Firman GS2201 User manual

P/N:710745450 Rev:01OPERATOR’S MANUAL22 TON GASOLINE LOG SPLITTER Record product information to reference when ordering parts or obtaining warranty coverage.GS2201Rev:00

1

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1Features Controls and on Product Hazard Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Maintenance - Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29Troubleshooting- Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36Parts Diagrams - Parts Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 8Service - Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43REGISTER YOUR PRODUCTRegister your product using the QR code provided or at www.firmanpowerequipment.com .INTRODUCTIONThank you for purchasing a FIRMAN log splitter. You have selected a high-quality, precision engineered log splitter designed and tested to give you years of satisfactory service. This manual contains safety information to make you aware of the hazards and risks associatedwith log splitter products and how to avoid them. It is important that you read and understand these instructions thoroughly before attempting to start or operate log splitter. Save these original instructions for future reference.All information in this publication is based on the latest production information available at the time of approval for printing. The manufacturer reserves the right to change, alter or otherwise improve the log splitter and this documentation at any time without prior notice.INTRODUCTION

2SIGNAL WORDSDANGERWARNINGCAUTIONIndicates a hazard which, if not avoided, will result in death or serious injury.Indicates a hazard which, if not avoided, could result in death or serious injury.Indicates a hazard which, if not avoided, could result in minor or moderate injury.Fire- Fuel and its vapors are extremely flammable which could cause burns or fire resulting in death or serious injury.Engine exhaust could cause fire resulting in death or serious injury.Hot Surface- Muffler could cause burns resulting in serious injury.Water contact with a power source could cause electrical shock resulting in death or serious injury.Safety Alert Symbol - Indicates a potential personal injury hazard.Operator's Manual- Failure to follow warnings, instructions and operator's manual could result in death or serious injury.English Customer Service: 1-844-FIRMAN1NOTICEIndicates information considered Important, but not hazard-related.INTRODUCTIONEye and Ear Protection - Always wear safety goggles or safety glasses with side shields, and as necessary a full face-shield as well as full ear protection when operating this product.Footwear - Always wear safety shoes or heavy boots when operating the machine.Gloves - Always wear nonslip, heavy-duty protective gloves when operating this product.Skin Injection Hazard - High pressure hydraulic oil can inject under your skin.Make sure all fittings are tightly secure before applying pressure. Relieve system pressure before servicing.Always keep hands away from the wedge slide and the hydraulic cylinder. Moving parts can crush or cut.

3English Customer Service: 1-844-FIRMAN1INTRODUCTIONAlways keep feet away from the wedge slide and the hydraulic cylinder. Moving parts can crush or cut.Hot Surface- Muffler could cause burns resulting in serious injury.Open Flame alert - Fuel and its vapors are extremely flammable and explosive. Keep fuel away from smoking, open flames, sparks, pilot lights, heat, and other ignition sources.Hold logs on sides when loading. Keep hands and feet away from cylinder, wedge, and partially split logs.Never place hands or any part of the body between a log and any part of the log splitter.Do not split logs against the grain. Split logs end to end in the direction of the grain only.Toxic Fumes- Engine exhaust contains carbon monoxide, a poisonous gas that will kill you in minutes. You cannot smell it or see it.Clearance - Keep all objects including others at least 10 feet (3m) from this machine. Only one person should operate the log splitter and load the logs.Never operate on an incline. Make sure the log splitter is on a level surface. Block tires and ensure support leg is secure to prevent unintended movement of the log splitter during operation.

4English Customer Service: 1-844-FIRMAN1WARNING! This product can expose you to chemicals including gasoline engine exhaust and lead and lead compounds, which are known to the state of California to cause cancer, and carbon monoxide, which is known to the State of California to cause birth defects or other reproductive harm. For more information go to www.P65Warning.ca.gov.INTRODUCTIONTraining1. Read the Operator’s Manual completely before attempting to use this log splitter.2. Do not allow anyone to operate your log splitter who has not read the Operator’s Manual or has not been instructed on the safe use of the log splitter.3. Never allow children or untrained adults to operate this machine.4. Many accidents occur when more than one (1) person operates the log splitter. If a helper is assisting in loading logs to be split, never actuate controls until helper is clear of the area.5. Never allow anyone to ride on the machine.6. Never transport cargo on the log splitter.7. High fluid pressures are developed in hydraulic log splitters. Pressurized hydraulic fluid escaping through a pin hole opening can puncture skin and cause sever blood poisoning. Therefore, the following instructions should be heeded at all times.7a. Do not operate the unit with frayed, kinked, cracked or damaged hoses, fittings, or tubing.7b. Stop the engine and relieve hydraulic system pressure before changing or adjusting fittings, hoses, tubing, or other system components.7c. Do not adjust the pressure settings of the pump or valve.7d. Do not check for leaks with your hand. Leaks can be detected by passing cardboard or wood over the suspected area. Look for discoloration. If injured by escaping fluid, see a doctor at once. Serious infection or reaction can develop if proper medical treatment is not administered immediately.8. Keep the operator zone and adjacent area clear for safe, secure footing.9. The log splitter is equipped with a spark arrestor for use near unimproved forest, brush, or grass covered land. Make sure you comply with local, state, and federal codes. Take appropriate fire-fighting equipment with you.10. Log splitters should be used only for splitting wood. Do not use for other purposes unless the manufacturer provides attachments and instructions.11. Only split wood with the grain. NEVER split perpendicular to the grain.12. Keep the area of operation clear of all persons, particularly small children.Preparation1. Be thoroughly familiar with all controls and with proper use of the equipment.2. Safety Gear:2a. Always wear safety shoes or heavy boots when operating the machine.2b. Always wear safety goggles or safety glasses with side shields, and as necessary a full face-shield when operating or servicing the machine.2c. Never wear jewelry or loose-fitting clothing that might become entangled in moving or rotating parts of the machine.2d. Always wear full ear protection when operating the machine.3. Make sure the log splitter is on a level surface. Block tires and ensure support leg is secure to prevent unintended movement of the log splitter during operation.3a. Always operate the log splitter from the manufacturer’s indicated operator zone.4. Logs to be split on ram-type units should be cut as squarely as possible.

55. Fuel:5a. Use an approved fuel container.5b. Never add fuel to a running or hot engine.5c. Fill fuel tank outdoors with extreme care. Never fill fuel tank indoors.5d. Replace gasoline cap securely and clean up any spilled fuel. If fuel is spilled on clothing, change clothing immediately.5e. Never fill fuel containers inside a vehicle or on a truck or trailer bed with a plastic liner. Always place container on the ground away from your vehicle before filling.5f. Keep the fuel nozzle in contact with the rim of the fuel tank or container opening at all times until fueling is complete. Do not use a nozzle lock open device.English Customer Service: 1-844-FIRMAN1INTRODUCTIONOperation1. Be sure to confirm all hose connections and hose clamps are tight before each use. It is possible for connections to vibrate loose over time.2. Never leave the machine unattended with the engine operating.3. Never operate the machine when under the influence of alcohol, drugs or medication.4. The machine owner shall instruct all operators to read and understand the operators manual to ensure safe log splitter operation.5. Always operate the log splitter with all safety equipment in place and all controls properly adjusted for safe operation.6. Always operate the log splitter at manufacturer’s recommended speed.7. Always keep hands and feet clear of moving parts and partially split logs during the splitting operation.8. When loading a ram-type log splitter, place your hands on the sides of the log, not the ends. Never place your hands or any part of your body between a log and any part of the log splitter.9. On ram-type log splitters, never attempt to split more than one (1) log at a time unless the ram has been fully extended and a second log is needed to complete the separation of the first log.10. On ram-type log splitters on which the logs are not cut square, the longest portion of the log should be rotated down and the most square end placed against the ram.11. Only split logs with the grain of the wood.12. Use only your hand to operate the log splitter controls.13. Do not refuel until the engine has been turned off and cooled for at least 2 minutes.Maintenance and Storage1. Always shut off the engine while repairing or adjusting the log splitter except as recommended by the manufacturer.2. Clean debris and chaff from the engine cylinder, cylinder head fins, recoil starter cover, and muffler areas. Clean engine muffler spark arrestor and inspect it regularly (follow manufacturer’s service instructions). Replace, if damaged.3. Never store the unit indoors with fuel in the tank. Fumes might reach an open flame spark. Allow the engine to cool before storing in any enclosure.4. Clear debris from movable parts, but only when the engine is shut off.5. Check to be sure all nuts and bolts are tight to assure the equipment is in safe working condition.WARNING! Before starting and using this log splitter, read and follow all the on product labels and safety information contained in the Operator's manual. Failure to follow all on product labels and Operator's manual could result in death or serious injury to the operator or bystanders.

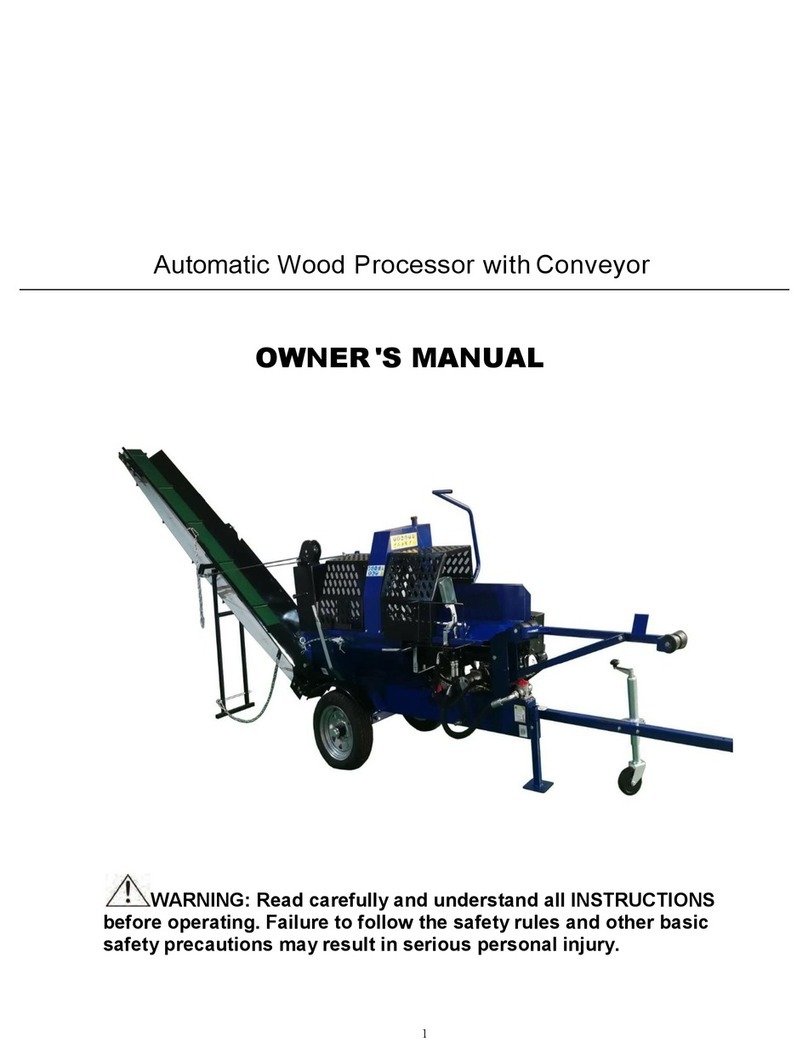

6English Customer Service: 1-844-FIRMAN1*We are always working to improve our products. Therefore, the enclosed product may differ slightly from the image on this page.FEATURES, CONTROLS AND ON -PRODUCT HAZARD LABELS⑯⑮⑭Log Splitter1234567891011121. 2 in. (5.1 cm) Ball Coupler – For towing the log splitter behind your vehicle.2. Mounting Plates – Holds hydraulic cylinder in place.3. Hydraulic Cylinder – Converts hydraulic pressure into linear force.4. Control Valve Handle – Controls the movement of the wedge slide.5. Wedge Slide6. Beam7. Log Cradle – Prevents log from rolling off the beam.8. Log Catchers9. Tires – Maximum travel speed is 45 MPH (72 KM/H).10. 196cc FIRMAN Engine11. Support Leg – Supports log splitter while operating. Raise leg for towing.12. Safety Chains with Hooks – For use while towing.13. Foot PlateSplitting control The machine shall have an operator-presence control (OPC) for its splitting function. For controls that move in the same direction as the ram or wedge, they shall move forward on horizontal machines and down wardon vertical machines for the splitting action. Hand-operated splitting controls (excludes power source controls) shall provide a minimum of 70 mm (2.75 in) of clearance in all directions from the control and through out the operating range. The control’s function and direction shall be identified by a durable label.13

7English Customer Service: 1-844-FIRMAN1125678910111. Fuel Cap2. 1 Gal (3.6L) Fuel Tank 3. Engine Switch 4. Oil Fill Cap/Dipstick – Used to check and fill oil level. 5. Oil Drain Bolt – Used to drain engine oil.6. Recoil Starter – Used to manually start the engine.7. Fuel Valve 8. Choke Lever - Used for cold engine starting.9. Throttle – Used to control the engine speed.10. Air Filter 11. Muffler34FEATURES, CONTROLS AND ON -PRODUCT HAZARD LABELS

8English Customer Service: 1-844-FIRMAN1FEATURES, CONTROLS AND ON -PRODUCT HAZARD LABELS⑩①②③④⑤⑥⑦⑧⑨

9English Customer Service: 1-844-FIRMAN1FEATURES, CONTROLS AND ON -PRODUCT HAZARD LABELS①②③④⑤

10English Customer Service: 1-844-FIRMAN1FEATURES, CONTROLS AND ON -PRODUCT HAZARD LABELS⑥⑦⑧⑨

11English Customer Service: 1-844-FIRMAN111Parts IncludedFEATURES, CONTROLS AND ON -PRODUCT HAZARD LABELSPartPart Qty.Hardware NeededHardware Qty.Tool NeededManual CanisterTow BarFendersWheelsBeamEngineHydraulic Hose (Pump-Valve)Oil Inlet HoseHydraulic Hose (Valve-Tank)Log Catchers1122111112Bolt M10 * 20Bolt M10 * 20Nut M10Lock Washer Ø10Washer Ø10 Screw M6*16 Lock Washer Ø6Washer Ø6 Bolt M12 * 100 Washer Ø12Lock Nut M12Bolt M10 * 25 Lock Washer Ø10Washer Ø10 Nut M10Castle NutCotter Pin Ø4 × 36Axle CapBeam PinWasher Ø20 R-PinBolt M8 * 50Base MountingSpecial Washer Ø8Washer Ø8Lock Nut M8Spring Loaded Hose Clamp33322266662221114444442266121 1 * 16mm wrench or socket 1x 6mm allen wrench1 * 16mm or 17mm wrenchCross Screwdriver1 * 18mm wrench or socket 1 * 19mm wrench or socket1 * 16mm wrench or socket 1 * 16mm or 17mm wrench1 * 30mm open-end wrenchNeedle nose pliersMallet1 * 13mm wrench1 * 13mm or 14mm wrench1 * 27mm open-end wrenchClamp tool1 * 27mm open-end wrenchAccessories– Engine Oil– Hydraulic Oil– Oil Funnel- Spark Plug Wrench

12English Customer Service: 1-844-FIRMAN1ASSEMBLYYour log splitter requires some assembly. If you have any questions regarding the assembly of your log splitter, call our help line at 1-844-347-6261. Please have your serial number and model number available.ASSEMBLYOpen Shipping Crate1. Set the shipping crate on a solid, flat surface.2. Carefully cut the shipping bands and remove lid of shipping crate.3. Locate all hardware and components on GS2201 Parts Diagram and Parts List before beginning assembly.1. Install The Manual CanisterAttach the manual canister (87) to the tow bar (86) with three M6*16 screws (90), Ø6 lock washers(89) and Ø6 washers (88).2. Install The Tow BarAttach the tow bar (86) to the bracket on top of the hydraulic oil tank (32) with two M12 * 100 bolts (35), Ø12 washers (39) and M12 lock nuts (9).

13English Customer Service: 1-844-FIRMAN1ASSEMBLY1. Remove the two plastic shipping caps from the wheel hubs.2. Slide the wheel (26) onto the axle. Be sure the tire valve stem is facing out.3. Thread the castle nut (27) on the axle and tighten by hand. Use a wrench to tighten another turn.4. Spin the wheel (26) to distribute the bearing grease.5. Loosen the castle nut (27) and re-tighten by hand.6. Install the cotter pin (28) through the axle and castle nut (27).7. Wheel (26) should spin freely but when grasped on both sides, should not move from side to side.8. Install the axle cap (29) using a soft face mallet or hammer and wood block.9. Repeat for the other wheel.NOTICE Keep dirt and debris away from the wheel bearings during assembly. 3. Install The Fenders1. Attach the left fender (22) to the side of the hydraulic oil tank (32) with three M10 * 25 bolts (25), Ø10 washers (4), Ø10 lock washers (3) and M10 nuts (33). The safety reflector should be facing the back of the hydraulic oil tank (32).4. Install the Wheels2. Repeat with right fender(44) on opposite side.Over-tightening the castle nut will cause the bearings to run hot and fail prematurely.

14English Customer Service: 1-844-FIRMAN1ASSEMBLY5. Install the Beam1. Unplug support pin (81), rotate the support leg (85) down, reinsert pin (81).2.Stand the beam vertical on the foot plate.3. Roll the tank into position so the pivot holes of the tank and beam are aligned.4. Insert the beam pin (36) and secure with Ø20 washer (39) and R-pin (40).5. Unplug the pin (16) and pivot the beam to the horizontal position, reinsert pin (16).Figure AFigure BNOTICE The pin (34) must move freely to be inserted or pulled.– When in the vertical position, the location of the pin (34) is shown in figure A.– When in the horizontal position, the location of the pin (34) is shown in figure B.WARNING! The beam is extremely heavy and shall only be handled with 2 or more people. To avoid muscle strain or back injury DO NOT try and lift or handle the beam without assistance.

15English Customer Service: 1-844-FIRMAN1ASSEMBLY6. Install The Engine1. Place the engine (56) on the engine mounting platform with the recoil cover facing outward towards the wheel and align the 4 holes on the engine base with the holes in the engine platform.2. Install base mounting (68)、Ø8 special washer(98)、 a M8*50 bolt (69) up through the hole on the engine platform and through the hole on the engine base.3. Place a Ø8 washer (55) on the M8*50 bolt(69) and thread a M8 lock nut (54) onto the bolt and tighten securely. Tighten to 10.3 lbf-ft – 11.8 lbf-ft (14-16 N.m) or fully, then a ¼ turn further.4. Repeat steps 2 and 3 for the remaining bolts, washers and lock nuts.56

16English Customer Service: 1-844-FIRMAN1ASSEMBLYNOTICE Red shipping plugs must be removed from hydraulic pump prior to installing hoses.NOTICE Pump-Valve Hydraulic Hose(High Pressure) and Valve-Tank Hydraulic Hose(Low Pressure)Some hoses may be preassembled by the factory, check your hoses per below instructions to ensure proper assembly.– These hoses are black and have swivel nuts on both ends.– The Pump-Valve Hydraulic Hose sends hydraulic oil from the pump to the control valve.– The Valve-Tank Hydraulic Hose returns hydraulic oil from the control valve to the hydraulic oil tank.– Hose connections do NOT require thread seal tape. The O-ring seals against the face of the fittings on the pump and hose.Oil Inlet Hose– This is the clear hose that connects the hydraulic oil tank to the pump inlet.Secure both ends of hose with hose clamps.7. Install the HosesPlace an o-ring into pump outlet fitting (A). Make sure the o-ring is properly placed in the inner groove. Connect the loose end of the pump-valve hydraulic hose (B) to the pump outlet (A). Securely tighten the high pressure hydraulic hose with a 27mm wrench. Tighten to 44 lbf-ft – 52 lbf-ft (60-71 N.m).Hydraulic Hose (Pump-Valve)

17English Customer Service: 1-844-FIRMAN1ASSEMBLYUsing the provided hose clamps, connect one end of the oil inlet hose (76) to the port on the hydraulic oil tank (C) next to the oil return filter and the other end to the pump inlet on the side of the pump (D). Securely tighten the clamps on both ends of the suction hose with either a flat head screw driver or 8mm socket. Torque to 2.9 lbf-ft - 4.4 lbf-ft (4-6 N.m).Hydraulic Hose (Valve-Tank)Connect the loose end of the valve-tank hydraulic hose (E) to the to the tapered hydraulic fitting on the oil return filter (F). The valve-tank hydraulic hose will only fit on this fitting to ensure correct connection. Securely tighten the hydraulic hose with a 27mm wrench. Tighten to 52 lbf-ft - 66 lbf-ft (71-90 N.m).Oil Inlet Hose

18English Customer Service: 1-844-FIRMAN1ASSEMBLY3. With the log catcher (97) angled downward and under the lip of the beam, align the two holes on the log catcher with the two holes on the beam lip.4. Place the two M10 * 30 bolts (96) through the holes on the beam and through the holes on the log catcher (97). Place a M10 flat washer (4) and a M10 lock washer (3) onto the bolt (96) from the bottom side and thread the M10 nuts (33) onto the bolts and tighten securely.8. Install the Log Catchers1. With the log catcher (1) angled upward, align the four holes on the log catcher with the four threaded holes on the log splitter beam.2. Place M10 flat washers (4) and M10 lock washers (3) onto the four M10*20 bolts (2) and thread them through the holes on the log catcher (1) and into the holes on the log splitter beam and tighten securely.CORRECT ASSEMBLYORIENTATIONINCORRECT ASSEMBLYORIENTATION

19English Customer Service: 1-844-FIRMAN11. LocationDANGER! Engine exhaust contains carbon monoxide, a poisonous gas that could kill you in minutes. You CANNOT smell it, see it, or taste it. Even if you do not smell exhaust fumes, you could still be exposed to carbon monoxide gas.Install carbon monoxide alarms inside your home. Without working carbon monoxide alarms, you will not realize you are getting sick and dying from carbon monoxide poisoning.20 ft. (6 m) min.OPERATIONInstall battery-operated carbon monoxide alarms or plug-in carbon monoxide alarms with battery back-up according to the manufacturer's instructions. Smoke alarms cannot detect carbon monoxide gas.Do not run this log splitter inside homes, garages, basements, crawlspaces, sheds, or other partially enclosed spaces even if using fans or opening doors and windows for ventilation. Carbon monoxide can quickly build up in these spaces and can linger for hours, even after this product has shut off.If you start to feel sick, dizzy, weak or your home’s carbon monoxide alarm sounds, get to fresh air right away. Call emergency services. You may have carbon monoxide poisoning. Use outdoors and downwind at least 20 ft. (6 m) from any home. Point exhaust away from all homes and occupied spaces. Install CO alarms inside your home.Operate log splitter only outdoors and downwind at least 20 ft.(6 m) from occupied spaces with exhaust pointed away to reduce the risk of carbon monoxide accumulating.

Table of contents