wrapping it with foil.

Storage over 30 days: relative humidity of no more than 85%, temperature below 50°C.

NOTICE: THE MANUFACTURER RESERVES THE RIGHT TO CARRY OUT

MODIFICATIONS TO THE PRODUCT DESCRIBED IN THIS INSTRUCTION

MANUAL AT ANY TIME AND WITHOUT ANY ADVANCE NOTICE.

10.ORDERING INFORMATION

Before ordering, please provide the data as in Appendix 1.

The Tables below show examples of the HDHESI Rod Part Numbers every 0.5 metre, power packs and spare parts for

HDHESI igniter.

To order a complete HDHESI igniter please specify a rod, cable and power pack suitable for your application.

Rod Part Number coding sample:

HE-ROD-24-1.5 - means HDHESI igniter rod of insertion length L = 1.5 metre.

HDHESI igniter rods can be ordered in size increments of 0.1 metre lengths, from 0.8 to 5.0 metres.

Table 1: HDHESI Igniter Rod with junction box, replaceable tip

Part No Description

HE-ROD-24-0.8 HDHESI rod, 0.8 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

HE-ROD-24-1.0 HDHESI rod, 1.0 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

HE-ROD-24-1.5 HDHESI rod, 1.5 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

HE-ROD-24-2.0 HDHESI rod, 2.0 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

HE-ROD-24-2.5 HDHESI rod, 2.5 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

HE-ROD-24-3.0 HDHESI rod, 3.0 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

HE-ROD-24-3.5 HDHESI rod, 3.5 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

HE-ROD-24-4.0 HDHESI rod, 4.0 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

HE-ROD-24-4.5 HDHESI rod, 4.5 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

HE-ROD-24-5.0 HDHESI rod, 5.0 mtr long, with IP67 j.box and replaceable tip: 685mm, for 24 Joules

Table 2: HDHESI Igniter: Power Packs, Cables

REMARK: Please specify the Power Pack requested supply voltage. Power Pack would be prewired accordingly.

Part No Description

HE-PP-24 HDHESI Igniter Power Pack 230/115VAC, 3 sparks/sec. x 24 J, with: lugs, door key, gland

for HV cable

HEC-24-5 HV Cable, shielded, 2 wire, length 5 mtrs

HEC-24-10 HV Cable, shielded, 2 wire, length 10 mtrs

13 © 2020 Carrier

Table 3: HDHESI Igniter: Spare Parts

Part No Description

HE-TIP-24-L HDHESI Rod Tip, Long, length 685mm, for 24Joules

HE-SG-24 Spark Gap 24 Joules

HE-TR-1150 HV Transformer 230/115 VAC / 1150 VAC

HE-CAP-10 Capacitor, 3600 VDC / 10μF

HE-CAP-2 Capacitor, 3200 VDC / 2μF

HE-CAP-05 Capacitor, 3750 VDC / 0.47μF

14 © 2020 Carrier

APPENDIX No 1 Proposal Data Sheet

SureFire II™HDHESI – Heavy Duty High Energy Igniter 24 Joules

Please provide the following data before placing the Order for HDHESI Igniter: 1.

1. Information about End User

— Plant Name: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

— Owner: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

— Country: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

— Localization (address): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

Insertion length:

— Insertion length “L”:

(see Instruction Manual)

L= . . . . . . [m]

3. Required Ingress Protection Level:

IP

. . . . . . . .

4. The operating temperature range: . . . . .

÷

. . . . . [°C]

5. Special power pack enclosure material:

stainless steel for aggressive atmospheres If YES

check the box

6. Power pack supply:

kind of supply:

230VAC or 115VAC

. . . . . . . . [VAC]

7.

Capacity of burner to be lit:

— Nominal (Max):

. . . . . . . .

[kW]

— Reduced for Ignition (Start capacity):

. . . . . . . .

[kW]

8. Kind of fuel:

type of Oil, Gas, enclose fuel composition sheet

. . . . . . . . . . . . . . . . . .

— Calorific value:

. . . . . . . .

[MJ/kg]

— Pressure: . . . . . . . . [MPa]

— Kinematic Viscosity:

in case of Heavy Oil

. . . . . . . . [cSt]

— Atomization method:

steam, air, mechanical . . . . . . . .

15 © 2020 Carrier

APPENDIX No 2 UNIT CONVERSION TABLE

Quantity

Metric Units

Imperial Units

Length 1 millimetre [mm] x 0.003281 = foot [ft; ’] x 0.03937 = inch [in; ”]

1 metre [m] x 3.281 = foot [ft; ’] x 39.370 = inch [in; ”]

Volume 1 cubic metre [m3] x 35.315 = cubic foot [cu. ft]

Air flow rate 1 cubic metre/hour [m3/h] x 0.589 = standard cubic feet/min [SCFM]

Weight 1 kilogram [kg] x 2.2046 = pound [lb]

Pressure 1 kilopascal [kPa] x 6.895 = pound square inch gauge [psig] x 4.015 = inch H2O

Power (capacity) 1 kilowatt [kW] x 293.1 = million BTU/hr [mmBTU/Hr]

Temperature Deg. Celsius [°C]

Formula:

°C x1.8 + 32 = Deg. Fahrenheit [°F]

NOTICE

When Fireye products are combined with equipment manufactured by others and/or integrated into systems designed or

manufactured by others, the Fireye warranty, as stated in its General Terms and Conditions of Sale, pertains only to the

Fireye products and not to any other equipment or to the combined system or its overall performance.

WARRANTIES

FIREYE guarantees for one year from the date of installation or 18 months from date of manufacture of its products to

replace, or, at its option, to repair any product or part thereof (except lamps, electronic tubes and photocells) which is

found defective in material or workmanship or which otherwise fails to conform to the description of the product on the

face of its sales order. THE FOREGOING IS IN LIEU OF ALL OTHER WARRANTIES AND FIREYE MAKES

NO WARRANTY OF MERCHANTABILITY OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED. Except

as specifically stated in these general terms and conditions of sale, remedies with respect to any product or part number

manufactured or sold by Fireye shall be limited exclusively to the right to replacement or repair as above provided. In no

event shall Fireye be liable for consequential or special damages of any nature that may arise in connection with such

product or part.

Fireye, Inc. SF-700

3 Manchester Road December 17, 2020

Derry, New Hampshire 03038 USA Supersedes May 15, 2019

fireye.com

Table of contents

Other Fireye Burner manuals

Popular Burner manuals by other brands

Jackson Grills

Jackson Grills JGSB-LP owner's manual

elco

elco VECTRON ECO 1.34 operating instructions

Unigas

Unigas HP60 Manual of installation - use - maintenance

Brouwland

Brouwland 90 P manual

Legendfires

Legendfires Phantom 500 Installation and user instructions

Honeywell

Honeywell Eclipse ImmersoJet Design guide

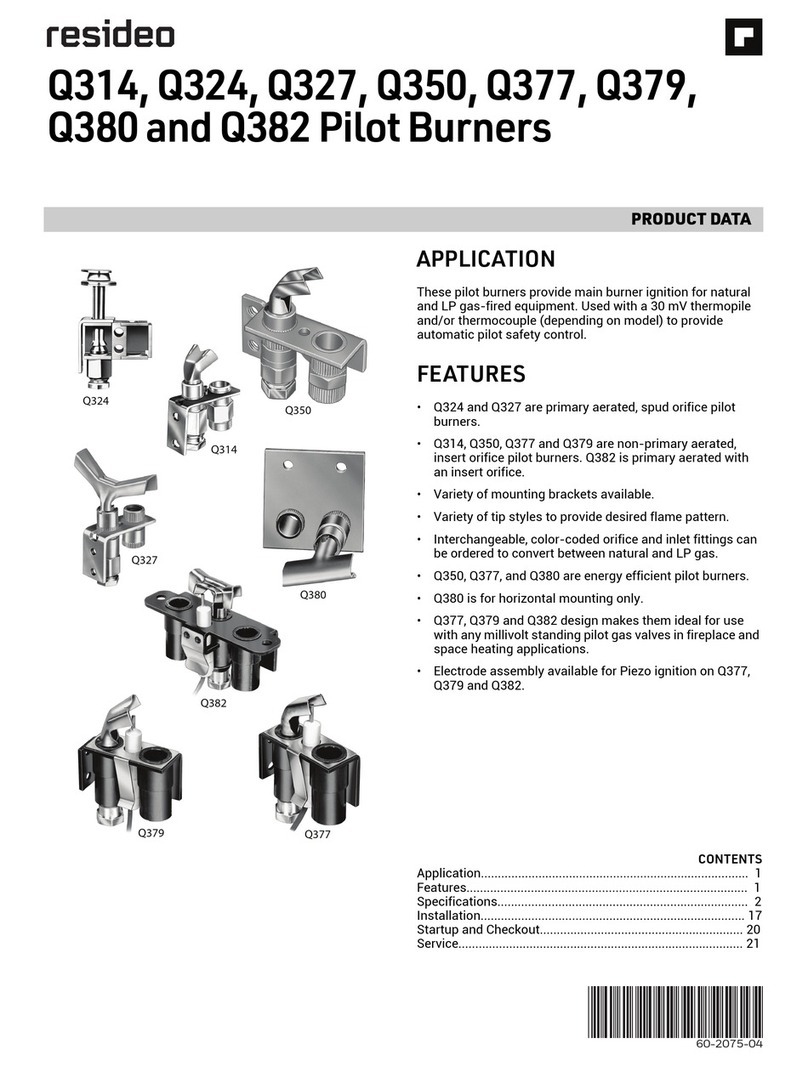

resideo

resideo Q314 manual

Midco

Midco Incinomite J83-DS Installation and service instructions

Sime

Sime MACK 5SP Installation, use and maintenance instructions

Riello

Riello 40 GS10 TL Installation, use and maintenance instructions

Riello

Riello 911T1 Installation, use and maintenance instructions

Riello Burners

Riello Burners PRESS 30N Installation, use and maintenance instructions