First Degree Fluid FR-E216 User manual

Owners Manual

FR-E216

Contents

1. Contents of E-216 Pack.

2. E-216 assembly instructions.

3. Tank filling and water treatment.

4. How to Row/Operational instructions.

5. The E-216 Computer.

6. Long term water treatment/basic

operation.

7. Maintenance and Maintenance Chart.

8. Troubleshooting guide.

9. Changing the Bungee cord.

10. Parts list.

11. Warranty.

Training with the E-216

1. As with any piece of fitness equipment, consult a physician

before beginning your E-216 Rower exercise program.

2. Follow instructions provided in this manual for correct foot

position and basic rowing techniques.

CAUTION

1. The E-216 can stand vertically for storage. When doing so,

please follow the instructions given in the basic operation sec-

tion of this manual.

CAUTION

2. Keep hands away from moving parts, as indicated by the warn-

ing sticker on the mainframe of your machine and inside the

PVC rear cover.

33.

X2

35

1.

1. Upper mainframe and tank

2. Lower mainframe

3. Seat Rail

4. Footplate

5. S-bend bar handle catch

6. Rower seat

7. Rear leg

8. Siphon

9. Owners Manual

10. 2X AA batteries

11. 8X Chlorine tablets

12. Blue dye

13. Touch up paint

14. M8X60mm Rear leg bolt.

15. Multi-tool

16. 8mm Hex key

17. 6mm Hex Key

18. Rear rubber bumper

19. Vertical seat rail bolt support bracket

20. Rear end cap

21. Vertical seat rail bolt dome cap

22. Rear leg bracket (internal)

23. 10mm Nylock nut

24. 10mm standard washer

25. 10mm Spring washer

26. 8mm standard washer

27. 140mm M10 footplate bolt

28. M10X90mm bolt (lower to upper frame)

29. M10X80mm S-bend bolt

30. M10 Vertical seat rail/upper/lower frame

bolt

31. M8X35mm transport wheel assembly bolt

32. M6X10mm rear bumper bolts

33. Transport wheel and bracket assembly

34. M10x15mm S-bend bolt

35. M10 S-bend Washer

34.

X2

35.

X1

X1

Step 2. Tilt upper frame to one side to allow transport wheel

bracket to fall into position. Attach using the black M8x35mm

bolt . Repeat on opposite side.

E-216 Assembly Instructions

1

2

Step 3. Attach lower frame to upper frame starting with middle

M10x70mm bolt and spring washer. Do not tighten.

3

Step 4. Install left and right side bolts (1x M10X90mm bolt and

1x 10m spring washer on each side). Tighten all three bolts.

4

Step 1. Remove contents from box, and lay upper frame (tank

assembly) on its back. Note: Use protected surface to prevent

scratching Perspex cover.

M10x70mm bolt and

spring washer

Once the lower frame is se-

curely attached, continue

steps 5-9 of the assembly

from this position. 5

Top View

M10x 70mm bolt

Plastic dome cap

Vertical seat rail

support bracket

5a Footplate

Check alignment here Next, attach the seat rail onto the footplate using the M10x70mm bolt,

Plastic dome cap, and Vertical seat rail support bracket as shown.

M10x70mm bolt, Plastic

dome cap, and Vertical

seat rail support bracket

Seat Rail

Footplate

Step 5: Insert the seat rail into the foot-

plate until the front of the seat rail just

protrudes slightly as shown.

Check alignment before installing vertical

seat rail bolt assembly.

Seat Rail 5b

6 Step 6. Install completed footplate/seat rail

assembly onto the main frame as shown, us-

ing M10X140mm bolt, M10 Nylock nut and

2x M10 washers.

Insert the 140mm footplate bolt with a stan-

dard M10 washer through the mainframe,

footplate and seat rail as shown left.

Secure with M10 Nylock nut, and standard

M10 Washer.

Note: For ease of assembly, keep the rower

in this position (with seat rail over the tank)

for Steps 8-9.

WARNING

Keep fingers clear of pivoting

parts during assembly.

M10 x 140mm Seat rail

bolt and M10 washer

M10 Nylock nut and

M10 Washer

Seat Rail

Hold seat rail/Footplate

assembly here

Step 8. Install rear rubber bump stop

using the two M6X10mm screws.

8

Step 9. Attach

the rear seat rail

leg using 2x

M8X60mm

bolts, M10

washers and

internal support

bracket. Insert

rubber seat rail

end cap (not

shown).

Step 7. Install the rower seat. (Make sure seat indentation is

facing rearward as pictured)

7 9 Rear Leg

Internal support

bracket

M8x60mm

Bolts and 10mm

washers

Carefully lower the rower to its nor-

mal operating position to complete

assembly with S-bend installation

and frame tensioning bolt.

Step 10. Install rear of S-bend onto the

upper frame using M10x80mmbolt,

M10Nylock and 2xM10washers.

Step 12. Install the Frame tensioning bolt

and tighten as far as it can go. This will pre-

tension the frame to the proper position and

complete the assembly.

Step 11. Attach the S-bend to the foot-

plate as shown. Tilt the upper frame

slightly forward to align in the proper po-

sition. Note the M10x15mm S-bend

bolt w/washer is pre-installed on the S-

bend.

Keep fingers clear of pivoting parts and rower

seat when lowering to operating position.

Caution

10

11

12

Tank Filling and Water Treatment

1. Filling requires a large bucket (not supplied) and the Fluid

Rower siphon (included). Filling will take approximately 7.6

liters of water.

2. Unscrew the right tank plug on the rear of the fluid tank and

insert the flexible tube into the rear of the tank while keeping

the rigid hose in the bucket. Note: The siphon tube may be

impeded by one of the impeller blades. Use the siphon only to

push the impeller down slightly.

Warning:

Do not insert fingers into tank.

3. Move the adjuster handle to level 16, and begin filling.

Note:

The siphon valve must be closed to allow siphoning action

to occur. Tip: Placing the bucket in an elevated position will

allow the siphon to continually pump water into the tank.

Do not fill past the calibration mark indicated on the tank!

Note: Opening the siphon valve will stop the pumping

action. Use this feature to avoid water spillage when

nearing filling completion.

4. Once filling is complete (to the proper calibration level as

indicated on the tank), follow water treatment schedule as

Shown left.

Caution: Use a drop cloth under the tank both when

filling the tank and adding blue dye to avoid

staining floor or carpet.

Water Treatment

Procedures:

1. Add Chlorine tablet.

2. Wait a minimum of 72

hours. Then add very small

amount of blue dye and

check for desired color. Im-

portant! Do not add blue

dye for at least 72 hours

following Chlorine treat-

ment. The blue dye adds

visual appeal as well as

cutting down the amount of

light affecting the tank wa-

ter, thus extending the

amount of time between

water treatments.

Blue dye

Siphon

valve

Fill tank as shown

left. Use the right

plug only for fill-

ing.

Fill with adjuster

handle at level 16

only.

Once filling is

complete, use a

coin or large

blade screwdriver

to tighten tank

plug into place.

How to row.

1. Begin the stroke comfortably forward and push strongly back with your legs while keeping your arms and back straight.

2. Begin to pull your arms back as they pass over your knees and continue the stroke through to completion rocking slightly

back over your pelvis.

3. Return to the starting position and repeat.

How often?

Begin with 5 minute training sessions once a day and aim for around 2:30 to 2:45 for 500m time. Row at a pace that keeps

the water circulating continuously between strokes.

Progress a few minutes more each day until you are comfortable with 30-45 minutes training time 3 or 4 times a week.

This is sufficient to provide aerobic endurance benefits, muscle toning and sufficient calorie burning to form part of a weight

loss program.

CAUTION

Always consult a doctor before beginning an exercise program.

Stop immediately if you feel faint or dizzy.

Catch

Comfortably forward

with straight back and

arms.

Drive

Push with the legs

while arms remain

straight.

Finish

Pull through with

arms and legs rocking

slightly back on your

pelvis.

Recovery

Upper body tips for-

ward over your pelvis

and move forward.

Catch

Catch and begin

again.

Operational Instructions Operational Instructions:

Heel support Adjustment:

The E-216 has a unique and easy to use Heel Support Ad-

juster (Pat. Pend.). Simply loosen the footplate knob and

slide the Adjuster up or down to required position. This

should place the ball of your foot directly under the horizontal

Foot Straps. Tighten knob and secure Foot Straps. The Heel

Support allows the user to row without shoes if desired.

Resistance:

The level of resistance is determined by the level indicator lo-

cated on the front of the tank. Level one indicates lightest re-

sistance, level sixteen represents heaviest resistance.

Important: Do not fill past the calibration mark as indicated

on the tank level sticker or water spillage will occur. See tank

filling/water treatment page for details.

Caution! FDF strongly recommends using a drop

Cloth under the tank when filling, and

especially when adding the blue dye.

The blue dye will readily stain carpet or

clothing.

Caution

Always row with your feet secured in the foot straps.

Computer Instructions The E-216 Computer:

TIME: Auto start elapsed time.

500M TIME: Time to row 500 meters, updated at the completion

of

each stroke.

PULSE: Requires optional receiver and chest strap.

SPM: Strokes per minute updated each stroke.

WATTS: Indication of watts at resistance level16.

CAL HOUR: Updated each stroke.

PROGRAMMING: Computer will auto start.

Note: Computer will reset and begin to count up after

10 seconds of inactivity

Options (Hold button down for one second first to reset computer)

1. Add 1000m distance each button push to accumulate required

distance then begin rowing.

2. Interval training.

Row distance as above.

Stop rowing. Computer will wait 10 seconds then begin a count up

to a maximum of 6 minutes to allow you to time your rest interval.

E-216

CAUTION

Important: Do not fill past the calibration mark as indi-

cated on the tank level sticker or water spillage can occur.

See tank filling/water treatment page for details.

Long term water treatment:

Do not use any water treatment other than the tablets

supplied with this machine. For replacement tablets, con-

tact your local First Degree Fitness distributor.

Water treatment schedules for the E-216 will vary according

to the fluid tanks exposure to sunlight, but expect 8-12

months near a bright, sunlit window and 2 years or more for a

darker location. At the point of finding the water slightly

cloudy, add a Chlorine tablet. Remember to wait 72 hours

Caution: It is critical that a drop cloth be used

Under.

The fluid tank whenever the tank plug is

opened for water treatment.

Resistance:

The level of resistance is deter-

mined by the level indicator located

on the front of the tank. Level one

indicates lightest resistance, level

sixteen represents heaviest resis-

tance. Allow three to four strokes

after adjusting resistance handle to

allow the water to move to the cor-

rect location.

Dyneema Rope drive

The unique Dyneema rope drive system allows for simplicity,

smoothness and unparalleled performance. The unique properties

of Dyneema make it extremely useful in harsh environments, such

as sailing, climbing, fishing lines, body armor, etc. It is quite literally

stronger than steel. The 6mm Dyneema rope used on the E-216 is

rated in excess of 1,000kg.

Note: If the Dyneema rope is twisted excessively, the rowing stroke

will feel lumpy. Use the rower handle to untwist the rope to its nor-

mal operating position.

Light fraying is normal. The Dyneema may have a slight “fuzzy” ap-

pearance after a period of use. Dyneema is extremely abrasion re-

sistant and to some degree self-lubricating. Expect many years of

trouble free performance.

Heel support adjuster:

The E-216 has a unique and easy to use Heel Support Adjuster. Sim-

ply slide the Adjuster up or down to the required position. This should

place the ball of your foot directly under the horizontal Foot Straps.

Secure Foot Straps. The Heel Support allows the user to row without

shoes if desired.

Long term water treatment and basic operation

Vertical storage: The E-216 can easily be stored in a ver-

tical, upright position. For safety, choose a suitable loca-

tion, such as a corner of a room. It is recommended that

something soft (such as carpet or a small towel) be placed

under the upper rear of the unit to avoid marring either the

paint or Perspex cover.

Item Timeframe Instructions Notes

Seat and seat rails. Weekly. Wipe seat rails with lint free cloth.

Spray seat rails with a light coat of

silicone spray.

Frame. Weekly. Wipe down with lint free cloth.

Tank and water treatment. 12 months to 2 years. Follow instructions as specified in

the “Water Treatment” section of

this manual.

Bungee cord. Check every hundred hours

for correct tension and for

signs of wear.

The bungee cord should last for

many years. If a bungee cord

change is required, please follow

the instructions provided in the

“Changing the bungee cord” sec-

tion of this manual.

Dyneema Rowing Rope. Check monthly for signs of

twisting, excess fraying or

other signs of premature

wear. Note that a light “fuzz”

is perfectly normal for

Dyneema rope and will not

affect performance or longev-

ity in any way.

The Dyneema rowing rope should

rarely require changing, but should

the need arise, please follow the

instructions provided in the

“Changing the Dyneema rope”

section of in the service section of

the First Degree Fitness website at

www.firstdegreefitness.com

Maintenance chart.

Fault Probable Cause Solution

Water changes color or becomes

cloudy. Rower is in direct sunlight or has not

had water treatment.

Change rower location to reduce direct exposure to

sunlight. Add water treatment and blue dye or change

tank water as directed in the water treatment section of

this manual.

Rowing stroke return too light. Bungee not under enough tension.

Open rear Perspex cover, cut bungee tie wrap .

Tighten by small increments using the bungee tie off

tab point and test tension by allowing the rowing handle

to return to its furthest point forward while still having

some slight tension. Note light fraying of the bungee

cord is normal.

Rower rocks from side to side when

sitting on floor Front/Rear frame levelers need ad-

justing Adjust the front two frame levelers or rear leg levelers

until stability is reached. Note: It is normal for the lower

rear leveler to rest slightly off the floor.

Front of rower lifts slightly during

vigorous rowing. Lower rear frame leveler too high.

Check to see that frame tensioning bolt is tightened

properly. Lower rear frame leveler should be approx

5mm off the ground.

Computer screen illuminates, but

does not register when rowing.

Loose or failed connection/Sensor

gap too wide (see erratic computer

display).

Check that the computer lead is connected properly. If

connected properly check sensor gap. Contact your

local service center if this fails to address the problem.

Rowing stroke feels lumpy, not

smooth..

Dyneema rope is twisted . You can untwist the Dyneema rope by simply pulling

the rowing handle to the end and turning the rowing

handle to untwist the rope.

Note: Light fraying is normal.

The E-216 computer does not illumi-

nate after battery installation. Batteries installed incorrectly or

need replacing. Reinstall batteries in correct position and try again. If

the LCD screen fails to illuminate, try rotating the batter-

ies slightly in the computer. If this fails, contact your lo-

cal service center.

The E-216 computer display is er-

ratic while displaying SPM and

500meter times.

Gap between sensor and magnetic

ring is too wide. Adjust sensor location using rear sliding adjustment lo-

cated inside rear Perspex cover.

Troubleshooting Guide

Replacing the E-216 bungee shock cord

Step 1. Remove the Perspex

cover from rear of upper

frame. Disconnect sensor

lead.

Step 2. Move the rowing handle

from the S-bend handle catch to

a point where it is resting on top

of the tank . This helps line up

the bungee cord hole for easier

removal/replacement. Detach

bungee cord from lower rear at-

tachment point.

Step 3. Unwrap the bungee

cord from all of the bungee

pulleys.

1

2

3

Replacing the E-216 bungee shock cord

Step 4. Next, remove the magnetic ring. To loosen the rear mainshaft bolt holding the magnetic ring in place, it is neces-

sary to keep the mainshaft and impeller assembly from turning with the bolt. Open the right rear tank plug, and insert a

wrench wrapped in a lint free cloth (to protect the electroplating finish on the blades) to catch the impeller blade and allow

the rear mainshaft bolt to be loosened as shown below right with a 6mm Allen key. Caution: Do not allow a dissimilar

metal to directly contact the impeller blade. Premature rusting could occur . Cover any tool inserted the tanks with a lint

free cloth and keep fingers clear.

WARNING

Do not insert fingers into tank!

4 4

Replacing the E-216 bungee shock cord

Step 5. After removing the magnetic ring, the

bungee cord will be accessible. Pull through the

rope/bungee pulley and remove. Note that the

rower handle should be resting on top of the tank

(as shown in step 2) for the bungee hole to line

up. Thread new bungee cord through and pull un-

til knotted end is held securely in the slot.

Step 6. Once the bungee cord is in position, make

two wraps on the rope/bungee pulley in a clockwise

direction, checking to see that the bungee cord

tracks in the proper grooves. Make sure the

bungee is wrapped behind the Dyneema rope when

threading to the first bungee pulley (shown next

page).. Once the bungee has reached the position

shown below, you may begin to rewrap the bungee

around the bungee pulleys, starting with the upper-

right rear pulley.

5 6

Bungee wrapping in order:

1. Rope/bungee pulley to upper rear right bungee pulley.

2. Upper rear right to lower rear right and left rear pulleys.

3. Lower left rear to upper left rear pulley.

4. Upper rear left to lower middle left and right pulleys.

5. Middle right pulley to upper right front pulley.

6. Upper front right pulley to lower front right and left pul-

leys.

7. Lower left front pulley to upper left front pulley.

8. Upper left front pulley to tie off point.

Replacing the E-216 bungee shock cord

1

3

Hint: Keep a slight

tension on the

bungee cord when

threading through

the bungee pulleys.

2

4

Replacing the E-216 bungee shock cord

5

6

7

8

Finish the bungee rewrap by tying

off the bungee. You may elect to

not use a tie wrap as the metal tab

is designed as a stand alone at-

tachment point. Thread the

bungee through to desired tension

and thread the bungee end through

the upper hole as shown.

Reattach the magnetic ring.

Tighten securely.

Finally, reattach the sensor

lead and replace the Per-

spex rear cover.

Table of contents

Other First Degree Fitness Equipment manuals

Popular Fitness Equipment manuals by other brands

Auvon

Auvon TU3424-F user manual

SPRI

SPRI IGNITE AGILITY CONES Setup, Workout Tips and Care & Safety Guide

Vectra Fitness

Vectra Fitness VX-DC owner's manual

SPORTSTECH

SPORTSTECH CX700 Assembly instructions

Misterstep

Misterstep EXTERIOR ZINK Assembly instructions

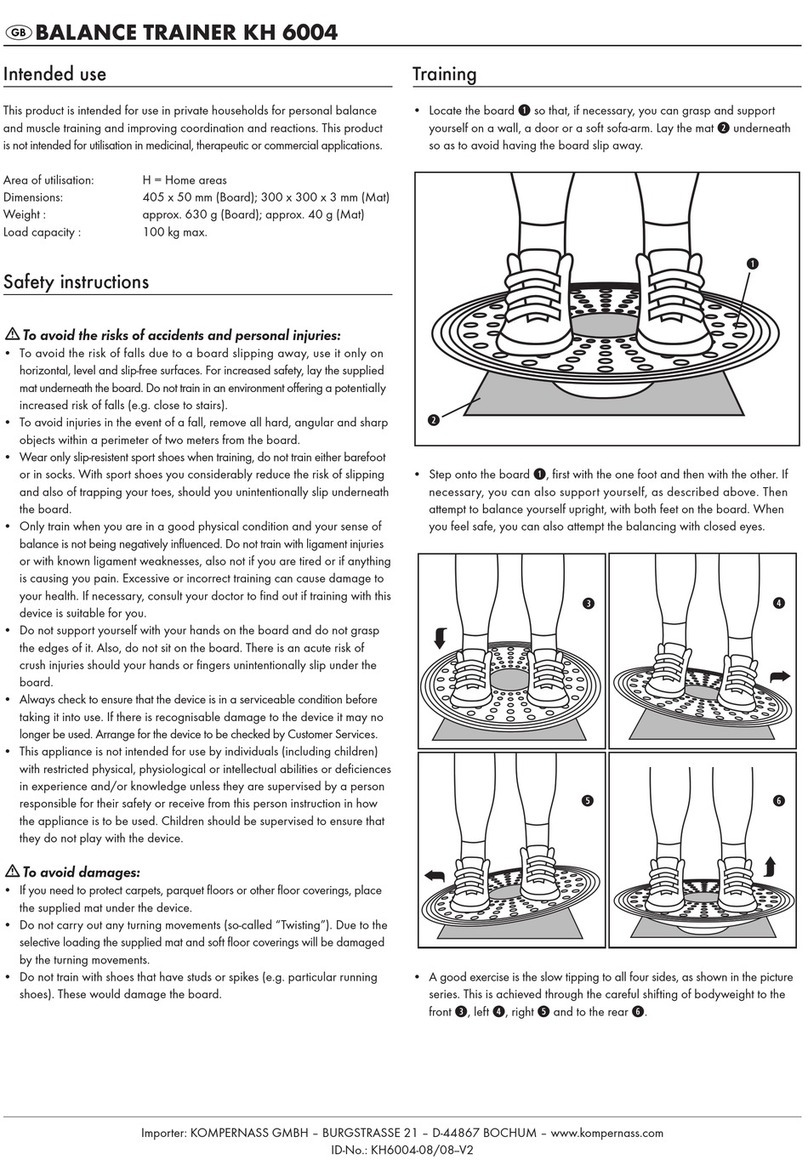

Kompernass

Kompernass KH 6004 quick start guide